3

Index

1. INTRODUCTION ............................................................................................................................................ 4

1.1 DISCLAIMER...................................................................................................................................................... 4

1.2 GENERAL.......................................................................................................................................................... 4

1.4 TERMS OF GUARANTEE........................................................................................................................................ 4

1.5 CHECK AT RECEIVE.............................................................................................................................................. 5

1.6 ORDERING SPARE PARTS...................................................................................................................................... 5

2. SAFETY .........................................................................................................................................................6

2.1 GENERAL SAFETY RULES....................................................................................................................................... 6

2.2 PERSONAL SAFETY .............................................................................................................................................. 6

2.3 SAFETY PRECAUTIONS RELATED TO THE COMBINATION OF TRACTOR,SLURRY TANKER AND MACHINE. .................................. 6

2.4 SAFETY INSTRUCTIONS REGARDING TO MACHINE OPERATIONS..................................................................................... 7

2.5 SAFETY REGULATIONS RELATED TO MAINTENANCE. ................................................................................................... 7

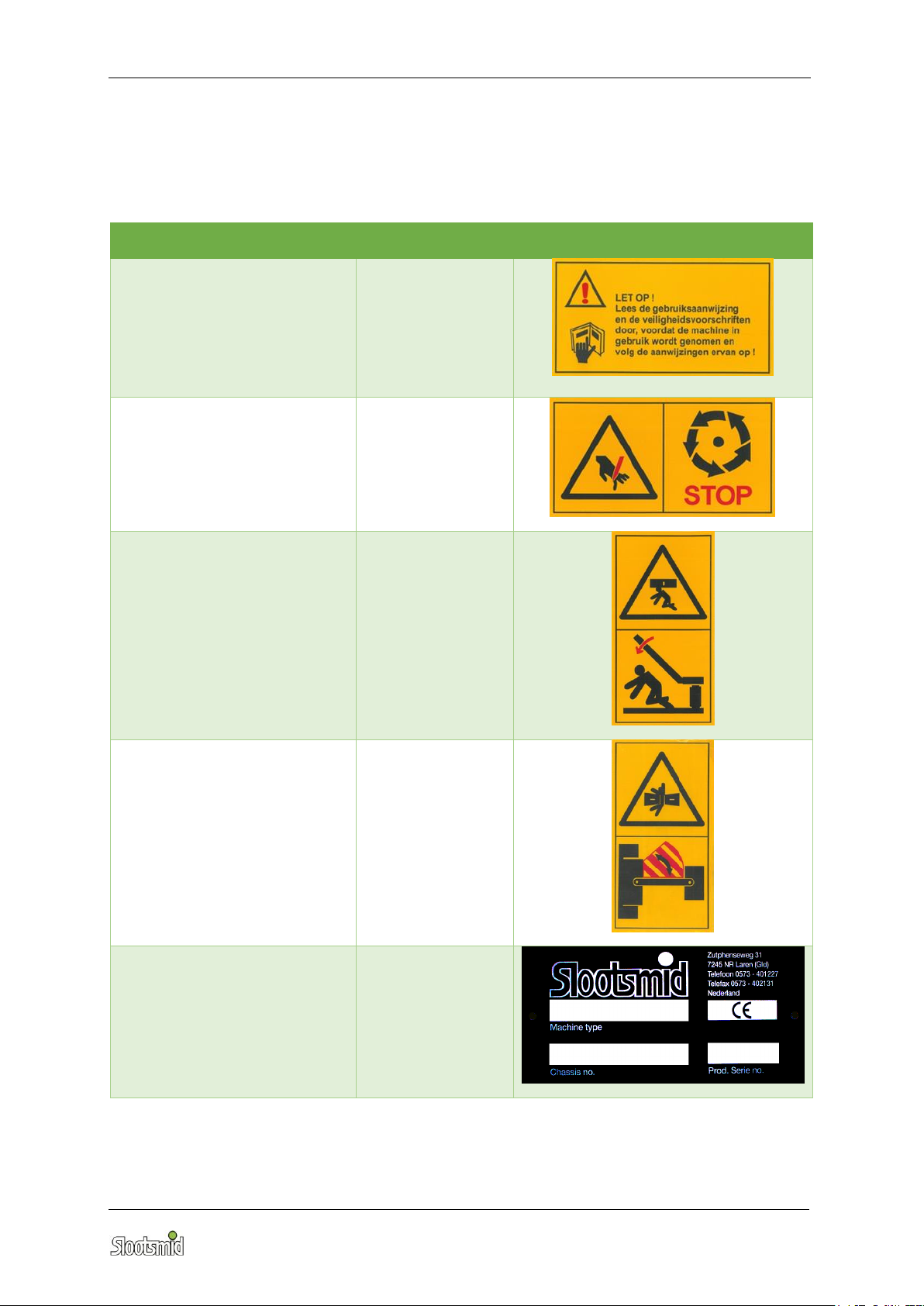

2.6 SAFETY STICKERS................................................................................................................................................ 8

2.7 PLACE FROM SAFETY STICKERS ON THE MACHINE. ..................................................................................................... 9

3. DESCRIPTION.............................................................................................................................................. 10

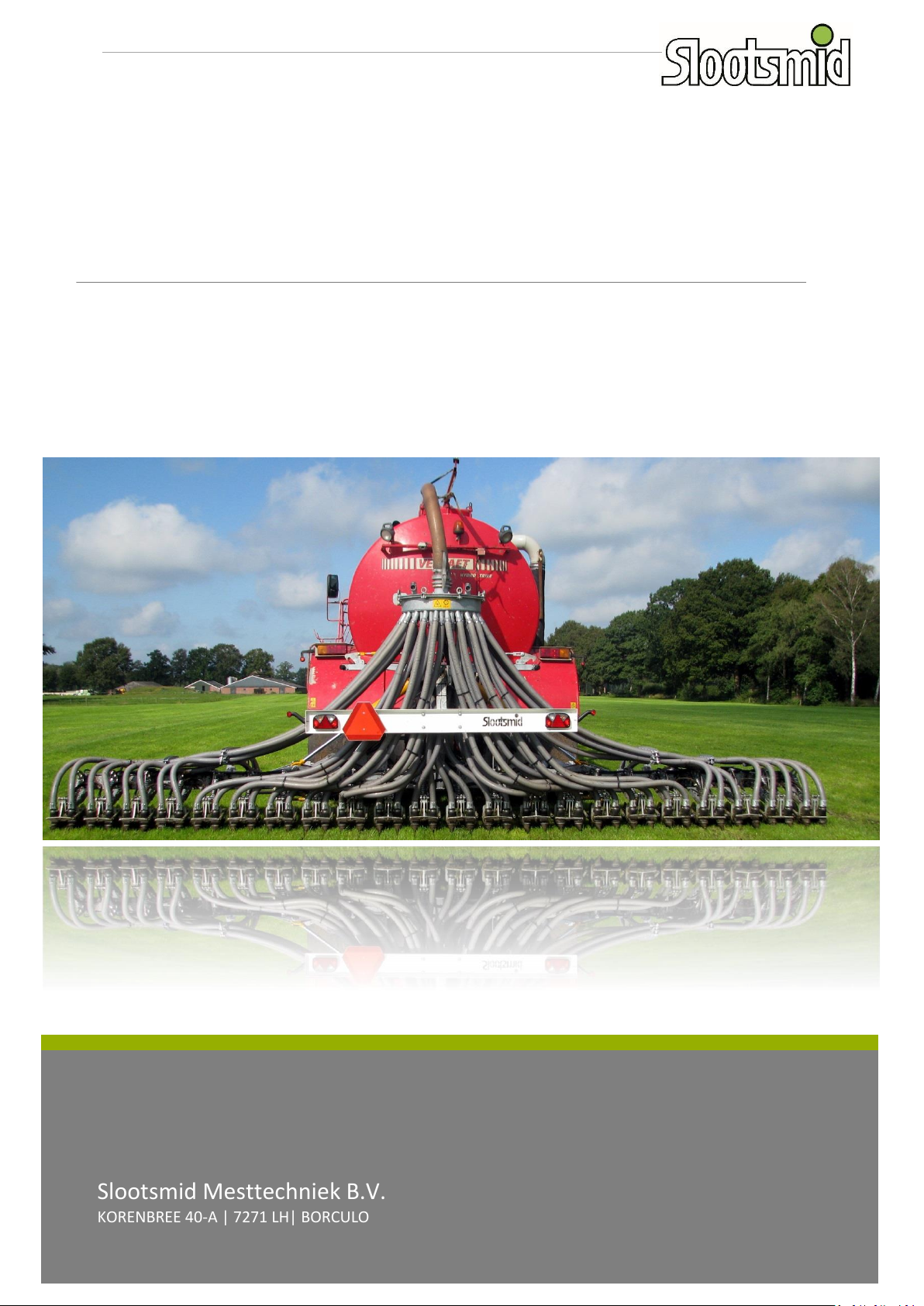

3.1 SZB SLURRY INJECTOR....................................................................................................................................... 10

3.2 DRIVE ............................................................................................................................................................ 10

3.3 OPERATION .................................................................................................................................................... 10

3.4 PRODUCT IDENTIFICATION ................................................................................................................................. 11

4. MACHINE ATTACH AND DETACH ................................................................................................................ 13

4.1 ATTACHING AFTER A TANKER OR SELF-PROPELLED MACHINE...................................................................................... 13

5. UTILIZE ....................................................................................................................................................... 15

5.1 WORKING WITH THE SLURRY INJECTOR ................................................................................................................. 15

6. ADJUSTING THE SLURRY INJECTOR............................................................................................................. 16

6.1 MECHANICAL GROUND PRESSURE ADJUSTMENT (STANDARD).................................................................................... 16

6.2 HYDRAULIC GROUND PRESSURE ADJUSTMENT (OPTIONAL)........................................................................................ 16

6.3 MECHANICAL COULTER CLOSURE......................................................................................................................... 17

6.4 HYDRAULIC COULTER CLOSING ............................................................................................................................ 17

6.5 SETTING THE SPEED OF UNFOLDING THE ARMS. ...................................................................................................... 18

6. MAINTENANCE........................................................................................................................................... 20

6.1 LUBRICATION MAP ........................................................................................................................................... 21

7. DISTRIBUTOR.............................................................................................................................................. 23

8. FAILURE...................................................................................................................................................... 24

9. TECHNICAL DATA........................................................................................................................................ 25

CONTACT........................................................................................................................................................ 28