SMERI PT-4S User manual

Popular Transmitter manuals by other brands

Sunstech

Sunstech FTM300BTUSB user manual

RadioLink

RadioLink RC8X Firmware Upgrade Instructions

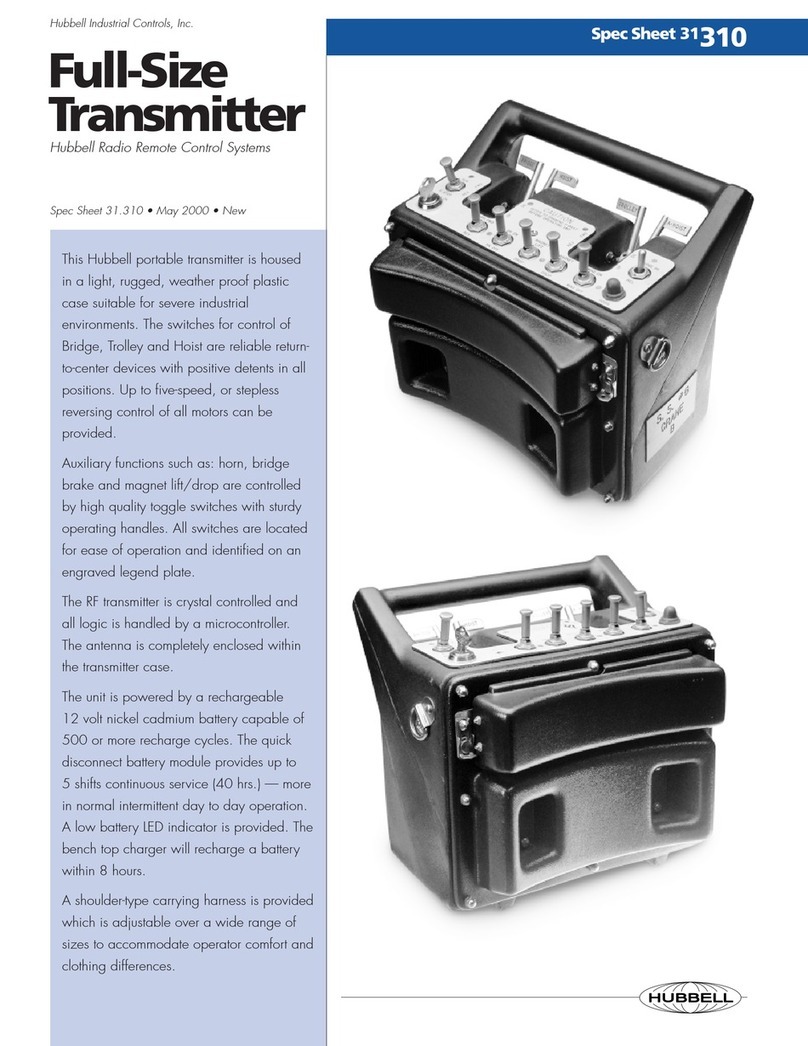

Hubbell

Hubbell Full-Size Transmitter 31.310 Spec sheet

Williams Sound

Williams Sound Personal PA PPA T36 Instructions for use and care

BD Sensors

BD Sensors DX14A-DMK 456 operating manual

BWI Eagle

BWI Eagle AIR-EAGLE SR PLUS TX Product information bulletin

Dometic

Dometic Waeco PerfectView VT100DIG Installation and operating manual

Vaisala

Vaisala HUMICAP HMT360 SERIES Safety guide

CYP

CYP COH-RX2 Operation manuals

Silicon Laboratories

Silicon Laboratories Si4010 Series user guide

Comnet

Comnet FVR1021 Series Installation and operation manual

Dwyer Instruments

Dwyer Instruments IEF Series Specifications-installation and operating instructions