SmartCockpit Dash8-200 User manual

FLIGHT CONTROLS

CONTROLS AND INDICATORS

Rudder and yaw damper

Dash8-200/300 - Flight Controls

Page 1

Elevators

Dash8-200/300 - Flight Controls

Page 2

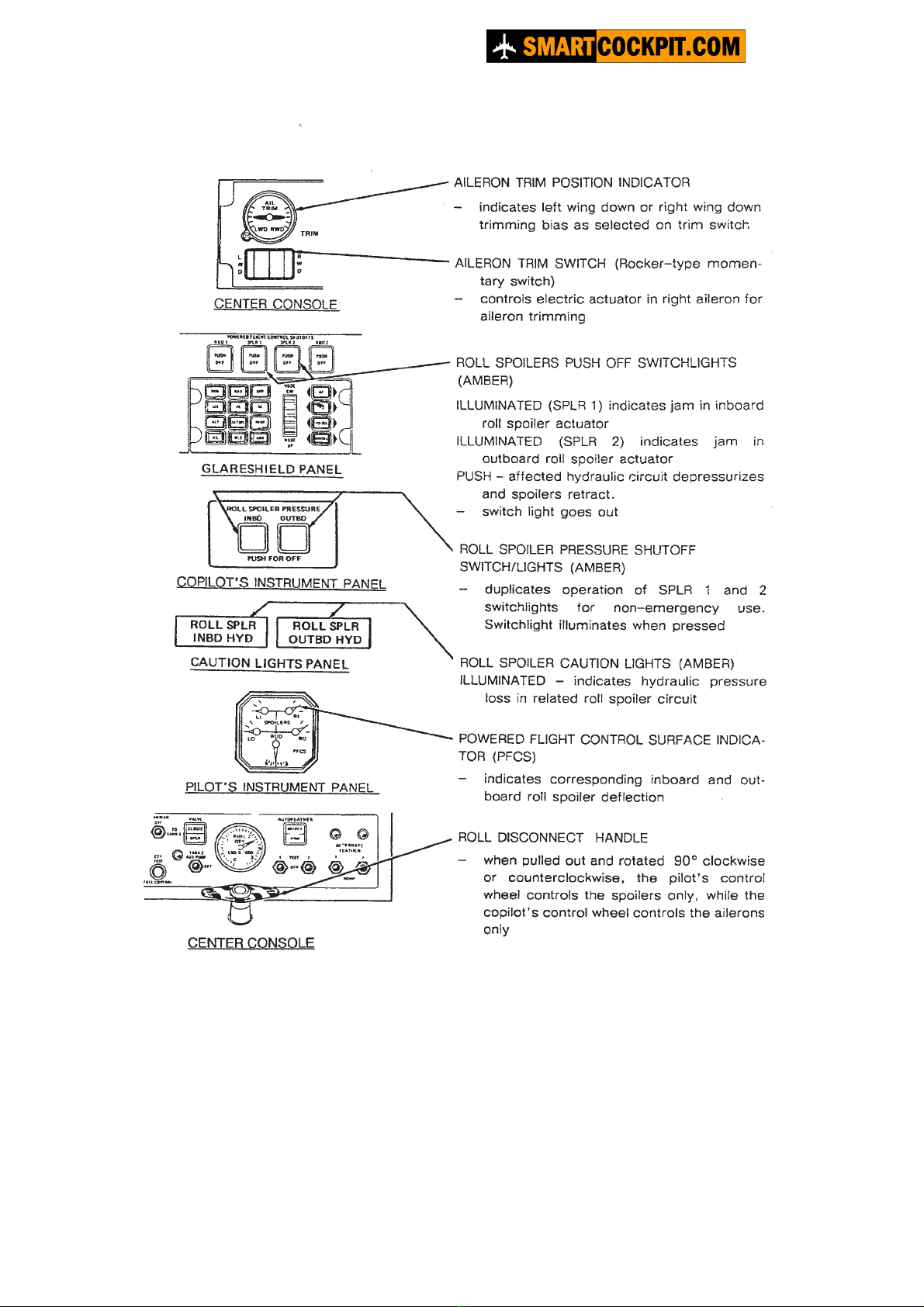

Spoiler and aileron

Dash8-200/300 - Flight Controls

Page 3

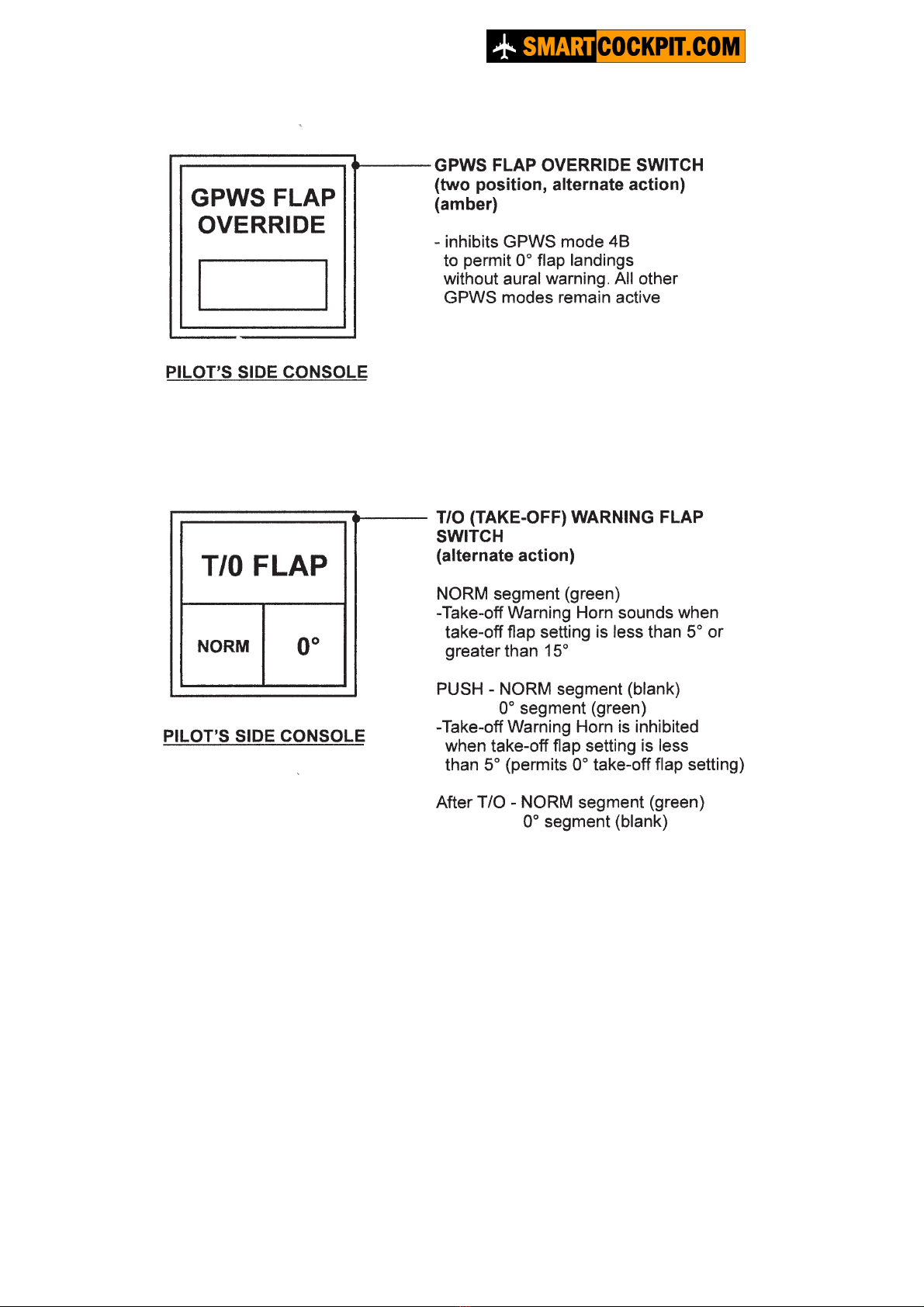

Flaps

Dash8-200/300 - Flight Controls

Page 4

Flaps

Dash8-200/300 - Flight Controls

Page 5

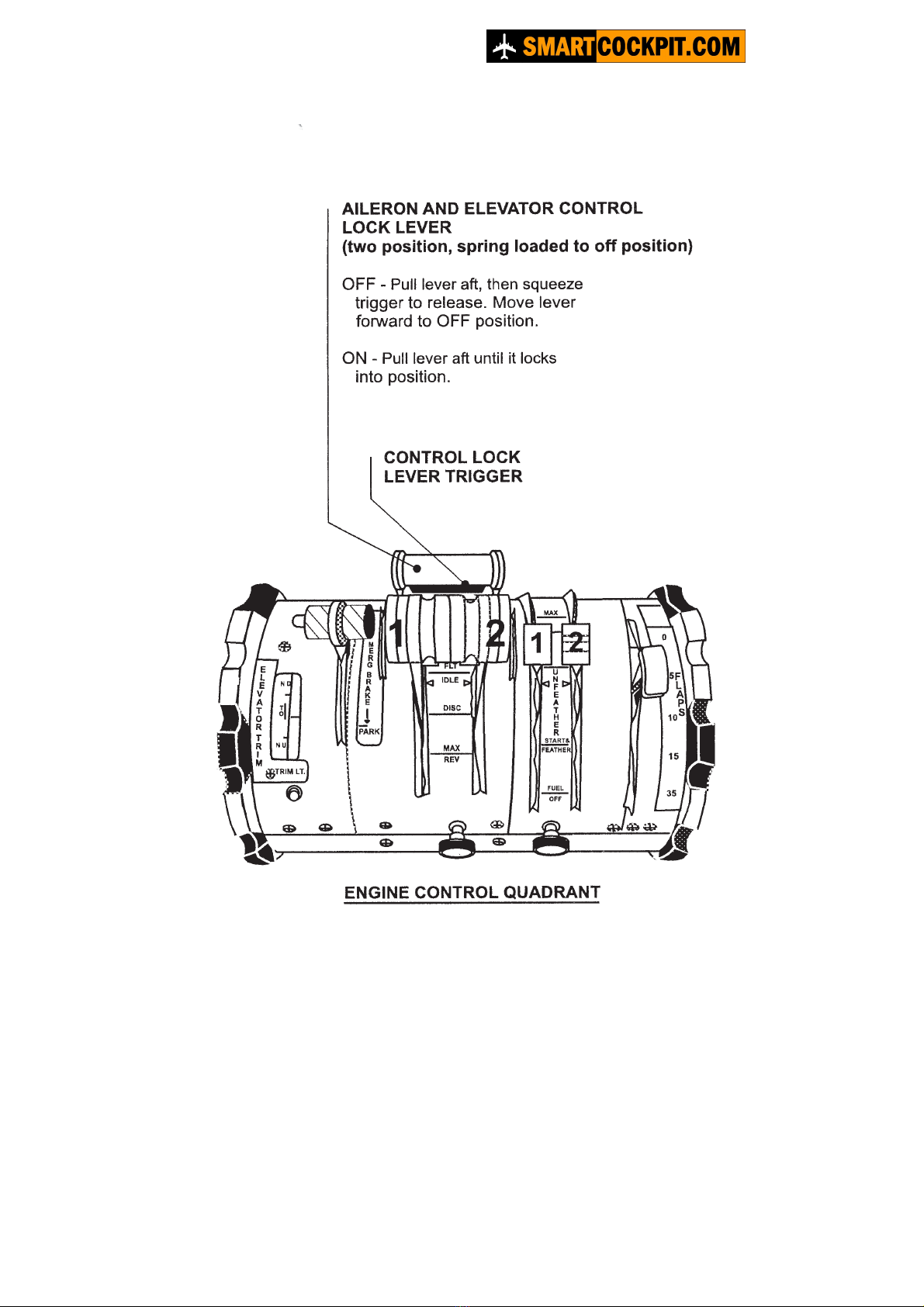

Miscellaneous controls

Dash8-200/300 - Flight Controls

Page 6

Powered flight control surface controls and indications

Dash8-200/300 - Flight Controls

Page 7

Powered flight control switches and indications

Dash8-200/300 - Flight Controls

Page 8

1SYSTEMS DESCRIPTION

General

The primary flight controls consist of ailerons and spoilers for roll control, elevator for pitch

control and a two sectioned (fore and trailing) rudder for yaw control. Roll spoilers and fore

rudder are hydraulically powered.

Secondary flight controls, consists of wing flaps and trimming systems for the primary flight

controls, and a flight control gust lock mechanism. All flight controls may be operated from

either the left or right pilots’ position.

Indications for flight control positions or malfunctions are provided by trim position indicators,

the powered flight control surface indicator and a series of caution lights.

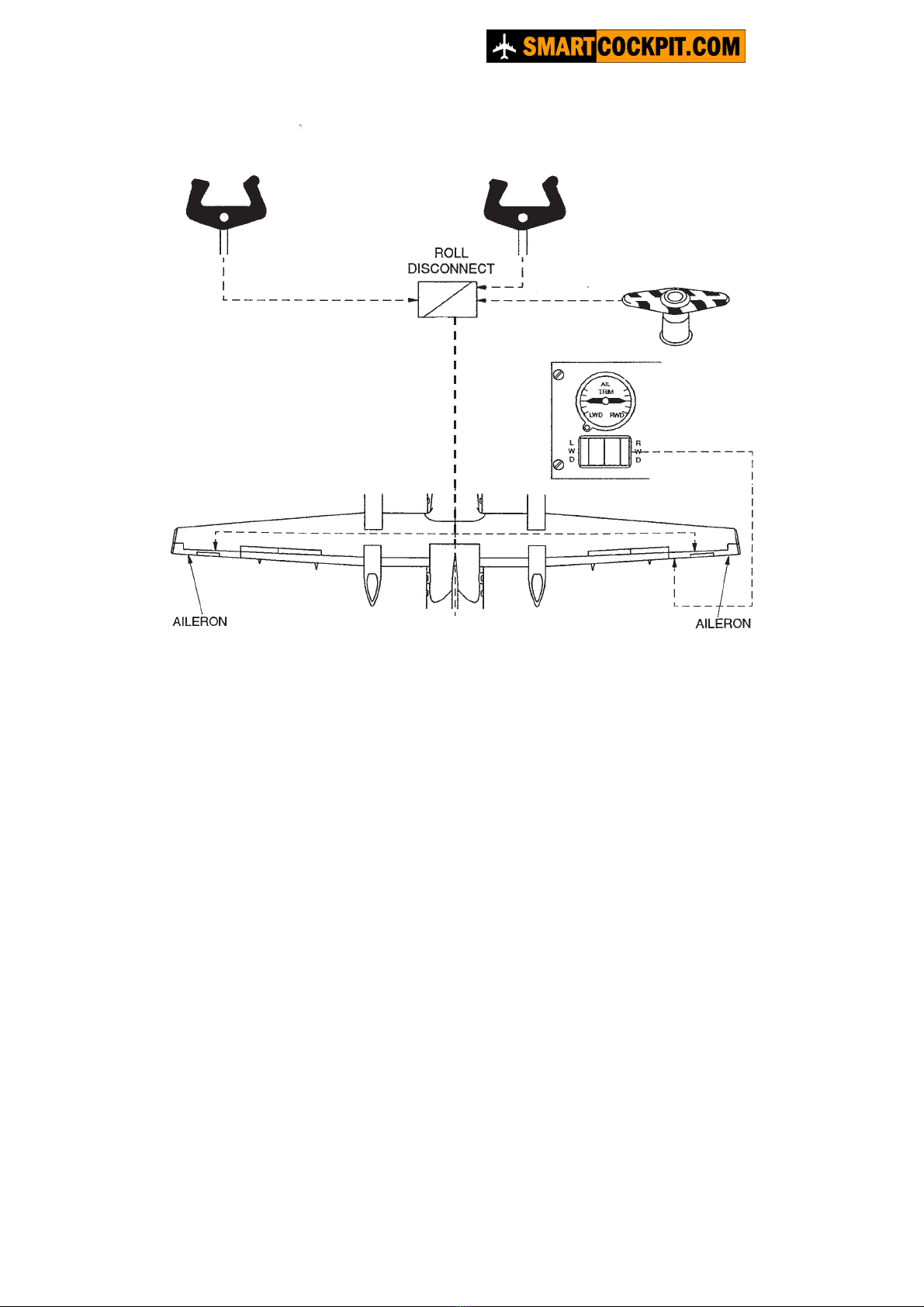

Flight control surfaces location

Dash8-200/300 - Flight Controls

Page 9

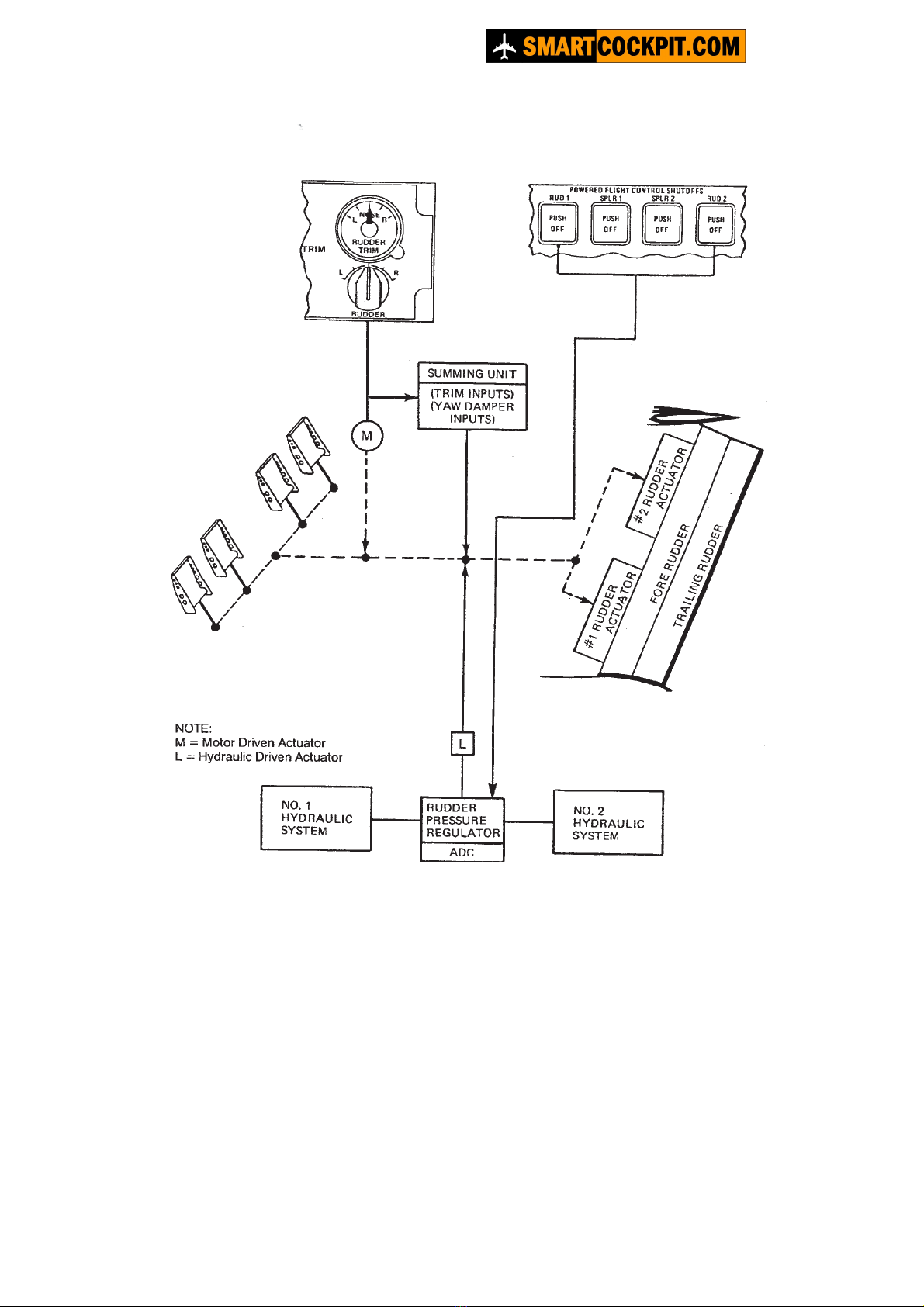

Yaw control

Directional control about the yaw axis is provided by the rudder control system. The rudder is

hydraulically powered and controlled through displacement of either pilot’s rudder pedals. A

yaw damper operates through the rudder control system to improve directional stability.

Rudder control system

The rudder has two sections (fore and trailing) driven by dual hydraulic actuators positioned

by either pilot’s rudder pedals.

The position of the rudder is shown on the PFCS indicator. Full-scale rudder deflection is

indicated by movement of the pointer to the index marks (16qleft marking, 18qright marking).

Rudder trim is provided by a two speed electric actuator, which has the capability to displace

the fore rudder 10º left or right of centre. Control of this actuator is by a spring-loaded rotary

switch on the TRIM panel to the rear of the aft electronics panel.

The fore rudder is hinged to the vertical stabilizer and is moved by both actuators. The

trailing rudder is hinged to the fore rudder and is geometrically geared to the vertical

stabilizer by push rods such that trailing rudder deflection is twice that of the fore rudder.

A pressure regulator controls hydraulic pressure to each rudder actuator. The regulator limits

actuator pressure to 1500 Psi at airspeeds below 150 KIAS and 900 Psi above 150 KIAS, in

response to speed signals from the air data computers (ADC’s), to reduce rudder sensitivity

at high speeds. Pressure switches, armed by ADC speed signals, are positioned in each

actuator's supply lines.

Maximum fore rudder travel is allowed only when the flap selector lever is out of the 0º

position to provide necessary authority at lower airspeeds. A mechanical rudder travel

restrictor limits rudder deflection to 12º with the flap selector lever at 0.

Yaw damper

A yaw damper system operates independently or in conjunction with the automatic flight

control system (AFCS) to provide compensating rudder inputs whenever the aircraft deviates

from coordinated flight. In level flight it acts to improve directional stability by damping

oscillation in yaw caused by turbulence. In turns initiated by the crew or the AFCS it provides

the necessary rudder deflection to maintain turn coordination.

Accelerometers within the flight guidance computer provide yaw data, which is combined

with other flight condition information. To provide output command signals to an electric yaw

damper actuator that can reposition the rudder up to 5º to left or right of an existing rudder

setting to maintain coordinated flight.

The yaw damper is engaged by means of an YD press-on/press-off switch light on the flight

guidance controller, located on the glareshield panel. Engaging the autopilot will

automatically switch on the yaw damper. The autopilot can not be engaged with the yaw

damper off.

Dash8-200/300 - Flight Controls

Page 10

Rudder control diagram

Dash8-200/300 - Flight Controls

Page 11

Rudder control diagram

Dash8-200/300 - Flight Controls

Page 12

Pitch control

The pitch control surfaces consist of two, spring tab assisted elevators.

Elevators

Pitch movement is controlled by two elevator surfaces, each having an independent control

system. The left elevator is controlled by fore and aft movement of the left pilot's control

column and the right elevator by fore and aft movement of the right pilot’s control column.

The control columns are mounted at each end of a torque tube below the flight compartment

floor, which normally joins the columns so that they move together. The torque tube

incorporates a latch mechanism, which permits the columns to be separated following a jam

in either elevator system. A pitch disconnect handle located on the left side of the centre

console, marked PITCH DISC, releases the latch when pulled out following an elevator jam.

With the columns separated, the jammed side is isolated and pitch can be controlled with the

remaining elevator system.

Each elevator has a torsion spring mechanism, which drives the elevator surface in

conjunction with a spring tab on its inboard trailing edge. With elevator control input, this

provides a servo assist, which reduces elevator control forces.

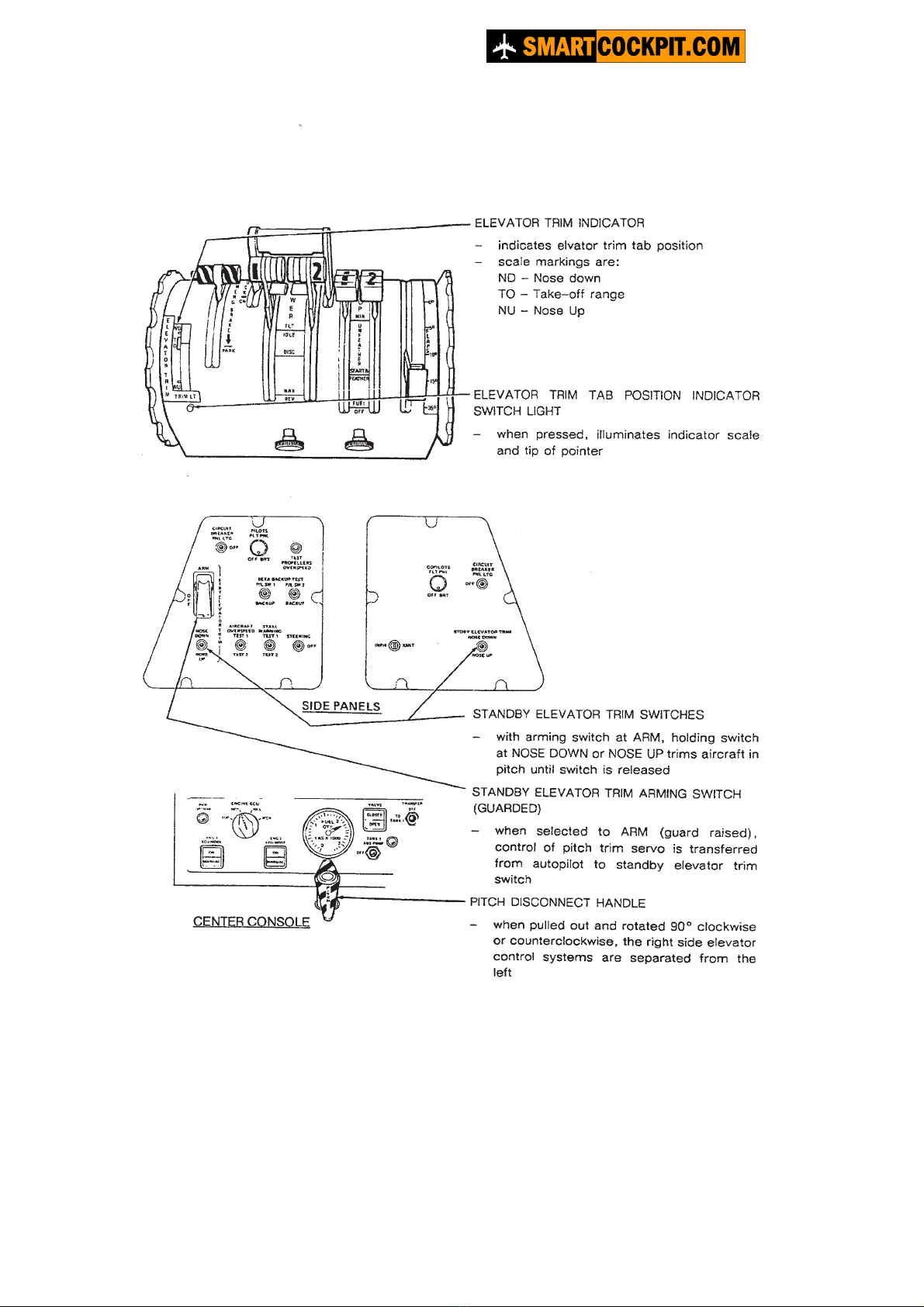

Elevator trim is provided by tabs on each surface, outboard of the spring tabs. Two trim

wheels, mounted on a common shaft, are provided on each side of the power lever quadrant

on the centre console.

A trim position indicator is geared to the trim wheel shaft, consisting of a window and pointer

in the top of the power lever quadrant beside the pilot's trim wheel. A potentiometer within the

indicator sends trim position signals to the flight data recorder.

The standby trim system provides a means of trimming the aircraft following failure of the

manual trim system. A guarded standby elevator trim switch is located on the left pilot’s side

console panel. When selected from OFF to ARM it switches control of the trim servo from the

autopilot to an adjacent NOSE UP/NOSE DOWN switch. A duplicate NOSE UP/NOSE

DOWN switch is provided on the right pilot’s side console panel. Selection of either switch to

its spring-loaded NOSE UP or NOSE DOWN position activates the servo to trim the aircraft

in pitch. Arming the standby trim system immobilizes the normal elevator trim system.

Dash8-200/300 - Flight Controls

Page 13

Elevator control diagram

Dash8-200/300 - Flight Controls

Page 14

Roll control

Roll control is by conventional cable-operated ailerons, augmented by cable-operated,

hydraulically activated, roll spoilers. The rotational movement of the pilot's control wheel

activates the roll spoilers while the co-pilot’s control wheel activates the ailerons. An

interconnect linkage joins the pilot's and co-pilot’s control wheels so that both systems are

operated from either wheel. A clutch within the linkage can be disengaged manually, by

means of a roll disconnect handle on the flight compartment centre console, to separate the

left and right roll control circuits in the event of a jam in either circuit. With the control circuits

separated, control can be maintained with the un-jammed control wheel.

Ailerons

An aileron is located on each wing outboard of the flaps. Rotation of either control wheel

actuates the ailerons differentially by means of a cable control loop, with inter-connection to

applicable roll spoilers.

Geared tabs on the trailing edge of each aileron assist aileron deflection. The tabs are

geared to a static position, which is aerodynamically neutral relative to the aileron. When the

aileron is deflected, the geared tab moves in the opposite direction creating a localized lifting

force about the tab in the direction of aileron deflection, thus assisting aileron movement.

The right aileron trim tab, using an electric actuator built into the aileron, provides aileron

trim. A L/R AILERON rocker switch, located on the TRIM panel on the centre console

operates the actuator when depressed to the left or right. The actuator trims aileron control

pressure by biasing the static neutral position of the trim tab. An indicator adjacent to the L/R

AILERON rocker switch shows the degree of trim actuator displacement from neutral.

Dash8-200/300 - Flight Controls

Page 15

Aileron control diagram

Dash8-200/300 - Flight Controls

Page 16

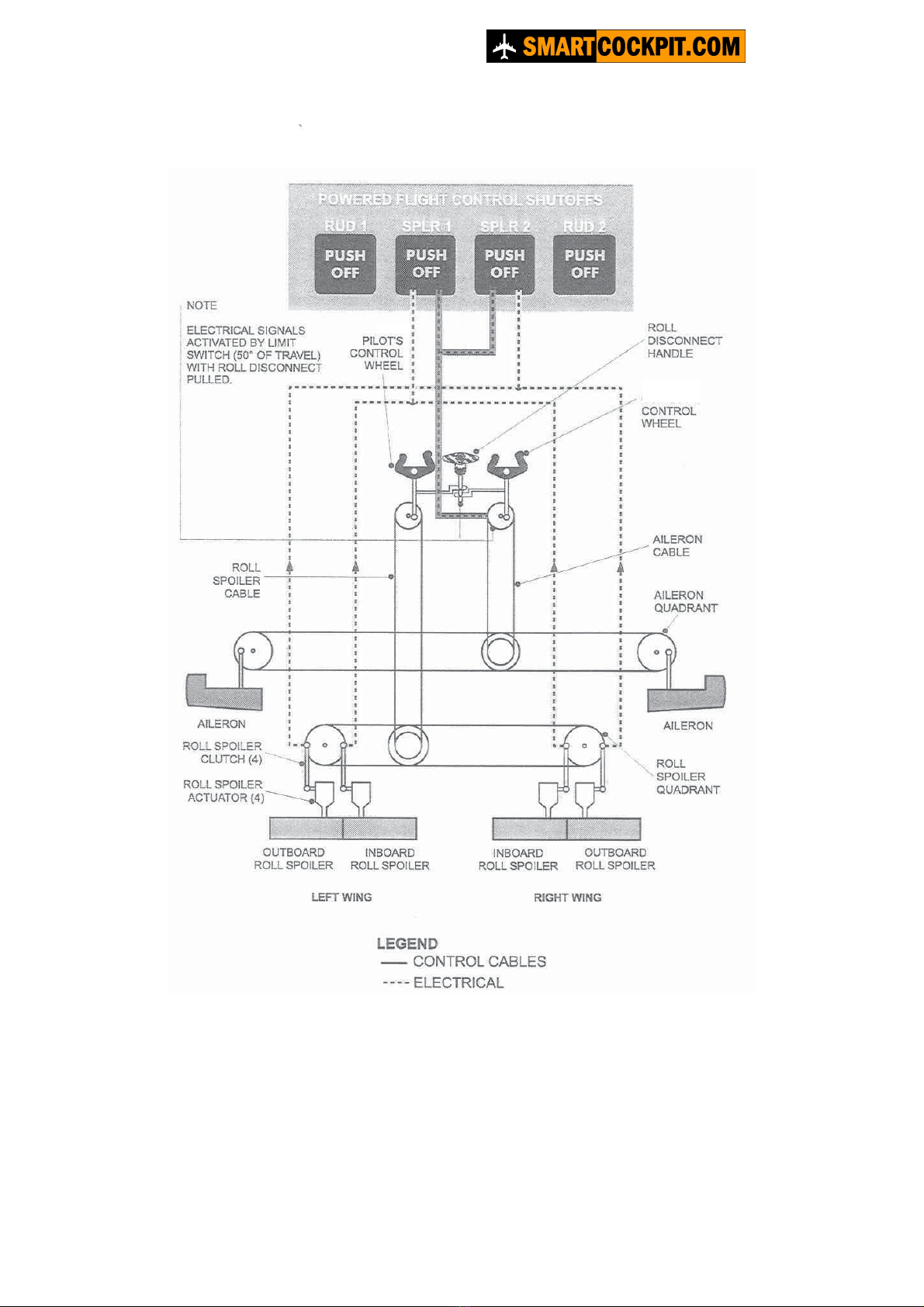

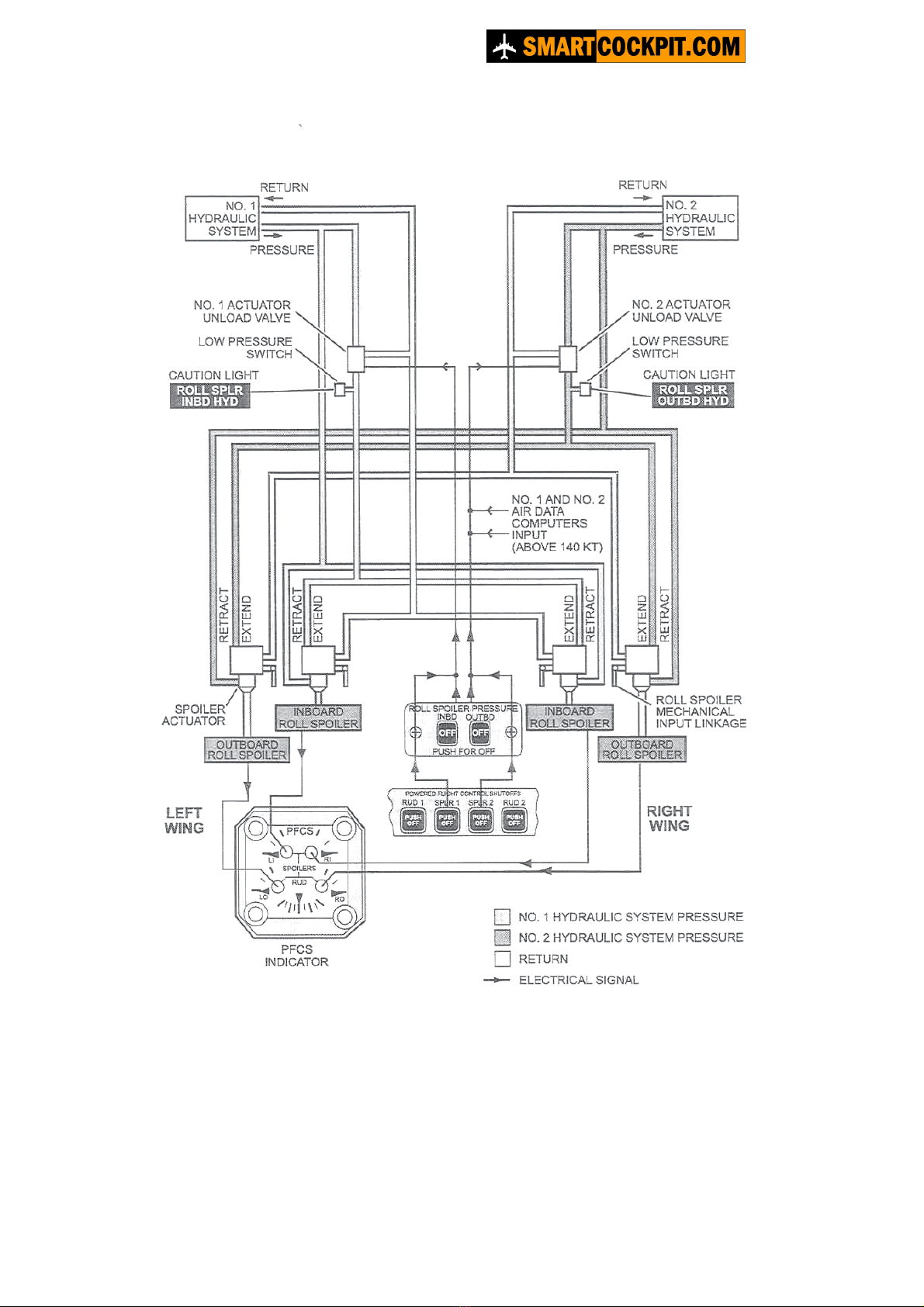

Roll Spoilers

The roll spoilers consist of four spoiler panels, two to a wing, positioned inboard of the

ailerons on the upper wing surfaces and driven by individual hydraulic actuators. The spoilers

respond differentially to control wheel movement by extending from the left or right wing in

proportion to associated upward displaced aileron. At airspeeds above 140 KIAS, the

outboard roll spoilers are disabled to reduce control sensitivity. Each actuator linkage is

connected so that in the event of a jam, overpowering force applied to the control wheel

disengages the linkage preventing the jam from immobilising the roll spoiler cable circuit.

A limit switch built into each mechanism illuminates one of the POWERED FLIGHT

CONTROL SHUTOFFS - SPLR switch lights (either SPLR 1 in the event of an inboard

actuator linkage jam or SPLR 2 for an outboard actuator linkage jam).

When pressed, each switch light disables the affected roll spoilers.

A roll spoiler cable circuit jam, necessitating operation of the ROLL DISC handle to control

the aircraft by ailerons alone, may result in partially extended roll spoilers if the jam occurred

during a roll input. The resulting counteracting aileron input necessary to control the aircraft

will illuminate both SPLR switch lights (via an under floor limit switch) if aileron travel

exceeds 50º of control wheel displacement from neutral. The switch lights must then be

immediately pressed to retract the spoilers and restore symmetrical aileron control.

Two caution lights, marked ROLL SPLR INBD HYD and ROLL SPLR OUTBD HYD are

provided to warn that extension pressure to the affected actuators has been removed

following operation of the switch lights mentioned above or hydraulic system failure. The

OUTBD HYD light, however, does not illuminate when its system is depressurised by ADC

signals.

Spoiler motion and position is at all times directly proportional to control wheel movement.

The PFCS indicator in the flight compartment displays roll spoiler position in response to

position sensors at each roll spoiler panel.

Alternate roll spoiler pressure switches

Two roll spoiler switch lights labelled INBD and OUTBD provide an alternate method of de-

activating a roll spoiler during flight training. These switch lights perform the same function as

the SPLR 1 and SPLR 2 switch lights on the glareshield panel. However when INBD and/or

OUTBD switch light is/are pushed ROLL SPLR OUTBD HYD (all airspeeds) caution light(s)

SPLR 1 and SPLR 2 switch light remain active in the event a genuine roll control malfunction

occurs.

Dash8-200/300 - Flight Controls

Page 17

Roll spoiler control diagram

Dash8-200/300 - Flight Controls

Page 18

LEFT

RIGHT

PILOTS

’

S

Dash8-200/300 - Flight Controls

Page 19

Roll spoilers diagram

Dash8-200/300 - Flight Controls

Page 20

Other manuals for Dash8-200

1

This manual suits for next models

1

Other SmartCockpit Aircraft manuals

Popular Aircraft manuals by other brands

Gin Gliders

Gin Gliders Genie Lite 2 Series Pilot's manual

FLIGHT DESIGN

FLIGHT DESIGN CTSW-2006 quick start guide

LittleCloud

LittleCloud Goose manual

Wipaire

Wipaire Wipline 3730 Service manual and instructions

Nirvana Paramotors

Nirvana Paramotors KATANA user guide

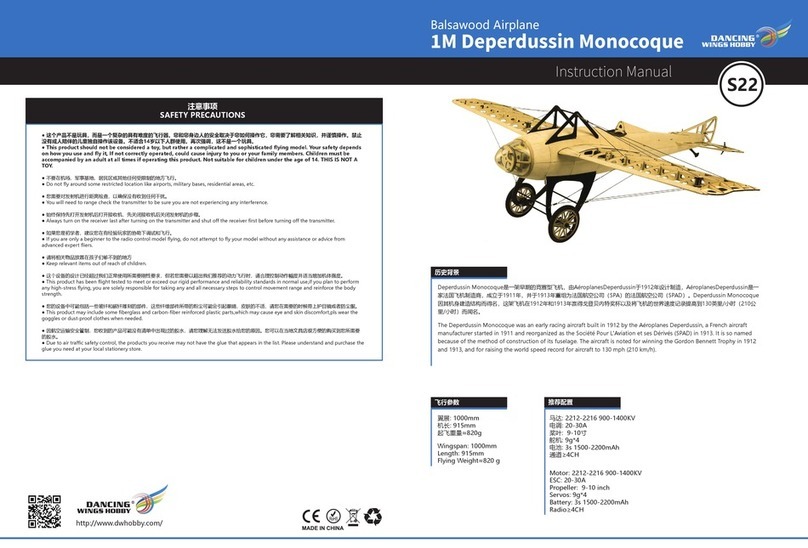

Dancing Wings Hobby

Dancing Wings Hobby S22 instruction manual