SmartCockpit Fokker 50 User manual

FLIGHT CONTROLS

The flight controls can be operated manually and automatically. From the flight deck, all

control surfaces are mechanically operated via rod-and-cable systems, except the electrically

operated aileron trim tab. To augment pitch attitude stability, an augment pitch attitude

stability system is installed. When the autopilot is engaged, ailerons, rudder, elevator, and

elevator-trim tab are controlled automatically.

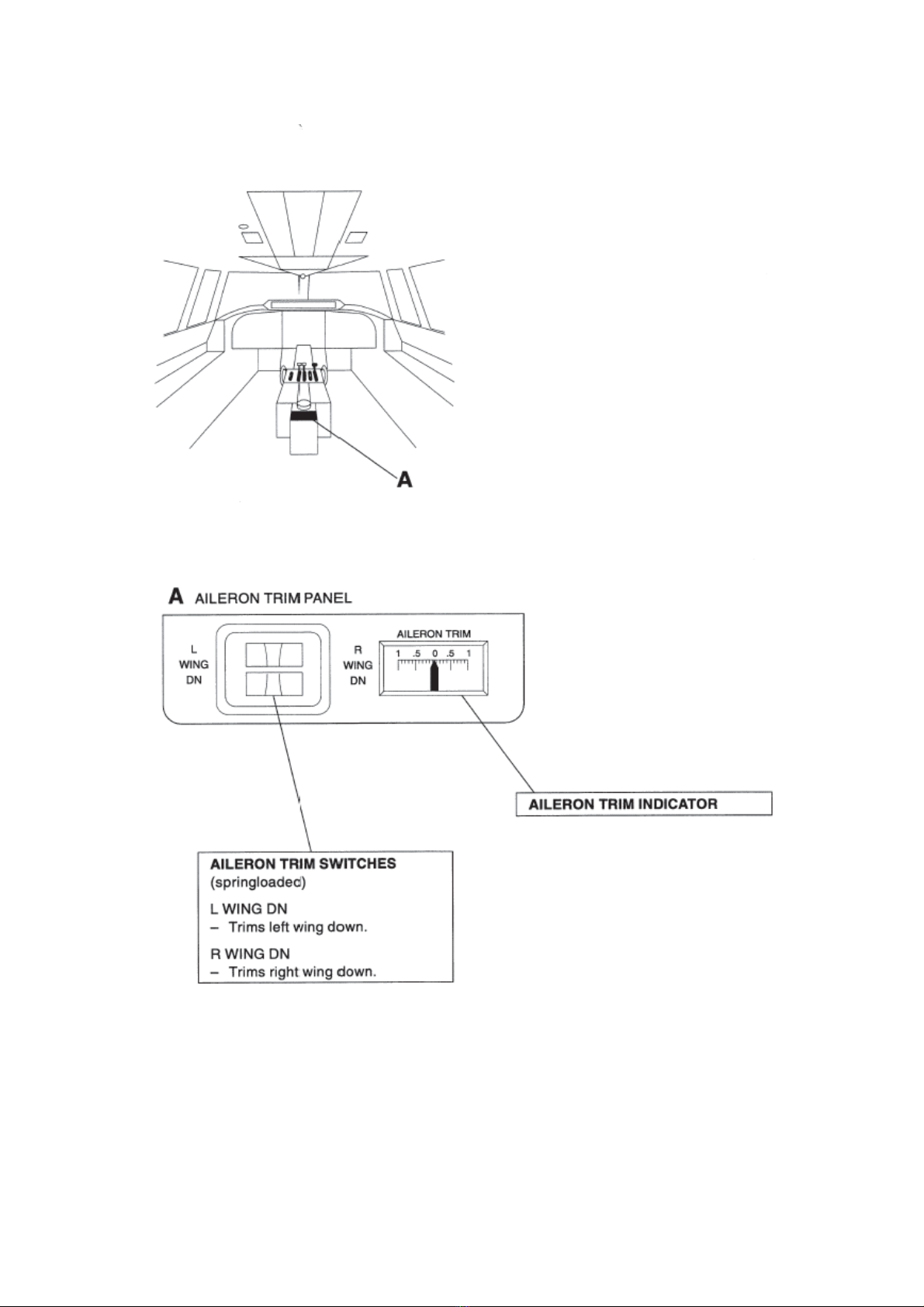

Ailerons

The ailerons are operated manually from the captain’s and first officer’s control wheels. The

ailerons are equipped with spring tabs and balance tabs. The balance tab at the RH aileron

can be electrically operated as a trim tab. The aileron trim control panel is installed at the

rear of the pedestal.

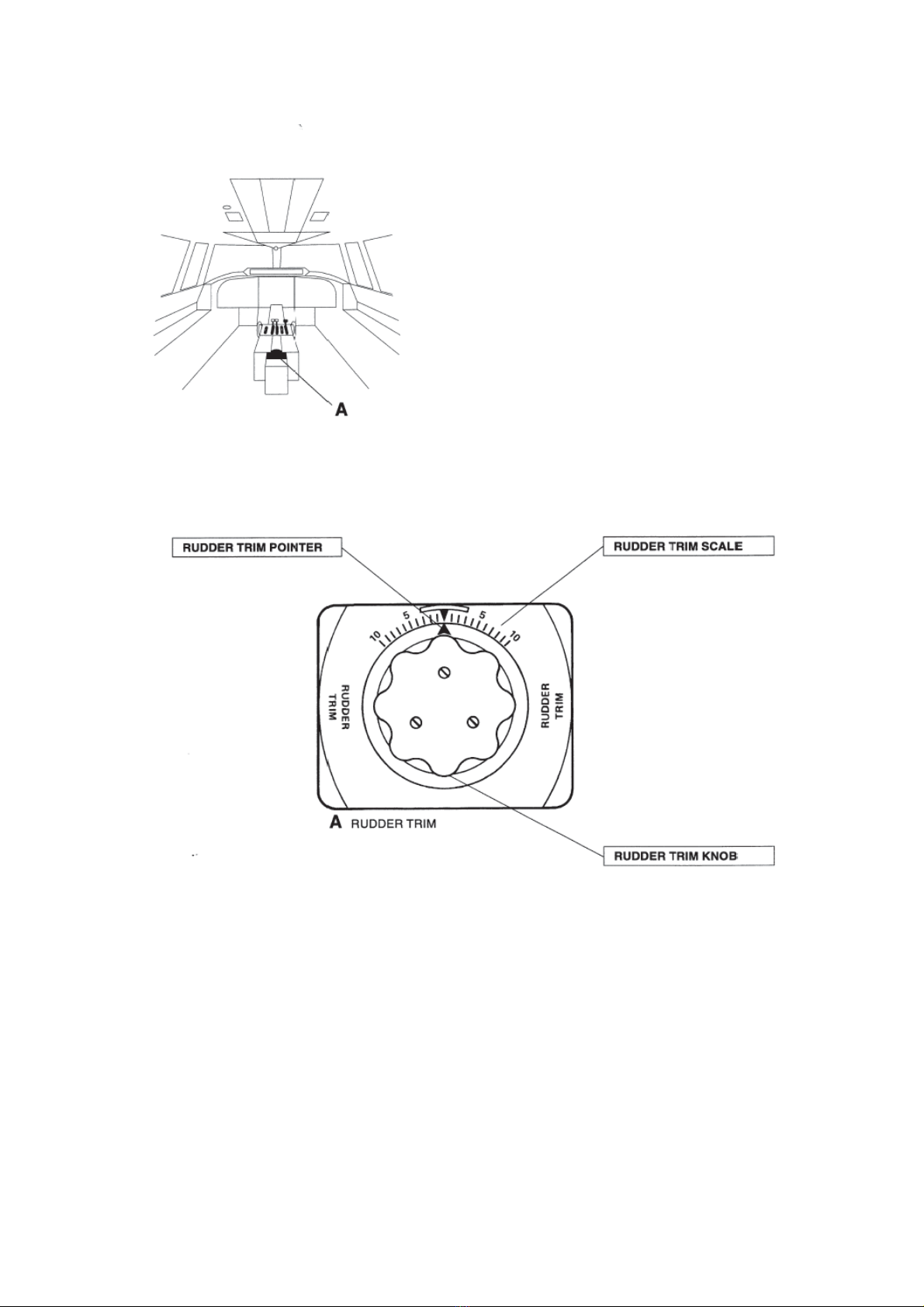

Rudder

The rudder is operated manually from the captain’s and first officer’s pedals. A trim tab and a

balance tab, one above the other, are attached to the trailing edge of the rudder. The trim tab

can be operated mechanically from the trim control panel on the pedestal.

Elevator

The elevators are operated manually from the captain’s and first officer’s control column.

Pitch trim is obtained by an elevator trim tab at the RH elevator. The trim tab is operated by

trim wheels on both sides of the pedestal. A position indicator near each control wheel shows

the trim setting.

Augment pitch attitude stability

There are two pitch stability systems:

• Elevator Feel Control System.

• Longitudinal Stability Augmentation System.

Type I

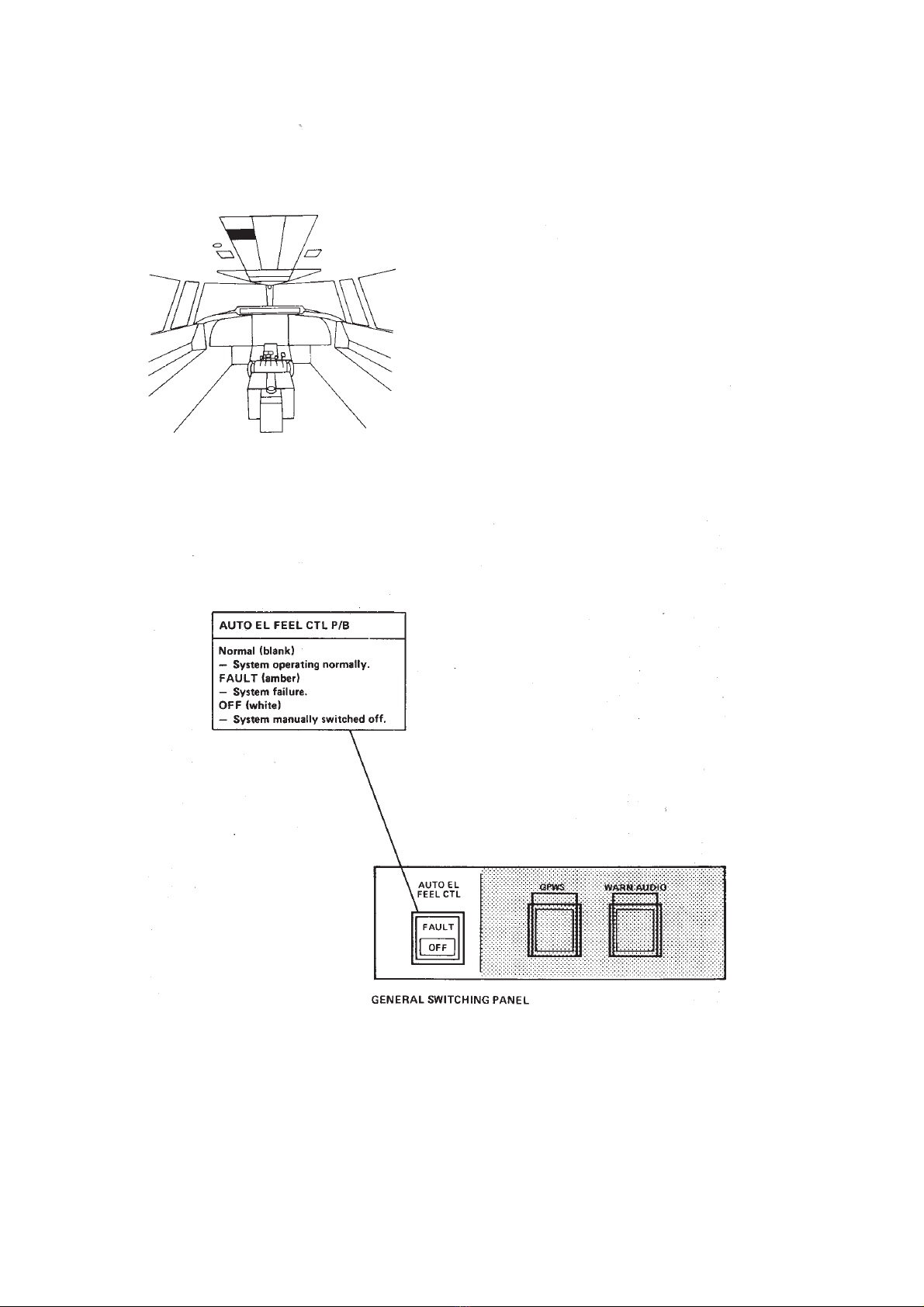

An automatic Elevator Feel Control System (EFCS) is provided to balance the out-of-trim

forces caused by transients due to power and flap selections that would otherwise be felt at

the control column. The system operation is automatic and is active only during flight. Flap

and power lever positions are used as input variables. If the system fails, an alert will be

presented. The fault annunciation due to the power levers and flaps is inhibited during flight,

the alert will be presented on the ground approximately 15 seconds after landing. The

system can be switched OFF with the AUTO EL FEEL CTL pushbutton at the general

Fokker 50 - Landing Gear & Flaps

Page 1

switching panel. Once switched OFF, the system cannot be reinstated from the flight deck. If

the system is switched OFF, or has failed, the elevator operation is not affected. The elevator

control forces will now be defined by the position in which the feel control unit ceased

operation. On the ground an automatic self-test of the system is initiated when the flight

control lock is engaged, and the system is placed into a parked condition.

Type II

The Longitudinal Stability Augmentation System (LSAS) is provided to correct for the

dynamic out of trim farces caused by changes in engine power, flap position and aircraft

speed, and to augment the longitudinal stability at forward CG in flight. System operation is

automatic and active during flight only. Inputs are provided by:

• Both Electronic Engine Control (ENG EC) units.

• Attitude and Heading Reference System no 1 (AHRS 1).

• Flap drive unit.

• Air Data Computer (ADC).

NOTE: For those aircraft equipped with two ADC’s, ADC 1 is used as input for this

system.

The system uses the inputs to vary the bungee spring tension. Controls and indicators are

installed at the general switching panel, located at the overhead panel. A DEGRADED light

indicates a system input failure (flap position, airspeed or pitch). A FAULT light in the STAB

AUG pushbutton indicates a complete system failure. In this case LSAS will freeze in its last

position. The system can be switched OFF by depressing the STAB AUG pushbutton. With

the DEGRADED or FAULT lights illuminated, or the system switched OFF, the elevator

control forces during manual flight may be slightly higher or lower than normal, depending on

flight phase. Some system input failures (power lever and flap positions) detected in flight will

result in a system failure alert after landing (15 seconds after touch down). On the ground an

automatic self-test of the system is initiated when the flight control lock is engaged, and the

system is placed into a parked condition.

Pre-stall warning

If the aircraft attitude approaches a stall condition, a stick shaker at the LH control column is

activated. Shaker activation will disengage autopilot and yaw damper. The angle-of-attack

vane is located on the RH side of the fuselage nose. The pre-stall warning, which operates

independent of the integrated alerting system, is armed in flight only.

Flight control lock

A mechanically operated system of locks is provided for the ailerons, the rudder, and the

elevators. This system locks the ailerons and rudder in neutral position and the elevators in

down position. Each lock is spring loaded to the unlocked position. The EFCS or LSAS

control unit is commanded to a parking position. When the flight controls are locked, then the

power levers are prevented from being set to take-off power simultaneously. The flight

control lock lever is located at the rear LH side of the pedestal.

Fokker 50 - Landing Gear & Flaps

Page 2

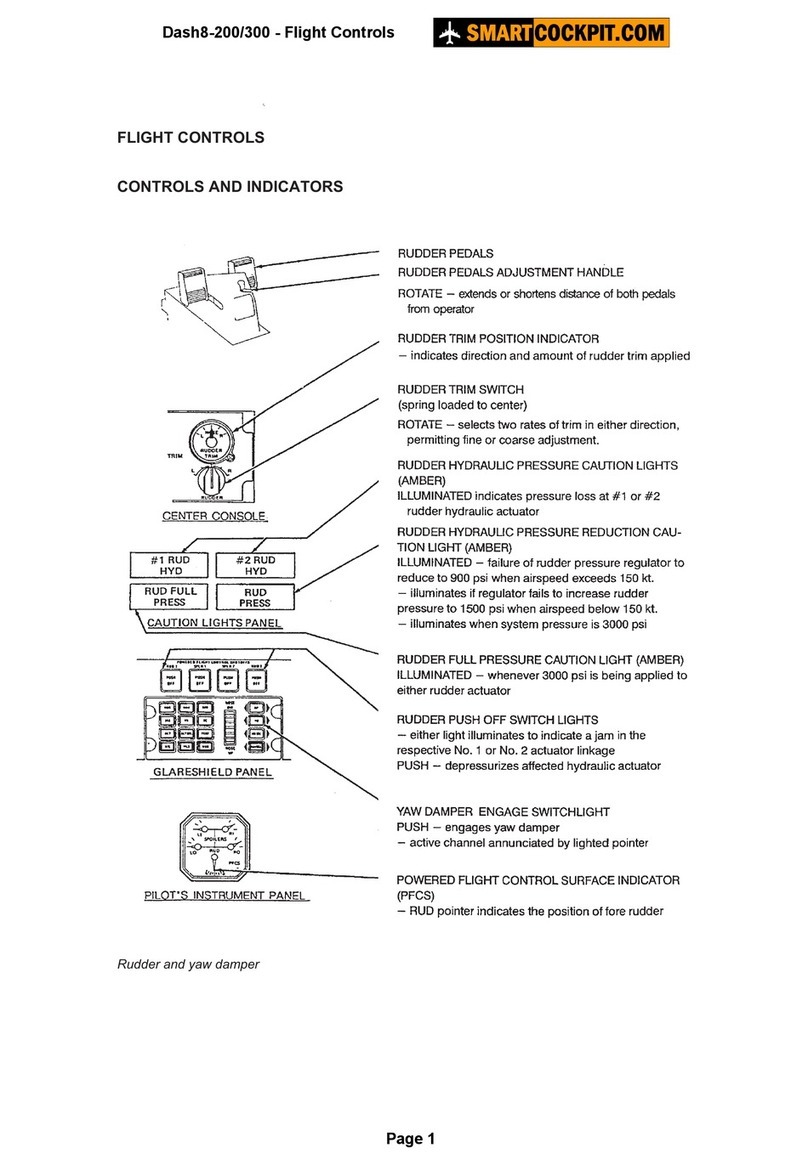

Controls and indicators

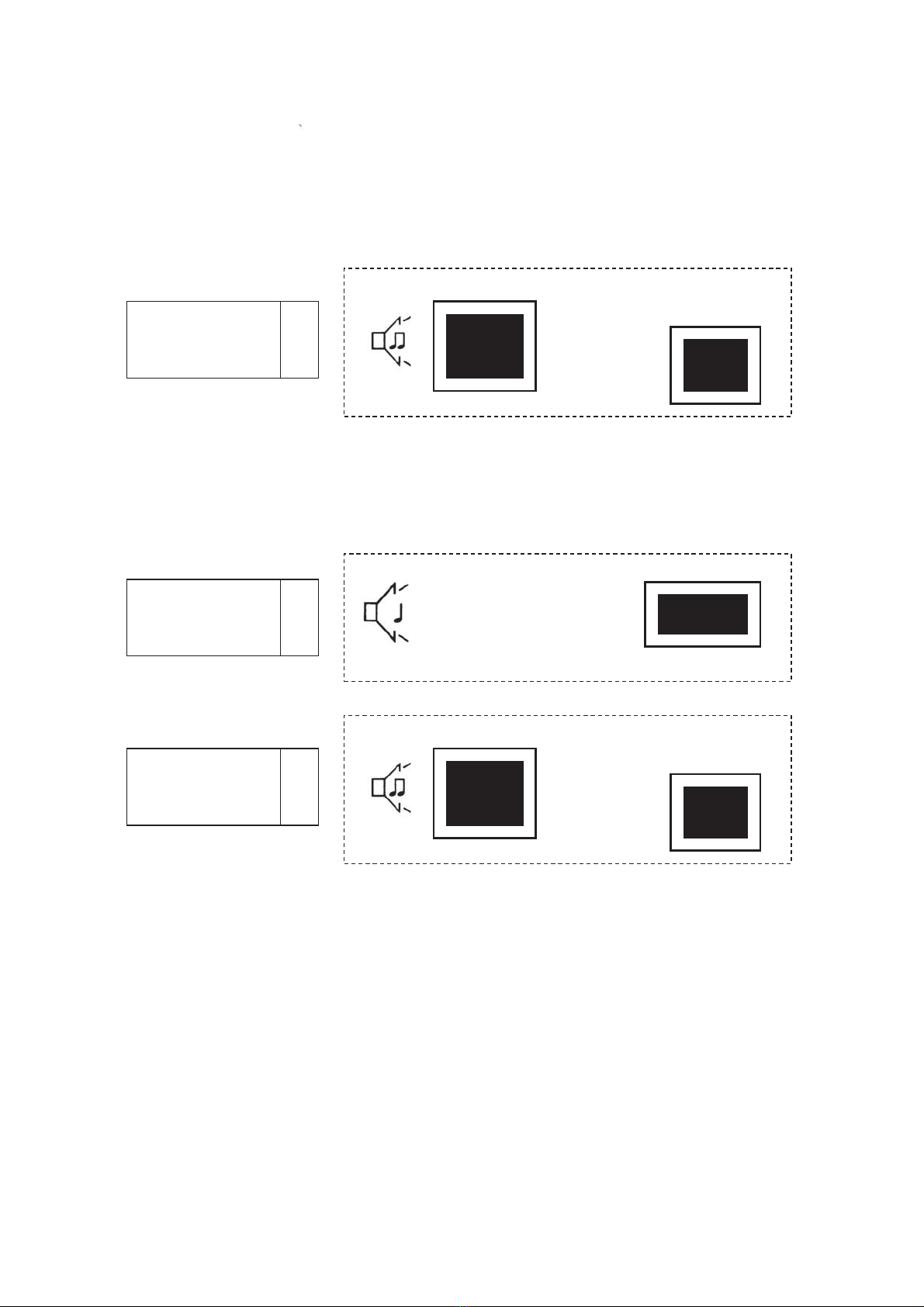

Controls and indicators - Type I

Fokker 50 - Landing Gear & Flaps

Page 3

Controls and indicators - Type II

Fokker 50 - Landing Gear & Flaps

Page 4

Controls and indicators - Type I

Fokker 50 - Landing Gear & Flaps

Page 5

Controls and indicators - Type II

Fokker 50 - Landing Gear & Flaps

Page 6

Fokker 50 - Landing Gear & Flaps

Page 7

Fokker 50 - Landing Gear & Flaps

Page 8

Fokker 50 - Landing Gear & Flaps

Page 9

Alerts

Alerts - Type I

Alerts - Type II

AUTOMATIC ELEVATOR

FEEL CONTROL

SYSTEM FAILURE

2

AURAL MWL/MCL CAP LOCALCONDITION(S) / LEVEL

CAUTION

FAULT

AUTO EL

FEEL CTL

LONGITUDINAL

STABILITY

AUGMENTATION

SYSTEM FAILURE

2

CAUTION

FAULT

STAB AUG

LONGITUDINAL

STABILITY

AUGMENTATION

SYSTEM FAILURE

1

AURAL MWL/MCL CAP LOCAL

CONDITION(S) / LEVEL

DEGRADED

Fokker 50 - Landing Gear & Flaps

Page 10

FLAPS

Operation

The flaps can be controlled by a seven position flap selector (UP, 5, 10, 15, 20, 25, 35). The

mechanically operated flap selector valve directs hydraulic pressure to the flap drive unit in

accordance with flap selector position. The position of the flaps is indicated by a flap position

indicator located at the center main instrument panel. Position markings are located at the

inboard side of the engine nacelles. A disagreement light illuminates when flap position is not

in accordance with flap selector position. The alert is inhibited during the period when the

flaps are in transit.

Alternate operation

Adjacent to the flap selector is an alternate flap control switch that operates the flap drive unit

electrically. The travel range is the same as in the hydraulic mode; however, the flaps extend

at a slower rate. After alternate operation, no hydraulic operation can be made before the

system is reset. Reset is obtained on the ground by moving the flap selector to an other

position.

Asymmetry protection

LH and RH flap positions are continuously compared and when an angular difference is

detected an alert is presented. When asymmetry is detected during hydraulic operation,

further flap movement is stopped.

Fokker 50 - Landing Gear & Flaps

Page 11

Functional diagram

Fokker 50 - Landing Gear & Flaps

Page 12

Controls and indicators

Fokker 50 - Landing Gear & Flaps

Page 13

Alerts

FLAP DISAGREMENT

2

AURAL MWL/MCL CAP LOCALCONDITION(S) / LEVEL

CAUTION

FLAP

FLAP ASYMMETRY

2

CAUTION

FLAP ASYM

Fokker 50 - Landing Gear & Flaps

Page 14

TAKE-OFF CONFIGURATION WARNING

Description

With the aircraft on the ground and either power lever in TO position, the TO CONF light at

the CAP illuminates when one of the following conditions is met:

• Elevator trim not in TO position.

• Rudder trim not in TO position.

• Flaps not in TO position.

• Parking brake not released.

• Neither TO nor FLX nor GA selected at the engine rating panel. See OM Part B section

POWER PLANT.

• Propeller autofeather system not armed. See OM Part B section POWER PLANT.

NOTE: The alerts cannot be cancelled by depressing MWL.

With the aircraft on the ground and either power lever not in TO position, the take-off

configuration can be tested by depressing the TO CONFIG button at the test panel for at

least 2 seconds. The TO CONF light at the CAP remains out when the take-off configuration

is complete.

NOTE: The test can be performed with the parking brake on.

Fokker 50 - Landing Gear & Flaps

Page 15

Controls and indicators

Fokker 50 - Landing Gear & Flaps

Page 16

Alerts

AIRCRAFT NOT IN

TAKE-OFF

CONFIGURATION

3

AURAL MWL/MCL CAP LOCALCONDITION(S) / LEVEL

WARNING

TO CONF

Fokker 50 - Landing Gear & Flaps

Page 17

SYSTEM OPERATION

Flight control lock

The flight-control lock should be engaged during taxiing and parking. After setting the flight-

control lock, move the control column slightly forward and bring the ailerons and rudder to

the neutral position; check the flight controls are locked. When releasing the lock, be aware

of flight control movement due to wind. The PF should keep his feet on the rudder bar while

the PNF should hold the control wheel.

CAUTION: Applicable for aircraft equipped with LSAS. If the flight control lock is engaged

while the flaps are traveling the system will see this as a wrong input during

the test phase of the LSAS, this might cause a non reset-able FAULT of the

LSAS.

Flaps

Normal operation

The flaps are hydraulically operated and the flap position is controlled by a flap selector.

Operating time from up (0) to 35 or reverse is approximately 15 seconds.

Alternate operation

The flaps are electrically operated and controlled by the alternate flap control switch.

Alternate flap operation inhibits normal flap selection. To avoid nuisance alerts select the

normal flap selector to the indicated flap position. Operating time from up (0) to 35 or reverse

is approximately 180 seconds.

Fokker 50 - Landing Gear & Flaps

Page 18

Table of contents

Other SmartCockpit Aircraft manuals