Smart Sensor AS930 User manual

Model: AS930

Film/Coating Thickness Gauge

User's Manual

Version number:SZ930-0-12

SENSOR

SMART

R

DEL

ZERO

/ON

Thank you for purchasing our company's product.

This manual provides relative information on how

to use this product and measurement functions of

it as well as warnings on its use. To make the best

use of this product's functions, read this manual

thoroughly before use. Please keep this manual

handy for ease of reference.

Please be sure to do some test measurement to

make sure it is performing properly before using it

for real.

Preface

Specific Declarations:

a. The product design and the manual updating, repairi-

ng by technician authorized by us, do not try any alte-

rnations or repair attempts.

b. Dispose of battery should in accordance with local

laws and regulations.

Warranty

1). About relative warranties please read provided

warranty card.

2). We disclaim any liability due to: transportation

damages; incorrect use or operation; manipu-

lation, alterations or repair attempts; without

warranty card, invoice.

-28-

Other Items

-27-

1. Before use notice

2.Operation instructions

3. Other items

Contents

Check-up---------------------------------------------(01)

Introduction------------------------------------------(02)

Features and functions ----------------------------(02)

Specifications --------------------------------------(03)

Main parts explanations -------------------------- (04)

Displays functions -------------------------------- (06)

Attentions --------------------------------------------(22)

Maintenance and warranty -----------------------(27)

Special declaration---------------------------------(28)

Know the Standard piece and Base material---(07)

Battery Installation ---------------------------------(08)

Instruments calibration ----------------------------(10)

Unit change------------------------------------------(15)

Continually measurement-------------------------(16)

Instruments tolerance measurement------------(17)

Coating tolerance measurement-----------------(18)

Memory data record, check and delete ---------(19)

Data analysis----------------------------------------(20)

Maintenance and warranty

Maintenance:

1). Replacement and maintenance of battery:

a. After power on, if a symbol appears on the LCD,

you need to replace the battery immediately, for details

please refer figures and contents on page 9 of this

manual.

b. Remove the battery from the unit if it is not required for

extended periods of time in order to avoid damage to

the battery compartment and the electrode resulting

from a leaking battery.

2. Do not store or use the unit in following locations whe-

re the unit may be subject to:

a. Splashes of water or high levels of dust.

b. Air with high salt or sulphur content.

c. Air with other gases or chemical materials.

d. High temperature or humidity (above50℃, 90%,) or

direct sunlight.

3. Do not disassemble the unit or attempt internal

alterations.

4. Never use alcohol or thinner to clean the unit casing

that will especially erode the LCD surface; just clean

the unit lightly as needed with little clean water.

-26--01-

1PCS

1PCS

1PCS

1PCS

1PCS

6PCS

1PCS

1PCS

1PCS

Check-up

1. Before use notice

Carefully unpack your kit after you purchased this

product and ensure that you have the following items. In

the event that any item is missing or if you find any mis-

match or damage or the manual appearing to lack page,

etc. seriously influencing the reading, promptly contact

your dealer.

Other Items

Digital coating thickness tester

9- Volt alkaline battery

Chinese Instruction Manual

English Instruction Manual

Maintenance Card

Standard sheet gauge

Iron base material for calibration

Transparent leather pack

Aluminum Packing Box

c. According to the international standard, the final

measure result can expressed as the following

formula:

CH=A+/-2D

CH---the thickness of the coating

A----the average value of the measure data (AVG)

D-----standard warp (dFR)

-02--25-

Introduction

Features and functions

Need To Know

Before Use

This product using magnetic induction thickness mea-

surement method, the thickness equipment specially

designed to perform small, fast, accurate and non-destr-

uctive thickness measurement of coating and plating on

steel magnetic conductor. it is widely used on manufact-

uring, workshop, chemistry or quality measuring range.

Easy- to- read LCD direct display measurement value

and status.

Using Hi- sensibility sensor for precise measure.

0 point, 2 point and basic, three different calibration

modes for quick and easy to process the system toler-

ance calibration.

Single, continually and difference, three different

measure mode.

Result data can record, check and delete into the unit

memory.

The Instruments can do some simple data analysis,

like maximum, minimum, mean, standard deviation,

and measure times.

Buzzer notice function.

Unit can convert between the metric system and British

system.

Low Battery notice function.

Auto power off function.

LCD backlight function.

Simple, compact structure and portable.

d. curvature:

You should not measured at the distorted surface.

e. the reading number:

Because the data you read will not same all the time,

so you should read several value at one measurem-

ent. The part difference of the coating also request

measure several time especially when the surface is

rough.

f. cleanness of surface:

You should clear all the attachment before the mea-

surement, for example, dust, ,grease, erode things

and so on, but do not removed anything contained in

the coating.

3. instruction about the measurement result:

a. single measurement is not credibility at statistics p-

oint. So all the value displayed by the tester are ave-

rage value. The time after time measurement is co-

mplete by detect head and tester within one second.

b. To make the measurement more precision, you can

measure several times, and then delete the big error

one, at last use the tester's analysis function to get

five statistical data: average value (AVG), MAX, MIN,

standard warp (dFR), data number (NO).

-24--03-

Specifications

1. Measurement range and tolerance:

Range Resolution Tolerance

0~1999μm 0.1um/1μm ±(3%H+1)

Remark: H=Nominal transformation ratio

3. Other Specification:

2. Condition of Objective material:

Suitable for measure about non magnetic coating on

magnetic conductor base material.

The base material minimum curvature radius.

Protruding: 2mm Concave =11mm

Base material minimum diameter: 12mm

Base material limit thickness : 0.5mm

Technical parameter

LCD display

Power supply

Operation current

Battery life

Auto off

LCD backlight function

Operation temperature

Operation humidity.

Low battery indication

Product size

Weight

Technical index

3 digits half number display

9V alkaline battery

Around 14mA

Continuously 20 hour usage.

After 1 min. haven't manipulated

After 7 sec. haven't manipulated

0~40℃

10~95% RH

7.0V ± 0.2V

67x 30x 183mm

147G (without battery)

h. the detect head's pressure:

The pressure on the target piece can affect the mea-

surement value, so the tester use spring to generate

a steady pressure.

i. Detect head's placement:

How the detect head placed can affect the measure-

ment. You should be sure the detect head and the

target piece's is vertical.

j. the target piece's distortion

The detect head can make the target piece of soft

coating distort, if the distortion is too big, the measu-

rement value will not correct.

2. the regulation when you are using the tester:

a. the basic metal property

The standard piece's metal magnetism and surface

roughness should similar with the target one.

b. the thickness of the substrate:

Check whether the substrate's thickness go beyond

the critical thickness or not.

c. verge effect:

You should not measured at the distortion, for exa-

mple, verge, hole or inner turn angle and so on.

Other Items

AS930

FILM/COATING THICKNESS GAUGE

DEL

ZERO

/ON

Fe

-04--23-

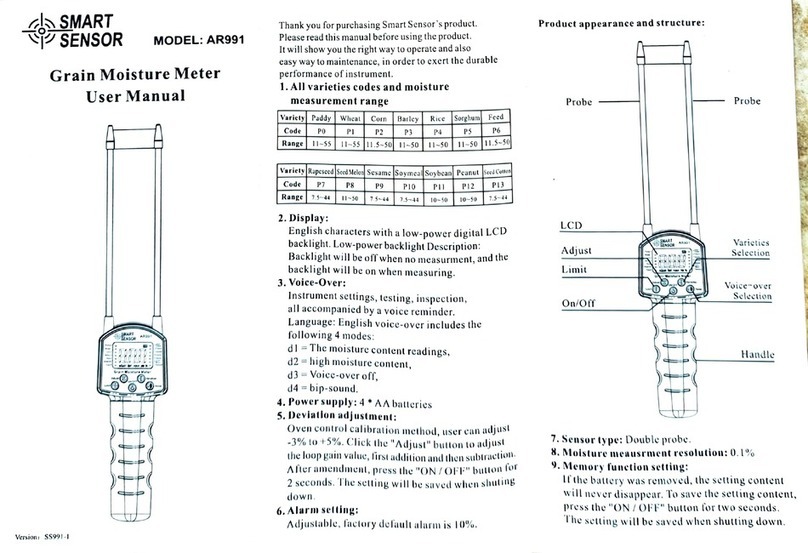

Main parts explanations

Need To Know

Before Use

1

2

3

4

5

7

6

d. Curvature:

The curvature of the target piece can affect the

measurement result. This effect will increased as the

curvature's radius reduced.

e. Roughness degree of the surface:

The roughness degree of substrate metal and

coating can affect the measurement. The bigger the

roughness degree is, the bigger the effect is. Rough

surface will cause system error and incidental error.

You should increase the measurement number at

different place to reduce incidental error. If the sub-

strate metal is rough, you must adjust ZERO point on

the substrate metal which is not coated and has

similar roughness with the target one; or you can use

impregnant which can not erode the substrate metal

to dissolve the coating, and then to adjust the ZERO

point.

f. magnetic field:

The strong magnetic which generated by wiring can

badly affect the measurement precision of magnetism

method.

g. Attachment:

The tester is sensitive to the attachment which can

prevent the test head contact the coating, so you

must clear the attachment to sure the tester's head

contact the surface target piece closely.

-22--05-

Note:

Above key function descriptions just are simply

introduction, for details please read operation

instructions part in this manual.

ZERO

/ON

DEL

1. LCD display

2. Sensor

3. Menu (single measure SNG, Continuously

measure CTN, Average measure AVG, Maximum

measure MAX ) Search upward and basic

calibration key.

4. Menu(single measure SNG, Continuously

measure CTN, Average measure AVG, Maximum

measure MAX ) Search upward and delete all

data key.

5. Power on/ set zero

6. Simple function indication

7. Battery door.

3. Other items

Attentions

1. Factors which affect the measurement precision and

some instruction:

a. magnetism of substrate metal:

The magnetism change of substrate metal affect the

measure result of magnetism method (the magnetism

change of low carbon steel can be considered lightly

in real life), to avoid the effect of heat treatment and

cold process, you should choose a standard piece

which have the same property as the target substrate

to adjust the tester, you also can use a piece which

is not coated to adjust.

b. thickness of substrate metal:

Erevy instrument has a substrate metal critical thic-

kness. Bigger than the thickness, the measurement

will not be affected by substrate metal thickness.

This tester's critical thickness is less than 0.5mm

according to the production specification.

c. verge effect:

The tester is sensitive to the steep change of the tar-

get piece you want to measure. So the measurement

which near the verge or inner turn angle of the piece

is not trustiness.

Other Items

-06--21-

Displays functions

Need To Know

Before Use

Fe

1 2

3

4

5

9

10

6 7 8

Fe

1. : Backlight indication, the backlight will off after

7 sec. haven't operation when measure.

2. Measurement value display area.

3.

4. : Measurements on steel or iron substrate.

5. : Memory recordation status.

6.Measurement mode, Data analysis indication.

7.Number of recorded data

8.Recorded data display.

9. : Imperial system unit (1mil= 0.0254mm = 25.4 )

10. : Metric system unit (1mm = 1000 )

Battery mark shows current residual battery power.

Has following 5 grades:

:battery is sufficient

:battery is comparative sufficient

:battery is nearly deficient

:battery is nearly exhausted, need to have a

replacement

:battery is exhausted completely.

μm

μm

Display dFR:

Display NO:

Caution:

a. when the measurement number is flashing, please

press ZERO/ON key to stop it, and then press UP /

DOWN key to change mode.

b. The displayed value in the operation instruction is

merely a example to explain the operate method,

you should follow the practice measured value.

c. If there is nothing operation for 1 min, the tester will

power off automatically.

-20--07-

2. Operation instructions

Operation

Explanations

Substrate and standard piece

Standard piece:

a. All the measured sample you can choose for

standard calibration piece. Shortened form stand-

ard piece.

b. The coated standard piece

The coated standard piece must choose inform thi-

ckness, uniformity and have a strong bonding non-

magnetic coating.

Substrate:

a. The standard substrate's roughness and magnetism,

must as close as the target testing material. For

identification the substrate suitability, can compare

standard substrate with the target testing piece

substrate's measured data.

b. If the target testing piece substrate's thickness

under the regulated thickness range, you can take

two methods to adjust as following.

1). adjust on the standard piece which has the same

thickness with the target testing piece.

2). use a standard metal gasket piece which have

enough thickness and similar magnetic and ele-

ctricity property or a testing piece, but must be

sure that there is not spacing between substrate

metal and gasket metal.

c. If the curvature is too big to adjust on plane, the

coating standard piece's curvature should the same

as the target testing piece's curvature.

Data analysis

The tester can analyze data automatically after have

measured several group data, press DOWN/ UP key to

change mode, LCD will display average value (AVG),

MAX, MIN, standard warp (dFR), data number (NO), LCD

displayed as following picture at this time:

Display Average:

Display MAX:

Display MIN:

-08--19-

1). Grip tightly the unit body with your left hand; hold down

the battery door with your right hand thumb to open it

according to the arrow referring direction, as shown in

following figure:

2). Insert the 9V battery into battery compartment, note

the battery polarity, and then close the battery door,

as shown in following figure:

Operation

Explanations

Memory data record/check and delete

1. Record:

The tester will record the measurement result automa-

tically and the measurement quantity will plus 1 after

every measurement, the quantity will increased until it

up to 15. If the measurement is go ahead at this time,

LCD will merely display the measurement value, but

not record it.

2. Check

you can press UP and DOWN key to look over the

measurement value when the measurement quantity

is flashing.

3. Delete

a. delete the current data: when the measurement

value is apparently error, you do not want it is recor-

ded, you can press the 'down' key to make the mea-

surement value back to the above one when the

measurement quantity is flashing, and then you can

measure for another time.

B. delete all the data: you can delete all the data by

press the ZERO/ON key for 2 second when the

measurement quantity is flashing.

Battery installment

+

-

AS930

FILM/COATING THICKNESS GAUGE

DEL

ZERO

/ON

-18--09-

Low battery

indication

3). Starting the unit and check-up battery

a. Press the key to start the unit, as shown in

following figure:

b. After the entire screen displays for 1 second, the

default state is acceleration mode, if this time on the

LCD screen displays the symbol or , please

promptly replace the battery, as shown in following

figure:

Operation

Explanations

ZERO

/ON

Coating tolerance measurement

Press ZERO/ON key to open the tester, and then press

UP /DOWN key to change the test mode, when LCD

display DIF, that is to say you have into Coating

tolerance measurement mode.

LCD displayed as following picture at this time:

Place the detect head to the target piece you want to

measure, and then press the detect head lightly to

measure, the buzzer will sounded, LCD will display the

absolute value which is the before value subtract the

current value, LCD displayed as following picture at

this time:

-10--17-

Operation

Explanations

Instrument calibration

To increase the test result is more correct; please cali-

brate the instrument at the test place. The instrument has

three different calibrations to suit the needs of the user. :

zero point calibration, two point calibration, basic

calibration.

Zero point calibration:

a. carry a measurement on a standard substrate or on

a uncoated substrate. LCD display a data, for

example ,0.3um, like the following picture:

b. do not lift the detect head and press the ZERO/ON

key, the buzzer will sound, that show you have com-

plete Zero point calibrate . LCD displayed like the

following picture at this time:

Continuous measurement

Fe

Fe

Press ZERO/ON key to open the tester, and then press

UP / DOWN key to change the test mode, when LCD

display CTN, that is to say you have into Continuous

measurement mode.

LCD displayed as following picture at this time:

Place the detect head to the target piece you want to

measure, and then press the detect head lightly to

measure, the buzzer will not sounded during the me-

asurement, LCD will display the measurement result

continuously until the detect is lifted, the last measure

value will be saved in the test automatically, the qua-

ntity of the data are also be memorized, LCD display

1 at the same time.

(when the second measurement is finished, the quan-

tity will increased to '2', like this,), LCD displayed as

following picture at this time:

Fe substrate

AS93 0

FILM/COATING THICKNESS GAUGE

DEL

ZERO

/ON

Fe

-16--11-

Operation

Explanations

Fe

c. If you want to correctly adjusted, you must repeat a

and b to make basic measure value less than 1 m,

this can improve measurement precision.

Two point calibration:

a. calibrate zero point first.

b. carry a measurement on the standard piece which

thickness approx. equal to the target piece.(like

1000 m). If the LCD display 1006 m, like the

following picture:

μ

μ μ

Fe

Fe

Single measurement

Prepared target piece you want to test.

Press ZERO/ON key to open the tester, the buzzer will

sounded, the tester into the tolerant test mode single

test mode, LCD displayed as following picture at this

time:

Make detect head contact the test surface vertically

and press the detect head lightly, LCD display a value,

for example, 136 um, and buzzer sounded at this time,

LCD displayed as following picture at this time:

Every time detect head contact the test surface vertic-

ally, buzzer will sounded at the same time, and LCD

will display test result, if you want to test for another

time, you must lift the detect head, and then repeat the

operation above.

Caution:

If the detect head contact the iron basic too closed

when you open the tester to self-check, LCD will

display ERR

Fe substrate

Standard piece

AS93 0

FILM/COATING THICKNESS GAUGE

DEL

ZERO

/ON

Fe

-15-

Operation

Explanations

Fe

c. do not lift the detect head and press the UP and

DOWN key to correct the read value, after these the

adjust is complete, you can measure at this time.

LCD displayed like the following picture at this time:

if you want To point calibration adjusted correctly,

you can repeat b and c to improve measurement

precision and reduce incidental error.

Basic calibration:

It is necessary to change the basic calibration under

the following conditions:

----------the top of the detect head is wear and tear

----------after the detect head is amended

----------Special use

----------the tester is not used or adjusted (zero adjust-

ment) for a long time

If the error go beyond the regulate range during the

measurement, it is necessary to adjust the detect head

for another time, this is named basic calibration.

Though input seven adjust value (zero and 6 thickness

value)can readjust the detect head. The operation

method of basic calibration is as following:

a. Prepare six standard pieces, the thickness is at

45~55, 95~105, 220~280, 450~550, 900~1050,

1900~1999, unit: m.μ

-12-

Unit change

Press ZERO/ON key to open the tester, the buzzer will

sounded, and then press UP / DOWN key to change

the test mode, when LCD display UINT, that is to say

you have into unit change mode.

The tolerant unit is μm, LCD displayed as following

picture at this time:

Press ZERO/ON key, you can change μm to mil or you

can change mil to μm, LCD displayed as following

picture at this time:

-14--13-

Operation

Explanations

b. press the UP key and ZERO/ON key when the tester is

closed until LCD displayed as following:

When appear the value 0.0 m, you can carry zero

adjustment to iron basic.

c. lift the detect head, appear a value at 45~55, for exa-

mple,48.0, LCD displayed as following at this time:

μ

Choose a standard piece, its thickness is at 45~55,

press UP and DOWN key to amend the display value,

make the display value accord with the standard

piece's thickness, and then place the standard piece

on the iron basic to adjust.

d. lift the detect head for another time, appear a value at

95~105, for example, 100, LCD displayed as following

picture at this time:

choose a standard piece, its thickness is at 95~105,

press 'up' and 'down' key to amend the display value,

make the display value accord with the standard

piece's thickness, and then place the standard piece

on the iron basic to adjust.

e. like this, until the last one is adjusted, the tester will

closed automatically and the new adjust value has

been saved in the tester. The tester will work follow the

new adjust value when you use it next time.

Table of contents

Other Smart Sensor Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Tekon

Tekon 960 user manual

Sierra

Sierra INNOVA-MASS 240-VT instruction manual

PCB Piezotronics

PCB Piezotronics B353B33 Installation and operating manual

Omega Engineering

Omega Engineering CL521 Operator's manual

BRUEL & KJAER

BRUEL & KJAER 2031 instruction manual

janitza

janitza UMG 96 RM Operating instructions and technical data