PAB-OM-B006-B

OperationManual-ProcessPumpPA3000Series-

Readthismanualcarefullyandthoroughlybeforeusing.

For construction and specification etc. of this product, refer todrawingand

catalogue.Thecontentofthisoperationmanualissubjecttochangewithout

priornotification.

1.Precautions

Warning

●Environment

Whenusinghazardousfluid,takemeasurestokeeppeopleawayfromthepump. Theoccurrenceofexternal

leakagecouldresultinseriousinjury.

●Externalleakageoftransportedfluid

Fluidmightleakexternallyduetolifeofdiaphragm,andthiscouldresultinhumaninjuryorequipmentdamage.

Takemeasuresagainstleakage.

Caution

●Qualityofsupplyair

Place filter with filtration 5μm.UseairhavingbetterqualitythanNo.Bmentionedincatalogues of Air

cleaningEquipment.

①Ifalargeamountofforeignmattercomesfromairsource(carbonpowder,etc.),takemeasuressuchasusing

speciallubricant,whichgenerateslesscarbonpowderorusingmist-separatortogetherwiththispump. Smooth

operationmightbehinderedbyresistanceincreasedduetoforeignmatterpilledup.

●Qualityoftransportedfluid

●Whenusingthepumptotransportliquidwhichcontainssolidmatter,installstrainermountthefilterwithfiltration

of0.2mmatleastonINport.

Diaphragmshouldbechangedbeforethelifeindicated. Ifdiaphragmshouldbedamaged,transportedfluidwill

leakintothepumpanddamageinnercomponents.

●Calculationmethodofdiaphragmlife.(varyingwithapplications)

2.Installment

Caution

●Mounting

Mountinhorizontalposture.Otherwise,internalpartsmaynotoperatesmoothlyandliquidisnottransported.

Tightenmountingbolts(4pcs.)securelytoavoidbreakageofmountingbracketduetovibration.

●Piping

ForpipingtotheportFLUIDINorFLUIDOUT,tightenitsecurelywithtoolingsuchasspanner. Useflexibletube,

notsteelpipetoavoidloadappliedtotheports.Excessiveloadappliedtotheinnersealcouldcauseliquid

leakage.

Flush the piping thoroughly. When installing piping or a fitting into a port, ensure that sealant material and

cuttingchipsofthreadsdonotenterpiping.Whenusingsealanttape,leavethefirst2threadsexposedatthe

endofpiping/fitting.

●Tighteningtorque

Under-tightening causes liquid or air

leakage while over-tightening causes

breakageofthreadsandotherparts.Refer

tothetablebelowforappropriate

tighteningtorque.

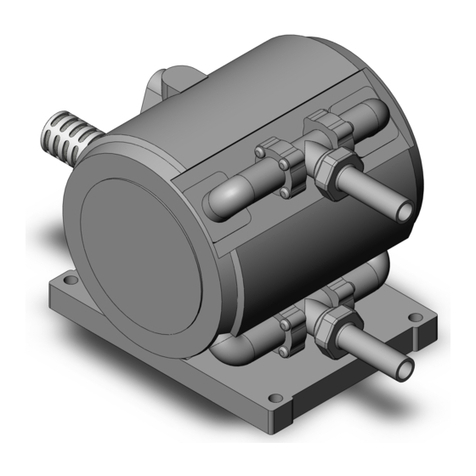

<Descriptionandpurposeofeachport>

Suctionport(FLUIDIN)Suckingtransportedfluid

Dischargeport(FLUIDOUT)Dischargingfluidssuckedintothepump. Connecttothedischargeport.

Pilotairsupplyport(AIRSUP)Supplyingpressuresetbyregulator.Usecleanair.

Pilotairexhaustport(AIREXH)Exhaustingpilotair.

ResetForresumingofnormaloperationaftermomentarystoppage.

3.Howtouse

Caution

[Start&Stop]

SeeCircuitExample1

①ConnectairpipingtotheportAIRSUP,andtransportedfluidpipingtothesuctionportFLUIDINandthe

dischargeportFLUIDOUTrespectively.

②Setpilotairpressureintherangeof0.2MPaand0.7MPa(2to7.1kgf/c ㎡)byusingregulator.Keepballvalve

openonthedischargeside. WhenairissuppliedtotheportAIRSUP,thepumpwilloperateandexhaustnoise

willstarttocomeoutoftheportAIREXH.FluidflowsfromthesuctionportFLUIDINtothedischargeport

FLUIDOUT.

③Tostopthepump.Exhaustpressuresuppliedtothepump.Pumpalsostopswhenballvalveisclosedonthe

dischargeside.Avoidstoppingthepumpforlonghours.,asthismaypreventrestartofthepump.Closing

valveabruptlycangeneratessurge,thatconsiderablyshortensthelifeofthepump.

[DischargeFlowAdjustment]

SeeCircuitExample2

①Toadjustflowfromthedischargeport,useballvalveonthedischargeside.

②Whenthepumpisoperatedwithdischargebelowthespecificationrange,usebypasscircuitfromthedischarge

Side to suction side for keeping the minimum flow inside the processpump.Thepumpmaystopdueto

unstableoperationwithdischargeflowlessthantheminimumdischargeflow.

Circuit(1) Circuit(2)

4.Maintenance

Caution

●Duringoperation

①Checkliquidandairleakage,andoperationconditionsregularlyduringpumpoperation. Ifanyabnormal

conditionsorunclearmattersarefound,stopthepumpimmediatelyandcontactSMCorthesalesofficeyou

purchasedthepump.

②Useprotectivetoolssuchasanti-corrosiveglovestoavoidaburnorotherhumaninjurywhentouchingthe

pumpforcheck.

●Atstop

①ExhausttheairontheSUPsideifthepumpwillbestoppedforacoupleofhours.

②Cleaninsidethepumptoavoidclottingoftransportedliquidandstickingofinternalpartsifitwillnotbeused

foralongperiodoftime.

●Check&Repair

①Checkliquidandairleakage,andoperationconditionsregularlyduringpumpoperation.Ifanyabnormal

conditionsorunclearmattersarefound,stopthepumpimmediatelyandcontactSMCorthesalesofficeyou

purchasedthepump.

②Replacediaphragmbeforetheindicatedlifecycles.

③Ifdiaphragmisbrokenduetothelife,theoperatingfluidwouldflowouttothepilotairside.Leadingtothe

failureofpump.

5.Replacementparts

PTFEdiaphragmset KT-PA3-31

NBRdiaphragmset KT-PA3-32

Switchingvalveassemblyset KT-PA3-36

Actuatorpartsset KT-PA3-37

Pilotvalveset KT-PA5-38

0.032liter× Max.indicatedcycle(ex.)

Lifespan(day) =Flow(ℓ/min)xoperatingtimeperday(hour)x60(min.)

Connectingport Correcttighteningtorque(N・m)

Rc(PT)1/4 Metal 12〜14

Rc(PT)3/8 Metal 12〜14

Model Max.indicatedcycle

PA3※10 100milliontimes

PA3※20 50milliontimes

!

!

!

!

!

URL http://www.smcworld.com

Akihabara UDX 15F,

4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021,JAPAN

Phone: +81 3 5207 8249 Fax: +81 3 5298 5362

Specifications are subject to change without prior notice and any obligation the part of the manufacturer.

2008 SMC Corporation All Rights Reserved