SMART-SCAN 8000 SERIES Assembly instructions

SMARTSCAN 8000 SERIES LIGHT CURTAIN 1

CD246/080610 INSTALLATION SHEET EXPLAINED

8000 Series Safety Light Curtain

Installation Sheet (CD159/030210)

Figure A -Unpacking

Remove all packaging material and retain it

Locate and keep the delivery note

Inspect all items for transit damage

Match goods supplied to those specified on the delivery note

Keep the Installation Sheet in a safe place

Each 8000 system supplied would normally include:

Light curtain

Cables (A) and (B)

Installation sheet

Service questionnaire form

Storage requirements

Humidity -<95%

Temperature range between -20C and +70C

SMARTSCAN 8000 SERIES LIGHT CURTAIN 2

CD246/080610 INSTALLATION SHEET EXPLAINED

Figure B shows important light curtain parameters. These parameters are shown as

C, M, K and R.

C - Light curtain column mounting centres. Use 6mm bolt for fixing

M -Length of the light curtain enclosures excluding end-caps

K - Detection height

R - Scanning range of the light curtain

Detection zone width (K) –Must be of a suitable height for each application to

prevent personnel access to the danger area, either over, under or around the light

curtains detection zone.

Range (R) –Ensure the particular light curtain specification is capable of satisfying

the range requirement for the application.

Fig. E also shows the connection points for the A cable between the transmitter (Tx)

and the receiver (Rx), B Cable connection and mute input connections.

To ensure correct operation of the system cable lengths as stated should not be

exceeded: A cable = 55 metres. B cable = 50 metres.

SMARTSCAN 8000 SERIES LIGHT CURTAIN 3

CD246/080610 INSTALLATION SHEET EXPLAINED

Figure C shows the use of a Perimeter light curtain and mirror arrangement.

A detailed explanation of the use of mirrors and safety light curtains in machine safety

applications can be found in Appendix 1.

If utilising mirrors to deflect the light curtain ensure the mirror length is 100mm longer

than the light curtain detection height and mounted centrally to the zone. To ensure

reliable operation the light curtain deflection angle from the mirror must not be less

than 40 degrees or greater than 100 degrees.

Figure D shows 8000 Series light curtain end-bracket dimensions. Use M6 bolts

for the mounting brackets.

SMARTSCAN 8000 SERIES LIGHT CURTAIN 4

CD246/080610 INSTALLATION SHEET EXPLAINED

Figure E -Operating Requirements

Humidity <95%

Temperature range between 0 and 50 degrees C

Vibration frequency <55Hz max. Displacement <0.35mm

Equipment should not be used in potentially explosive atmospheres. The units

are not ‘EX’ rated. Do not use the equipment in explosive atmospheres. For

further information on explosive-proof enclosures contact Smartscan Ltd.

Noise generated by the equipment will never exceed 70 dB

Note: Restart controls must be located such that the danger area can be seen to be

clear of persons before the system is activated.

SMARTSCAN 8000 SERIES LIGHT CURTAIN 5

CD246/080610 INSTALLATION SHEET EXPLAINED

When installing a Smartscan 8000 Series light curtain your attention is drawn to the

following: (Figure F)

3. Ensure the mounting position of the light curtain in respect to the nearest danger

point meets the requirements of European Standard EN ISO 13855.

4. Ensure the light curtain transmitter and receiver units are mounted accurately in

line with each other and are both perpendicular and parallel to each other within the

parameters shown for each axis.

1. Consider reflective surfaces that

may give rise to optically ‘short

circuiting’ the direct path of the light

curtains as shown. To ensure the

light curtain is mounted far enough

away from reflective surfaces use

the formulae provided to calculate

the minimum dimension between

the light curtain and reflective

surface.

X = minimum distance (mm) between

reflective surface and light curtain.

2. To prevent intermittent tripping of

the light curtain ensure extraneous

infra-red energy between 800 and

1000 nanometres is not directed

towards the Perspex window of the

receiver unit (RX). Extraneous

sources would include infra-red

sensors, infra-red remote controls

or scanning systems.

SMARTSCAN 8000 SERIES LIGHT CURTAIN 6

CD246/080610 INSTALLATION SHEET EXPLAINED

Figure G shows colour and function of the status LED’s associated with the

Smartscan 8000 Series.

LED Status Indicators on the R/X

F10 Green Guard Clear

F11 Yellow Mute 1 Clear

F12 Yellow Mute 2 Clear

F13 Red Guard Blocked

F16 Yellow Status relay off (Auxiliary / Non-safety Output)

F17 Yellow Mute on

F15 Red Safety outputs off

F14 Green Safety outputs on

LED Status Indicators on the T/X

F9 Red Beam(s) transmitting

SMARTSCAN 8000 SERIES LIGHT CURTAIN 7

CD246/080610 INSTALLATION SHEET EXPLAINED

Figure H defines the features found in the 8000 Series including, where appropriate,

maximum power rating, ‘guard on’ and ‘guard off’,, and status of input and output

connections.

SMARTSCAN 8000 SERIES LIGHT CURTAIN 8

CD246/080610 INSTALLATION SHEET EXPLAINED

Figure I shows the range of 8000 Series light curtains and cables. It describes

model codes, number of beams, aluminium extrusion length (M), detection zone width

(K), light curtain mounting centres (C) weight in (Kg) of the transmitter (Tx) and

receiver (Rx) columns and the maximum scanning range (R).

For example, model number 083E903 will provide a 900mm high detection zone, 3

beam light curtain with standard software option. Model number 183E903 will provide

the following, 900mm high detection zone, 3 beam light curtain with a blue integrated

mute beacon and standard software option.

SMARTSCAN 8000 SERIES LIGHT CURTAIN 9

CD246/080610 INSTALLATION SHEET EXPLAINED

Figure J shows all input and output connections to and from the 8000 Series light

curtain. The drawing also shows wire colour coding. Please see Appendix 2for

examples of typical 8000 Series wiring configurations.

SMARTSCAN 8000 SERIES LIGHT CURTAIN 10

CD246/080610 INSTALLATION SHEET EXPLAINED

Figure K shows examples of the identification labels that are affixed to the

transmitter (Tx) and receiver (Rx) columns.

SMARTSCAN 8000 SERIES LIGHT CURTAIN 11

CD246/080610 INSTALLATION SHEET EXPLAINED

Figure L –Activate control

The ACTIVATE control has two functions.

1) Restart. At power-up or, following a tripped condition, the activate switch is

used to restart (reset) the output relays to an ON state. The switch must be

activated and released to enable a restart condition.

2) Override. If the safety system trips when a pallet load is interrupting the

beams in the light curtain the safety system cannot be restarted. To

overcome this condition the activate switch can be used to establish the

light curtain output relays to an ON state for a period of 3 minutes. This

period is normally enough time for an operator to restart the machine and

remove the pallet load from the detection field of the light curtain. For the

output relays to remain energised the activate switch, normally ‘spring

return’, must be held in the ‘closed’ position during the entire 3 minute

mute override period.

The activate input requires a 24V DC source voltage.

SMARTSCAN 8000 SERIES LIGHT CURTAIN 12

CD246/080610 INSTALLATION SHEET EXPLAINED

Figure M -Test and Maintenance

The Transmitter (Tx) and Receiver (Rx) windows should be cleaned regularly as

indicated on the Installation Sheet.

Dirt build up on the windows may lead to intermittent tripping or a totally blocked

condition of the light curtain. Clear adhesive tape may be applied to the windows of

curtains in dirty or abrasive conditions. Renew the clear adhesive tape periodically.

Clean the windows with a clean damp cloth using a mild detergent. Never use

abrasive, corrosive cleaners or spray detergents.

Power-up the light curtain and

activate the output switching

circuits to an ON condition.

Insert a test piece of appropriate

size into the top light beam,

150mm from the transmitter unit.

At this point the output switches

will turn OFF as the test piece

totally obscures the beam.

Repeat this process through each

of the beams in the light curtain.

Ensure that while the test piece

is obscuring each beam the

output switches are OFF.

SMARTSCAN 8000 SERIES LIGHT CURTAIN 13

CD246/080610 INSTALLATION SHEET EXPLAINED

Figure N shows an operations chart for the 8000 Series.

Before installation, read and

understand the Installation Sheet

provided paying particular attention to

the information provided in Figure F.

Refer to Figure M for test and

maintenance procedures.

Every 24 hours carry out tests as

indicated in Figure M.

Every six months check the entire

installation, paying particular attention

to Figure F.

If the equipment fails to operate as

intended check the electrical

connections as shown in Figure J.

SMARTSCAN 8000 SERIES LIGHT CURTAIN 14

CD246/080610 INSTALLATION SHEET EXPLAINED

Figure O outlines the procedure for returning a Smartscan product.

If a fault occurs that cannot be resolved or the equipment is damaged return the

system to the nearest Smartscan distributor or Smartscan Ltd. Indicate the nature of

the fault and the symptoms displayed on the form provided.

Returned guards must be matching serial number pairs. This is to ensure that

the Service department can carry out a full and proper inspection of the

returned light curtain system.

SMARTSCAN 8000 SERIES LIGHT CURTAIN 15

CD246/080610 INSTALLATION SHEET EXPLAINED

Figure P shows abbreviation code for ‘B’ cable colours. Refer to the electrical

connection drawing (J) for more detail.

SMARTSCAN 8000 SERIES LIGHT CURTAIN 16

CD246/080610 INSTALLATION SHEET EXPLAINED

Figure Q –Declaration of Conformity

SMARTSCAN 8000 SERIES LIGHT CURTAIN 17

CD246/080610 INSTALLATION SHEET EXPLAINED

Figure R –shows the standard timer software (E) used in the 8000 Series for pallet

entry/exit applications. The software version is shown against the corresponding part

number. E.g. 083E903. The timers used in both cross-beam and parallel beam

modes are shown below. Please refer to the separate document on the 8000 Series

muting modules for further information.

Cross Beam

T1 (Mute 1 and Mute 2 Disparity Time) = Maximum time allowed between

activation of signals mute 1 (M1) and mute 2 (M2) prior to the pallet entering the light

curtain.

T2 (Mute Time Out Period) = A maximum pre-determined time the light curtain will

remain in a muted condition. Following this timed period, if the pallet is still

interrupting the mute beams or light curtain the OSSD’s will de-energise thus

initiating a stop condition. Providing the pallet clears the light curtain before the

maximum time T2 is exceeded then automatic transfer of the pallet will continue.

T3 (Mute Off Delay Time) = A predetermined time that the light curtain will remain in

a muted condition following de-activation of one or both of the mute signals.

Note: It is assumed that the Mute enable signal is energised during the entire pallet

transfer process.

Software version example

The standard 8000 Series is supplied with ‘E’ version software, for example 083E903

This provides the following functions for cross-beam,

T1 = 2.5 Sec T2 = 15 min T3 = 2.5 Sec.

SMARTSCAN 8000 SERIES LIGHT CURTAIN 18

CD246/080610 INSTALLATION SHEET EXPLAINED

Parallel Beam control timers

T1 (Pallet Transfer Time) = Minimum to maximum time during the pallet transfer

between, activation of mute beam 1 (M1) and the light curtain. Then T1 is repeated

again for pallet transfer between the light curtain and mute beam 2 (M2).

T2 (Mute Time Out Period) = A maximum pre-determined time the light curtain will

remain in a muted condition. Following this timed period, if the pallet is still

interrupting the mute beams (M1 and M2) and the light curtain then the OSSD’s will

de-energise thus initiating a stop condition. Providing the pallet clears the mute

beams and the light curtain before the maximum time T2 is exceeded then automatic

transfer of the pallet will continue.

T3 (Mute Off Delay Time) = A predetermined time that the light curtain will remain in

a muted condition following de-activation of one or both of the mute signals.

Note: It is assumed that the Mute enable signal is energised during the entire pallet

transfer process.

Software version example

The standard 8000 Series is supplied with ‘E’ version software, for example 083E903

This provides the following functions for parallel beam,

T1 = 0.15 -7.0 Sec T2 = 15 min T3 = 2.5 Sec.

SMARTSCAN 8000 SERIES LIGHT CURTAIN 19

CD246/080610 INSTALLATION SHEET EXPLAINED

Figure S provides a glossary of words and terminology used in the Installation

Sheet in a number of International languages:

SMARTSCAN 8000 SERIES LIGHT CURTAIN 20

APPENDIX1

CD246/080610 INSTALLATION SHEET EXPLAINED

Mirrors

Reflector mirrors can be provided enabling two or three sides of a machine to be

safeguarded with, what is effectively a single light curtain.

When mirrors are employed it is essential that the mounting of the transmitter unit,

receiver unit and mirrors themselves are sufficiently rigid. Alignment becomes

increasingly critical as the range and number of mirrors increase. Mirrors cause a

reduction in optical efficiency, reducing the effective range. A guide to the

practicality of using mirrors is given below.

Range of the

light curtain

Maximum range

through 1 mirror

Maximum range

through 2 mirrors

4m -40m 30m20m

Total Light Path 1 Mirror 2 Mirror

10m Easy Medium

15m Easy Not Feasible

20m Hard Not Feasible

30m Not Feasible Not Feasible

Based upon a 085 -903

Note: The angle of the light curtain striking the reflective surface must be within

defined limits.

Popular Protection Device manuals by other brands

Kemper

Kemper 620 00 Installation and operating instructions

Arcteq

Arcteq AQ-101 instruction manual

DIADEM

DIADEM DiaSafe Single Technical manual

Palmer Safety

Palmer Safety ANCHOR2WAYSEAM instruction manual

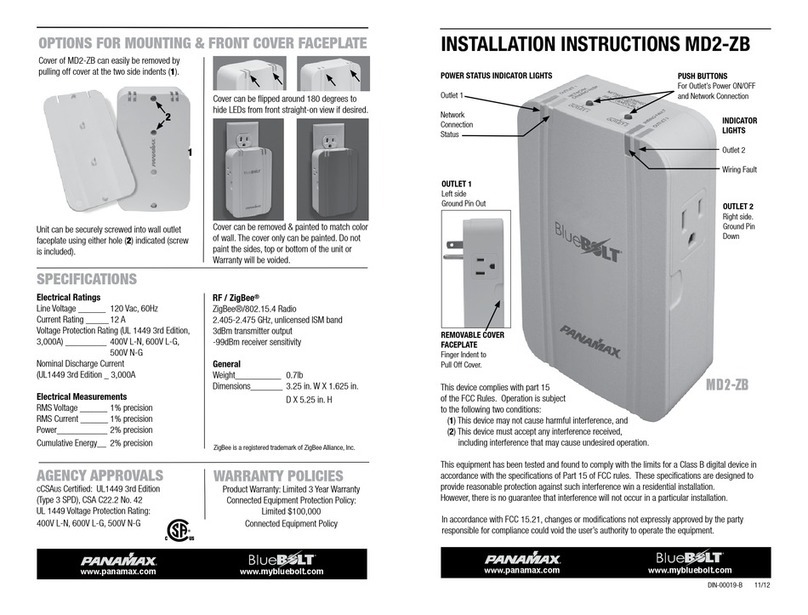

Panamax

Panamax BlueBolt MD2-ZB installation instructions

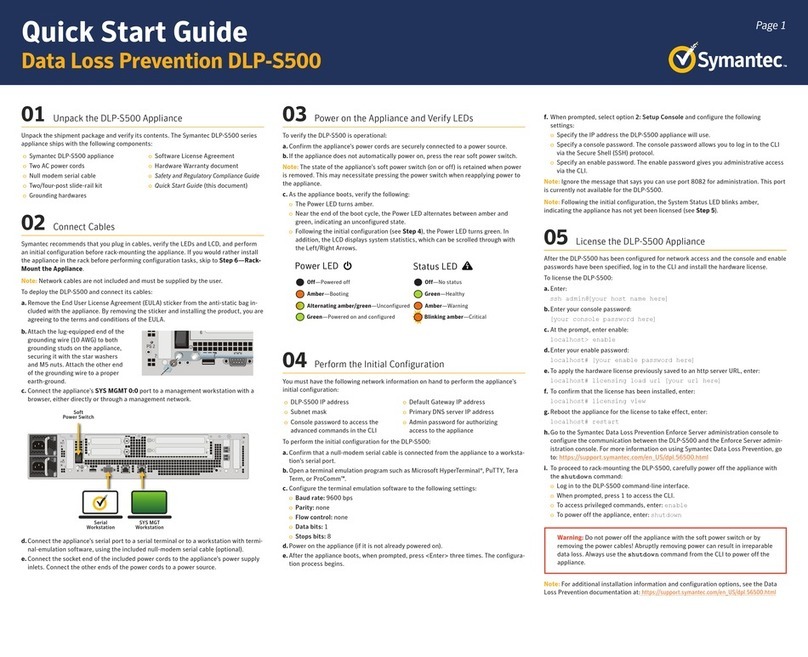

Symantec

Symantec DLP-S500 quick start guide

Intermatic

Intermatic SG160 user manual

Bitzer

Bitzer SE-E1 technical information

Arcteq

Arcteq AQ-S254 instruction manual

Tsubaki

Tsubaki SHOCK RELAY TSBSA Series instruction manual

Manson Engineering Industrial

Manson Engineering Industrial SSB-2180 user manual

Siemens

Siemens TPS4 13 Installation, operation and maintenance manual