SME AC-M1 User manual

AC-M1

AC-M1

PRELIMINARY VERSION

Table of Contents

1 Introduction.....................................................................................................................4

1.1 About SME Company................................................................................................4

1.2 About this manual......................................................................................................4

1.3 About warning, caution and information notices........................................................4

1.4 Product warranty informations...................................................................................4

1.5 How to find us...........................................................................................................5

2 AC_SmartMotion AC-M1 Overview................................................................................6

2.1 Product Description...................................................................................................6

2.2 General Technical Specifications..............................................................................7

2.3 Packaging configuration............................................................................................8

2.4 Product indication labels.........................................................................................10

3 Installation and wiring...................................................................................................11

3.1 General description.................................................................................................11

3.2 Mounting the controller............................................................................................11

3.3 Cooling requirements..............................................................................................12

3.3.1 AC-M1 with Heat Sink.....................................................................................12

3.3.2 AC-M1 with Aluminium Baseplate...................................................................12

3.3.3 Clearances......................................................................................................12

..................................................................................................................................13

3.4 List of complete pin-out...........................................................................................14

3.4.1 AC-M1 pin-out for PUMP application.............................................................14

3.4.2 AC-M1 pin-out for DRIVE application............................................................17

3.4.3 Connector Parts..............................................................................................19

3.5 Typical connection diagrams...................................................................................20

3.5.1 General electrical vehicle................................................................................20

3.5.2 Pump motor application in a twin drive system...............................................20

3.5.3 Screw torque for the power connections.........................................................20

3.6 External devices description....................................................................................23

3.6.1 Encoder...........................................................................................................23

3.6.2 COMPACT Display..........................................................................................24

3.7 Programmable parameters......................................................................................25

3.8 Initial set-up.............................................................................................................25

3.9 Technical specifications ..........................................................................................25

4 Main function management..........................................................................................29

4.1 Static return to off....................................................................................................29

4.2 Buzzer management...............................................................................................29

4.3 BDI measure management.....................................................................................29

5 User interfaces..............................................................................................................30

5.1 Introduction.............................................................................................................30

5.2 EyePlus software....................................................................................................30

PRELIMINARY VERSION 2

5.2.1 Overview.........................................................................................................30

5.2.2 Serial interconnection cable............................................................................31

5.2.3 System requirements......................................................................................31

5.3 COMPACT Display..................................................................................................33

5.3.1 Overview.........................................................................................................33

5.3.2 General characteristics ..................................................................................33

5.3.3 Connections....................................................................................................34

5.3.4 Mechanical drawings.......................................................................................34

6 Diagnostic and troubleshooting..................................................................................37

6.1 Overview.................................................................................................................37

6.2 Alarm list and description........................................................................................38

7 EMC Suggestions..........................................................................................................47

7.1 General overview on EMC......................................................................................47

7.2 EM emissions..........................................................................................................47

7.3 Immunity to EM disturbances..................................................................................47

8 Maintenance...................................................................................................................49

8.1 Spare part list..........................................................................................................49

9 Appendix A. General technical overview of SME technology...................................50

9.1 History of AC induction motors and AC controllers..................................................50

9.2 Technical advantages of AC induction motors.........................................................50

9.3 AC motor general description and principles of operation .....................................51

9.3.1 General description of an AC motor................................................................51

9.3.2 Principle of operation .....................................................................................51

9.3.3 Electrical model...............................................................................................53

9.4 ITC vector drive system ..........................................................................................54

9.4.1 Basic operation of ITC vector drive system.....................................................54

9.4.2 Main ITC components.....................................................................................56

9.4.3 Basic ITC functions.........................................................................................56

9.4.4 ITC characteristics..........................................................................................57

10 Appendix B: Programmable parameters...................................................................58

PRELIMINARY VERSION 3

1 Introduction

1.1 About SME Company

SME group, founded in 1974, is a high technology company, manufacturer of electronic

controllers and related products for application in battery powered vehicles, particularly

forklift trucks and specialized in the development of AC power controllers.

The group provides intelligent and innovative solutions to satisfy market requirements,

achieving worldwide customer satisfaction.

SME group is able to offer a complete motion system for the different industrial lift truck

ranges guaranteeing a high and safe performance customized to the client's requirements.

1.2 About this manual

This manual presents important information on configuring lift and drive systems using the

AC_SmartMotion AC-M1 as well as details on sizing and selecting system components,

options and accessories in an electrically powered vehicle utilizing CAN Bus (CAN Open

protocol) for communications and control.

This manual also presents an overview of AC induction motor and AC drives technology.

This version replaces all previous existing versions of the manual, if any.

1.3 About warning, caution and information notices

Special attention must be paid to the information presented in Warning, Caution and other

kinds of information notices when they appear in this manual.

Failure to follow those recommendations may result in dangerous situations or in damages

to the components, for which SME will not respond.

Warnings. A Warning informs the user of a hazard or a potential hazard

which could result in serious or fatal injury if the precautions or

instructions given in the warning notice are not observed.

Cautions. A caution informs the reader of a hazard or a potential

hazard which could result in a serious damage to the appliance.

Information notices. An information notice contains additional, not

essential pieces of information to complete or to clarify the meaning of

the paragraph they are placed into.

1.4 Product warranty informations

SME offers a two-year warranty on all the products, unless a different agreement has been

put in place. Refer to the sales agreement or contract under which the AC_SmartMotion

was purchased for a complete statement of the product warranty.

PRELIMINARY VERSION 4

1.5 How to find us

All the World Regions (except Asia):

●

For any information on commercial and technical issues, please contact either your

dealer or directly SME Headquarter at the following address:

SME S.p.A.

Via della Tecnica, n°40

36071 Arzignano (VI) - ITALY

Tel: +39 0444 470511

Fax: +39 0444 451803

Email: [email protected]

Asia Region:

●

For any information on commercial and technical issues, please contact either your

dealer or SME Shanghai headquarters at the following address:

SME (SHANGHAI) CO. LTD

1288, Zhangxiang Road

20180 Anting Town

Jiading District

Shanghai - PEOPLE'S REPUBLIC OF CHINA

Tel: +86 (0)21 59501530

Fax: +86 (0)21 59501502

PRELIMINARY VERSION 5

2 AC_SmartMotion AC-M1 Overview

2.1 Product Description

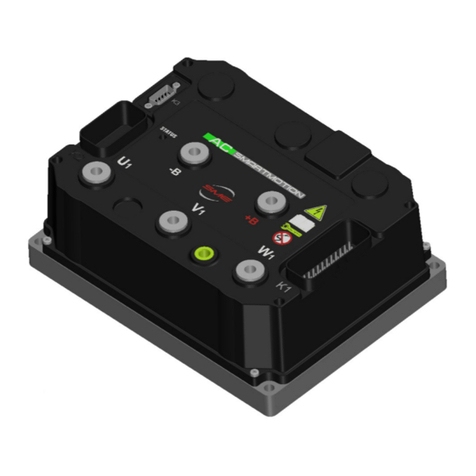

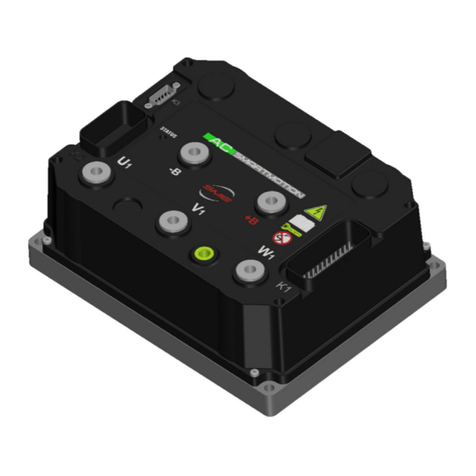

The AC-M1 Controller is designed to control AC motors up to 10kW.

Being based on high reliable DCB technology and exceptionally stable ITC Control

Algorithm, AC-M1 Controller is a revolutionary and high quality solution for medium power

applications.

AC-M1 Controller can be easily connected to other peripherals to perform a complex

network in which all nodes can communicate with the others via CAN bus.

When used in pump configuration, it can be connected to an AC-M2 controller customized

for twin drive motors applications.

The product is suitable for the following range of applications: Counterbalanced Lift Trucks,

Cleaning Machines, Golf cars, Aerial Lifts, Tractors, Utility Vehicles, Tow Trucks.

PRELIMINARY VERSION 6

2.2 General Technical Specifications

AC-M1 has the following remarkable features:

✔

Low R

DS,on

MOSFET

✔

16 bits DSP controlling 1 AC motor

✔

High Speed FLASH Memory

✔

Switching Frequency: 9kHz

✔

Integrated Hall Effect Current Sensors

✔

Communication: RS232, LIN and CAN-Bus

✔

Available Supply Voltages (Volts): 24,36,48,72,80

✔

Maximum Current, measured in a two-minute time interval.

○

24V version: 350-450-600 A

rms

○

36/48V version: 375-500 A

rms

○

80V version: 350-450 A

rms

✔

Working temperature range: -30°C/+40°C

✔

Maximum heat sink temperature: 100°C

✔

Mechanical Characteristics:

○

Dimensions: 210x145x91 mm

○

Connectors: 2x23 Ampseal terminals

○

Environmental Protection: IP65

○

Available with Aluminum baseplate or finned Heatsink

✔

I/O specifications:

○

N°21 Digital Inputs

○

N°8 Analogue Inputs

○

N°5 Outputs

PRELIMINARY VERSION 7

The following model charts provide further details on the product family:

Model Chart for 24V version

Model Name AC Inverter Max Arms(2’) Max Power (2’)

AC-M1 24V 350A 350A

rms

9.7 kVA

AC-M1 24V 450A 450 A

rms

12.5 kVA

AC-M1 24V 600A 600 A

rms

16.6 kVA

Model Chart for 36/48V version

Model Name AC Inverter Max Arms(2’) Max Power (2’)

AC-M1 36/48V 375A 375 A

rms

20.8 kVA

AC-M1 36/48V 500A 500 A

rms

27.5 kVA

Model Chart for 72/80V version

Model Name AC Inverter Max Arms(2’) Max Power (2’)

AC-M1 72/80V 350A 350A

rms

32.3 kVA

AC-M1 72/80V 450A 450 A

rms

41.6 kVA

2.3 Packaging configuration

AC-M1 is available in one of the following packages:

1. with an Aluminum baseplate, or

2. with a heat sink, which uses the convection and therefore requires a fan.

PRELIMINARY VERSION 8

Figure 1: AC-M1 . All the dimensions are in millimetres.

PRELIMINARY VERSION 9

2.4 Product indication labels

The product label shows important data regarding the specific product.

The product label is placed in the same position for all the versions of AC-M1 (see fig. 1).

The meaning of each field is described in the table below.

Field Description

Type Code It is the code that SME assigns to the specific family of

products.

Product Code It is the code that SME assigns to the specific customer.

Rating Data It can contain the indication of the input voltages and the output

currents supplied by the product.

Production Number It is the production lot number.

Customer Code It is the customer's internal reference to the application to which

AC-M1 is applied.

PRELIMINARY VERSION 10

3 Installation and wiring

3.1 General description

The AC-M1 is composed by a control section and a power section, both enclosed in a

plastic cover with an aluminium baseplate or a heat sink on the bottom of the enclosure.

There is a power module which can be connected to a three-phase AC motor through the

power outputs labelled as U, V, W. There can be an optional output (labelled as P) for a

DC pump motor.

Two 23 ways ampseal connectors ( named K1and K2), permits to interface control board

to lift truck electrical/electronic sub-devices. See tables on pages 14 and followings for the

complete pin-out of this connector.

There are two connectors +B and -B which supply the power module.

Please see figure 1 on page 9 for AC-M1 drawing.

SME recommends you to protect the AC-M1 against reversed battery

polarity.

3.2 Mounting the controller

AC-M1 can be oriented in any direction and meets IP65 environmental protection rating.

However, the location should be carefully chosen to keep the controller clean and dry.

If a clean, dry mounting location cannot be found, a cover should be used to shield the

controller from water and contaminants.

The outline and mounting hole dimensions for the AC-M1 controller are shown in figures

Errore: sorgente del riferimento non trovata and 1 on page 9.

To ensure full rated power, the controller should be fastened to a clean, flat metal surface

with four 6.5 mm diameter bolts, using the holes provided.

A thermal joint compound must be used to improve heat conduction from the controller

heatsink to the mounting surface.

During the design and development of your end product, you will need to ensure that its

EMC performance complies with applicable regulations.

The AC-M1 controller contains ESD-sensitive components. Use

appropriate precautions in connecting, disconnecting, and handling the

controller.

For EMC and ESD purposes, SME strongly recommends that both the

AC-M1 heat sink and the houses of the motors are connected to the

chassis of the truck.

PRELIMINARY VERSION 11

Working on electrical systems is potentially dangerous; you should

protect yourself against :

Uncontrolled operation: some conditions could cause the motor to run

out of control: disconnect the motor or jack up the vehicle and get the

drive wheels off the ground before attempting any work on the motor

control circuitry.

Voltage hazard and high current arcs: batteries can supply high

voltage and very high power, and arcs can occur if they are short

circuited. Always disconnect the battery circuit before working on the

motor control circuit.

Wear safety glasses and use properly insulated tools to prevent shorts.

Lead acid batteries: charging or discharging generates hydrogen gas,

which can build up and go around the batteries. Follow the battery

manufacturer’s safety recommendations and wear safety glasses.

3.3 Cooling requirements

3.3.1 AC-M1 with Heat Sink

A massive heat sink comprising the entire bottom surface of the AC-M1 transfers heat out

of the power conversion section to the surrounding air.

Drives operating at or near continuous power output require forced air cooling to maintain

heat sink temperature in the safe operating zone.

We recommend ambient temperature air to be directed over the heat sink fins to maintain

heat sink temperature below 85 °C.

Either an axial blower or two small muffin fans can provide the necessary airflow.

3.3.2 AC-M1 with Aluminium Baseplate

A massive heat sink comprising the entire bottom surface of the AC-M1 transfers heat out

of the power conversion section to the vehicle body.

Drives operating at or near their continuous power output require different thermal

resistance depending on AC-M1 size for dissipation of heat to maintain heat sink

temperature in the safe operating zone.

In this case, AC-M1 is cooled by the surface contact to the vehicle body, so it is important

to pay much attention to the flatness and the roughness of the surface of the vehicle frame

where AC-M1 is mounted.

Apply thermal grease to the AC-M1 before mounting for better cooling effect.

You should keep the planarity of the surface under 0.5mm, as shown in Figure 2.

3.3.3 Clearances

For all AC-M1 models 50 mm clearances in front of and behind the AC-M1 are required for

airflow; 50 mm clearance above the AC-M1 is required for installation/removal of interface

connectors and wiring. Refer to figures 1 on pages 9 for the dimensions of AC-M1.

PRELIMINARY VERSION 12

Figure 2: Planarity specifications for the AC-M1with aluminium baseplate.

PRELIMINARY VERSION 13

3.4 List of complete pin-out

3.4.1 AC-M1 pin-out for PUMP application

K1 connector pin-out for AC-M1 : PUMP application

Pin Name I/O Specification Function

1 +KEY (B) Supply

input

Rated battery +25/-30%,

6Amax

Positive supply of the control

section of the AC-M1

2digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

3digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

4digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

5digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

6 TILT digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Tilt request

7 SIDE SHIFT digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Side shift request

8 BUZZER output Low side 0,5A Buzzer command

9 COMMON Positive

output High side 5A max Positive common

10 RX Input Diagnosis interface

11 TX Out Diagnosis interface

12 digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

13 digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

14 LIN I/O 12mA pull-up LIN display connection or LED

diagnosis

15 CAN-H I/O CAN-bus H line input for CAN (No internal

PRELIMINARY VERSION 14

K1 connector pin-out for AC-M1 : PUMP application

Pin Name I/O Specification Function

termination resistor)

16 output Low side 2A Reserve command

17 output Low side 1,5A Reserve command

18 GND Negative logic supply

19 FAN output Low side 1,5A FAN command

20 OUT1 output Low side 1,5A Reserve command

21 +12V auxiliary

supply 12V 300mAmax 12V supply

22 GND CAN CAN- bus negative supply

23 CAN-L I/O CAN-bus L line input for CAN (No internal

termination resistor)

K2 connector pin-out for AC-M1 : PUMP application

Pin Name I/O Specification Function

1 +5E auxiliary

supply

5V+/-5%

200mAmax 5V supply

2digital

input

20mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

3digital

input

20mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

4 ENC.B1 digital

input

20mA pull-up,

VL<=1V,

VH>=3,5V

Phase B signal of the sensor

bearing mounted in the AC

pump motor.

5 ENC.A1 digital

input

20mA pull-up,

VL<=1V,

VH>=3,5V

Phase A signal of the sensor

bearing mounted in the AC

pump motor.

6digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

7digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

8 LIFT digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Max LIFT speed request

PRELIMINARY VERSION 15

K2 connector pin-out for AC-M1 : PUMP application

Pin Name I/O Specification Function

9 GND ENC Negative logic supply

10 analogue

input Pull-up Reserve

11 T. MOTOR 1 analogue

input Pull-up Analogue input for pump motor

thermal sensor

12 digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

13 LIFT PRESSURE analogue

input 0/12V pull-down Lift pressure sensor

14 AUX 1 digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Aux1 request

15 AUX2 digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Aux2 request

16 digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

17 LIMITATION 1 digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Limitation speed 1

18 digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

19 analogue

input 0/12V pull-down Reserve

20 analogue

input 0/12V pull-down Reserve

21 analogue

input 0/12V pull-down Reserve

22 LIFT LEVER analogue

input 0/12V pull-down Lift speed request

23 LIMITATION 2 digital

input

pull-down,

max input: 24V 4mA,

VL<=1V,

VH>=3,5V

Limitation speed 2

PRELIMINARY VERSION 16

3.4.2 AC-M1 pin-out for DRIVE application

K1 connector pin-out for AC-M1 : DRIVE application

Pin Name I/O Specification Function

1 +KEY (B) Supply

input

Rated battery +25/-30%,

6Amax

Positive supply of the control

section of the AC-M1

2 SEAT digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Safety contact signal; the safety

contact should be normally

open.

3 REVERSE digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reverse direction selection

4FORWARD

digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Forward direction selection

5 START digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Throttle start selection

6digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

7digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

8 BUZZER output Low side 0,5A Buzzer command

9 COMMON Positive

output High side 5A max Positive common

10 RX Input Diagnosis interface

11 TX Out Diagnosis interface

12 PEDAL BRAKE digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Pedal brake request

13 PARK BRAKE digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Park brake request

14 LIN I/O 12mA pull-up LIN display connection or LED

diagnosis

15 CAN-H I/O CAN-bus H line input for CAN (No internal

termination resistor)

16 OUT3 output Low side 2A NEGATIVE BRAKE command

17 MAIN output Low side 1,5A Main contactor command

PRELIMINARY VERSION 17

K1 connector pin-out for AC-M1 : DRIVE application

Pin Name I/O Specification Function

18 GND Negative logic supply

19 FAN output Low side 1,5A FAN command

20 OUT1 output Low side 1,5A Reserve command

21 +12V auxiliary

supply 12V 300mAmax 12V supply

22 GND CAN CAN- bus negative supply

23 CAN-L I/O CAN-bus L line input for CAN (No internal

termination resistor)

K2 connector pin-out for AC-M1 : DRIVE application

Pin Name I/O Specification Function

1 +5E auxiliary

supply

5V+/-5%

200mAmax 5V supply

2digital

input

20mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

3digital

input

20mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

4 ENC.B1 digital

input

20mA pull-up,

VL<=1V,

VH>=3,5V

Phase B signal of the sensor

bearing mounted in the AC

right drive motor.

5 ENC.A1 digital

input

20mA pull-up,

VL<=1V,

VH>=3,5V

Phase A signal of the sensor

bearing mounted in the AC

right drive motor.

6digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

7digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

8digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

9 GND ENC Negative logic supply

10 analogue

input Pull-up Reserve

PRELIMINARY VERSION 18

K2 connector pin-out for AC-M1 : DRIVE application

Pin Name I/O Specification Function

11 T. MOTOR analogue

input Pull-up Analogue input for drive motor

thermal sensor

12 digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

13 analogue

input 0/12V pull-down Reserve

14 digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

15 digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

16 digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

17 digital

input

pull-down,

max input: 24V 4mA,

VL<=1V,

VH>=3,5V

Reserve

18 digital

input

4mA pull-up,

VL<=1V,

VH>=3,5V

Reserve

19 PEDAL BRAKE

SENSOR

analogue

input 0/12V pull-down Brake pressure sensor

20 STEERING analogue

input 0/12V pull-down Steering angle sensor

21 ACCELERATOR analogue

input 0/12V pull-down Throttle pedal

22 analogue

input 0/12V pull-down Reserve

23 digital

input

pull-down,

max input: 24V 4mA,

VL<=1V,

VH>=3,5V

Reserve

3.4.3 Connector Parts

The K1 and K2 connectors are AMPSEAL 23 Pins, manufactured by AMP.

The external plug assembly is AMP cod. 770680-1, with contact 0,5-1,4mm2 cod. 770854-1.

PRELIMINARY VERSION 19

3.5 Typical connection diagrams

3.5.1 General electrical vehicle

Figure 3 shows a connection diagram of a general electrical vehicle using the AC-M1 as

control board and traction motor drive. Pump motor is not present.

3.5.2 Pump motor application in a twin drive system

Figure 4 shows a typical connection diagram showing AC-M1 control powering an A.C.

pump motor in a twin drive motors system.

3.5.3 Screw torque for the power connections.

The recommended screw torque for fixing the connections +B, -B, U,V and W is 6 Nm.

This value is reported on the label placed on the cover: exceeding the recommended

value may cause damages.

PRELIMINARY VERSION 20

Other manuals for AC-M1

1

Table of contents

Other SME Controllers manuals

Popular Controllers manuals by other brands

Andover Controls

Andover Controls DCX 250 installation guide

amiad

amiad ADI-X IOM Installation, operation & maintenance instructions

Dometic

Dometic Go Power! GP-SB-PWM-10 user manual

Emerson

Emerson PACSystems RX3i IC695CPE330 quick start guide

WEG

WEG PLC500 Application note

Belimo

Belimo NF24A-SR-S2 Technical data sheet