SME AC-X1 User manual

AC Asynchronous/Synchronous Motor Controller

U

US

SE

ER

R

M

MA

AN

NU

UA

AL

L

(

(R

Re

ev

v.

.

1

1.

.0

0:

:

M

Ma

ar

rc

ch

h

2

20

01

17

7)

)

M

M

o

o

d

d

e

e

l

l

A

A

C

C-

-X

X1

1

SME S.p.A.

Via della Tecnica, n° 40

36071 Arzignano (VI) - ITALY

Phone +39 (0444) 470511

Fax +39 (0444) 451803

E-mail sales@sme-group.com

www.sme-group.com

ACX1_TAU_SYNC_UserManual_En

Page 2 of 37

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

Table of Con en s

Table of Contents .............................................................................................................................................. 2

1. Introduction .............................................................................................................................................. 4

1.1 About SME Company ....................................................................................................................... 4

1.2 About this manual ............................................................................................................................ 4

1.3 About warning, caution and information notices ............................................................................ 4

1.4 Product warranty information ......................................................................................................... 5

1.5 How to find us .................................................................................................................................. 5

2. AC SmartMotion AC-X1 Overview ............................................................................................................ 6

2.1 Product description .......................................................................................................................... 6

2.1.1 Product Indication Label .............................................................................................................. 7

2.2 General Specifications ...................................................................................................................... 8

2.3 Electrical Specifications .................................................................................................................... 8

2.3.1 Input and Output Ratings ............................................................................................................ 8

2.3.2 Signal Inputs and Outputs........................................................................................................... 9

2.3.3 Interfaces ................................................................................................................................... 12

2.3.4 EMC ............................................................................................................................................ 12

2.3.5 Safety ......................................................................................................................................... 12

2.4 Operating Environment Specifications .......................................................................................... 12

3. Installation and Wiring ............................................................................................................................ 13

3.1 Controller ....................................................................................................................................... 15

3.2 Power Terminals ............................................................................................................................ 19

3.3 Main Contactor .............................................................................................................................. 20

3.4 Fuse ................................................................................................................................................ 21

3.5 Signal .............................................................................................................................................. 22

3.5.1 Digital Inputs .............................................................................................................................. 24

ACX1_TAU_SYNC_UserManual_En

Page 3 of 37

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

3.5.2 Analog Inputs ............................................................................................................................. 25

3.5.3 Driver Outputs (PWM) ............................................................................................................... 26

3.5.4 Digital Outputs (ON/OFF)........................................................................................................... 27

3.5.5 Speed/Position Sensor Inputs .................................................................................................... 28

3.5.6 Thermal Probe ........................................................................................................................... 29

3.5.7 Serial .......................................................................................................................................... 30

3.5.8 CAN Network ............................................................................................................................. 31

3.6 SME external devices description .................................................................................................. 32

3.6.1 Quad Encoder ............................................................................................................................ 32

3.6.2 Sin/Cos Encoder ......................................................................................................................... 32

3.6.3 Displays ...................................................................................................................................... 33

4. Graphical Interface ................................................................................................................................. 33

5. Diagnostic and troubleshooting .............................................................................................................. 34

5.1 Overview ........................................................................................................................................ 34

6. EMC suggestions ..................................................................................................................................... 35

6.1 General overview on EMC .............................................................................................................. 35

6.2 EM emissions ................................................................................................................................. 35

6.3 Immunity to EM disturbances ........................................................................................................ 36

Appendix B Document History ....................................................................................................................... 37

ACX1_TAU_SYNC_UserManual_En

Page 4 of 37

1. In roduc ion

1.1 Abou SME Company

SME group,

founded in 1974, is a high technology company, manufacturer of electronic controllers

and related products for application in battery powered vehicles, particularly forklift trucks and

specialized in the development of AC power controllers.

The group

provides intelligent and innovative solutions to satisfy market requirements, achieving

worldwide customer satisfaction.

SME group is able to offer a complete motion system for the different industrial lift truck ranges

guaranteeing a high and safe perform

1.2 Abou his manual

This manual presents important information on configuring traction or pump systems using the

SmartMotion AC-X1

as well as details on sizing and selecting system components, options and

acce

ssories in an electrically powered vehicle.

This version replaces all previous existing versions of the manual, if any.

1.3

Abou warning, cau ion and informa ion no ices

Special attention must be paid to the information presented in Warning, Caution and other

of information notices when they appear in this manual.

Failure to follow those recommendations may result in dangerous situations or in damages to the

components, for which SME will not respond.

Warnings.

A Warning informs the user of a hazard or a potential hazard

which could result in serious or fatal injury if the precautions or instructions

given in the warning notice are not observed.

Cau ions.

A caution informs the reader of a hazard or a potential hazard

which could result in a serious damage to the appliance.

Informa ion No ices.

essential pieces of information to complete or to clarify

paragraph they are placed into.

In erac ive Documen a ion Tips:

section in the Interactive Documentation

founded in 1974, is a high technology company, manufacturer of electronic controllers

and related products for application in battery powered vehicles, particularly forklift trucks and

specialized in the development of AC power controllers.

provides intelligent and innovative solutions to satisfy market requirements, achieving

worldwide customer satisfaction.

SME group is able to offer a complete motion system for the different industrial lift truck ranges

guaranteeing a high and safe perform

ance customized to the client's requirements.

This manual presents important information on configuring traction or pump systems using the

as well as details on sizing and selecting system components, options and

ssories in an electrically powered vehicle.

This version replaces all previous existing versions of the manual, if any.

Abou warning, cau ion and informa ion no ices

Special attention must be paid to the information presented in Warning, Caution and other

of information notices when they appear in this manual.

Failure to follow those recommendations may result in dangerous situations or in damages to the

components, for which SME will not respond.

A Warning informs the user of a hazard or a potential hazard

which could result in serious or fatal injury if the precautions or instructions

given in the warning notice are not observed.

A caution informs the reader of a hazard or a potential hazard

which could result in a serious damage to the appliance.

Informa ion No ices.

An information notice contains additional, not

essential pieces of information to complete or to clarify

the meaning of the

paragraph they are placed into.

In erac ive Documen a ion Tips:

An advice about where to find the related

section in the Interactive Documentation

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

founded in 1974, is a high technology company, manufacturer of electronic controllers

and related products for application in battery powered vehicles, particularly forklift trucks and

provides intelligent and innovative solutions to satisfy market requirements, achieving

SME group is able to offer a complete motion system for the different industrial lift truck ranges

ance customized to the client's requirements.

This manual presents important information on configuring traction or pump systems using the

AC

as well as details on sizing and selecting system components, options and

Special attention must be paid to the information presented in Warning, Caution and other

kinds

Failure to follow those recommendations may result in dangerous situations or in damages to the

A Warning informs the user of a hazard or a potential hazard

which could result in serious or fatal injury if the precautions or instructions

A caution informs the reader of a hazard or a potential hazard

An information notice contains additional, not

the meaning of the

An advice about where to find the related

ACX1_TAU_SYNC_UserManual_En

Page 5 of 37

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

1.4 Produc warran y informa ion

SME offers a two-year warranty on all the products, unless a different agreement has been put in

place. Refer to the sales agreement or contract under which the AC SmartMotion was purchased

for a complete statement of the product warranty.

1.5 How o find us

For any information on commercial and technical issues, please contact either your dealer or SME

at the following address for your region

SME Group

Head Office

(Europe

)

Via della Tecnica, n°40

36071 Arzignano (VI), Italy

Phone:+39 (0444) 470511

Fax: +39 (0444) 451803

E-mail: sales@sme-group.com

SME Shangai Co. L d

(Asia)

No 2, Bldg. 8, 1

st

floor,

388, Xujing Shuanglian Road

201702 Qingpu District

Shanghai, China

Phone: +86 (021) 6025.3818

Fax: +86 (021) 59501502

E-mail: sales@sme-group.com

SME NA Inc

(America)

1404 King St N, Box 154,

St Jacobs

Ontario, Canada

N0B 2N0

Phone: +1 (519) 591-0965

E-mail: sales@sme-group.com

ACX1_TAU_SYNC_UserManual_En

Page 6 of 37

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

2. AC Smar Mo ion AC-X1 Overview

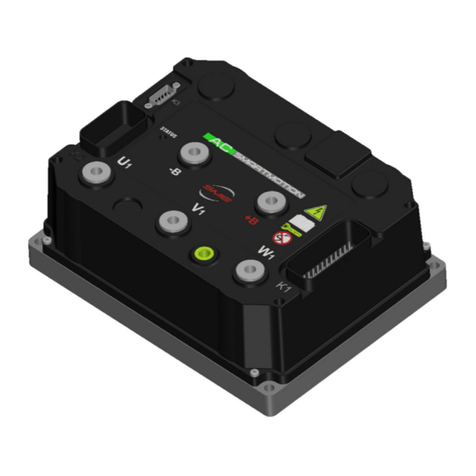

Figure 1 - AC-X1

2.1 Produc descrip ion

The AC-X1 Controller is designed to control AC asynchronous and synchronous motors.

Being based on high reliable DCB technology and exceptionally stable Field Oriented Control (FOC)

Algorithm, AC-X1 Controller is a revolutionary and high quality solution for medium power

applications.

The product is suitable for the following range of applications Counterbalanced Lift Trucks,

Cleaning Machines, Golf cars, Aerial Lifts, Tractors, Utility Vehicles, Tow Trucks.

ACX1_TAU_SYNC_UserManual_En

Page 7 of 37

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

2.1.1 Produc Indica ion Label

The product label shows important data

regarding the specific product.

The meaning of each field is described in the table below.

Field Description

Model Product description.

Type Code SME code for the specific product.

Rating Data It contains the indication of the input voltages and the output currents supplied

by the product.

Batch Number Production batch number (the same value as in barcode below).

Lot Production Month and Year

ACX1_TAU_SYNC_UserManual_En

Page 8 of 37

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

2.2 General Specifica ions

•

Mo or Type: AC Asynchronous/Synchronous 3-Phase

•

Braking: Regenerative

•

Modula ion: PWM (Pulse Width Modulation)

•

Swi ching Frequency: 9kHz

•

Low R

DS,on

MOSFET

•

16 bi s DSP controlling 1 AC motor

•

In egra ed Hall Effec Curren Sensors

2.3 Elec rical Specifica ions

2.3.1 Inpu and Ou pu Ra ings

Model Char for 100V version

Model Name AC Inver er Max Arms(2’) Max Power(2’) a 100V

AC-X1 100V 250A 250 A

rms

29.3kVA

AC-X1 100V 375A 375 A

rms

44.0kVA

AC-X1 100V 500A 500 A

rms

58.7kVA

AC-X1 100V 625A 625 A

rms

73.1kVA

AC-X1 100V 750A 750 A

rms

88.1kVA

ACX1_TAU_SYNC_UserManual_En

Page 9 of 37

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

2.3.2 Signal: Inpu s and Ou pu s

•

Digi al Inpu s: 9

•

Analog Inpu s: 5

•

Digi al Ou pu s (ON/OFF): 2

•

Driver Ou pu s (PWM): 4

•

Mo or Speed/Posi ion Sensor Inpu s: 2 (A+B Channels/Sin+Cos Analog)

Refer to following tables for a complete AC-X1 controller K1 and K3 connectors pin-out.

K1 connec or pin-ou for AC-X1 SPECIFICATIONS

Pin Name I/O Specifica ion Typical Func ion

1 GND I/O Ground Do not exceed 0.5A Negative Logic Supply

2 CAN-L CAN BUS CAN-BUS 1 MBit/s max CAN L (No internal termination

resistor)

3 CAN-L RES CAN BUS Connected to CAN-L with a series

120Ohm Termination resistor

4 DIGITAL INPUT 1 Digital Input

VL<=2V,VH>=4.5V

Resistor pull-down(active high) or pull

up(active low)

ON rated voltage +12V/24V

TO BE ASSIGNED

5 DIGITAL INPUT 2 Digital Input

VL<=2V,VH>=4.5V

Resistor pull-down(active high) or pull

up(active low)

ON rated voltage +12V/24V

TO BE ASSIGNED

6 DIGITAL INPUT 3 Digital Input

VL<=2V,VH>=4.5V

Resistor pull-down(active high) or pull

up(active low)

ON rated voltage +12V/24V

TO BE ASSIGNED

7 DIGITAL INPUT 4 Digital Input

VL<=2V,VH>=4.5V

Resistor pull-down(active high) or pull

up(active low)

ON rated voltage +12V/24V

TO BE ASSIGNED

8 DIGITAL INPUT 5 Digital Input

VL<=2V,VH>=4.5V; resistor pull-

down(active high) or pull up(active

low)

ON rated voltage +12V/24V

TO BE ASSIGNED

9 I/O GROUND I/O Ground Do not exceed 0.5A Negative Logic Supply

10 +12V OUT Supply Output 12V ±5% 200mA 12V Supply

11 ANALOG INPUT 1 Analog Input 0÷12V 125KΩ pull-down TO BE ASSIGNED

ACX1_TAU_SYNC_UserManual_En

Page 10 of 37

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

K1 connec or pin-ou for AC-X1 SPECIFICATIONS

Pin Name I/O Specifica ion Typical Func ion

12 I/O GROUND I/O Ground Do not exceed 0.5A Negative Logic Supply

13 CAN-H CAN BUS 1 MBit/s max CAN H (No internal termination

resistor)

14 CAN-H RES CAN BUS Connected to CAN-H Connected to CAN-H

15 LIN Com

Input/Output

19.2KBit/s 12V 1,1KΩ Pull-up RX

VL<=3.0V dominant, VH>=7.0V

recessive

LIN Display Connection

16 DIGITAL IN 6 Digital Input

VL<=2V,VH>=4.5V

Resistor pull-down(active high) or pull

up(active low)

ON rated voltage +12V/24V

TO BE ASSIGNED

17 ANALOG INPUT 2 Analog Input 0÷12V 125KΩ pull-down TO BE ASSIGNED

18 DIGITAL IN 7 Digital Input

VL<=2V,VH>=4.5V

Resistor pull-down(active high) or pull

up(active low)

ON rated voltage +12V/24V

TO BE ASSIGNED

19 DIGITAL IN 8 Digital Input

VL<=2V,VH>=4.5V

Resistor pull-down(active high) or pull

up(active low)

ON rated voltage +12V/24V

TO BE ASSIGNED

20 DIGITAL IN 9 Digital Input

VL<=2V,VH>=4.5V

Resistor pull-down(active high) or pull

up(active low)

ON rated voltage +12V/24V

TO BE ASSIGNED

21 ENCODER 1A /

ENCODER 1 Sin Peripheral Input

4V 470Ω pull-up, VL<=1.5V, VH>=3.4V

/

0,5 – 4,5 mV input

Quad Encoder Channel A /

Sin/Cos Encoder Sin

22 ANALOG INPUT 3 Analog Input 0÷12V 125KΩ pull-down TO BE ASSIGNED

23 ANALOG INPUT 4 Analog Input 0÷12V 125KΩ pull-down TO BE ASSIGNED

24 KEY SWITCH IN Supply Input

+ Battery supply Max = Rated +20%,

Min Batt = Rated -30%,

Supply consumption logic board 2A

Max + coil return 8A max

Positive Supply of the control

section of the AC-X1

25 COIL RETURN Supply Output (+KEY ±0.3V) Do not exceed 8A Positive Common of Auxiliary

26 DRIVER OUTPUT 1 PWM Output Active low

Internal diode to coil return Main Contactor, Brake, Valve

27 DRIVER OUTPUT 2 PWM Output Active low

Internal diode to coil return Main Contactor, Brake, Valve

28 DRIVER OUTPUT 3 PWM Output Active low

Internal diode to coil return Main Contactor, Brake, Valve

ACX1_TAU_SYNC_UserManual_En

Page 11 of 37

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

K1 connec or pin-ou for AC-X1 SPECIFICATIONS

Pin Name I/O Specifica ion Typical Func ion

29 DRIVER OUTPUT 4 PWM Output Active low

internal diode to coil return Main Contactor, Brake, Valve

30 DIGITAL OUTPUT 1 Digital Output active low

No internal diode to coil return Buzzer-Fan-ON/OFF valve

31 DIGITAL OUTPUT 2 Digital Output active low pull-down

No internal diode to coil return Buzzer-Fan-ON/OFF valve

32 MOTOR THERMAL

PROBE Analog Input 5V 1KΩ pull-up Motor Temperature Probe

33 ENCODER 1B /

ENCODER 1 Cos Peripheral Input

4V 470Ω pull-up, VL<=1.5V, VH>=3.4V /

0,5 – 4,5 mV input

Quad Encoder Channel B /

Sin/Cos Encoder Cos

34 ANALOG INPUT 5 Analog Input 0÷12V 125KΩ pull-down TO BE ASSIGNED

35 +5V OUT Supply Output 5V ±5% 200mA 12V Supply

K3 connec or pin-ou for AC-X1 SPECIFICATIONS

Pin Name I/O Specifica ion Typical Func ion

1 - - - -

2 DIAGNOSTIC RX Input 38.4-115.2 KBit/s, RS232 output

compatible levels Rx Diagnosis

3 DIAGNOSTIC TX Output 38.4-115.2 KBit/s, RS232 output

compatible levels Tx Diagnosis

4 - - - -

5 I/O GROUND I/O Ground Do not exceed 0.5A Negative Logic Supply

6 - - - -

7 - - - -

8 - - - -

9 +5V Out Bluetooth

Supply ±10% 50mA 6Ω output impedance -

ACX1_TAU_SYNC_UserManual_En

Page 12 of 37

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

2.3.3 In erfaces

•

Serial Communica ion: RS-232

•

CAN:

Pro ocol: CAN Open

Physical layer: ISO11898-2

Baud ra es: 1Mbps, 800kbps, 500kbps, 250kbps, 125kbps, 50kbps

•

Lin Bus

2.3.4 EMC

•

EN12895 (Industrial Trucks – Electromagnetic Compatibility)

2.3.5 Safe y

•

EN1175-1 (Safety of Industrial Trucks – Electrical Requirements)

The vehicle OEM takes full responsibility of the regulatory compliance of the

vehicle system ith the controller installed.

2.4 Opera ing Environmen Specifica ions

•

S orage ambien empera ure range: -40°C ÷ +70°C

•

Opera ing ambien empera ure range: -40°C ÷ +55°C

•

Hea sink opera ing empera ure range: -40°C ÷ +95°C

With linear derating: +80°C ÷ +95°C

•

Pro ec ion Level: IP65

•

Vibra ion: Tested under conditions suggested by EN60068-2-6

[

5g, 10÷500Hz, 3 axes]

•

Shock & Bump: Tested under conditions suggested by EN60068-2-27

•

Cold & Hea : Tested under conditions suggested by EN60068-2-1

•

Mechanical size: 210 x 160 x 85 [mm]

•

Weigh : 3.5 kg

ACX1_TAU_SYNC_UserManual_En

Page 13 of 37

3. Ins alla ion and W

iring

For specific application, refer to the

Interactive Documentation

Figure 2a -

AC

iring

For specific application, refer to the

About Controllers

Area of the

Interactive Documentation

.

AC

-X1 with Asynchronous Motor

iring Diagram

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

Area of the

iring Diagram

ACX1_TAU_SYNC_UserManual_En

Page 14 of 37

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

Figure 2b - AC-X1 with Synchronous Motor iring Diagram

ACX1_TAU_SYNC_UserManual_En

Page 15 of 37

3.1 Con roller

The C

ontroller contains

connecting,

disconnecting, and handling it

Mechanical Drawing

Working on electrical systems is potentially dangerous; you should protect yourself against

Uncon rolled opera ion

disconnect the motor or jack up the vehicle and get the drive wheels off the ground before

attempting any work on the motor control circuitry.

Vol age hazard and high curren arcs

and arcs can occur if they are short circuited. Always disconnect the battery circuit before

working on the motor control circuit.

Wear safety glasses and use properly insulated tools to prevent shorts.

Never energi

ze the system if the terminals

Lead acid ba eries

charging or discharging generates hydrogen gas, which can build up and

go around the batteries. Follow the battery manufacturer’s safety recommendations and

wear safet

y glasses.

For high resolution diagram, refer to the About Controllers Area of the

Interactive Documentation.

Figure

3

ontroller contains

ESD-sensi ive componen s.

Use appropriate precautions in

disconnecting, and handling it

.

AC -

Working on electrical systems is potentially dangerous; you should protect yourself against

Uncon rolled opera ion

some

conditions could cause the motor to run out of control

disconnect the motor or jack up the vehicle and get the drive wheels off the ground before

attempting any work on the motor control circuitry.

Vol age hazard and high curren arcs

batteries can

supply high voltage and very high power,

and arcs can occur if they are short circuited. Always disconnect the battery circuit before

working on the motor control circuit.

Wear safety glasses and use properly insulated tools to prevent shorts.

ze the system if the terminals

–

B and +B are not tightly connected.

charging or discharging generates hydrogen gas, which can build up and

go around the batteries. Follow the battery manufacturer’s safety recommendations and

y glasses.

For high resolution diagram, refer to the About Controllers Area of the

Interactive Documentation.

–

Top View

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

Use appropriate precautions in

X1 Top View

Working on electrical systems is potentially dangerous; you should protect yourself against

conditions could cause the motor to run out of control

disconnect the motor or jack up the vehicle and get the drive wheels off the ground before

supply high voltage and very high power,

and arcs can occur if they are short circuited. Always disconnect the battery circuit before

B and +B are not tightly connected.

charging or discharging generates hydrogen gas, which can build up and

go around the batteries. Follow the battery manufacturer’s safety recommendations and

For high resolution diagram, refer to the About Controllers Area of the

ACX1_TAU_SYNC_UserManual_En

Page 16 of 37

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

AC - X1 General View

AC - X1 Side View

AC - X1 Back View

Figure 4 – Side View

Figure 3 – General View

Figure 5 - Back View

ACX1_TAU_SYNC_UserManual_En

Page 17 of 37

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

Moun ing and Replacemen

The Controller meets IP65 environmental protection rating against dust and water.

The mounting location should be carefully chosen in order to be clean and dry, to minimize shock,

vibration, temperature changes and exposure to water & contaminants. If this kind of location

can’t be ensured, then a cover should be used to shield the controller. Cables must be routed to

prevent liquids flowing into the connections. The mounting location should also allow access to all

connections.

The replacement of the Controller must be done with the hand brake engaged, the drive wheels

off the ground, the key switch in off position, battery plug disconnected and the capacitors of the

inverter completely discharged.

The capacitors in the inverter can be discharged by connecting a load across the inverter’s +B and

–B terminals.

Cooling

It is recommended that the Controller is assembled to a flat, free of paint surface preferably lightly

coated with a thermal transfer compound using the 4 holes provided. Ideally, this surface will

provide maximum heat dissipation and ensure full rated power output. When designing a cooling

system, please refer to the following step

1. Apply thermal grease to the Controller before mounting for better cooling effect.

2. The Controller is cooled by the surface contact to the vehicle body, so it is important to pay

much attention to the flatness and the roughness of the surface of the vehicle frame where

it is mounted. The roughness R

z

should be between 1.6 μm and 3.2μm, while the planarity

of the surface should be under 0.5mm, as shown in the following image

Planari y specifica ions for he AC-X1

wi h aluminium basepla e.

3. Any airflow around the controller will further enhance the thermal performance.

Figure

6

-

Planarity

ACX1_TAU_SYNC_UserManual_En

Page 18 of 37

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

4. Additional heatsink could be necessary to meet the desired continuous ratings. The heat

sink material and system should be sized on the performance requirement of the machine.

We recommend ambient temperature air to be directed over the heatsink fins to maintain

heatsink temperature below 75 °C.

5. In systems where either ventilation is poor, or heat exchange is difficult, forced air

ventilation should be used.

Clearances

For all AC-X1 models 50 mm clearances in front of and behind the AC-X1 are required for airflow;

50 mm clearance above the AC-X1 is required for installation/removal of interface connectors and

wiring.

ACX1_TAU_SYNC_UserManual_En

Page 19 of 37

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

3.2 Power Terminals

Wiring

The Controller has five Power Terminals, which are clearly marked on Controller’s body as B+, B-,

U, V, W (figure 4).

Power Terminals on Con roller

Terminal

Meaning

B+ Positive Battery coming from the Main Contactor

B- Negative Battery

U U Motor Phase

V V Motor Phase

W W Motor Phase

The recommended screw orque for fixing the Power Terminals is 6.5 Nm. This value is reported

on the label placed on the cover, exceeding the recommended value may cause damages.

Sizing

The environment conditions strongly affect the current carrying capacity of a single wire.

Temperature and wire length can decrease the cable performance and other factors such as

Controller duty cycles and airflow should also be taken into consideration when sizing the power

cables.

The following formula gives an advice on the cable size needed in welding cable, not grouped with

other cables

•Ambien Tempera ure = 25°C

•Maximum Tempera ure rise on he cable surface = 60°C

•Sugges ed Curren Densi y [A

rms

/mm

2

] = 5 A

rms

/mm

2

ACX1_TAU_SYNC_UserManual_En

Page 20 of 37

SME S.p.A. Via della Tecnica 40 Z.I.

36071 ARZIGNANO (VI) ITALY

Phone +39 0444 470511 - Fax +39 0444 451803

[email protected] - www.sme-group.com

The following table shows you the most common cases

S andard Wire Dimensions

Average Curren [Arms]

Minimum Wire

Sec ion Sugges ed

[mm

2

]

Wire Size

mm

2

AWG

100 20 21.1 4

150 30 33.6 2

200

40 42.4 1

250

50 53.5 0

300

60 67.4 2/0

350

70 85 3/0

3.3 Main Con ac or

The Controller must be connected to one Main Contactor for two basically reasons

•Capaci ors Pre-Charge The Controller handles all this phase internally by

discharging/charging its DC-Bus through the Key Input. As soon as a certain voltage value is

reached by the DC-Bus, the Controller can close the Main Contactor connecting it to the

Battery. In this way dangerous shocks on Controller's capacitors are avoided.

•Safe y In case of dangerous situations, the Main Contactor must be opened disconnecting

the Battery from Controller. If he main con ac or coil is no connec ed o he con roller,

he sys em will no mee EEC safe y requiremen s.

Sizing

In order to select the Main Contactor, it must be considered the Controller Ratings, the Duty Cycle

of the System and several other working conditions. The following empirical formula can be useful

to quickly find the Main Con ac or minimum ra ing I

MC

with

Other manuals for AC-X1

1

Table of contents

Other SME Controllers manuals