Terrasmart TerraGlide User manual

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 1 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

TerraGlide Portrait Installation Manual

REV 10: November 2022

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 2 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

Table of Contents

1General Document Overview......................................................................................................................3

1.1 Introduction ..................................................................................................................................3

1.2 Installer Responsibility Checklist...................................................................................................3

1.3 Notice............................................................................................................................................4

1.4 Safety Symbols and Signal Words.................................................................................................4

1.5 Notes.............................................................................................................................................5

1.6 Common Terms.............................................................................................................................5

2TerraGlide Portrait Details Pre-Installation.................................................................................................6

2.1 Steel Members and Bracket Components Overview ....................................................................6

2.2 TerraGlide Portrait Hardware Components Overview..................................................................7

2.3 TerraGlide Portrait Torque Values..............................................................................................10

2.4 Required Tools for TerraGlide Landscape Installation................................................................11

2.5 Component On-Site Storage Prior to Installation .......................................................................12

3TerraGlide Portrait Mounting System Installation ....................................................................................13

3.1 Installation Warning, Caution and Notice Statements ...............................................................13

3.2 Workflow Overview for TerraGlide Portrait Assembly ...............................................................14

3.3 Specific Installation Steps ...........................................................................................................15

3.4 Bonding and Grounding Requirements ......................................................................................34

3.5 PV Module Bonding Section........................................................................................................37

Appendix 1 Terrasmart, Inc. UL 2703 Approved PV Module Bonding List………………………………………………….45

Appendix 2 Jinko Solar High Loading PV Module Mounting With 6 Connection Points ................................51

Appendix 3 Document Revision History Log..................................................................................................52

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 3 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

1General Document Overview

1.1 Introduction

The TerraGlide Portrait Ground Mount Solar Racking System (TGP) is specifically designed in conjunction with Terrasmart

ground screw foundations. Terrasmart custom engineers each racking system based upon site-specific loading

requirements, soil and terrain conditions, and other client specifications.

The TGP racking system is designed to meet or exceed applicable ASCE, IBC, NEC, and UL standards. Modules are to be

installed in a Portrait orientation with a maximum rack size of 2X12. Because each racking system is subjected to different

loads and/or module specifications, structural and mechanical components may vary slightly from one rack to another.

This document outlines the installation of a generic racking system and should be interpreted as such when installing

racking systems designed specifically for a project. Signed and sealed project specific construction plans take precedence

over this manual. For details regarding module compatibility, refer to section 3.5 and Appendix 1. Failure to comply with

installer responsibilities as outlined below, may void the product warranty, cause legal implications, and/or make it

impossible for Terrasmart to replace defective, damaged, or missing parts. Please contact Terrasmart project manager

with any questions, comments, complaints, or suggestions.

1.2 Installer Responsibility Checklist

1. Comply with all applicable local, state, and national building codes and laws, including any that supersede this

manual.

2. Procure all required permits prior to installation and ensure that component design parameters are not ex-

ceeded.

3. Provide appropriate method of direct-to-earth grounding in accordance with the latest edition of the National

Electric Code (NEC), including NEC 250: Grounding and Bonding and NEC 690: Solar Photovoltaic Systems. See

section 3.4 for details.

4. Use only parts supplied by Terrasmart specifically designed for use with the TGP.

5. Ensure PV modules are physically compatible with the dimensions of the TGP prior to installation. PV modules

vary between brands, models, and dates of manufacture; each TGP Rack is custom designed to accommodate

dimensions of the PV module as specified by the client.

6. Inspect the quality of the ground screw installation and that the foundations are within acceptable tolerances,

as defined in the Approved Project Specific Engineering/Construction Plans.

7. Upon delivery of materials, inspect all packages and refuse any that contain damaged parts. Take an inventory

of all delivered parts to ensure that all required parts are in your possession.

8. Follow the steps outlined in this installation manual and notify Terrasmart within 48 hours of delivery of any

missing or defective parts or any other concern with regards to the installation process, including conflicts

between this installation manual and codes, regulations, laws and/or other documentation.

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 4 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

1.3 Notice

Changes to certain components are common as Terrasmart continuously strives to improve its products. All products

within the same model classification remain functionally equivalent and compatible with one another, even though there

may be slight differences. Any modifications to the TerraGlide racking system requires Terrasmart’s prior written approval.

Terrasmart reserves the right to make changes to design and specifications applicable to any TGP Mounting System

component at any time without notice. Accordingly, the owner is responsible for verifying that data sheets are current

before placing orders or finalizing system permitting and/or design. Neither Terrasmart nor its affiliates assume any

responsibility for use of information furnished by Terrasmart or its affiliates, nor for any infringements of patents or other

rights of third parties that may result from the use of such information. No license is granted by implication or otherwise

under any patent or patent rights of Terrasmart or its affiliates.

For information regarding Terrasmart and its products, please visit www.Terrasmart.com. For technical support, please

contact Terrasmart project manager.

1.4 Safety Symbols and Signal Words

Indicates a safety hazard or unsafe practice.

Indicates an electrical shock hazard.

DANGER Indicates a hazardous situation that, if not avoided, will result in death or serious injury.

WARNING Indicates a hazardous situation that, if not avoided, could result in death or serious injury.

CAUTION Indicates a hazardous situation that, if not avoided, could result in injury.

NOTICE Indicates information considered important, but not hazard-related.

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 5 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

1.5 Notes

System Safety Information:

Owner, owner’s agents, general contractors, maintenance personal and/or anyone in contact with this

racking system should read and understand all instructions and safety information before attempting to

install, operate and/or maintain this system. Failure to comply with instructions and safety information

may result in death, serious injury, or damage to the product.

•Installation and Service is to be performed only by qualified personnel.

•Installation must be completed according to the project site drawings.

•Proper personal protective equipment (PPE) shall be used when working with this system.

oElectrically rated PPE should be worn when working on modules or other electrical system

components.

oCut-resistant gloves should be worn when working on non-electrically-interconnected mod-

ules or components.

oSafety glasses should always be worn when working with this system.

DANGER To avoid death or serious injury due to electric shock:

•Disconnect incoming power sources before servicing.

•More than one disconnect switch may be required to de-energize the equipment.

•Follow lockout –tagout procedures before servicing.

•Avoid working on system in rain or standing water.

Proper Installation and Maintenance:

The TerraGlide Portrait Mounting System must be installed, operated, and maintained as specified in this manual and the

TerraGlide O&M manual. If not, then personal safety and product reliability may be compromised. Inspections of all

components should be performed yearly to ensure there are no loose components, fasteners or corrosion. Any affected

components need to be immediately replaced.

1.6 Common Terms

Colloquial terms and abbreviations

Proper names and explanations

Cable

Wire, Wiring, PV Double Insulated Wire, Seismic Bracing, Gripple Kit

Post, Leg

Vertical Support (not foundation), North Post, South Post

Beam

Cee Purlin

Panel

PV Module

Frame Assembly

Assembled Rafter, Lateral Brace, North Post, and South Post

Rafter, Strut

Proprietary Hat Section

Ground Screw

Ground Screw Foundation

Nuts, Bolts

Fasteners, Hardware

ASTM

American Society for Testing and Materials

ANSI

American National Standards Institute

SAE

Society of Automotive Engineers

DIN

German Institute for Standardization

SEMS

Screw and Integrated or Encapsulated Washer Assemblies

Loose Fit

Nut/Bolt Threaded Together. Allows Connection to Rotate

Snug

Nut/Bolt Finger Tight (or with Tool) Not Fully Torqued

Torqued

Nut/Bolt Fully Torqued Per Specification

Table 1.6.1. List of items that may be found in site design drawings and their corresponding correct definitions or equivalents used in this Installation Guide.

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 6 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

2TerraGlide Portrait Details Pre-Installation

2.1 Steel Members and Bracket Components Overview

DESCRIPTION

LOCATION USED

Ground Screw

FOUNDATION

Leg Post

FRAME ASSEMBLY

Internal Diagonal Lateral Brace

Internal Horizontal Lateral Brace (upper and/or lower)

FRAME ASSEMBLY

External Diagonal Lateral Brace

External Upper Horizontal Lateral Brace

FRAME ASSEMBLY

TPF External Lower Horizontal Lateral Brace

TPF External Diagonal Lateral Brace (When Horizonal Brace is required)

FRAME ASSEMBLY

North South Rafter

FRAME ASSEMBLY

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 7 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

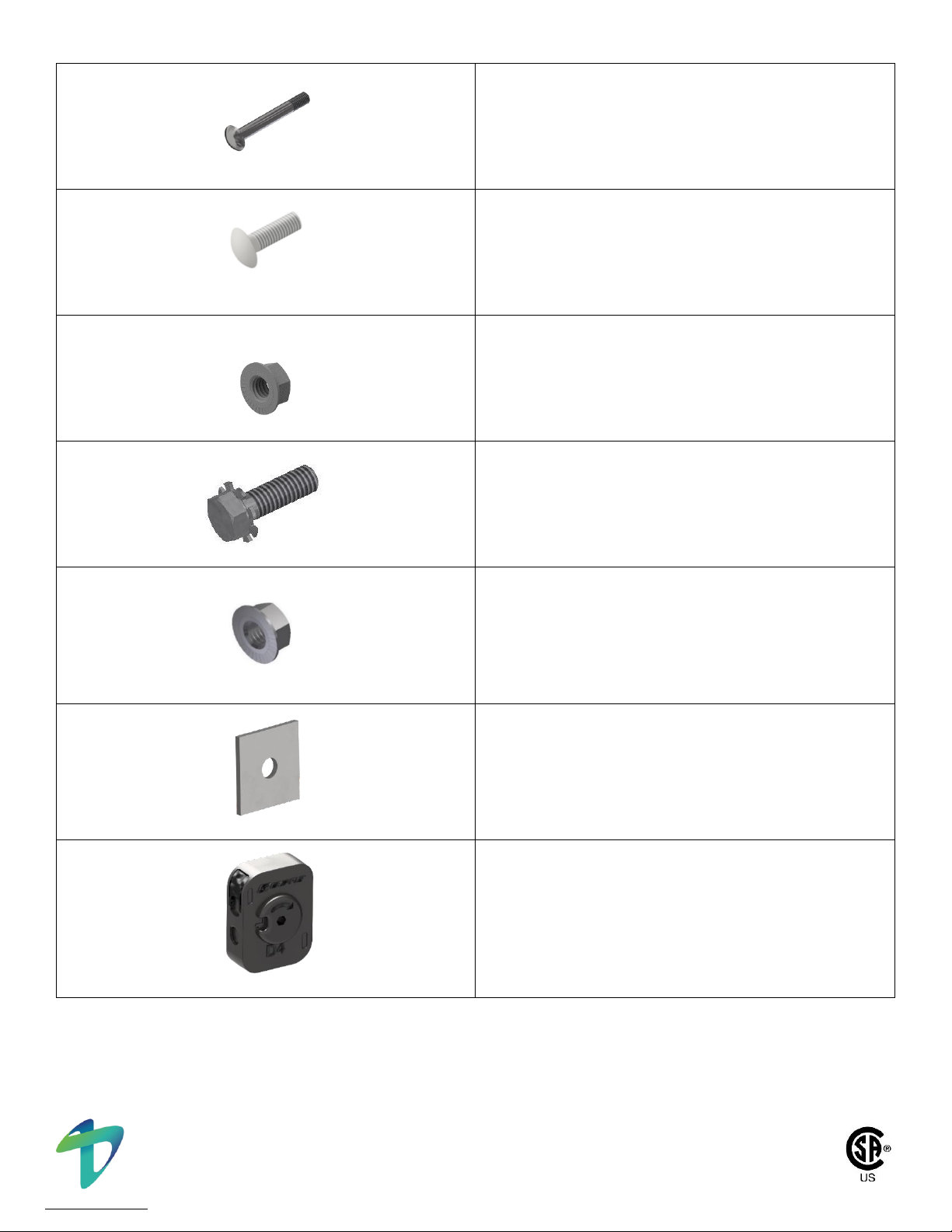

2.2 TerraGlide Portrait Hardware Components Overview

DESCRIPTION

LOCATION USED

M16 x2x25 Hex Bolt

GROUND SCREW SET BOLTS

1/2”-13 x 1-1/2” Carriage Bolt

SLOPE BRACKET FASTENER

FASTENS CEE PURLIN AND RAFTER TO SLOPE BRACKET

1/2”-13 x 4” Serrated Flange Hex Bolt

FRAME ASSEMBLY FASTENER

FASTENS RAFTER TO POSTS

1/2”-13 Serrated Flange Hex Nut

FRAME ASSEMBLY FASTENER

FOR USE WITH

1/2”-13 X 1-1/2” SERRATED FLANGE HEXBOLT AND

1/2” -13 x 4” SERRATED FLANGE HEX BOLT

Cee Purlin

EAST-WEST BEAM

AND

MODULE MOUNTING RAIL

Slope Bracket

FRAME ASSEMBLY TO

CEE PURLIN CONNECTION

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 8 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

3/8”-16 x 3” Carriage Bolt

FRAME ASSEMBLY FASTENER

FASTENS LATERAL BRACE INTERNAL TO

LATERAL BRACE EXTERNAL

3/8”-16 x 1-1/2” Carriage Bolt

FRAME ASSEMBLY FASTENER

FASTENS BRACE CLAMPS

3/8”- 16 Serrated Flange Nut

FRAME ASSEMBLY FASTENER

FOR USE WITH

3/8”-16 X 3” HEX BOLT AND

3/8”-16 X 1-1/2" CARRIAGE BOLT

M6-1.00 x 20mm OR M8-1.25 x 20mm SEMS Hex Bolt

UNDERMOUNT MODULE FASTENER

DIAMETER VARIES PER MODULE SPECIFICATION

M6-1.00 OR M8-1.25 Serrated Flange Nut

UNDERMOUNT MODULE FASTENER

DIAMETER VARIES PER MODULE SPECIFICATION

Washer Plate

FRAME ASSEMBLY

FASTENS TO RAFTER AND POSTS

Gripple Dynamic

SEISMIC BRACING LOCK

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 9 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

Wire Rope

SEISMIC BRACING CONNECTOR

LENGTH VARIES BY TABLE SIZE

Brace Clamp Half

FRAME ASSEMBLY

5/8”-11 x 6” Serrated Flange Hex Bolt

FRAME ASSEMBLY

* THROUGH BOLT FOR GROUND SCREW

5/8”- 11 Serrated Flange Nut

FRAME ASSEMBLY

* THROUGH BOLT FASTENER

*Note: The through bolt is only needed if the leg install process damages the set bolts or welded nuts on ground screw.

Hole will be drilled and through bolt will be used.

NOTICE

Reference the project construction drawings for a complete part list for each specific project site.

Specific projects may have additional or alternate component requirements.

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 10 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

2.3 TerraGlide Portrait Torque Values

Hardware Nominal Diameter

& Thread Pitch

Bolt Location

Material/Grade

Nominal Torque

(ft-lbs)

Torque Range

(ft-lbs)

M6-1.00

Module to Purlin

Stainless Steel

(304/316)

7

6 - 9Note 3

M8- 1.25

11

8 –18.5Note 3

1/2”x 1-1/2” Carriage Bolt

Rafter to Slope

Bracket

Carbon Steel

SAE Grade 5

64

45 - 80

Purlin to Slope

Bracket

1/2”-x 4” Serrated Flange

Hex Bolt

Leg to Rafter

64

45 –80 Note 1

Brace to Rafter

30

20 –80 Note 2

3/8” x 1-1/2” Carriage Bolt

Lateral Brace

Clamp Connections

Carbon Steel

SAE Grade 5

26

23 - 30

3/8” x 3” Carriage Bolt

Internal to External

Brace Connection

Carbon Steel

SAE Grade 5

26

23 - 30

M16-2.00 Set Bolt

Ground Screw bolt

to Leg Connection

Carbon Steel

Class 45H

Bottomed out –bolt head touching ground

screw weld nut.

Table 2.3.1 - Torque values for listed hardware

NOTICE

Due to variations in tools, environmental conditions, and plastic deformation over time; quality

control checks performed after 48 hours may observe a reduction in nominal torque, up to a 30%

reduction is allowable. No torque adjustment is required if within the specified range.

Table 2.3.1; Note 1 - Leg to Rafter Connection; The min/max torque range is 45 –80 ft-lbs. The

nominal torque is 64 ft-lbs as stated in the table above. For torques over > 64 ft-lbs, it is acceptable

to have visual loading deformation of the leg to rafter joint connection.

Table 2.3.1; Note 2 - Brace to Rafter Connection; The min/max torque range is 20 –80 ft-lbs. The

nominal torque is 30 ft-lbs as stated in the table above table. It is acceptable to have visual loading

deformation of the brace to rafter joint connection.

If bolt installation results in continual deformation of the Hat Rafter without achieving full torque,

then it is acceptable to achieve torque by driving the nut until it reaches the end of the threaded

portion of the bolt.

Table 2.3.1; Note 3 –Refer to section 3.5, PV Module Bonding, and Appendix 1, Terrasmart, Inc. UL

2703 Approved PV Module Bonding List, for additional information on specific PV module bonding

method torque values.

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 11 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

2.4 Required Tools for TerraGlide Landscape Installation

Below is a table of tools required to install the TGP PV module racking system.

TOOL DESCRIPTION

PURPOSE

Torque Wrench

Torque fasteners to specification in

accordance with section 2.3

Sockets

7/16” Socket for Seismic Cable Saddles

9/16” Socket for 3/8” Hardware

3/4” Socket for 1/2” Hardware

10mm Socket for M6 Hardware

13mm Socket for M8 Hardware

*Deep Sockets Recommended for above*

15/16” Shallow Well Socket for M16 Set Bolt

Socket Extension

3” Min Socket Extension. Install Slope

Bracket to Hat Rafter

Digital Level

Verify tilt angle and plumbness of steel

members

String Line

Used for alignment

(Optional)

Cold Galvanizing Compound

(minimum 93% Zinc)

Repair exposed steel after installation

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 12 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

Racking Alignment Tool, 48" Square, or Jig

Align module mounting purlins

3/8" and 1/2" Cordless Impact

To snug all hardware/fasteners

3/8” Cordless 90 Degree Impact

To snug module hardware/fasteners

2.5 Component On-Site Storage Prior to Installation

The following items are to be stored indoors or covered to prevent contact with water and snow:

•Fasteners and hardware

•Any packaging that could deteriorate

The material described below may be stored outdoors, so long as the storage area is not at risk of flooding, water

submersion or snow coverage. However, it is required to cover this material and provide proper dunnage so that material

is not in direct contact with ground. Additionally, if the material is stored outside under coverage, the coverage must

provide proper air flow thus not capturing moisture. The material described in this section is as follows:

•Posts

•Purlins

•Rafters

•Brackets

If components are to be stored off site, then indoor storage is recommended.

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 13 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

3TerraGlide Portrait Mounting System Installation

3.1 Installation Warning, Caution and Notice Statements

DANGER Wear electrically rated PPE when working on interconnected modules or other electrical

system components.

WARNING Wear appropriate hard hats and safety glasses (ANSI Z87.1-2003) and cut-resistant gloves

during installation of TerraGlide Portrait Mounting System.

CAUTION Installation is to be performed only by qualified personnel.

CAUTION DO NOT use bolts that have been previously tightened or pre-stressed bolts that are

structurally compromised as they may not retain their strength if recycled.

CAUTION Edges of cee purlins may be sharp, wear cut-resistant gloves at all times when handling and

installing these items.

NOTICE

All TGP Mounting System bolting torque specifications as detailed in this manual must be followed.

Usage of the right tool to complete torque is needed. If battery operated devices are used, efforts

need to be made to ensure a calibrated torque wrench is used to complete tightening process.

NOTICE

All bolts shall be marked with an appropriate marker to indicate proper torque was applied.

NOTICE

No holes shall be added to structural components without prior analysis and approval by Terrasmart,

except for holes necessary for UL467 and UL2703 bonding devices.

NOTICE

A process shall be established with regards to tools and methods to achieve specified torque consist-

ently across the site. For example, a recommended process may involve verifying torque setting with

all applicable tools prior to use in installation and re-verifying every month thereafter.

NOTICE

This racking system may be used to ground and/or mount a PV module complying with UL 1703 only

when the specific module has been evaluated for grounding and/or mounting in compliance with the

included instructions.

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 14 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

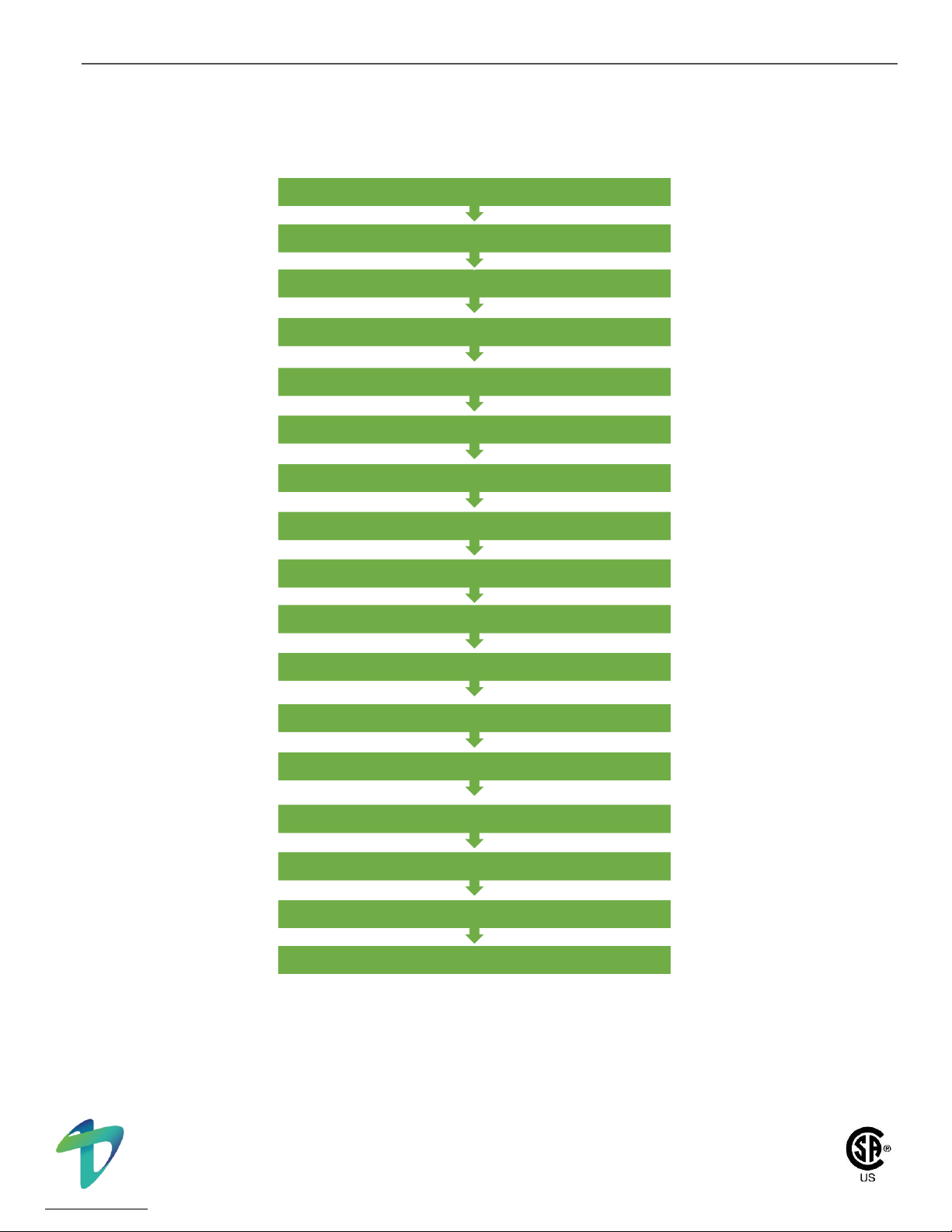

3.2 Workflow Overview for TerraGlide Portrait Assembly

The sequence below provides a suggested workflow guide for assembly of the TerraGlide Portrait Mounting System. This

is one option and other sequences may exist.

Figure 3.2.1 - Suggested workflow for the TerraGlide Portrait Mounting System installation

17. QUALITY CONTROL

16. TORQUE ALL FASTNERS

15. VERIFY TOLERANCES AND ALIGNMENTS

14. INSTALL CROSS BRACES

13. INSTALL PV MODULES

12. ALIGN ADJACENT RACKS

11. ADJUST AND TORQUE SLOPE BRACKETS

10. SQUARE PURLINS

9. FEATHER PURLINS

8. INSTALL CEE PURLINS

7. INSTALL LATERAL BRACES

6. INSTALL RAFTER

5. SET POST HEIGHT

4. DISTRIBUTE NORTH AND SOUTH POSTS

3. PREASSEMBLE/DISTRIBUTE MATERIALS

2. CHECK GROUND SCREWS

1. RECEIVE MATERIALS/STAGING

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 15 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

3.3 Specific Installation Steps

The TerraGlide Portrait Mounting System installation should be coordinated with site-specific structural drawings and the

trenching for underground cables.

STEP 1: Receive Materials/Staging

Unload material from trucks and place in designated laydown area. Take inventory of all parts as they are received and

notify Terrasmart immediately if any discrepancies are identified.

STEP 2: Check Ground Screws

Ground Screws are installed by Terrasmart Construction. Ground Screw location guidance is provided by the TGP

Construction Drawings. Prior to rack installation, check to ensure that Ground Screws are installed within tolerance as

defined in the signed and sealed project specific construction plans and in alignment East to West and North to South as

shown in Figure 3.3.1.

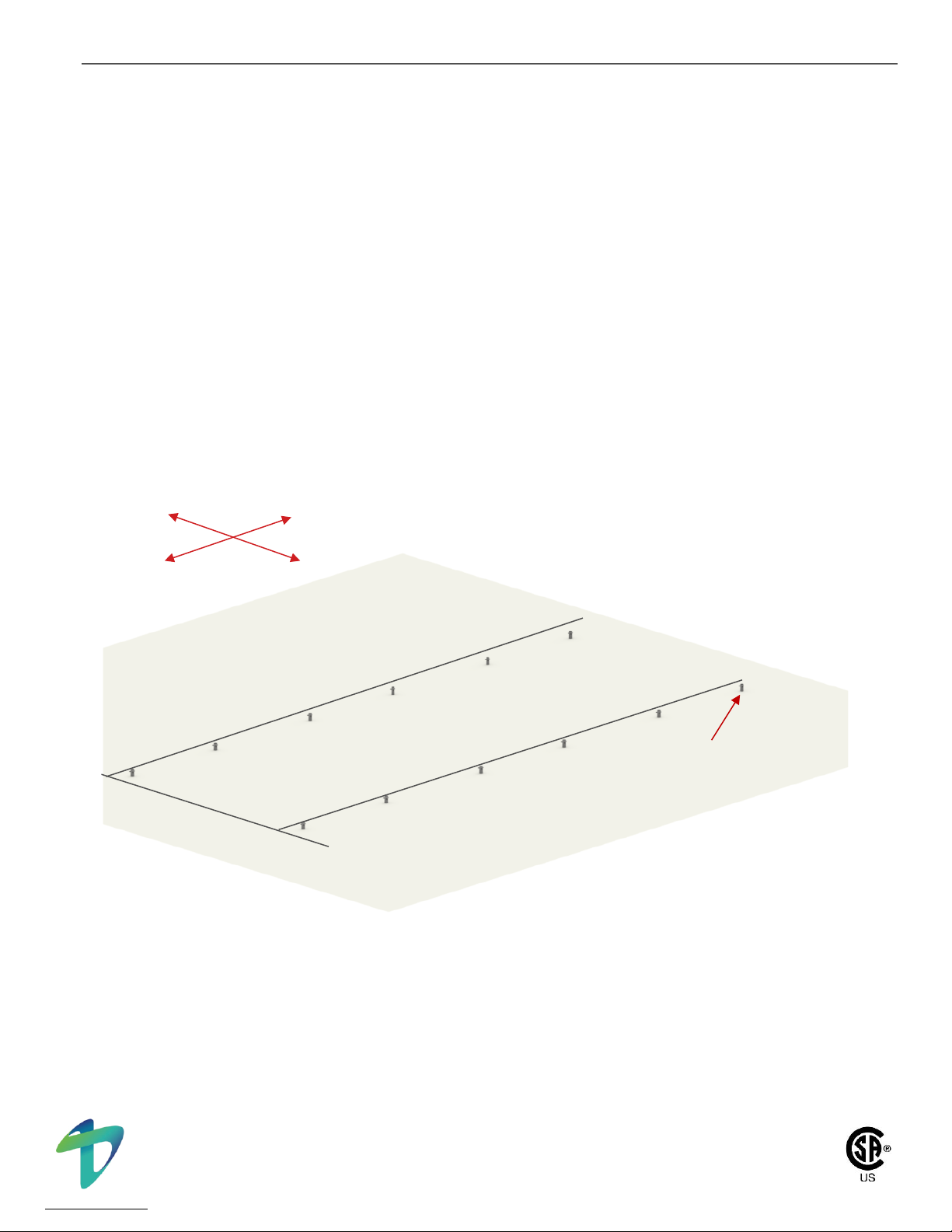

Figure 3.3.1 - Depiction of an Array Row of Ground Screws Installed

N

W

E

S

Installed Ground

Screw

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 16 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

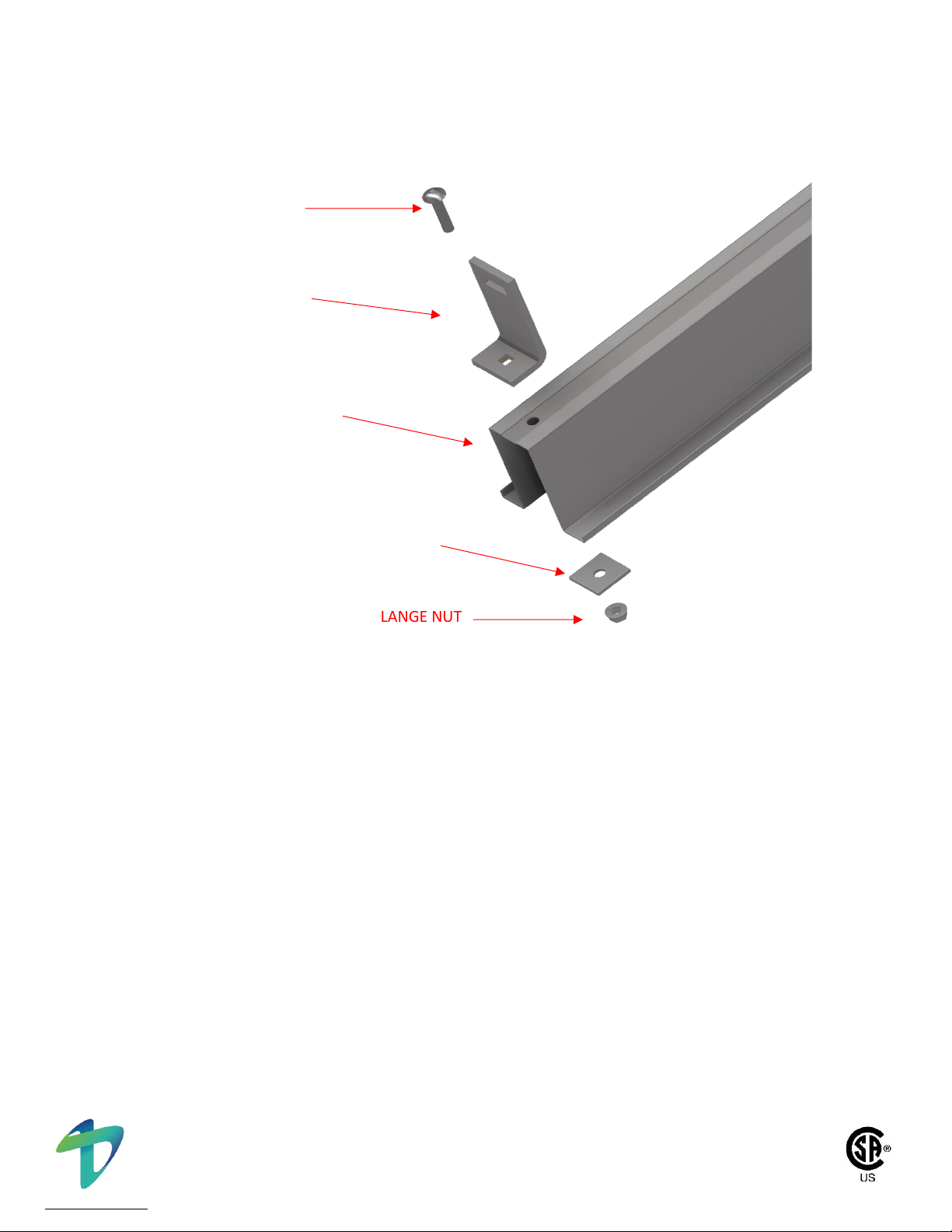

STEP 3: Preassembly/Distribute Materials

Preassembly of Rafter may occur at a centralized station or at each rack. Preassemble Slope Brackets on the rafter as

shown in Figure 3.3.2. Leave bolt loose and distribute materials to the field. Final bolt torque will be performed in Step

11: Adjust and Torque Slope Brackets.

Figure 3.3.2 - Depiction of Slope Bracket to Rafter Assembly

STEP 4: Distribute North and South Posts

Identify the North and South Ground Screw within a rack or Array Row. Place the North Post (typically the longer of the

two posts) next to the North Ground Screw and the South Post (typically the shorter of the two posts) next to the South

Ground Screw.

1/2” - 13 SERRATED FLANGE NUT

1/2”-13 x 1-1/2” CARRIAGE BOLT

Nominal Torque = 64 ft-lbs

Torque Range = 45 - 80 ft-lbs

SLOPE BRACKET

RAFTER

WASHER PLATE

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 17 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

STEP 5: Set Post Height

Place both the North and South the post into the corresponding screws and raise the posts to the height shown in the

project specific construction plans. Use the M16 Set Bolt as shown in Figure 3.3.3. To set height. Ensure posts are rotated

such that a bolt passing through both slots at the top of the post would align east-west and the post are within plumbness

tolerance. Temporarily snug set bolt to 50% embedment from weld nut to clamp the post at the desired height. If there is

damage to the leg set bolts, it is acceptable to use a Grade 5 Magni 565 or hot-dipped galvanized 5/8” x 6” Serrated Flange

Hex Head Bolt and serrated flange locknut to secure the ground screw to leg connection.

NOTICE

Be careful not to allow the leg to fully drop into the ground screw. This can result in the leg being

stuck within the ground screw, making it difficult to retrieve. Additional precautions may be taken

through use of through bolt or metal bar that is inserted in the slot at the top of the post.

WARNING The clamp load is sufficient to hold the dead load of the structure and is not intended to

be left permanently. Ensure Set Bolts are bottomed out on weld nut for final installation.

NOTICE

Array Row Installation Consideration: The heights of the posts are infinitely variable within the

tolerances given in the site specific plans, which allows the East-West Array Row to have an

aestheticallty pleasing, smooth, rolling appearance. This is achieved by setting the heights of the

posts with consideration of adjacent racks and slopes. One method is to set the post heights at the

ends of the array row and string line between them as shown in Figure 3.3.4. In long array rows,

intermediate posts may need to be used to prevent a visible sag. At sloping sites, intermediate stakes

may be required at inflection points where the slope changes as shown in Figure 3.3.5. In all instances

a story board should be used.

SET BOLT

NORTH POST ASSEMBLY

GROUND SCREW

SLOTTED TOP OF POST

VERTICAL ADJUSTMENT

GROUND

ANGLE = ± 3 degrees

Figure 3.3.3 - Use Set Bolt to Clamp South Post

ACCEPTABLE

BOLT

CONNECTION

IF DAMAGE TO

THE SET BOLTS

OCCURS

DURING LEG

INSTALLATION

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 18 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

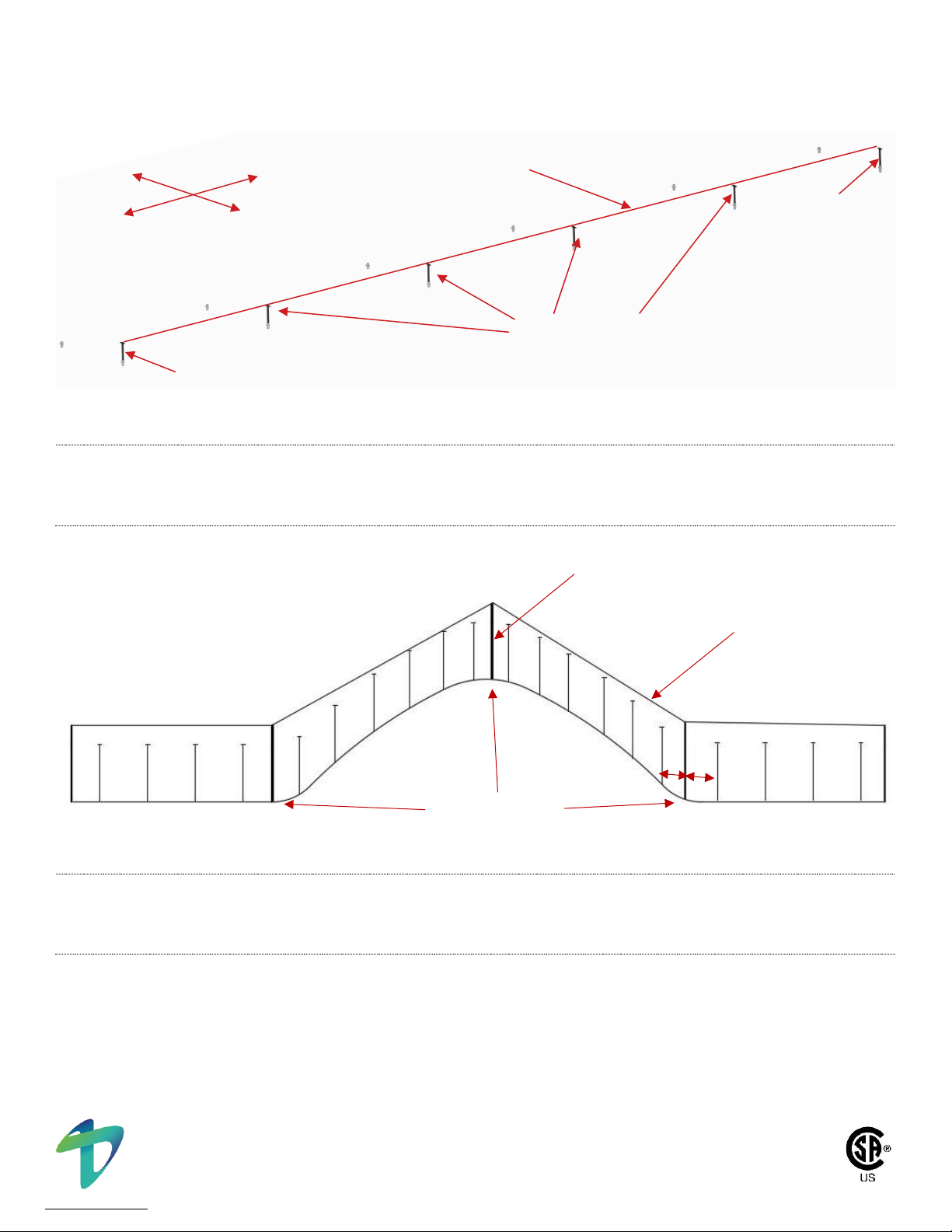

Figure 3.3.4 - String Line South Post Assemblies

NOTICE

String Line Technique Consideration: To avoid visible sag in alignment due to gravity on string line, it

is recommended that no more than 4 racks are stringlined at a time.

Figure 3.3.5 - String Lining Between Inflection Points

NOTICE

String Line Technique Consideration: When string lining on undulating surfaces additional feathering

will need to be done at the inflection points. Legs should be moved to that beam ends line up while

leg tolerances are still met.

N

W

E

S

SET HEIGHT

SET HEIGHT

RAISE TO MEET STRING LINE

STRING LINE

INFLECTION POINTS

STRING LINE

STAKE

X

X

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 19 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

STEP 6: Install Rafter

Lift Rafter Assembly onto North and South Posts. Insert 1/2”-13 x 4” bolt through the Rafter and top slot of the North and

South Posts as shown in Figure 3.3.6 and tighten fastener finger-tight. Adjust height of the North Post until tilt angle is

within tolerance as shown in Figure 3.3.7. Tighten Set Bolt to clamp the post at the desired height. The Gripple Seismic tab

is to be installed on the interior side of the rack, with cable loop directly below the bolt.

Figure 3.3.6 - Rafter Fastened to North and South Post Assembly

Figure 3.3.7 - Tilt Adjustment of Rafter

GROUND

LEVEL

TILT ANGLE

RAISE/ LOWER

TO ADJUST

TILT ANGLE

SOUTH POST

1/2”-13 X 4” SERRATED FLANGE HEX BOLT

NOMINAL TORQUE = 64 FT-LBS

TORQUE RANGE = 45 –80 FT-LBS

1/2”-13 SERRATED NUT

RAFTER

NORTH POST

GRIPPLE SEISMIC TAB

WASHER PLATE

1/2”-13 X 4” SERRATED FLANGE HEX BOLT

NOMINAL TORQUE = 64 FT-LBS

TORQUE RANGE = 45 –80 FT-LBS

WASHER PLATE

WASHER PLATE

This system conforms to UL Standard 2703 Edition One.

© Copyright 2022, Terrasmart, Inc. All rights reserved. | TerraGlide Portrait Installation Manual | Page 20 of 52

Proprietary and confidential. The information contained in this document is the sole property of Terrasmart.

Any reproduction in part or as a whole without written permission of Terrasmart is prohibited

www.terrasmart.com

271167

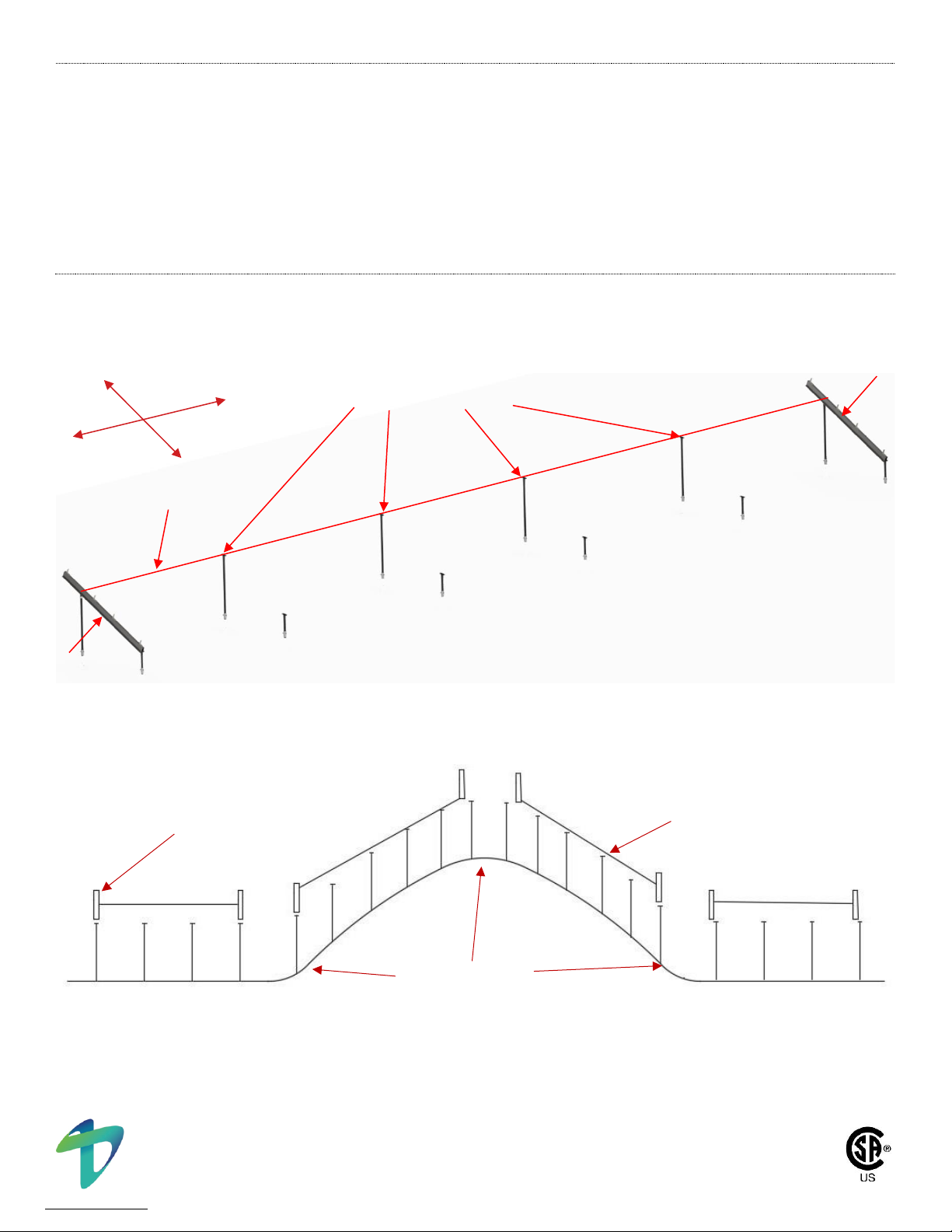

NOTICE

Array Row Installation Consideration: The heights of the posts are infinitely variable within the

tolerances given in the site specific plans, which allows the East-West Array Row to have an

aestheticallty pleasing, smooth, rolling appearance. This is achieved by setting the heights of the

posts with consideration of adjacent racks and slopes. In order to achieve this, feathering of the posts

will be needed. One method is to set the post heights at the ends of the array row and string line

between them as shown in Figure 3.3.8. In long array rows, intermediate posts may need to be used

to prevent a visible sag. At sloping sites, set Rafters and North Posts to the required tilt angle on each

side of the inflection points and stringline between them as shown in Figure 3.3.9. In all instances a

story board should be used.

Figure 3.3.8 - String Line North Post Assemblies

Figure 3.3.9 - Rafters Set at Inflection Points

N

W

S

E

RAFTER

RAFTER

STRING LINE

RAISE TO MEET STRING LINE

INFLECTION POINTS

STRING LINE

RAFTERS

Table of contents

Other Terrasmart Inverter manuals

Popular Inverter manuals by other brands

Mitsubishi Electric

Mitsubishi Electric FR-A8AY E KIT instruction manual

Generac Power Systems

Generac Power Systems 20 kW Synergy owner's manual

INVT

INVT iMars BG10KTR Operation manual

Toshiba

Toshiba VLP Technology Q9 Plus Installation & operation manual

RND power

RND power 320-00133 user manual

IOTA

IOTA IIS3P Series user manual