12345678910

Cycle (Hz)

45

40

35

30

25

20

15

10

5

0

Air consumption (l/min [ANR])

1 2 3 4 5 10 20 30 40 50 100

Viscosity (mPa·s)

100

50

0

Ratio of amount of discharge against clean water (%)

50 100 150 200 250

SUP = 0.7 MPa

SUP = 0.5 MPa

SUP = 0.35 MPa

SUP = 0.2 MPa

0

Discharge (ml/min)

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

Discharge pressure (MPa)

0

Discharge (ml/min)

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

Discharge pressure (MPa)

400 800 1200 1600

SUP = 0.7 MPa

SUP = 0.5 MPa

SUP = 0.35 MPa

SUP = 0.2 MPa

0

Discharge (ml/min)

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

Discharge pressure (MPa)

500 1000 1500 2000

SUP = 0.7 MPa

SUP = 0.5 MPa

SUP = 0.35 MPa

SUP = 0.2 MPa

0

Discharge (ml/min)

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

Discharge pressure (MPa)

50 100 150 200

SUP = 0.7 MPa

SUP = 0.5 MPa

SUP = 0.35 MPa

SUP = 0.2 MPa

0

Discharge (ml/min)

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

Discharge pressure (MPa)

200 400 600 800 1000

SUP = 0.7 MPa

SUP = 0.5 MPa

SUP = 0.35 MPa

SUP = 0.2 MPa

0

Discharge (ml/min)

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

Discharge pressure (MPa)

200 400 600 800 1000

SUP = 0.7 MPa

SUP = 0.5 MPa

SUP = 0.35 MPa

SUP = 0.2 MPa

Flow-rate Characteristics

Built-in Solenoid Valve (PB1011A)

Required specification example

Find the pilot air pressure for a

discharge rate of 600 ml/min and a

discharge pressure of 0.15 MPa for

built-in solenoid valve type.

<The transferred fluid is clean water

(viscosity of 1 mPa·s, specific gravity of

1.0) and solenoid valve cycle is 5 Hz.>

∗

When the total pump head is required

instead of the discharge pressure, a

discharge pressure of 0.1 MPa

corresponds to a total pump head of

10 m.

Selection procedure

1. First, mark the intersection point for

a discharge rate of 600 ml/min and

a discharge pressure of 0.15 MPa.

2.Find the pilot air pressure for the

marked point. In this case, the point

is between the discharge curves for

0.35 MPa and 0.5 MPa, and based

on the proportional relationship to

these lines, the pilot air pressure for

Cycle (1 Hz)

Selection from Flow-rate

Characteristic Graph

Air Operated (PB1013A)

Cycle (5 Hz) Cycle (7 Hz)

Cycle (1 Hz) Cycle (5 Hz) Cycle (7 Hz)

Air Consumption: Built-in Solenoid Valve/Air Operated

Viscosity Characteristics: Built-in Solenoid Valve/Air Operated

Required specification example

Find the pilot air pressure and pilot air consumption for a discharge rate of 270 ml/min, discharge

pressure of 0.15 MPa, and a viscosity of 15 mPa·s.

Selection procedure

1. First, find the ratio of the amount of discharge against clean water when viscosity is 15 mPa·s

from the graph to the left. It is determined to be 45%.

2.

Next, the viscosity of 15 mP·s and the discharge rate of 270 m

l

/min in the required specification

example are converted to the amount of discharge for clear water.

Since 45% of the clear water discharge is equivalent to 270 m

l

/min in the required specifications,

270 m

l

/min 0.45 = approximately 600 m

l

/min, indicating that a discharge rate of 600 m

l

/min is

required for clean water.

3. Finally, find the pilot air pressure and pilot air consumption based on the flow-rate characteristic

graphs.

Viscosity

Transfer is possible up to about 100 mPa·s.

Selection from Viscosity Characteristic Graph

1. The air consumption differs greatly depending on properties (viscosity, specific gravity) of the

transferred fluid and operating conditions (pump head, transfer distance), etc.

Find the air consumption for operation with a 5 Hz switching cycle and pilot air pressure of 0.35

MPa from the air consumption graph.

Selection procedure

1. Look up from the 5 Hz switching cycle to find the intersection with SUP = 0.35 MPa.

2. From the point just found, draw a line to the Y-axis to find the air consumption. The result is

approximately 10 l/min (ANR).

Calculation of Air Consumption

Air Consumption

Viscosity Characteristics

(Flow rate correction for viscous fluids)

Caution

Caution

1. Flow-rate characteristics are for clean

water (viscosity of 1 mPa·s, specific

gravity of 1.0), no piping for suction and

discharge.

2. The amount of discharge differs greatly

depending on properties (viscosity,

specific gravity) of the fluid being

transferred and operating conditions

(pump head, transfer distance), etc.

SUP = 0.2 MPa

SUP = 0.5 MPa

SUP = 0.7 MPa

SUP = 0.35 MPa

ν= μ

ρ

Kinematic viscosity ν= Viscosity μ/Density ρ

ν(10–3m2/s) = μ(mPa·s)/ρ(kg/m3)

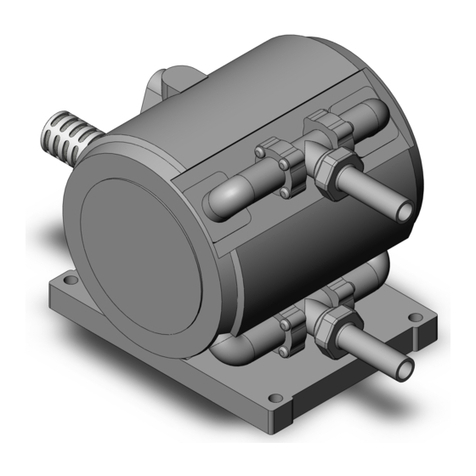

Series PB1000A

Process Pump

Built-in Solenoid Valve/Air Operated

2