Smart power HR-6.2 User manual

9991035 Rev. N

A.C. MODULAR

GENERATOR SYSTEM

OWNERS MANUAL

MODEL#: HR-6.2, HR-8, HR-10 and HR-110

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 1 of 56

Table of Contents

Section Page

Disclaimer..........................................................................................................................5

Description of Product......................................................................................................6

System Specifications......................................................................................................9

Pre-Installation Guide.....................................................................................................13

Installation Guide............................................................................................................20

Hose Installation Guidelines .......................................................................................... 25

Operation......................................................................................................................... 32

Special Operating Instructions ......................................................................................39

Maintenance Instructions............................................................................................... 40

Troubleshooting Guide...................................................................................................43

Pump Adjustment............................................................................................................ 52

SPS Model Matrix............................................................................................................56

Doc. 9991035 Rev. N

ECO # 16417

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 2 of 56

WARNING:

Do not install or operate the A.C. modular generator system without reading this entire

manual.

The A.C. modular generator system will generate enough voltage to produce a fatal

electrical shock. Do not perform any wiring installations or modifications while the system

is operating. Nevertouch any live connections while the system is operating. Never operate

the system with the generator wiring enclosure open. Install and secure cover before

operating.

The installation of the Smart Power A.C. modular generator system is to be done in

accordance with applicable sections in the National Fire Protection Association’s document

NFPA 1901, National Electrical Code®, and/or other applicable, recognized electrical codes

and by a certified electrician.

Never directly expose the generator to any liquids, especially water, oil, or solvents.

Electrical shock, fire and/or damage to the generator can occur and will void the system’s

warranty.

Smart Power hydraulic generators, as well as all generators, must be sufficiently protected

from the environment to prevent damage to the stator. Smart Power stators go through a

very important double-dip coating process prior to generator assembly, however, exposure

to direct water sprays can cause the stator to electrically short. Generator damage and

electrical shock can occur.

Caution should be taken during truck pressure washing, since water damage to the

generator can occur if directly sprayed with high water pressure. Though Smart Power

Systems®(SPS) generators are enclosed as much as possible, direct spray through the

cooler, fan or open lid can still cause such damage.

Excessive road spray/salt can also cause an electrical short of the stator in the generator

and can also shorten the generator’s operating life. To prevent this type of damage, do not

mount the system where it will be exposed to road spray.

Evidence of water damage, road spray/salt infiltration, and improper mounting will void the

generator warranty.

Avoid physical contact with any of the components of the A.C. modular generator system

during its operation or immediately after its use. The components of this system will get hot

enough to cause burns and could ignite combustible materials.

Do not mount or locate anything inside of the framework. System overheating could result

and void the system’s warranty.

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 3 of 56

Never operate the system with leaks of any type. Clean up any hydraulic fluid that is spilled

or has leaked out of the system. Hydraulic fluid is combustible, and ignition may occur.

With the exception of instructions within this manual, never modify or remove any of the

components within the tray assembly.

Never modify or remove any of the components within the pump or the controls mounted to

the pump. This includes all fittings and tubing that are originally provided with the A.C.

modular generator system.

Never make any adjustments to the pump other than for flow control. If it appears the pump

needs to be adjusted, contact Smart Power Systems®at (231) 832-5525 before proceeding.

Damage to the generator from improper pump adjustment will void the system’s warranty.

Never attempt any adjustments or repairs to the A.C. modular generator system (other than

pump flow control) while the vehicle engine is running and the PTO is engaged.

Never operate the system with the hydraulic fluid exceeding 195

F. Above this temperature,

hydraulic fluid can rapidly oxidize and deteriorate causing generator performance problems.

Operating the system while the hydraulic fluid is above 195

Fwill void the system’s warranty.

Hydraulic fluid is combustible and toxic. In the event of human contact with hydraulic fluid,

generously flush body part (eyes, skin, etc.) with running water. Avoid inhalation of any oil

mist or vapor. Do not ingest hydraulic fluid. In case of fire, use foam, dry chemical or carbon

dioxide to extinguish flame.

Do not exceed the wattage rating of the generator. The generator may be permanently d

amaged and the generator and hydraulic components may reach temperatures that could

cause severe burns upon human contact with the components. Operating the generator

system at wattages above the system’s rating will void the system’s warranty.

Disengage the system immediately if a hydraulic fluid leak is detected. Operation of the

A.C. modular generator system with low fluid level will result in permanent damage to the

hydraulic components in the system and will void the system’s warranty.

Do not tamper with the hydraulic fluid level sensor.

Never attempt to operate the system without hydraulic fluid. Always maintain a fluid level

between ½ to ¾ full in the sight plug.

Operating the A.C. modular generator system in the presence of flammable vapors may

result in an explosion.

Use only hoses that meet or exceed the minimum requirements specified in this manual. A

ruptured hose can cause personal injury and/or damage to the generator system.

Do not operate the system under electrical load with air in the hydraulic fluid (the system will

make a growling sound). Do not allow anything to contact the hydraulic hoses that will cause

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 4 of 56

a kink, pinch or chaffing. The A.C. modular hydraulic system generates hydraulic pressures

approaching 3600 psi. A ruptured hose may result from abrasion, discharging hot, high-

pressure hydraulic fluid, which can cause serious personal injury, fire, and/or damage to the

system.

Never remove the guards on the generator to expose the rotating fan or motor coupling.

Personal injury will result if fingers, hair or loose clothing come in contact with rotating

components.

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 5 of 56

Disclaimer

Although SPS has taken all reasonable care to ensure that the information contained in this

installation manual (including without limitation, references, databases, resources,

specifications, illustrations and instructions) was accurate in all material respects at the time

of publication, SPS PROVIDES NO ASSURANCE, REPRESENTATION, WARRANTY OR

GUARANTEE, expressed or implied (including third party liability), with regard to this

manual, including without limiting the generality of the foregoing, with regard to its accuracy,

reliability or completeness. The entire information contained in this installation manual is

provided by SPS “AS IS” and without warranty of any kind, express or implied, including (but

not limited to) any implied warranties or merchantability, fitness for any particular purpose,

or non-infringement. Accordingly, by using the SPS unit and this information, you agree

that, to the greatest extent permitted by law, SPS (including, without limitation, its

subsidiaries, affiliates, agents, officers, directors, employees and insurers) is not and will not

be liable for losses or damages resulting from this installation manual, its use, any

information contained therein or the installation of the SPS unit.

This installation manual contains references to certain database and resources. As SPS

has no control over these database and resources, you acknowledge and agree that SPS

is not responsible or liable for any content, advertising, products, information or other

materials on or available from such database or resources. You further acknowledge and

agree that SPS shall not be responsible or liable, directly or indirectly, for any damage or

loss caused or alleged to be caused by or in connection with use of or reliance on any such

content, information goods or services available on or through any such database or

resources. All product illustrations and specifications are based upon current information at

the time of publication. Although descriptions are believed correct, complete accuracy

cannot be guaranteed. SPS reserves the right to make changes of any kind at any time,

without notice or obligation, in the information contained on this installation manual. All data

and information of any kind are subject to change without notice and SPS assumes no

obligation to update or correct information in this manual.

As some states do not allow the exclusion or limitation of liability for consequential or

incidental damages, the limitation contained herein may not apply to you. In such states,

SPS’ liability is limited to the greatest extent liability limitation is permitted by applicable law.

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 6 of 56

Description of Product

Hydraulic Generator Applications:

This heavy-duty electronically controlled generator system has been designed to meet the

most demanding mobile applications. It provides 120/240 volt AC @ 60 Hz, or 115/230 volt

AC @ 50hz from no-load to full load, handling electrical loads of 6200, 8000 and 10000

watts, depending on model.

How our System works:

A generator driven by a hydraulic motor delivers the electrical power. The motor turns at

3600 RPM for 60hz, or3000 RPM for 50hz as controlled by the flow of hydraulic fluid through

an electrically controlled proportional valve. The proportional valve is directly driven by the

system controller. The piston pump delivers fluid to the proportional valve through installer-

supplied PTO mounted to the vehicle’s transmission.

Heat generated in the hydraulic fluid as it passes through the various components in the

system is cooled by a heat exchanger and fan. A filter removes impurities in the fluid. A

venturi boost assembly monitors the volume of oil in the hydraulic circuit and feeds the

system from the reservoir as needed.

Essentially, the only system maintenance required is periodic replacement of the hydraulic

fluid filter and adding hydraulic fluid to maintain the fluid level (when the hydraulic fluid is

between 70and 80F, it should be at the ¾ mark on the sight gauge).

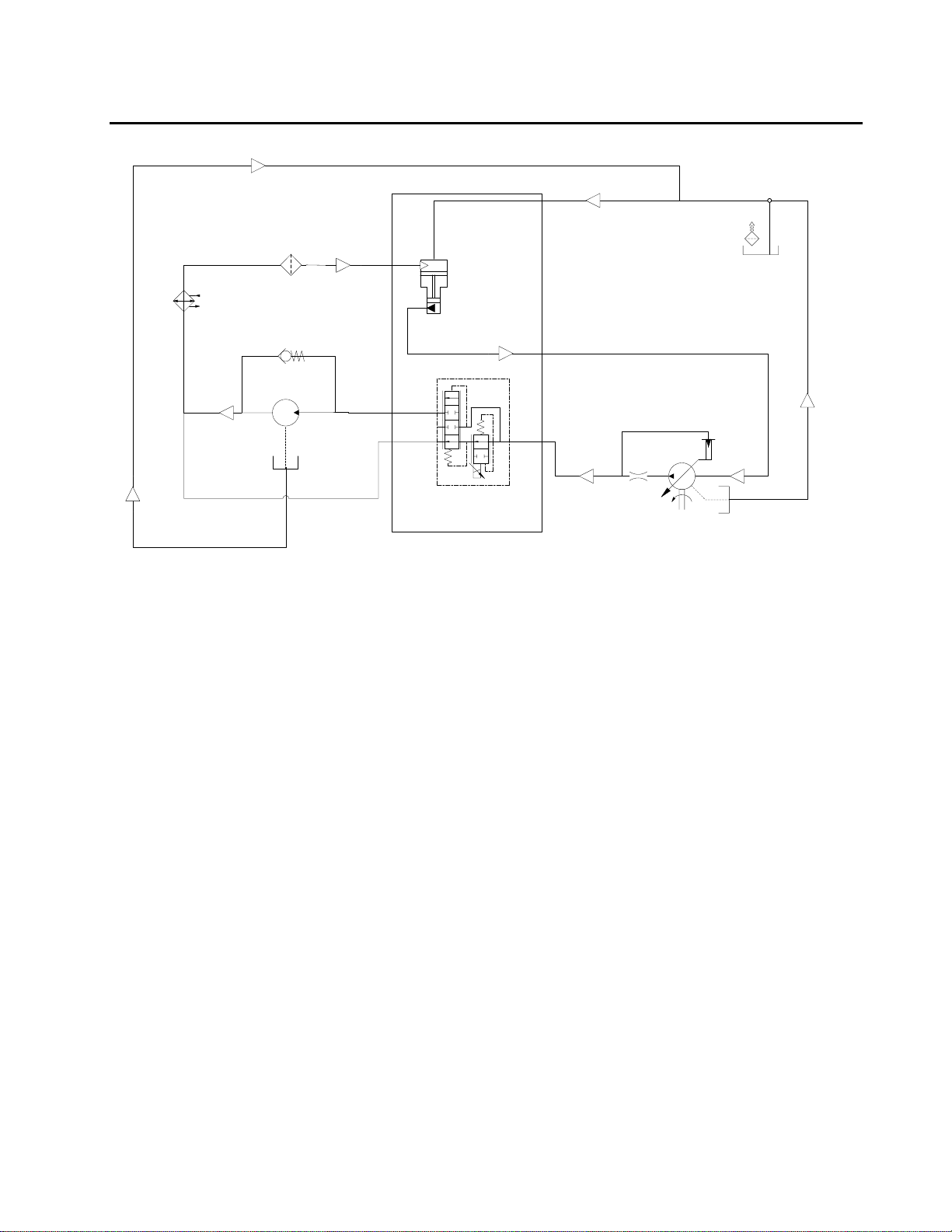

Generator hydraulic and electrical schematics: Reference Figures 1 and 2.

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 7 of 56

CASE DRAIN

xy

RESERVOIR

PUMP

PROPORTIONAL

VALVE

CASE DRAIN

MOTOR

COOLER

FILTER

BOOST BLOCK

VENTURI BOOST

CHECK

VALVE

IN

BP

REG

Figure 1 –Hydraulic Generator Schematic for HR-6.2, HR-8, HR-10 and HR-110

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 8 of 56

Figure 2 –Generator Electrical Schematic for HR-6.2, HR-8, HR-10 and HR-110

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 9 of 56

System Specifications

MODEL OF

GENERATOR

HR-6.2

HR-8

HR-10

HR-110

Generator

Type

Speed

Frequency

Voltage

Amperage

Output

Power

AC Inductive

3600 RPM

60 Hz

120/240 VAC or

120 VAC

52A @ 120 VAC or

26A @ 240 VAC

6.2 KW continuous

7.5 KW peak

AC Inductive

3600 RPM

60 Hz

120/240 VAC or

120 VAC

67A @ 120 VAC or

34A @ 240 VAC

8 KW continuous

9 KW peak

AC Inductive

3600 RPM

60 Hz

120/240 VAC or

120 VAC

84A @ 120 VAC or

42A @ 240 VAC

10 KW continuous

12 KW peak

AC Inductive

3600 RPM

60 Hz

120/240 VAC or

120 VAC

84A @ 120 VAC or

42A @ 240 VAC

10 KW continuous

12 KW peak

50hz

Generator Type

Speed

Frequency

Voltage

Amperage

Power

Output

AC Inductive

3000 RPM

50Hz

230 VAC or

115/230 VAC

70A @ 115 VAC or

35A @ 230VAC

8 KW continuous

9 KW peak

Hydraulic

Motor

Maximum

Speed

Motor Shaft

Size

Port Size

Gear Type, 8cc

4000 RPM

0.626 inches

9 tooth spline

7/8” – 14 SAE

7/8” – 14 SAE

Gear, 8cc or 11cc 50hz

4000 RPM

0.626 inches

9 tooth spline

7/8” – 14 SAE

7/8” – 14 SAE

Gear Type, 11cc

4000 RPM

0.626 inches

9 tooth spline

7/8” – 14 SAE

7/8” – 14 SAE

Gear Type, 11cc

4000 RPM

0.626 inches

9 tooth spline

7/8” – 14 SAE

7/8” – 14 SAE

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 10 of 56

Hydraulic

Pump

Operating

Speed

Standard Shaft

Optional Shaft

Mounting

Flange

Displacement

Continuous

Pressure (Max)

Peak Pressure

Standard

Rotation

Dry Weight

Piston w/pressure

compensated control

880-3000 RPM

continuous duty

SAE B 7/8”-13

Tooth Spline

SAE 1” parallel with key

SAE B-B 1” 15T Spline

SAE B-2 bolt mount

45cc per revolution

3500 psi (250 bar)

4600 psi (315 bar)

Engine right-hand

rotation (opposite

engine rotation

available upon request)

46 lbs

Piston w/pressure

compensated control

880-3000 RPM

continuous duty

SAE B 7/8”-13

Tooth Spline

SAE 1” parallel with key

SAE B-B 1” 15T Spline

SAE B-2 bolt mount

45cc per revolution

3500 psi (250 bar)

4600 psi (315 bar)

Engine right-hand

rotation (opposite

engine rotation

available upon request)

46 lbs

Piston w/pressure

compensated control

1100-3000 RPM

continuous duty

SAE B 7/8”-13

Tooth Spline

SAE 1” parallel with key

SAE B-B 1” 15T Spline

SAE B-2 bolt mount

45cc per revolution

3500 psi (250 bar)

4600 psi (315 bar)

Engine right-hand

rotation (opposite

engine rotation

available upon request)

46 lbs

Piston w/pressure

compensated control

850-2700 RPM

continuous duty

SAE B-B 1” 15

Tooth Spline

SAE 1¼” parallel with key

SAE B-2 bolt mount

60cc per revolution

3500 psi (250 bar)

4600 psi (315 bar)

Engine right-hand rotation

(opposite engine rotation

available upon request)

51 lbs

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 11 of 56

Table 1

MODEL OF GENERATOR

HR-6.2, HR-8

HR-10, HR-110

Oil Cooler

Dimensions (Core)

9.75”D x 22.6” W x 2.25” H

9.75”D x 22.6” W x 2.25” H

Fan

Voltage

Amperage

12 Inch Pusher

12 Volts DC

22 Amps

12 Inch Pusher

12 Volts DC

22 Amps

Filter

10 Micron

10 Micron

Hydraulic Oil

(recommended)

(alternate)

Op. Temp. range

(deg. F.)

ISO Approved Hydraulic Fluid

Dexron III

-13° F to 195° F

ISO Approved Hydraulic Fluid

Dexron III

-13° F to 195° F

Hoses

Motor Inlet

All Others

3600 psi, SAE

1250 psi, SAE

3600 psi, SAE

1250 psi, SAE

Hose Fittings

JIC STD

JIC STD

Dry Weight

(without pump)

HR-6.2 255 lbs

HR-8 255 lbs

HR-10 280 lbs

HR-110280 lbs

Dimension of Tray Asm.

32” L x 13.5” W x 17” H

(Including Reservoir)

32” L x 13.5” W x 17” H

(Including Reservoir)

Ambient Operating

Temperature Range

0F to 120F

0F to 120F

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 12 of 56

Table 1 (cont.)

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 13 of 56

Pre-Installation Guide

Pre-Installation Check List

1. Verify that the Power Take Off (PTO) and the pump rotations match.

To identify the pump rotation, check the pump part number found on the metal tag

attached to side of the pump. A right hand rotating pump (the standard pump offered

by Smart Power®Systems), will have the letter “R” in its part number.

Example: A10VO (45 or 60) DFR-1/52 R PUC.

A left hand rotating pump will have the letter “L” in its part number.

Example: A10VO (45 or 60) DRF-1/52 L PUC.

Depending on genset model, a 45cc or 60cc pump is supplied. To determine the PTO

rotation, check the PTO manufacturer’s specification or observe the PTO when it is

engaged with the vehicle’s engine running.

A right hand rotating pump requires a PTO that turns counter-clockwise when looking

at the free end of the PTO shaft. A left hand rotating pump requires a PTO that turns

clockwise when looking at the free end of the PTO shaft.

WARNING:

Operating the pump with reverse rotation will damage the pump and void the

system’s warranty.

Verify that the PTO ratio is properly sized to provide adequate speed to the hydraulic

pump during normal operation of the generator system. The PTO speed must be

between the range specified in

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 14 of 56

2. Table 1 for your model generator.

Example: For an HR-8 System that is to operate at 650 RPM engine speed:

PTO Ratio = 880 RPM ÷ 650 RPM = 1.35 or 135% (or higher)

WARNING:

Never exceed the maximum pump shaft speed. Pump failure or premature pump wear

will result. Doing so will void the system’s warranty.

3. Verify the combined weight of the pump and hoses filled with hydraulic fluid do not

exceed the PTO manufacturer’s weight restriction. If the pump weight does exceed

this restriction, the installer has two options: A) a bracket to support the pump can

be implemented, or B) the pump can be mounted to the vehicle chassis, connected

to the PTO with a drive shaft.

4. Verify that the pump shaft will mount to the PTO. Pumps supplied by Smart Power

Systems®have an SAE B 2 bolt flange. The standard pumps supplied by Smart

Power Systems®have either a SAE B 7/8” 13 tooth spline for Models HR-6.2, HR-8

and HR-10; OR a SAE B-B 1” 15 tooth spline on the HR-110 model.

Upon special order, a 1” keyed shaft or 1” 15 tooth spline is available on Models HR-

6, HR-8 and HR-10. A 1 ¼” keyed shaft is available on the HR-110 Model. Check

the PTO manufacturer’s specification to verify that the pump supplied with the system

will mount to the PTO installed on the vehicle.

Note: In some cases it may be necessary to mount the pump remote from the PTO

and drive it with a drive shaft. Contact the PTO manufacturer for information on the

proper mounting configuration under these conditions.

WARNING:

The installer must provide guarding to prevent damage to the pump seals from road

debris if the pump is remotely located. Also, properly sized and installed vibration

isolators must be used if the pump is mounted to the chassis. Failure to do either

will void the system’s warranty.

Never use an unbalanced drive shaft to drive a remotely located pump. An

unbalanced drive shaft will cause premature wear of the pump and will void the

system’s warranty.

Do not approach a running A.C. modular generator when wearing long, loose items

such as hair, jewelry, ties, clothing, etc. Direct contact with a rotating drive shaft can

cause serious personal injury and/or damage to the system.

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 15 of 56

5. Obtain the following hoses of the necessary length for the installation:

a) Pump inlet hose: 1” SAE 100R1AT-16 hose (use Parker hose ends P/N 10643-

16-16). Note: Maximum hose length is 20’.

b) Pump outlet hose: 1/2” SAE 100R9AT-8 rated to 4000 PSI (use Parker hose ends,

part number 10643-8-8). Note: Maximum hose length is 20’.

c) Pump case drain hose: 5/8” SAE 100R1AT-10 (use Parker hose ends, part

number 10643-10-10). Note: Maximum hose length is 20’.

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 16 of 56

WARNING:

Do not install hose ends until proper hose length has been determined.

Ensure debris is kept out of the hoses and hydraulic system prior to installation.

Never install a hose in a location where it will rub against another surface or abrasive

member.

Do not position hoses with tight bend radii. Consult the hose manufacturer’s

installation guidelines. Tight bends may kink and cause serious damage to the

system and will void the system’s warranty.

Use caution when tightening the hose ends to prevent the hose from becoming

twisted.

Never install a 90° fitting at the pump inlet or outlet. Avoid the use of flow restricting

fittings.

Do not form loops in the hose that may collect air or kink. Run hoses as straight as

possible (but not taut) between connections.

Do not exceed hose lengths of 20 feet.

Smart Power has fully tested and approved ISO fluids

ISO #32, #46 and #68 are approved for use in all Smart Power hydraulic generators.

Complete testing was performed using U.S. Oil Multi-Vis R Hydraulic Fluid under

controlled environments ranging from below freezing to above NFPA’s high temperature

requirements. The systems ran within our tight performance specifications using all three

listed grades.

ISO #32 is recommended when ambient temperatures are generally between 2 and 56°F.

ISO #46 is recommended when ambient temperatures are generally between 10 and

74°F.

ISO #68 is recommended when ambient temperatures are generally between 27 and

95°F.

For additional information on ISO fluids, contact U.S. Oils, or your local ISO grade fluid

supplier.

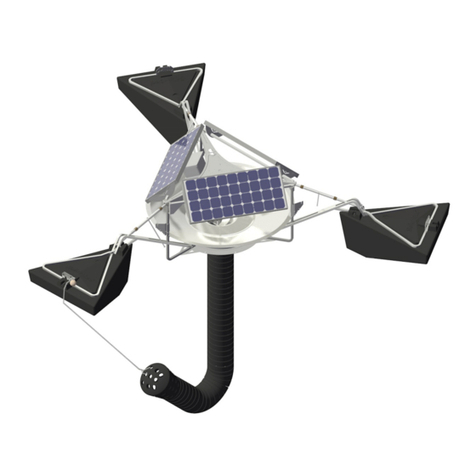

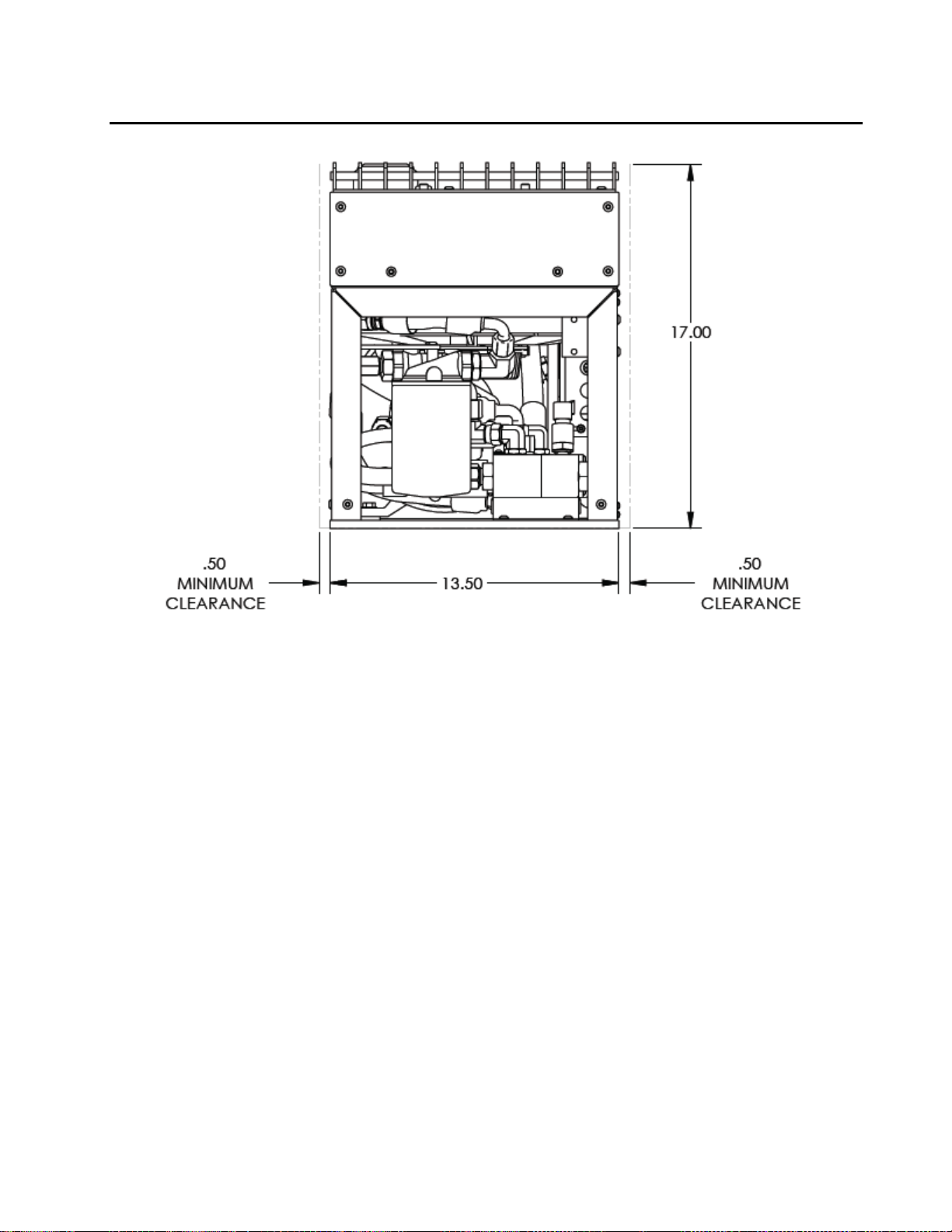

6. SPS models HR-6.2, HR-8, HR-10 and HR-110 can be mounted on top of a vehicle,

in the open, without requiring any additional coverings. Reference Figure 3 and

Figure 4 for the minimum clearances around the perimeter of the generator tray

assembly. Also, do not position any obstructions directly in front of the system’s oil

cooler. If the system cannot be installed without maintaining the minimum clearances

as indicated, or if you have any questions relative to the installation of these systems,

contact Smart Power Systems®at (231) 832-5525.

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 17 of 56

MINIMUM

1.00

CLEARANCE

CLEARANCE

MINIMUM

.50

.50

MINIMUM

CLEARANCE

15.00

AIR VENT OPTION A

(IF AIR VENT OPTION B OR C IS USED

.50 CLEARANCE REQUIRED ON THIS SURFACE)

AIR VENT OPTION B

(IF AIR VENT OPTION A OR C IS USED

.50 CLEARANCE REQUIRED ON THIS SURFACE)

AIR VENT OPTION C

(IF AIR VENT OPTION A OR B IS USED

.50 CLEARANCE REQUIRED ON THIS SURFACE)

Figure 3 - HR-6.2, HR-8, HR-10 and HR-110 Bottom View

Figure 4 - HR-6.2, HR-8, HR-10 and HR-110 Front View

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 18 of 56

Figure 5 - HR-6.2, HR-8, HR-10 and HR-110 End View

Smart Power Systems®

A. C. MODULAR GENERATOR SYSTEM Page 19 of 56

WARNING:

Do not mount the hydraulic pump or tray assembly in any location that is not well

ventilated. External heat sources elevating the hydraulic fluid and/or the generator

temperature will result in premature wear and degraded system performance and void

the system’s warranty.

7. The tray assembly must be mounted in a position that is higher than the pump. If the

pump inlet hose is 10’ in length or less, the tray and reservoir assemblies must be a

minimum of 12” higher than the pump. If the pump inlet hose is longer than 10’,

elevate the tray and reservoir assemblies an additional 12” for every additional 10’ of

pump inlet hose length. See below for examples of minimum tray assembly

elevations above the pump:

Pump inlet hose length

Minimum tray and reservoir elevation

(above pump)

0 –10 ft.

12 inches

15 ft.

18 inches

20 ft.

24 inches

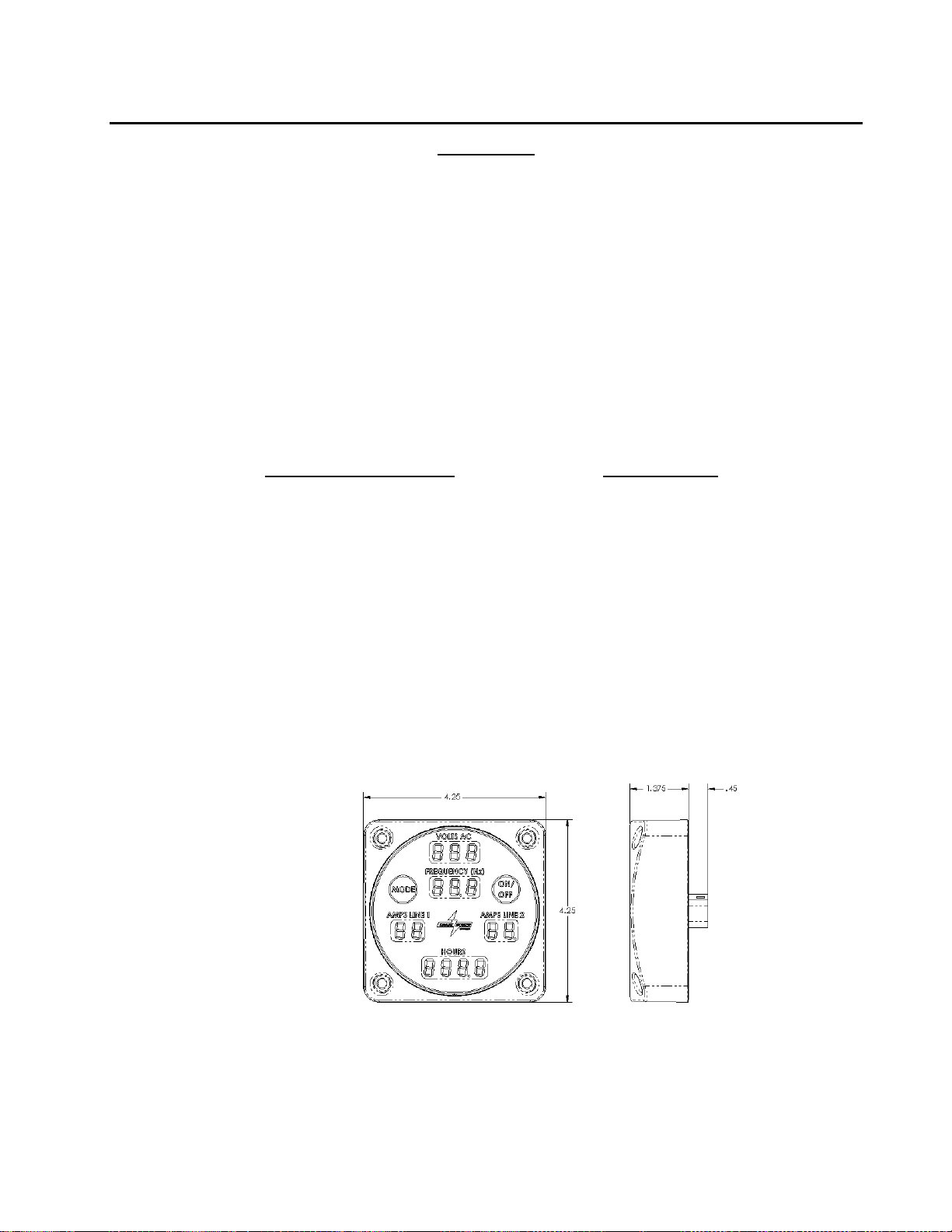

8. Locate a position to mount the SPS Command & Control Center. The ideal location

for the Command & Control Center will be in an area that iseasily seen and accessed

by the generator operator. When the generator system is in use, the Command &

Control Center will continuously show the status of the generator, including faults

(warnings) if theyoccur. The Command & Control Center can also beused to engage

and disengage the generator. The Command & Control Center is water sealed, and

operates on low voltages so pump house mounting is permissible. A 15 ft. water

sealed harness is provided to connect the Command & Control Center to the system

controller mounted within the generator tray assembly. See Figure 6 for the

dimensions of the Command & Control Center.

Figure 6 - Command & Control Center, P/N 1500047C

This manual suits for next models

3

Table of contents

Other Smart power Inverter manuals

Popular Inverter manuals by other brands

Minarik

Minarik MM21051C user manual

Flexsolar

Flexsolar C120 Instruction manual & warranty information

SolaX Power

SolaX Power X3-Fit-8.0-E Quick installation guide

Hitecsa

Hitecsa ACVIBA HE Series Installation, operation & maintenance manual

SHENZHEN ENCOM ELECTRIC TECHNOLOGIES CO.

SHENZHEN ENCOM ELECTRIC TECHNOLOGIES CO. EDS1000 series Service manual

Lust

Lust CDA3000-PLC System manual