Smart Sensor Model AS850 User manual

Ultrasonic Thickness Gauge

Instruction Manual

Model:AS850

1. Introduction----------------------------(01)

2. Operation instruction-----------------(04)

3. Operations procedure----------------(05)

4. Measurement tips --------------------(09)

5. Precautions for accurcy -------------(11)

6. Maintenance---------------------------(13)

7. Notice -----------------------------------(14)

8. Table of sound velocity---------------(15)

Table of Contents

Over warranty period, any repairing / maintenance will charge the fee

on the buyer in standard rate by local distributor.

The standard rate is not including the accessories which not packing

in standard package(For example, abnormity transducer, lengthen

lead-wire, special software) .

We disclaims any liability due to: transportation damages; incorrect

use or operation; manipulation, alterations or repair attempts; without

warranty card, invioce.

7.2. Non-warranty list

LCD, battery, probe, sample block, plastic case, coupling agent

8. Table of sound velocity

Sound velocities of common materials

Aluminum

Zinc

Silver

Glod

Tin

Iron/Steel

Brass

Copper

SUS

Acrylic resin

Water(20℃ )

Glycerinl

soluble glass

2670

3530

4430

5440

5720

6310

6020

5630

5850

5660

6070

4650

2620

Acetate resin

Phosphor bronze

Turpentine

Glass

Incoloy alloy

Magnesium

Monel alloy

Nickle

Steel 4330(mild)

Steel 330

Titanium

Zirconium

Nylon

6320

4170

3600

3240

3230

5900

4640

4700

5790

2730

1480

1920

2350

Material Velocity(m/s)

-15-

Material Velocity(m/s)

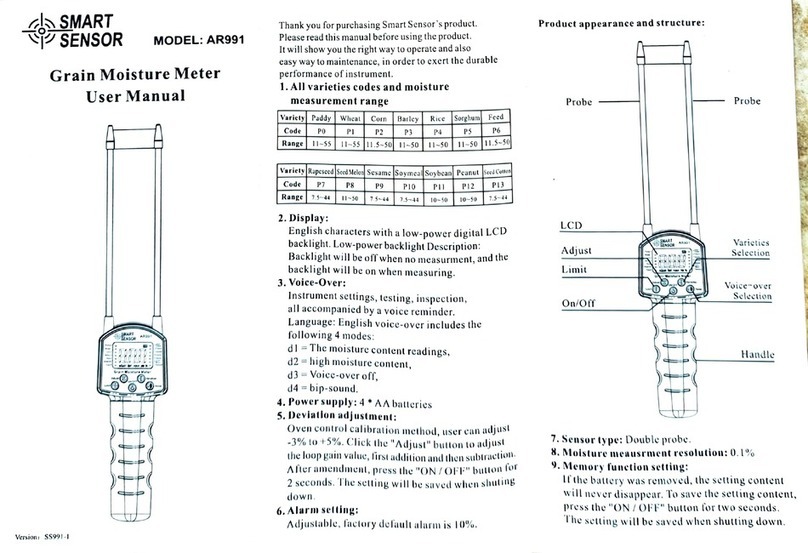

1.Introduction

Smart sensor AR850 ultrasonic thickness gauge is an intelligent hand-

hold product, which adopts ultrasonic measuring principle, and is

controlled by micro processor, provides quick and precise measurem-

ent of thickness for most of industrial material. This unit is widely used

in various precise measurement for different hardware / parts in indus-

trial realm; one of its important application is to monitor the level of thi-

ckness-decreasing during operation of various and pressure container.

Diffusely applied in manufacture fields, metal processing, and comme-

rcial inspection. The material that conduct and reflect constant sonic

velocity, this product is to be applicable to used.

1. 1 Scope of application

This unit is suitable for measuring materials that are good ultrasonic

conductor such as metal, plastic, ceramic, glass etc., as long as the

measured part in two parallel surfaces for measurement of thickness.

This unit is not suitable for cast iron due to its big crystalloid composition.

1.2 How it work

This unit is comprised of transimtting circuit, receiving circuit, Hi-freq-

uency oscillator, counter, central unit processor, keypad, and moniter

etc., adopting ultrasonic pulse reflect principle. Similar to light-wave

measure principal, the sonic pulse occurs from the unit travels through

the material being measured till reach the interface and reflects back

to determine the thickness of the target material.

See the diagram below:

-01- -14-

Hardware

Display driver

Transmitting

Receiving Feedback wave

C

P

U

LCD display

Keypad

Counter

Hi-frequency oscillator

6.3 Cleaning the cabinet

Do not use solvent/alcohol for cleaning which erode the cabinet & LCD

window, brush and sweep only with a moist cotton cloth.

6.4 Cleaning the sample block

Because of coupling agent should be put on the sample block during

calibration, after use the sample block should be cleaned for preve-

nting rust. In higher temperature environment, be sure protect the block

form the droplet of water. If the gauge is not use for a long period, please

apply some antirust on the sample block.

6.5 Avoid shocking/impact. Do not store the unit in high humidity enviro-

ment.

6.6 When the tolerance is over than stated in this manual, please refer

to the 3, 4, 5 chapter, in this manual.

6.7 Please contact us or our distributor if the following occurs:

A. Component being destroyed, no readout and enable to measure.

B. Abnormal LCD display.

C. The tolerance is too big in proper operation.

D. Malfunction of keypad.

6.8 This gauge is a advanced technology product, the repairing only by

technician authorized by us, do not try any alterations or repair attempts.

7.Notice

7.1. Warranty and warranty policy

Please fill the warranty card with your cachet/chop after purchasing

this products, the warranty period for repaired is 12 months form the

date of original purchase. During warranty period, product must be

returned with the invoice(copy) and warranty card to our customer service

department. The product will not be warranted which without the warra-

nty card.

-13- -02-

LCD display

1.3 Standard packing & Parts description

1. Standard packing:

Main unit-1PCS Transducer-2 PCS(Φ10mm 5MHz ,Φ10mm 2.5MHz)

Coupling agent-1PCS(50ml)

4mmSample block-1PCS

2. Parts description

3. LCD diagram:

---- Low battery indicator

---- Coupling indicator

m/s ---- Sound velocity unit

mm ---- Thickness unit

VEL ---- Sound velocity indicator

THICKNESS ---- Thickness indicator

---- Store / recall indicator

-- ---- Stored unit indicator

---- Calibration indicator

Keypad

LCD

Keypad

Receive socket Transmit socket

Transducer

micrometer/caliber.

5.8 Abnormal reading

A seasoned operator should be capable to distinguish the abnormal

reading, practically result from rusting, erosive recess surface / incorrect

calibrate sample block/ the inner flaw of material.

5.9 Choose and using coupling agent

Coupling agent serves the high frequency ultrasonic wave transmit-

ting between the transducer to the hardware. Choose incorrect agent or

wrong operation man cause error or poor coupling which lead to failure

of measuring. The coupling agent should be used in proper way, typic-

cally, a single droplet of agent is sufficient.

It is important to use proper coupling agent, low viscosity agent(the

provided agent / machining oil) is suitable for smooth surface. For

rough / veritcal / aluminum surface, high viscosity agent like glycerin

and lubrication grease is applicable. All kinds of coupling agent is

available in local market, you can buy it form local distributor as well.

6. Maintain

6.1 Battery replacement

When low battery icon is showed, please replace the batteries.

A. Press ON/OFF to turn off.

B. Open the battery door properly.

C. Replace the low power batteries by new batteries in correct polarity.

When the gauge is not use for long period, please take out the batteries.

.

6.2 Protection of transducer

Because the wear face of transducer is propylene material which easy

to be scratched. During taking measurement on rough material, please

using the transducer in gentle motion. The temperature of the hardware

should not over 60℃, otherwise it will cause damage on the transducer.

Adhering oil, dust on the wear face will speed up aging of transducer

and lead to rupture. Clean the lead-wire & transducer after use.

-03- -12-

Keypad

1.4 Specification

Display: 4-digital LCD display

Minimum display unit: 0.1 mm

Working frequency: 5MHz

Measuring range: 1.2 to 225.0mm (steel)

Minimum limit for tube measuring: Φ20*3mm (steel)

Accuracy: +/- (1%H+0.1)mm,H denotes the measured thickness.

Sound velocity range: 1000 to 9999 m/s

Measuring sound velocity with a given thickness: measuring range:

1000 to 9999 m/s. When the given thickness over 20mm, the accuracy

is +/-5%; when the given thickness less than 20mm, the

accuracy is +/-1mm/H*100%.

Operation temperature: 0 to 40

Power supply: 3*1.5V AAA alkaline batteries

Operation current: Normal operation current 50mA

With Backlight turn on current 120mA

Stand-by current: 20uA

Size: 70.0*145.5*28mm

1.5 Features

Auto calibration to assure the accuracy.

Auto linear compensation: this advanced software program enha

nces the precision by correcting the non-linear accuracy of transducer.

℃ ℃

≤

≤

≤

Take care for measurement while measuring the known rusting spot/

suspicious area. or using sound insulation boardcelotex to locates the

spot in different testing angles.

5.3 Identify different velocity with vary material

A fault reading would obtains, when measuring the hardware with the

velocity calibrated by prior material. So a correct velocity should be ad-

opted. The fault reading may also result form the difference between

the actual velocity with the calibrated value.

5.4 Abrasion fo the transducer

Because the transducer is made of propylene, long period use will cause

the surface of transducer became more rough which will decline the sen-

sitivity lead to the wrong reading. Please polish the surface with sand

paper or whetstone to assure the smoothness and parallel. If the reading

still unsteady, the transducer should be replaced with new one.

5.5 “ CAL ” function

“ CAL ”(calibration) is used to calibrate the unit with the standard block

on the panel, do press this key for calibration with other materials or the

wrong measuring will take place.

5.6 Multilayer / composite material

It is impossible to read out the thickness of the uncoupled multilayer for

the ultrasonic wave can not go through the uncoupled space. Further

more, the sonic wave cannot travel in the composite material at an even

speed, so ultrasonic reflect principle cannot be applied for measuring

the multilayer/composite material.

5.7 Influence from the oxidized surface

For some metals, such as aluminum a layer of oxide being generated

on their surface. The oxidized layer combined with the substrate tightly,

but the sonic wave travel within 2 different material which will lead to

error reading, the more oxidized layer the reading will be more tolerant.

Please calibrated the unit with the sample block that pick up along the

hardware to be measured, and obtain the thick of sample block by using

4. Keypad diagram

ON/OFF -- ON/OFF key

CAL -- Calibration key

VEL -- Sound velocity key

STORE -- Measurement

data stored key

CAL+ON/OFF --Backlight active keys

--Sound velocity, thickness,

thickness unit adjust/recall key

--Sound velocity, thickness,

thickness unit adjust/recall key

VAL

LIGHT CAL

STORE

-11- -04-

2. Operation instruction

2.1 Operation area condition: this unit can measure hardware all that

areas is equal to or bigger than the transducer’s area. To measure the

slim parts axially that is not vertical to the surface, the area shall not be

too small, otherwise the error measure may happen.

2.2 Curved surface condition: When the material is curved surface like

boiler wall or tubing, the curvature radius must be more than or equal to

10 mm, and the wall thickness must be more than or equal to 3 mm. This

requirements is referring in steel material, as for the curve surface of

other materials measuring requirements we still can not provide exact

data, we highly appreciate if you feedback us and share with your prec-

ious experience.

2.3 Roughness condition: This gauge wildly applies upon the rough

hardware/material, for most cases, our provided transducer can make

exact measurement. However, if the roughness is too big due to the rust

etc. the error measure may happen, in such case, please try to minimize

the roughness or select the 2.5MHz transducer. If the transducer is worn

out, please re-purchase on the local distributor.

In most situations, using one referring block will get a satisfying

measurement. This referring block must be the same material with

same thickness as the parts to be tested. The referring block should

be read out the thickness by micrometer.

When measuring thin material which thickness close to the minimum

limit range of this unit, please use a referring block to define exact

limit of this material( 1.2mm for steel material). Do not measuring the

material that the thickness under the minimum limit.

When material is a complex alloy in a large size. A block that has a

similar thickness with the material should be selected for calibration.

For most hardware by forging / casting, they have different inner

structure, so that the sound velocity slight different. To reach the exact

reading, the referring block has similar structure as the hardware.

In comment measurement, you check the sound velocity on the table

stated on this manual instead of taking calibration for the referring

block. However, this table just for reference, sometimes the sound vel-

ocity will be different cause by different physical / chemical factors. The

sound velocity of mild steel is adopted on the reference table.

This gauge with the function to measure the sound velocity, so the

velocity can be obtained before thickness measurement, and then pro-

ceed with measurement of thickness.

5. Precautions for accuracy

5.1 For very thin material

Any ultrasonic thickness gauge, when the thickness of the material to

be measured is less than the minimum limit the fault reading will occurs.

Using sample block compare method to get a minimum limit of this ma-

terial.

In measuring the thin material, an error may happen that the reading

is two times as the actual dimension. Another error which display the

reading much more bigger than the actual. To prevent the wrong reading

by double check out the minimum limit in the thin material.

5.2 For stained, rusting surface

The stained/rusting surface on the contra side will occurs the ruleless

wrong readings. Sometimes a small stained spot is hard to find out.

Use and keys to make a quick adjustment for the sound velocity

/thickness,and a quick recall to the stored data.

Coupling status indication: Observing the coupling icon to learn if

the coupling is accomplished or not.

10 thickness measurement storage and recall function is available,

which facilitates the height work or working in wild area.

Sound velocity measurement: With a given thickness by a sample

hardware to measure the sound velocity, which avoid the further

conversion or consultation of the table.

12 sound velocity for different material

Low battery indication

Auto power off mode designed to conserve battery power.

More than 10000 times long lift keys.

Manual power off: Press the “ ” button to turn it off

-05- -10-

2.4 Working temperature condition

Material thickness and sound velocity will change along with tempera-

ture. In normal measurement, environment temperature impact can be

ignored.

The transducer is made of propylene material, considering the protec-

tion of the transducer and its precision we recommend that the surface

temperature of the hardware/workpiece should not over 60℃, otherwise

the transducer can not put into use.

Operation temperature: 0~40℃

Relative humidity: <90%RH

Hardware/workpiece/material temperature: <60℃

Do not apply in violent vibration / erosive material.

Avoid impact and humidity.

3. Operation procedure:

3.1 Before measurement

(1) Connect the transducer with the main unit, press ON/OFF to turn on,

LCD display full screen for 0.5 second with backlight,then vertical bar

is displayed twice circularly, meanwhile the main display area show

0000 to 9999 progressively.After that, LCD display the last applied

sound velocity with registered memory unit, indicating the gauge is

ready for use.

(2) Sound velocity selected & adjustment

Press “VEL” to enter sound velocity interface, press “VEL” again, you

can select reserved velocity data by pressing “ ” or “ ” with the

word “VEL” blinking on LCD ; If you need to adjust sound velocity data,

Full screen Last applied sound velocity

& registered unit

The standard of selecting the angle between the crosstalk segregating

board of the transducer and axis of the measured part is up to material

curvature. For bigger pipe diameters, choose vertical orientation between

the crosstalk segregating board of the transducer and axis of the measured

pipe, and for the smaller ones, two measurement should be performed, one

with the axis of pipe perpendicular, another is parallel, and the smaller of

two displayed values should then be taken as the thickness at that point.

4.5 Complex shape material

For complex shape material measurement, please refer to the 4.4,

the smaller of the two reading should then be taken as the thickness.

4.6 Non-parallel surface

To get a satisfying ultrasonic response, the surface must have its one

measuring side parallel with another, otherwise will obtain wrong result.

4.7 Influence of the material temperature

The size & sound velocity of material will change with the temperature,

when the precision is critical, please make measurement in 2 samples

of the material under the same temperature to determine the proper

reading resulting from the temperature. When taking measurement

for steel parts in high temperature, this method may be adopted to

obtain the correct reading.

4.8 High acoustic reduction material

For materials in fiber, poriferous or big granular, acoustic dispersion

will cause the energy attenuation that may result in abnormal readings

(practically the reading less than the actual thickness), in this case, the

material is not suitable for the gauge.

4.9 Reference sample block

For calibration for the gauge, a given thickness or sound velocity of

the material is very import. Calibration needs at lest one referring stan-

dard sample block. This gauge is provided with a 4.0mm sample block

on the front cabinet, please see for calibration operations.

In different material & situation, only one sample block may not

satisfy every calibration. The more similar sample block, the more exact

reading obtained. Ideally, referring block is a group of different thickness

and same material, by calibrating to the referring block, the effect of var-

iation of sound velocity will be minimized. To get the most exact measure,

a set of referring block is very important.

-09- -06-

unit is on adjusting status. Then, increase or decrease the sound velocity to

the data you want by pressing “ ” and “ ”,and this data will be automatically

stored into current sound velocity memory unit. After that, press “ VEL” to

confirm new sound velocity, and the icons of “VEL” and “m/s” stop blinking.

press “VEL” once more, the “VEL” and “m/s” will keep blinking, indentifying the

3.2 Calibration

A calibration should be made for every replacement of transducer or

batteries, this operation is sufficiently important to assure the measuring

precision. If necessary,this step should be repeated. Pressing “CAL” for

2 seconds, LCD displays “CAL”, indicating that the unit is on calibration

status, vertical bar displayed circularly on the left of LCD. put few provided

coupling agent on the stan-dard sample block to couple the transducer and

the sample block. Until the LCD display 4.0mm indicating the calibration

is completed. After calibration, sound velocity will back to your selected

value, and ready to measurement.

Calibration accomplished

3.7 Low battery indication

When icon flashes, please replace the batteries for further mea-

surement.

3.8 LCD back light & Automatic power off

Before turn on the gauge, hold pressing “ CAL ”, and press ON/OFF

button to turn on, the back light will active, every operation will turn on

the back light for 7 seconds until press ON/OFF to turn off the unit.

If no any operation for 2 minutes, the gauge will turn off automaticly

and the back light function will be cancelled.

4. Measurement Tips

4.1 Cleaning surface

Before measuring, the dust, dirt, rusting and grease etc that adheres

on the hardware/workpiece must be removed off and cleaned.

4.2 Decreasing the roughness of surface

Too rough surface may result in measure error/ fault reading. Please

try to make the surface smooth by milling, polishing, filling or using high

viscosity coupling agent.

4.3 Rough machining surface

The regular tiny texture/slots resulting from rough machining process

may cause error, and the compensation method is the same as in 4.2,

adjusting the angle between the crosstalk segregating board of the

transducer ( a metal membrane crossing the detector bottom centre) and

linear texture/slots (parallel or vertically) may also get a better result.

4.4 Measuring the surface of cylindrical parts

When measuring the material of cylindrical parts, like pipe 、oil tub etc,

it is critical to select the angle between the crosstalk segregating board

of the transducer and axis of the measured material. In simple terms,

couple the transducer and measured material, keep the crosstalk

segregating board of the transducer and axis of the measured material

parallel or vertical, wave the transducer slowly and perpendicularly along

the axis of the measured part. The reading on the screen will be changed

orderly, select the smallest one as the exact thickness.

Velocity adjustment Velocity revision

Calibration statu

-07- -08-

3.3 Thickness measurement

Put the coupling agent on the area to be measured to couple the trans-

ducer with the hardware/workpiece, LCD will display the thickness

reading.

Notes: icon on the screen indicates a well coupling, if the icon fla-

shes or not shows that means a poor coupling. After remove the trans-

ducer, the reading will be hold.

In a well coupling measurement Measurement accomplished

3.4 Sound velocity measurement

With a given thickness to read out sound velocity of material: Obtains

the thickness of material by using vernier caliper / micrometer, then

couple the transducer with that sample material until a reading displays

on the LCD, remove the transducer and press or to adjust the

reading match the thickness by caliper/mirometer, then press VEL to

display the sound velocity and save in current velocity memory unit.

Measuring the thickness Adjusting actual thickness Velocity read out

(1) Keep pressing STORE for 2 seconds to enter save thickness data mode,

LCD display THICKNESS, mm, icon with first memory unit. If the first

memory unit is not being registered, so LCD will display 0.0.

(2) Press or to select your desired memory unit (1-10).

(3) After picked up the memory unit, it will begin to work. While measuring,

the memory unit NO will flash and the new measurement will be renew

the memory unit, when the measurement completed, the last reading will

be stored in the selected memory unit automatically with the memory unit

NO stop blinking.

“ ”

3.6 Review the saved data

Press the memory unit NO and stored data displayed. You can

review the saved data in 1-10 units by pressing “ ” and “ ” and they

are read-only. Press “STORE” will back to measurement mode.

“CAL”,

Select memory unit Taking measurement &

saving data Measurement & storage

accomplished

3.5 Data storage

Review saved data

Other Smart Sensor Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Schaller

Schaller Humimeter BLW operating manual

Pittsburgh

Pittsburgh 63731 Owner's manual & safety instructions

Hanna Instruments

Hanna Instruments HI 9812-0 instruction manual

VOLTCRAFT

VOLTCRAFT AM-39X14/TEMP Operatoring Instructions

Hanna Instruments

Hanna Instruments HI 4321 instruction manual

Geokon

Geokon 4050 instruction manual