SMAR FY302 Manual

FY302ME

MAR / 05

web: www.smar.com

smar

Specifications and information are subject to change without notice.

For the latest updates, please visit the SMAR website above.

BRAZIL

Smar Equipamentos Ind. Ltda.

Rua Dr. Antonio Furlan Jr., 1028

Sertãozinho SP 14170-480

Tel.: +55 16 3946-3510

Fax: +55 16 3946-3554

e-mail: insales@smar.com.br

CHINA

Smar China Corp.

3 Baishiqiao Road, Suite 30233

Beijing 100873, P.R.C.

Tel.: +86 10 6849-8643

Fax: +86-10-6894-0898

FRANCE

Smar France S. A. R. L.

42, rue du Pavé des Gardes

F-92370 Chaville

Tel.: +33 1 41 15-0220

Fax: +33 1 41 15-0219

e-mail: smar.am@wanadoo.fr

NETHERLANDS

Smar Nederland

De Oude Wereld 116

2408TM Alphen aan den Rijn

Tel: +31 172 494 922

Fax: +31 172 479 888

e -mail : info@smarnederland.nl

GERMANY

Smar GmbH

Rheingaustrasse 9

55545 Bad Kreuznach

Germany

Tel: + 49 671-794680

Fax: + 49 671-7946829

MEXICO

Smar Mexico

Cerro de las Campanas #3 desp 119

Col. San Andrés Atenco

Tlalnepantla Edo. Del Méx - C.P. 54040

Tel.: +53 78 46 00 al 02

Fax: +53 78 46 03

SINGAPORE

SmarSingapore Pte. Ltd.

315 Outram Road

#06-07, Tan Boon Liat Building

Singapore 169074

Tel.: +65 6324-0182

Fax: +65 6324-0183

e-mail: info@smar.com.sg

UNITED KINGDOM

SmarUK Ltd

3, Overhill Road - Cirencester

Gloucestershire -

GL7 2LG

Tel: +44 (0)797 0094138

Fax: +44 (0)797 4747502

e-mail: info@smarUK.co.uk

USA

Smar International Corporation

6001 Stonington Street, Suite 100

Houston, TX 77040

Tel.: +1 713 849-2021

Fax: +1 713 849-2022

e-mail: sales@smar.com

Smar Laboratories Corporation

6001 Stonington Street, Suite 100

Houston, TX 77040

Tel.: +1 713 849-2021

Fax: +1 713 849-2022

e-mail: sales@smar.com

Smar Research Corporation

4250 Veterans Memorial Hwy. Suite 156

Holbrook , NY 11741

Tel: +1-631-737-3111

Fax: +1-631-737-3892

e-mail: sales@smarresearch.com

Introduction

III

INTRODUCTION

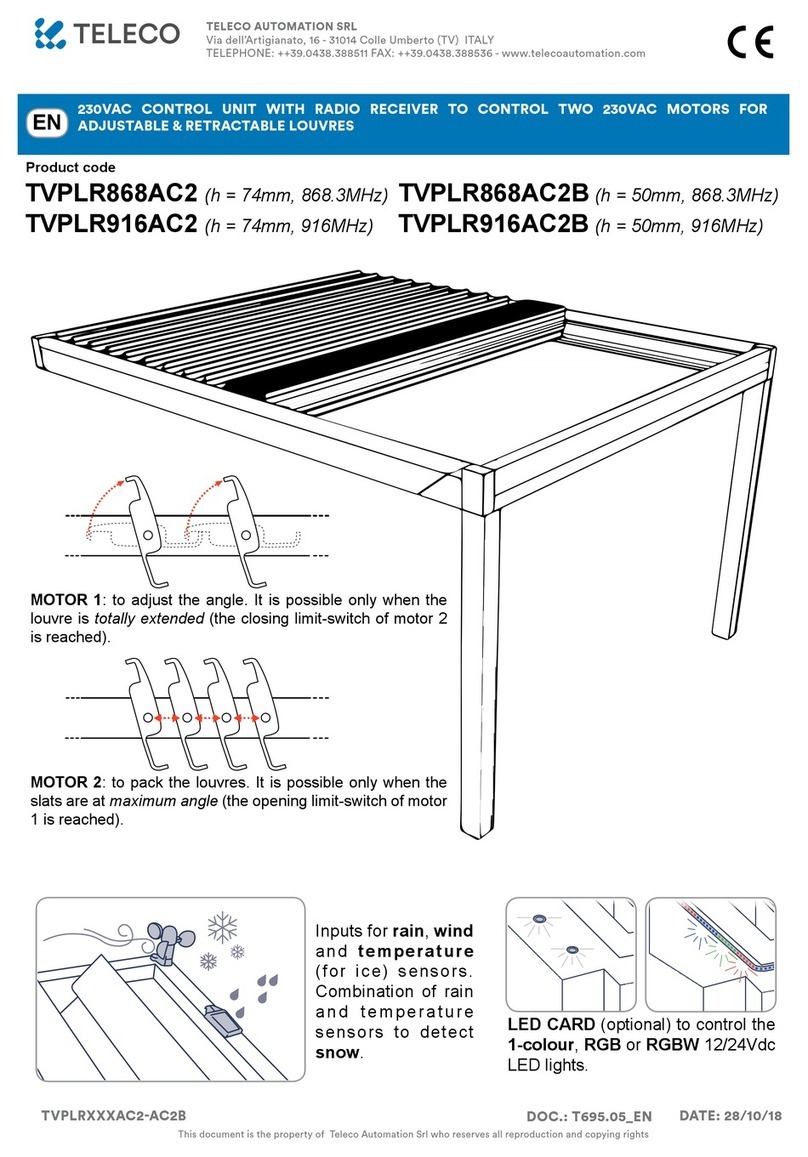

The FY302 is a Fieldbus valve positioner for Single (spring return) or Double acting Linear motion

type control valves e. g. Globe, Gate, Diaphragm, Pinch or Clamp and Rotary motion type control

valves e. g. Ball, Butterfly or Plug with pneumatic type actuators e. g. Diaphragm, Piston, Vane, or

Bellows. It is based on a field-proven piezo flapper and non-contacting Hall-effect position sensor

that provides reliable operation and high performance. The digital technology used in the FY302

enabled the choice of several types of flow characterizations, an easy interface between the field

and the control room and several interesting features that considerably reduce the installation,

operating and maintenance costs.

The FY302 is part of Smar's complete 302 line of Fieldbus devices.

Fieldbus is not only a replacement for 4-20 mA, or intelligent/smart transmitter protocols, it contains

much more. Fieldbus is a complete system enabling distribution of the control function to equipment

in the field.

Some of the advantages of bi-directional digital communications are known from existing smart

transmitter protocols: Higher accuracy, multi-variable access, remote configuration and diagnostics,

and multi-dropping of several devices on a single pair of wires.

The main requirements for Fieldbus were to overcome these problems. Closed loop control with

performance like a 4-20 mA system requires higher speed. Since higher speed means higher power

consumption, this clashes with the need for intrinsic safety. Therefore a moderately high

communication speed was selected, and the system was designed to have a minimum of

communication overhead. Using scheduling the system controls variable sampling, algorithm

execution and communication so as to optimize the usage of the network, not loosing time. Thus,

high closed loop performance is achieved.

Using Fieldbus technology, with its capability to interconnect several devices, very large control

schemes can be constructed. In order to be user friendly the function block concept was introduced

(users of SMAR CD600 should be familiar with this, since it was implemented there years ago). The

user may now easily build and overview complex control strategies. Another advantage is added

flexibility; the control strategy may be edited without having to rewire or change any hardware.

The FY302, like the rest of the 302 family, has several Function Blocks built in, like PID controller,

Input Selector and Splitter/Output Selector, eliminating the need for separate device. This takes to

reduced communication and thereby less dead-time and tighter control, not to mention the reduction

in cost.

The need for implementation of Fieldbus in small as well as large systems was considered when

developing the entire 302 line of Fieldbus devices. They have the common features of being able to

act as a master on the network and be configured locally using a magnetic tool, eliminating the need

for a configurator or console in many basic applications.

Get the best result of the FY302 by carefully reading these instructions.

WARNING

Throughout the operation of the positioner, including self-setup, do not touch the moving parts of

valve/actuator/positioner assembly as they may unexpectedly move automatically. Make sure to

disconnect supply air before touching any moving parts.

FY302 – Operation, Maintenance and Instructions Manual

IV

NOTE

This manual is compatible with version 3XX, where 3 denotes software version and XX software

release. The indication 3.XX means that this manual is compatible with any release of software

version 3.

Table of Contents

V

TABLE OF CONTENTS

SECTION 1 - INSTALLATION.................................................................................................1.1

GENERAL..............................................................................................................................1.1

MOUNTING............................................................................................................................1.1

ROTARY MOVEMENT..............................................................................................................1.1

LINEAR MOVEMENT ...............................................................................................................1.2

PNEUMATIC CONNECTIONS....................................................................................................1.2

ELECTRONIC HOUSING ROTATING..........................................................................................1.5

ELECTRIC WIRING .................................................................................................................1.5

TOPOLOGY AND NETWORK CONFIGURATION...........................................................................1.6

INTRINSIC SAFETY BARRIER...................................................................................................1.8

JUMPER CONFIGURATION ......................................................................................................1.8

POWER SUPPLY ....................................................................................................................1.8

RECOMMENDATIONS FOR AN INSTRUMENT AIR SYSTEM...........................................................1.8

SECTION 2 - OPERATION......................................................................................................2.1

FUNCTIONAL DESCRIPTION -OUTPUT MODULE.......................................................................2.1

FUNCTIONAL DESCRIPTION-ELECTRONICS..............................................................................2.2

INTRODUCTION TO FIELDBUS APPLICATION .............................................................................2.4

FUNCTION BLOCKS................................................................................................................2.4

TRANSDUCER BLOCKS...........................................................................................................2.4

RESOURCE BLOCK ................................................................................................................2.4

THE LOCAL INDICATOR ..........................................................................................................2.5

FOUR DIFFERENT POSITIONS TO THE LCD DISPLAY................................................................2.6

SECTION 3 - CONFIGURATION.............................................................................................3.1

TRANSDUCER BLOCK.............................................................................................................3.1

TRANSDUCER BLOCK DIAGRAM..............................................................................................3.1

FIELDBUS POSITIONER TRANSDUCER .....................................................................................3.2

TRANSDUCER BLOCK PARAMETER DESCRIPTION ....................................................................3.7

TRANSDUCER BLOCK PARAMETER ATTRIBUTES......................................................................3.9

HOW TO CONFIGURE A TRANSDUCER BLOCK........................................................................3.11

AUTO-SETUP ......................................................................................................................3.11

CALIBRATION ......................................................................................................................3.13

POSITION TRIM....................................................................................................................3.14

Via SYSCON....................................................................................................................................3.14

SENSOR PRESSURE ............................................................................................................3.18

FLOW CHARACTERIZATION...................................................................................................3.19

TEMPERATURE CALIBRATION ...............................................................................................3.21

DISPLAY TRANSDUCER BLOCK.............................................................................................3.21

DEFINITION OF PARAMETERS AND VALUES............................................................................3.22

CALIBRATING VIA LOCAL ADJUSTMENT.................................................................................3.24

PROGRAMMING USING LOCAL ADJUSTMENT .........................................................................3.25

SECTION 4 - MAINTENANCE PROCEDURES ......................................................................4.1

GENERAL..............................................................................................................................4.1

DISASSEMBLY PROCEDURE ...................................................................................................4.2

REASSEMBLY PROCEDURE ....................................................................................................4.3

SECTION 5 - TECHNICAL CHARACTERISTICS...................................................................5.1

FUNCTIONAL SPECIFICATIONS................................................................................................5.1

PERFORMANCE SPECIFICATIONS............................................................................................5.2

PHYSICAL SPECIFICATIONS....................................................................................................5.2

SMAR -GENERAL TERMS OF WARRANTY ..............................................................................5.5

FY302 – Operation, Maintenance and Instructions Manual

VI

Section 1

1.1

INSTALLATION

General The overall accuracy of measurement and control depends on several variables. Although the

converter has an outstanding performance, proper installation is essential, in order to maximize its

performance.

Among all factors, which may affect converter accuracy environmental conditions are the most

difficult to control. There are, however, ways to reduce the effects of temperature, humidity and

vibration.

The FY302 has a built-in temperature sensor to compensate for temperature variations. At the field,

this feature minimizes the temperature variation effect.

Locating the positioner in areas protected from extreme environmental changes can minimize

temperature fluctuation effects.

In warm environments, the positioner should be installed to avoid, as much as possible, direct

exposure to the sun. Installation close to lines and vessels subjected to high temperatures should

also be avoided.

Use of sunshades or heat shields to protect the positioner from external heat sources should be

considered, if necessary.

Humidity is fatal to electronic circuits. In areas subjected to high relative humidity, the O-rings for the

electronics cover must be correctly placed. Removal of the electronics cover in the field should be

reduced to the minimum necessary, since each time it is removed; the circuits are exposed to

humidity. The electronic circuit is protected by a humidity proof coating, but frequent exposures to

humidity may affect the provided protection. It is also important to keep the covers tightened in

place. Every time they are removed, the threads are exposed to corrosion, since painting cannot

protect these parts. Code approved sealing methods on conduit entering the positioner should be

employed.

Although the positioner is virtually insensitive to vibration, installation close to pumps, turbines or

other vibrating equipment should be avoided.

Mounting The mounting of positioner FY302 will depend on actuator type, single (spring return) action or

double action and on actuator movement, if it is linear or rotary. Two supports are required for

mounting, one for the magnet and the other for the positoner itself. Smar may supply them both

since they are specified in the order code. (See Table 5.2 – Bracket Ordering Code).

Rotary Movement

Install the magnet on the valve stem using the magnet support (See Figure 1.2 - Positioner on

Rotary Actuator).

Install the positioner support on the actuator. The actuator should be in accordance with standard

VDI/VDE 5845, all you have to do is tighten the four screws with the lock washers on the standard

support.

For special supports, refer to specify instructions. After installing the support on the actuator, it is

possible to mount the positioner FY302 on the support by means of the four screws with lock

washers.

Make sure that the arrow engraved on the magnet coincides with the arrow engraved on the

positioner when the valve is in mid travel.

If the installation of the positioner or magnet should be altered, or if there should be any other

modification, the positioner will require a recalibration.

As to the type of valve action, refer to paragraph "Pneumatic Connections".

FY302 – Operation, Maintenance and Instructions Manual

1.2

Linear Movement

Install the magnet on the valve stem using the magnet support (See Figure 1.3 - Positioner on

Linear Actuator).

Install the positioner support on the actuator. The actuator support may be secured in place as per

standard NAMUR/IEC 536-4 or in accordance with user specified boring. Install the positioner on the

support and tighten the four screws in the threaded bores located on the side opposite to the

pressure gages (See Figure 1.3 - Positioner on Linear Actuator). Use lock washers in order to

prevent screw slackening.

Make sure that the support is not obstructing the exhaustion outlets.

NOTE

Make sure that arrow engraved on the magnet coincides with the arrow engraved on the positioner when the

valve is in mid travel. The magnet mounting in relation to the hall sensor:

1 . Must not have attrict between the internal magnet face and the hall sensor salience during the travel

(rotary or linear), through the magnet.

2. The magnet and the salience of hall sensor must not be distant.

A minimum distance of 2mm and a maximum distance of 4mm is recommended between the magnet external

face and the positioner face. For that, a centralizer device (linear or rotary) must be used. The centralizer

device is in the positioner packing.

If the installation of the positioner or magnet should be altered, or if there should be any other

modification, the positioner will require a recalibration.

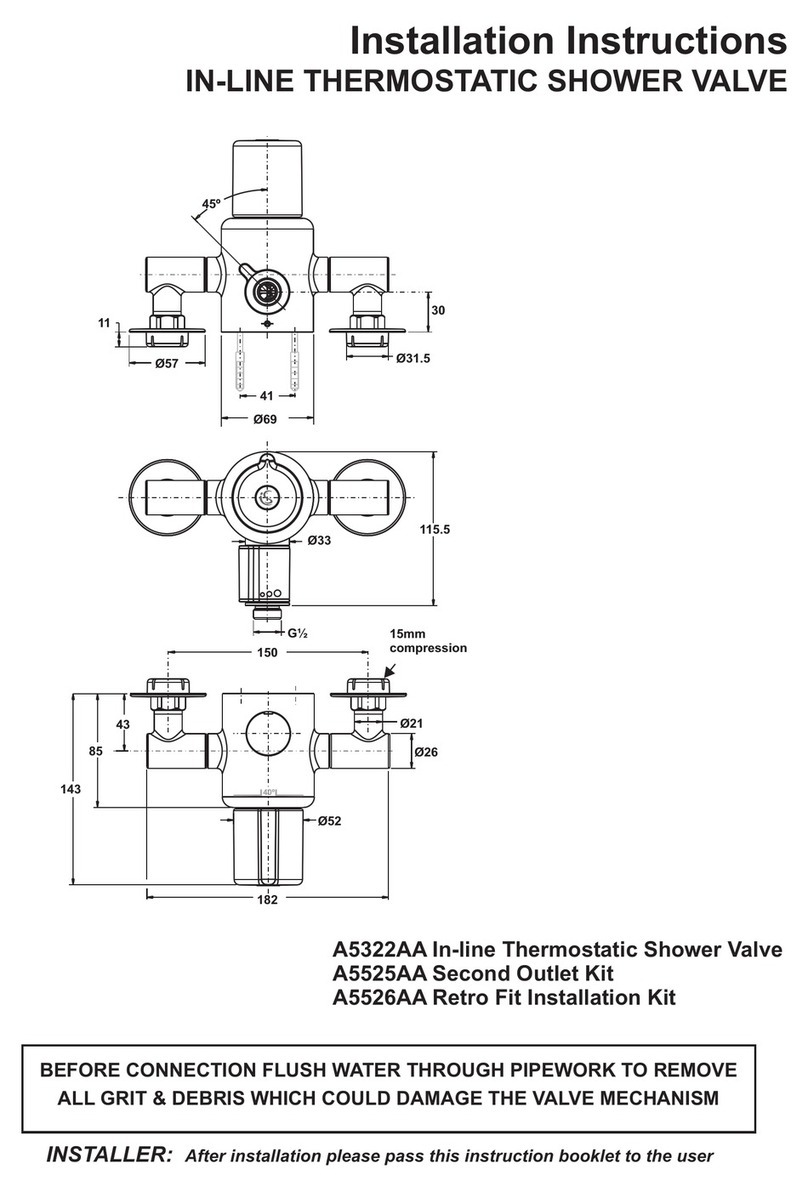

Pneumatic Connections

Air supplied to the positioner FY302 shall be quality instrument air, i. e., dry, clean and non-

corrosive. Refer to the American National Standard. “Quality Standard for Instrument Air” (ANSI/ISA

S7.0.01 - 1996).

The FY302 is supplied with input and outputs air filters; but these filters do not substitute a

preliminary instrumentation air treatment. We recommend a periodic cleaning of such filters each 6

months or less, case the air instrument quality is not good.

Air supply pressure to the FY302 shall be between 1.4 bar (20 psi) and 7 bar (100 psi). In case such

requirements can not be fulfilled, the use of an air pressure regulator is acceptable.

Use sealant on threads. Sealants like PTFE (Teflon) tape shall be avoided because they may

fragment and eventually obstruct internal parts.

The positioner FY302 may be supplied with pressure gages. There are taps available for IN, OUT1

and OUT2. Before connecting the pressure gages, make sure that all lines be completely purged.

Valve positioner FY302 has two pneumatic outputs. They work on opposite directions to open or

close the valve.

WARNING

The FY302 should fail, for example, because of a power failure. The output identified as OUT1 (output 1)

goes to nearly zero; while the output identified as OUT2 (output 2) goes to nearly the air supply pressure.

Pneumatic connections are identified as IN (input) for the air supply, and OUT1 and OUT2 for

Output 1 and Output 2 respectively (See Figure 1.1 - FY302 Dimensional Drawing). Use 1/4 NPT

connections. Sealant may be used NPT threads. Connect the air supply tubing to the connection

identified as IN. Make sure that the air supply pressure does not exceed the maximum rating

accepted by the positioner or actuator. The tubing used to connect the positioner FY302 to the

actuator shall be as short as possible. The manometer supply is optional.

NOTE

When ordering the positioner in stainless steel 316, combined with the local pressure gauges, the gauge

case is in SS 316. For wet parts and threads in SS 316, please, consult Smar.

ATTENTION

Make sure that sealant does not enter the positioner.

Installation

1.3

There are six exhaust outputs in the FY302, all of them fitted with filters (See Figure 1.1 - FY302

Dimensional Drawing).

It is very important that such outputs are neither blocked nor obstructed, because the air must

circulate freely.

All filters shall be inspected to make sure they will not obstruct the outputs (Refer to Section 4 -

Maintenance Procedures).

Double Action - Air to Open (Fail Close)

Connect Output 1 (OUT1) of the positioner to the input identified as OPEN in the actuator, and

connect Output 2 (OUT2) of the positioner to the input CLOSE in the actuator (See Figure 1.1 -

FY302 Dimensional Drawing).

Double Action - Air to Close (Fail Open)

Connect Output 2 (OUT2) of the positoner to the input identified as OPEN in the actuator, and

connect Output 1 (OUT 1) of the positioner to the input CLOSE of the actuator.

Single Action

Connect Output 1 (OUT1) of the positioner to the input of the actuator. Use a plug to block Output 2

(OUT2). (The Figure 1.2 - Positioner on Rotary Actuator and Figure 1.3 - Positioner on Linear

Actuator show the positioner in rotary and linear actuators).

OUTPUT 1

1/8 - 27 NPT

55

4

6

,5

69

21

24

50

(

1,97

)

(0,954)

(0,83)

(2,72)

24

(0,94)

113

(4,45)

(1,83)

83

39 45 45 260

83

33

22,5

HOLE 6,3 (0,25)

(2 PLACES)

10

A

(0,59)

(0,89)

(1,30)

(2,10)

53,3

49,5 56

(2,17)

(1,95)

24 24

EXHAUST ORIFICIES

(0,94) (0,94)

(1,54) (1,77)

6,5

MOUNTING ROLES FOR M6x1

SCREWS (2 PLACES)

Up to 15 mm (0,59)

TRAVEL DIMENSION A

Up to 50 mm (1,97)

43 mm (1,7)

105 mm (4,13)

181 mm (7,12)

Up to 100 mm (3,94)

(0,25)

22 22

39

(

1,54

)

(0,87) (0,87)

(1,77) (10,24)

(3,27)

OUTPUT 1

1’/4 - 18NPT OUTPUT 2

1’/4 - 18NPT

(2,16)

(3,27)

64,5

18

(2,54)

(0,71)

AIR SUPPLY

1/8 - 27 NPT

AIR

SUPPLY

1/8 - 27 NPT

OUTPUT 2

1/8 - 27 NPT

VALVE POSITIONER

ROTARY MAGNET

LINEAR MAGNET

A

ll dimensions are in mm

(

in

)

Up to 30 mm (1,18) 67 mm (2,64)

Figure 1.1 - FY302 Dimensional Drawing

FY302 – Operation, Maintenance and Instructions Manual

1.4

ROTATING

MAGNET BASE

ROTARY

MAGNET

POSITIONER

BASE

POSITIONER

VALVE STEM

Figure 1.2 - Positioner on Rotary Actuator

LINEAR MAGNET

BRACKET

VALVE YOKE

VALVE STEM

LINEAR MAGNET

CENTRALIZER

DEVICE

POSITIONER

POSITIONER

BRACKET

Figure 1.3 - Positioner on Linear Actuator

Installation

1.5

Electronic Housing Rotating

The electronic housing can be rotated in order to have a better position of the digital display. To

rotate it, use the Housing Rotation Set Screw. (See Figure 1.4 – Cover Locking and Housing

Rotation Set Screw).

The local indicator itself can also be rotated. (See Figure 2.4 – Rotating the position of the LCD

Display).

Electric Wiring

Reach the wiring block by removing the Electrical Connection Cover. This cover can be locked by

the cover locking screw. To release the cover, rotate the locking screw clockwise.

The wiring block has screws on which fork or ring-type terminals can be fastened.

(See Figure 1.5 – Wiring Block).

Figure 1.4 - Cover Locking and Housing Rotation Set Screw

or convenience there are two ground terminals: one inside the cover and one external, located

Figure 1.5 - Wiring Block

HOUSING ROTATION

SET SCREW

COVER

LOCKING

SCREW

F

close to the conduit entries. (See Figure 1.5 – Wiring Block).

GROUND

TERMINA

L

POWER

SUPPLY

TERMINALS

COMMUNICATION

TERMINALS

FY302 – Operation, Maintenance and Instructions Manual

1.6

WARNING

In hazardous areas with explosion proof requirements, the covers must be tightened with at least 8 turns. In

order to avoid the penetration moisture or corrosive gases, tighten the O’ring until feeling the O'ring touching

the housing. Then, tighten more 1/3 turn (120°) to guarantee the sealing. Lock the covers using the locking

screw.

In hazardous zones with intrinsically safe or non incendive requirements, the circuit entity parameters and

applicable installation procedures must be observed.

Cable access to wiring connections is obtained by the two conduit outlets. Conduit threads should be sealed

by means of code-approved sealing methods. The unused outlet connection should be plugged and sealed

accordingly.

Should other certifications be necessary, refer to the certification or specific standard for installation

limitations.

The Figure 1.6 - Conduit Installation Diagram shows the correct installation of the conduit, in order

to avoid penetration of water, or other substance, which may cause malfunctioning of the

equipment.

Figure 1.6 - Conduit Installation Diagram

NOTE

Please refer to the General Installation, Operation and Maintenance Manual for more details.

Topology and Network Configuration

Bus topology (See Figure 1.7 - Bus Topology) and tree topology (See Figure 1.8 - Tree Topology)

are supported. Both types have a trunk cable with two terminations. The devices are connected to

the trunk via spurs. The spurs may be integrated in the device giving zero spur length. A spur may

connect more than one device, depending on the length. Active couplers may be used to extend

spur length.

Active repeaters may be used to extend the trunk length.

The total cable length, including spurs, between any two devices in the Fieldbus should not exceed

1900m.

The connection of couplers should be kept less than 15 per 250m.

CO

RRE

C

T

WIRES

IN

CO

RRE

C

T

Installation

1.7

Figure 1.7 - Bus Topology

Figure 1.8 - Tree Topology

PS302

FAIL

ON

smar

PSI302

FAIL

1

FA

ON

IL

FAIL

FAIL

smar

smar

0

FUSE

2,5A

PS

I3

02

3.

(P

ow

er

Su

ppl

y

Im

pe

da

n

c

1A

2A

3A

4A

IN

24VDC

BT

OUT 1

Fieldbus H1

OUT 2

Fieldbus H1

OUT 3

Fieldbus H1

OUT 4

Fieldbus H1

5A

6A

7A

8A

9A

10A

Spur

Terminator

Enabled

Spur Spur

Junction

Box

Terminator

Shield

+

++

PS302

FAIL

ON

smar

PSI302

ON

FAIL

FAIL

smar

FAIL

FAIL COUPLER

smar

FUSE

2,5A

y

Im

pe

da

PS

I3

02

3.

ppl

0

(P

ow

er

Su

nc

1A

2A

3A

IN

24VDC

OUT 1

Fieldbus H1

OUT 2

Fieldbus H1

4A

BT

OUT 3

Fieldbus H1

OUT 4

Fieldbus H1

5A

6A

7A

8A

9A

10A

FY302 – Operation, Maintenance and Instructions Manual

1.8

Intrinsic Safety Barrier

on the trunk

Jumper Configur

st be correctly

When the Fieldbus is in an area requiring intrinsic safety, a barrier must be inserted

between the power supply and the power supply end terminator.

Use of SB302 is recommended.

ation

In order to work properly, the jumpers J1 and W1 located in the FY302 main board mu

configured (See Table 1.1 - Description of the Jumpers).

J1 This jumper enables the simulation mode parameter in the AO block.

W1 This jumper enables the local adjustment programming tree.

Table 1.1 - Description of the Jumpers

The FY302 receives power from the bus via the signal wiring. The power supply ma

separate unit or from another device such as a controller or DCS.

The voltage should be between 9 to 32 Vdc for non-intrinsic safe applications.

A special requirement applies to the power supply used in an intrinsically safe bus an

the type of barrier used.

Use of PS302 is recommended as power supply.

Power Supply

y come from a

d depends on

Recommendations or an Instrum

ity, airborne

y in case of

, instrument air shall

f

ent Air System

Instrument air quality shall be superior to that of industrial compressed air. Humid

particles and oil may impair the instrument operation, either temporarily or permanentl

internal parts wearing.

As per standard ANSI/ISA S7.0.01 - 1996 - Quality Standard for Instrument Air

the following characteristics:

Dew point 10°C below minimum plant temperature

Size of particles (airborne) 3 m (maximum)

Oil content 1 ppm w/w (maximum)

Contaminants free from toxic flammable gases

Table 1.2 - Quality Standard for Instrument Air

This standard recommends that the compressor intake be located in an area free from pro

and fitted with and adequate filter. It also recommends the use of non-lubricated type c

in order to prevent air contamination by lubricating oil. Where lubricated type compr

adopted, there shall be used means to make the air oil free.

The Figure 1.9 - Air Supply System and Figure 1.10 - Air Quality Conditioning System sho

system for Air Supply and Air Quality Conditioning.

cess spills

ompressors,

essors are

w a typical

Installation

1.9

emote Hall Sensor

me vibrations applications. It prevents excessive wear of the equipment and,

onsequently, the reduction of its useful lifetime.

mote sensor’s connection cable are of low intensity. Therefore, it is

commended to install the cable inside a conduit (maximum length 20 meters) away from possible

s nduction and/or e cable supplied by Smar is shielded

in ord ite this protection, it is not

r e e conduit with other cables.

T the sensor’s c

Fig. 1.13 –Hall Sensor cable and its accessories

Figure 1.9 - Air Supply System

Figure 1.10 - Air Quality Conditioning System

R

The remote Hall magnetic sensor is recommended for applications where there are high

temperatures and extre

c

The electric signals on the re

re

ources of i

er to protect it agai

electromagnetic interferences. Th

nst electromagnetic interferences. Desp

ecommended for the cabl to share the sam

he parts for onnection cable are:

COMPRESSOR

INTAKE

RAIR RECEIVER

ITH DRAIN

COMPRE AFTERCOOLER CONDENSATE

SEPARATO

SSOR

WITH DRAIN W

OIL AND

MIST PR

WITH

WATER

EFILTER

RAIN

D

A

IR

DRYER

DRY AIR

A

FTER FILTER

FY302 – Operation, Maintenance and Instructions Manual

1.10

Disassembly Procedure

he steps for

for the

1.13 and

Figures 1.11 to 1.14 show the correct disassembling order for the Hall sensor. T

disassembling are:

Unscrew the cover, by turning it on counter-clockwise direction (direction of the arrow)

remote Hall side according to figure 1.11.

Pull the cable following the arrow as in figure 1.12,

Pull the cable connector base, to release it from the block connector, according to figures

1.14.

Fig. 1.14 – Disconnecting the cover of the Hall

sensor cable Fig. 1.15 – Disconnecting the Hall sensor cable

Fig. 1.16 –Unfastened connector Fig. 1.17 – Connector with the cable’s wires

maintained in their orifices

Fig. 1.18 – Wires position in the connector Fig. 1.19 – Release the cables’ connector

Assembly Procedure

Installation

1.11

Mount the components following the sequence:

gh the base connector orifice (Figure 1.18);

Pass the cable through the cover orifice (Figure 1.17);

Pass the cable throu

The red, white, and black wires should be inserted in the base connector orifice marked by numbers

beside them, look at Figure 1.19 e 1.20.

Fig. 1.20 – Assembling the cover Fig. 1.21 – Assembling the wire bracket

Fig. 1.22 – Inserting the wires in the connector. Fig. 1.23 – Orifice Cable’s Connector with

Numbers beside them.

Insert the cable connector in the remote Hall's block connector as figure 1.21. The block connector

has internal saliencies that perfectly fit the groove, in order to prevent errors in the assembly. The

cutting p will cut th us

establi the cable and the ha

o finish, fasten the cover to the Hall sensor’s connection (figure 1.2

ins inside of the block connector

shing the electric contact between e wire insulators and press against them, th

ll sensor’s circuit.

2).T

Fig. 1.24– Fasten the cover to the remote Hall. Fig. 1.25 –Assembly finished.

FY302 – Operation, Maintenance and Instructions Manual

1.12

Section 2

2-1

OPERATION

Functional Description - Output Module

The main parts of the output module are the pilot, servo, Hall effect sensor and the output control

circuit. (See Figure 2.1 - Pneumatic Transducer Schematic).

The control circuit receives a digital setpoint signal from the CPU and a feedback signal from the

Hall effect sensor.

The pneumatic circuit is based on a well-known and widely adopted technology, which is described

on item Nozzle-and-Vane and Spool.

PILOT

RESTRICTION

PILOT DIAPHRAGM

SPOOL DIAPHRAGM

AIR SUPPLY

NOZZLE

PIEZO

VANE

SPOOL

PILOT

CHAMBER

VENT 2

OUTPUT 2

OUTPUT 1

VENT 1

SPRING

Figure 2.1 - Pneumatic Transducer Schematic

A piezoelectric disk as flapper in the pilot stage. The flapper is deflected when the control circuit

applies a voltage. A small stream of air flowing through the nozzle is obstructed causing an increase

in pressure in the pilot chamber, this is called the pilot pressure.

The pilot pressure is too low, with flowing capacity, and for this reason it must be amplified in the

servo section. The servo section includes a diaphragm in the pilot chamber and a smaller one in the

spool chamber. The pilot pressure applies a force at the pilot chamber's diaphragm which, in the

equilibrium state, will be equal to the force applied by the spool valve at the smaller diaphragm

which is in the spool chamber.

Therefore, upon every position change caused by the positioner, the pilot pressure increases or

decreases as explained in the pilot stage section; such change in pilot pressure causes an upward

or downward valve travel wich alters the pressure at output 1 and output 2 until a new equilibrium is

reached, which results in a new valve position.

FY302 – Operation, Maintenance and Instructions Manual

2-2

Functional Description-Electronics

Refer to the block diagram (See Figure 2.2 - FY302 Block Diagram). The function of each block is

described below.

MAIN CIRCUIT BOARD DISPLAY

FIELDBUS

A

IR SUPPL

Y

(PIN)

TRANSDUCER ASSEMBLY

VALVE

P1

P2 ACTUATOR

M

A

G

N

E

T

VALVE

S

T

E

M

DISPLAY

CONTROLLE

R

SUPPLY

POWER

SUPPLY

COMMUNICATIO

N

FIELDBUS

CONTROLLE

R

EEPROM

RAM

FLASH

LOCAL

ADJUST

D/A

A/D

CPU

CONTROL

TEMPERATUR

E

SENSOR

ISOLATION

HALL

SENSOR

CIRCUIT

PIEZO

FLAPPER

NOZZLE

RESTRICTIO

N

SPOOL

VALVE

HALL

SENSOR

ANALOGIC BOARD

RECEIVER

FILTER AND

SIGNAL

SHAPING A/D

FIRMWARE

DOWNLOAD

INTERFACE

Figure 2.2 - FY302 Block Diagram

Other manuals for FY302

2

Table of contents

Other SMAR Control Unit manuals

Popular Control Unit manuals by other brands

Allen-Bradley

Allen-Bradley 1794-IE8H user manual

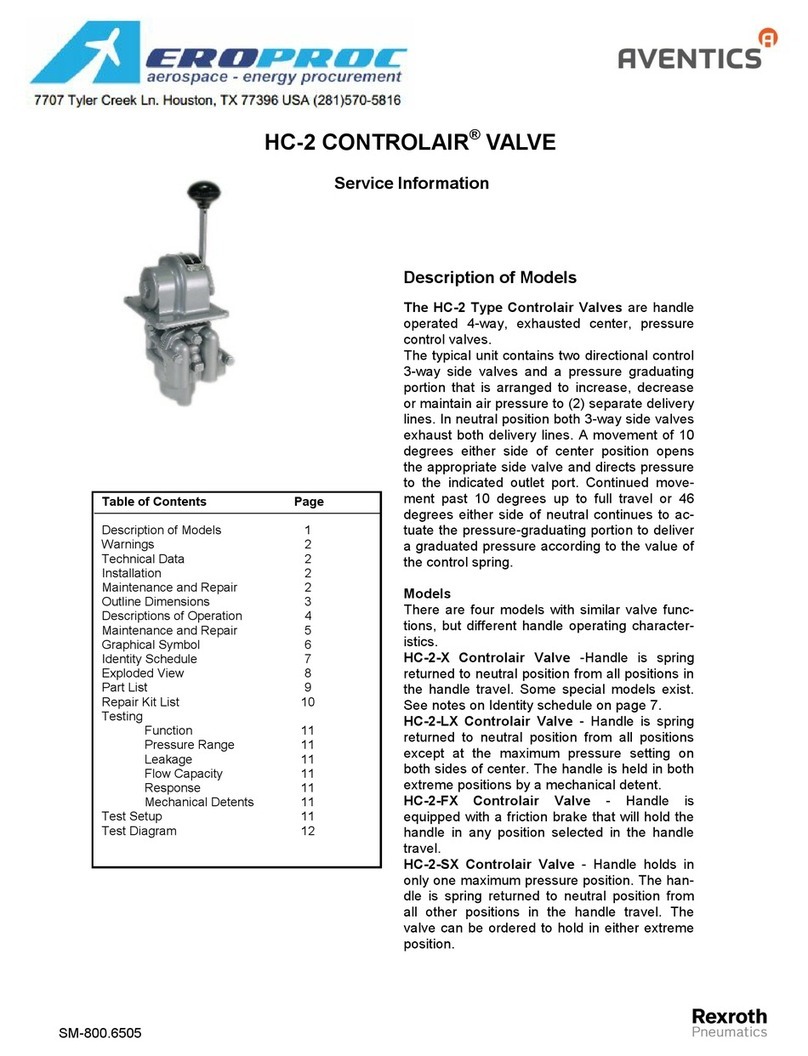

Aventics

Aventics CONTROLAIR HC-2 Series Service information

Siemens

Siemens Simatic ET200pro Product information

Vexve

Vexve X Series installation, operation, adjustment and maintenance manual

TAMURA

TAMURA EPM Series Application notes

Wirepath

Wirepath WP-MOD-RJ45-TEL1X12 installation guide