LS6500 System Specifcations

1. LF at -10dB, HF -6dB at 40kHz on-axis however response above

20kHz is limited by air absorption and DSP sampling rates in typical PA

applications.

2. Full bandwidth pink noise is applied and amplified to a level and

measured at the loudspeaker terminals - corresponding to 1 Watt as

referenced to the loudspeakers nominal impedance. SPL is measured in

an anechoic environment in the loudspeakers far field. Data is

extrapolated to 1 Meters distance from the loudspeaker.

3. Averaged from 1000Hz to 10kHz

4. AES established with ambient temperature at 22C in accordance with

AES/2-1984 standard. IEC stated in RMS voltage according to IEC 268-5

5. Typical SPL for one box only, for array SPL refer to LASS calculations.

Ribbon SPL calculated from IEC long term and short term

118dB Cont. / 123dB Peak

Power Handling - Low Freq.

Sensitivity (1W/1M) - Low Freq.

Horizontal CoverageAngle -6dB

3

4

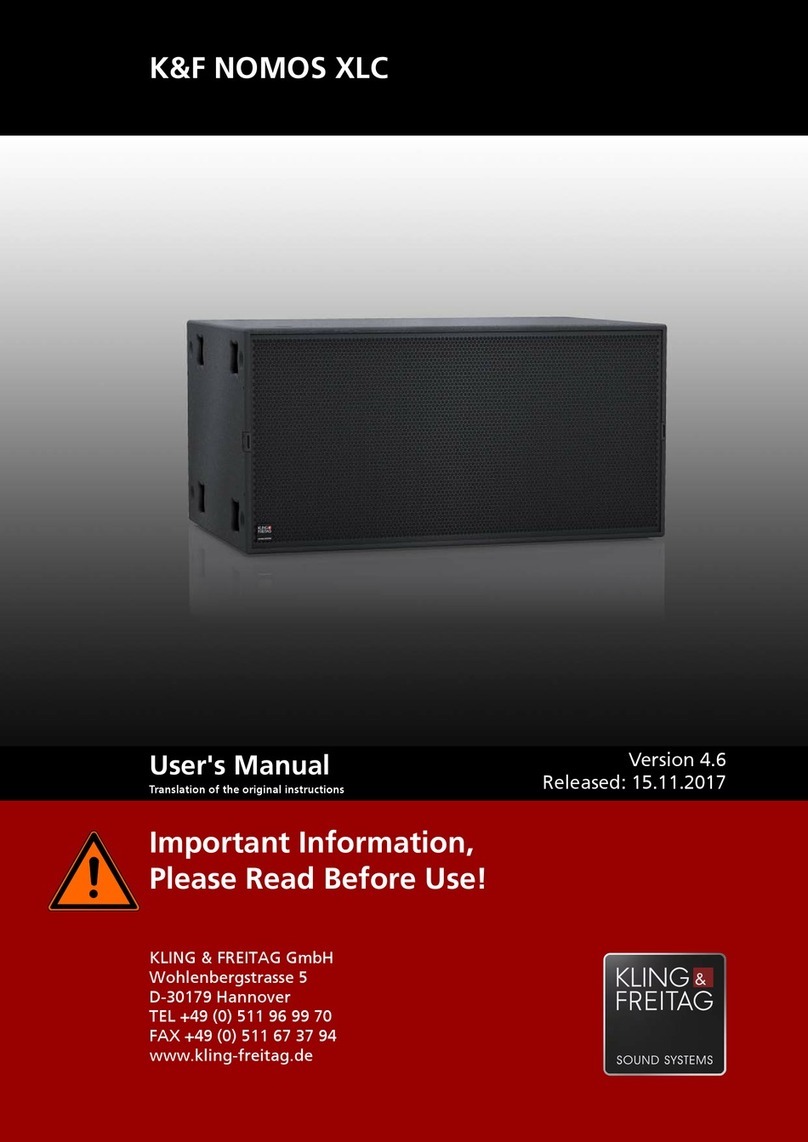

Product Specifications

85Hz - 20,000HzOperating Range 91dB

101dB

110 Degrees

Defined by height and configuration of the

array

100W (28 Volts) AES/2

145W (32 Volts) IEC Short Term

111dB Cont. / 117dB Peak

200 Watts @ 8 ohms

150 Watts @ 8 ohms

8 Ohms

7 Ohms

DSP Settings Provided

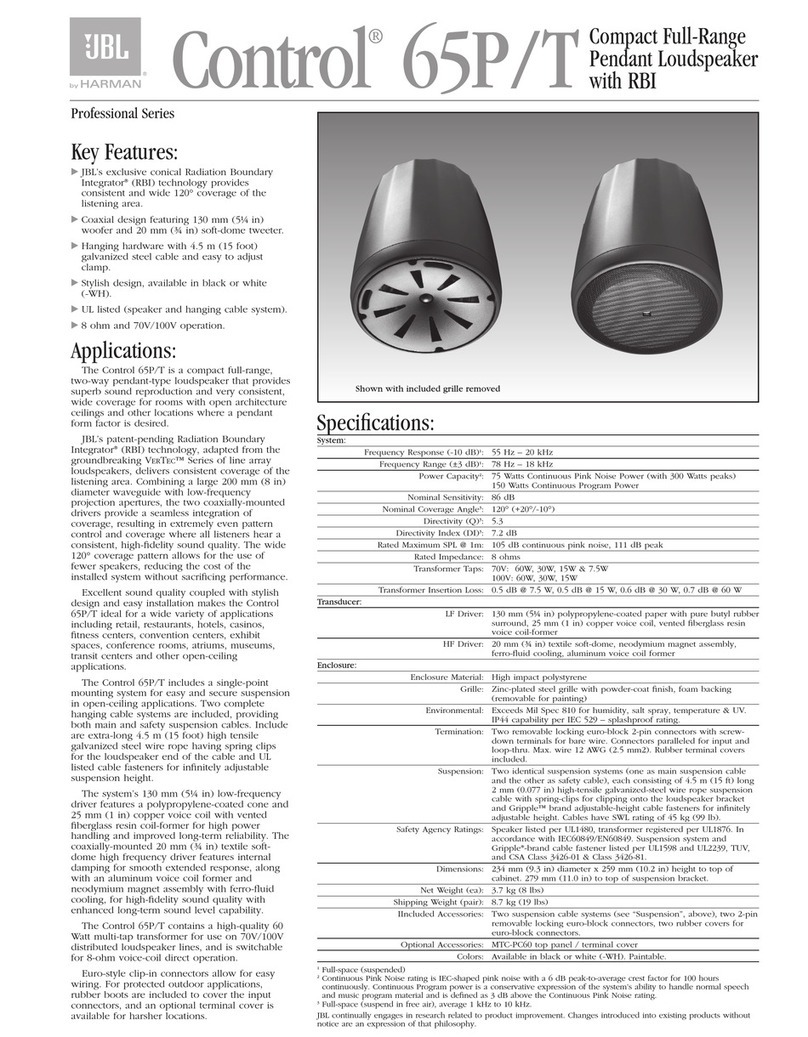

6.5” Bass/Midrange

PRD500 Ribbon

NL4 x2 (Pair 1 = LF, Pair 2 = HF)

7.25” (18.4cm) H (front side)

5.5” (14cm) H (rear side)

14” (35.6cm) W

10” (25.4cm) D

13ply Baltic Birch

20lbs (9kg) Shipping 26lbs (11.8kg)

All array rigging is included

RLA/3-BB - Rigging Frame

Black Latex

White Latex (w/ white rigging)

Paintable Natural Finish (w/ black rigging)

High Freq.

Vertical Coverage Angle

High Freq.

Max SPL (calculated) 1 Meter - Low Freq.

High Freq.

RecommendedAmp Power for Max Output

Low Freq.

High Freq.

Nominal Impedance - Low Freq.

High Freq.

Crossover Frequency

Transducers - Low Freq.

High Freq.

Input

Dimensions

Enclosure

Weight

Rigging

OptionalAccessories

Finish Options

2

RC-LS6500 Road Case (holds 8 LS6500s)

46W (18 Volts) IEC Long Term

35W (15.6 Volts) AES/2

5

Barrier strip for I version

1