Smithy Midas 1220 XL User manual

MIDAS 1220 XL

COMBINATION LATHE/MILL/DRILL

OPERATOR’S MANUAL

Updated August, 2008

170 Aprill Dr., Ann Arbor, MI, USA 48103

Toll Free 1-800-476-4849

www.smithy.com

©2008 Smithy Co. All rights reserved (Revision 1).

170 Aprill Dr., Ann Arbor, Michigan, USA 48103

Toll Free Hotline: 1-800-476-4849

Fax: 1-800-431-8892

International: 734-913-6700

International Fax: 734-913-6663

All images shown are from Midas 1220 XL machine.

All rights reserved. No part of this manual may be reproduced or transmitted in any form

by any means, electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of Smithy Co. For information on getting permission for

While every precaution has been taken in the preparation of this manual, Smithy Co. shall not

have any liability to any person or entity with respect to any loss or damage caused or

alleged to be caused directly or indirectly by the instructions contained in this manual.

Please see section on warranty and safety precautions before operating the machine.

Printed and bound in the United States of America.

Table of Contents

Inventory Check List ............................................i-iv

Chapter 1: Introduction .........................................1-1

Chapter 2: Safety ................................................2-1

Chapter 3: Knowing Your Machine ............................3-1

Chapter 4: Caring For Your Machine .........................4-1

Chapter 5: Basic Parts of the MI-1220 XL ..................5-1

Chapter 6: Uncrating and Setting Up the MI-1220 XL

Moving the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Uncrating and Positioning the machine . . . . . . . . . . . . . . . . . . . . . .6-1

Millhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Tailstock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Three Jaw Chuck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Selecting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Cleaning and Lubricating the MI-1220 LTD . . . . . . . . . . . . . . . . . . . .6-4

Oiling the Headstock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Oiling the Ways . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Oiling the Carraige . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Oiling the Tailstock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Oiling the Apron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Oiling the Leadscrew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Oiling the Compound Angle Toolpost . . . . . . . . . . . . . . . . . .6-7

Setting Up Your MI-1220 XL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Setting Lathe and Mill Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Adjusting Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Adjusting Gibs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

Reducing Backlash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

Crossfeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

Longfeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

Running in the MI-1220 XL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

Chapter 7: Turning

Turing Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Gear Ratios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Chapter 8: Metalcutting Theory

Tool Sharpness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

Chapter 9: Grinding Cutter Bits for Lathe Tools

High Speed Steel Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Materials Other than Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

Bits for Turning and Machining Brass . . . . . . . . . . . . . . . . . . . . . . . .9-4

Special Chip Craters and Chipbreakers . . . . . . . . . . . . . . . . . . . . . . .9-4

Using a Center Gauge to Check V-Thread Forms . . . . . . . . . . . . . .9-4

Acme or Other Special Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

Carbide-Tipped Cutters and Cutter Forms . . . . . . . . . . . . . . . . . . . . .9-5

Chapter 10: Setting Up Lathe Tools

Cutting Tool Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

Turning Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

Threading Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

Cutoff, Thread Cutting and Facing Tools . . . . . . . . . . . . . . . . . . . . .10-3

Boring and Inside Threading Tools . . . . . . . . . . . . . . . . . . . . . . . . .10-3

Chapter 11: Setting Up with Centers, Collets and Chucks

Centering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

Centering a Round and Rectangular Steels . . . . . . . . . . . . . . . . . .11-2

Mounting Work between Centers . . . . . . . . . . . . . . . . . . . . . . . . . .11-4

Using a Clamp Dog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-4

Setting Up Work on Mandrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-6

Steady Rest and Follow Rest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-6

Setting Up Work in a Chuck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-8

Mounting Work in a Four-Jaw Independent

Lathe Chuck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-8

Mouting Work in a Three-Jaw Universal Chuck . . . . . .11-10

Collet and Collet Attachements . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-11

Toolpost Grinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-12

Chapter 12: Lathe Turning

Rough Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

Finish Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-2

Turning to Shapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-2

Machining Square Corners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-3

Taper Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-4

Boring a Tapered Hole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-6

Chapter 13: Lathe Facing and Knurling

Facing Across the Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-1

Knurling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-2

Chapter 14: Changing Gears ..................................14-1

Chapter 15: Cutting Screw Threads

Threading Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-1

Cutting Right Hand Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-3

Cutting Left Hand Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-4

Cutting Multiple Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-4

What Not To Do When Cutting Threads . . . . . . . . . . . . . . . . . . . . .15-5

Finishing Off a Threaded End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-5

Cutting Threads on a Taper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-5

Chapter 16: Lathe Drilling and Boring

Reaming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-1

Boring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-2

Cutting Internal Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-4

Cutting Special Form Internal Threads . . . . . . . . . . . . . . . . . . . . . .16-5

Chapter 17: Cutting Off or Parting with a Lathe .........17-1

Chapter 18: Milling .............................................18-1

Chapter 19: Workholding

Mounting to the Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-1

Using a Vise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-1

Dividing Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-2

Rotary Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-2

Chapter 20: Holding Milling Cutters

Arbors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20-1

Collets and Holders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20-1

Adaptors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20-2

Chapter 21: Milling Cutters

End Mill Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21-1

Plain Milling Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21-3

Side Milling Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21-3

Inventory Check List

It is a good idea to take inventory of the parts of your machine soon after it is unpacked.

By doing so, you can quickly determine if any parts are missing. In addition, should you

find it necessary to return the machine to Smithy for any reason, the inventory will ensure

that all the parts you received have been returned. It is also good to take a look at the

inventory before you operate the machine so that you can be familiar with the names of

all the parts of your Smithy machine.

qAllen Wrench, 4mm

Item #: C30540

Quantity 1

qAllen Wrench, 5mm

Item #: C30542

Quantity 1

qAllen Wrench, 6mm

Item #: C30537

Quantity 1

qAllen Wrench, 8mm

Item #: C30536

Quantity 1

qWrench, 14 mm

Item #: 81-500

Quantity 1

qArbor

, JT33-MT3

(No Tang)

Item #: C30523

Quantity 1

qDrift, MT2

Item #: C30558

Quantity 1

qDead Center, MT3

Item #: 41-003

Quantity 1

qDead Center, MT4

Item #: 41-004

Quantity 1

qDrill chuck, 1/2”

Item #: 72-001

Quantity 1

qGear, 32 Teeth

Item #: C30145

Quantity 2

qGear, 33 Teeth

Item #: C30146

Quantity 1

qGear

,39 Teeth

Item #: C30148

Quantity 1

qGear

,40 Teeth

Item #: C30149

Quantity 1

i

Or Visit www.smithy.com

qGear, 42 Teeth

Item #: C30150

Quantity 1

qGear, 45 Teeth

Item #: C30156

Quantity 1

qGear, 48 Teeth

Item #: C30151

Quantity 1

qGear, 49 Teeth

Item #: C30152

Quantity 1

qGear, 50 Teeth

Item #: C30153

Quantity 1

qGear, 56 Teeth

Item #: C30157

Quantity 1

qGear, 60 Teeth

Item #: C30159

Quantity 1

qGear, 70 Teeth

Item #: C30202

Quantity 1

Gears on the machine:

qGear, 27 Teeth

Item #: C30143

Quantity 2

qGear, 30 Teeth

Item #: C30144

Quantity 1

qGear, 60 Teeth

Item #: C30159

Quantity 1

qGear, 63 Teeth

Item #: C30160

Quantity 1

qJaws (3), 5”

Item #: 9-10

Quantity 1 set of 3

qKey, Lathe Chuck

Item #: C30532

Quantity 1

qKey, Drill Chuck

Item #: C30533

Quantity 1

qOpen End Wrench,

8/10mm

Item #: C30539

Quantity 1

qOpen End Wrench,

17/19mm

Item #: C30535

Quantity 1

qAdapter Precision

End Mill

Item #: 65-010

Quantity 1

qEnd Mill Single

4FHSS3/8 1/4”

Item #: 50-402

Quantity 1

Midas 1220 XL Operator’s Manual

ii For Assistance: Call Toll Free 1-800-476-4849

qEnd Mill Single

4 FHSS 3/8 3/8”

Item #: 50-406

Quantity 1

qEnd Mill Single

4 FHSS 3/8 1/4”

Item #: 50-410

Quantity 1

qT-Slot Nut, 7/16”

Item #: 35-105

Quantity 2

qAir Mask

Item #: 15-020

Quantity 1

qGoggles

Item #: 15-015

Quantity 1

qEar Plug

Item #: 15-025

Quantity 1

qDrawbar

,

3/8 x 16 x 14”

Item #: 75-A

Quantity 1

qNut, 3/8 16

Item #: 7-6

Quantity 1

qWasher,

Flat 5/16”

Item #: 7-8

Quantity 1

qWasher,

Anti-Back Lash Shim

Item #: 82-050

Quantity 3

qVise, Bracket Bolt

3/8 x 1-1/4”

Item #: 36-610

Quantity 2

qPlug, Drill Chuck Arbor

Item #: S12898

Quantity 1

qVise, 0-90 Degrees

Adjustable Angle 3-1/4” Jaw

Item #: 32-110

Quantity 1

qCarbide Bit Set

Item #: 43-000

Quantity 1

qMachine Tool

Basics (DVD)

Item #: 12-004

Quantity 1

qCutting Fluid/ Tapping

Item #: 49-101

Quantity 1

Inventory Checklist

iii

Or Visit www.smithy.com

qOperator’s Manual

Item #: 83-949

Quantity 1

qManual Cover

Item #: 83-942

Quantity 1

qOil Can

Part # 80-100

Quantity 1

q5”3Jaw Chuck

Part # C30532

Quantity 1

qCompound

Angle Toolpost

Part # 45-110

Quantity 1

Missing Items?

If you find that an item is missing or defective from your Quick Start Tool Pack

Call Us TOLL FREE 1-800-476-4849

or send an e-mail to info@smithy.com

within 30 days of receiving your machine so that we may assist you immediately.

Our sales and service technicians are available 8am to 5pm ET, Mondays to Fridays.

iv For Assistance: Call Toll Free 1-800-476-4849

Midas 1220 XL Operator’s Manual

Chapter 1

Introduction

Congratulations on purchasing a Smithy Midas 1220 XL lathe-mill-drill. We are pleased

you chose Smithy to fulfil your machining needs.

The purpose of this manual is to give the machinist, beginniner or advanced, the

information he needs to operate the Smithy Midas 1220 XL. It will teach you about the

machine's parts and how to care for them. In fact, education is our primary goal. We'll

explain how to grind cutters, set up lathe tools, hold workpieces, and do all basic

machining operations.

Please read this operator's manual carefully. If you don't understand how your machine

works, you may damage it, your project, or yourself. If you want to learn more about

machining practices, Smithy offers books that meet the needs of machinists at all level of

experience. We also suggest using your local library as a resource. Enrolling in a

machining class will give you the best knowledge of machining.

If you have any questions not covered in this operator's manual, please call Smithy Co.

Our trained technicians will help you with any machining problems you may have. You

can reach them by dialing 1-800-476-4849 Monday through Friday, 8:00 am to 5:00 pm

Eastern time.

We are always interested in your suggestions to improve our products and services. Feel

free to contact us by phone or in writing. If you have comments about this operator's

manual, or if you have a project you'd like to share with other Smithy owners, contact the

Communications Director

, Smithy Co., PO Box 1517, Ann Arbor, MI48106-1517.

We look forward to a long working relationship with you. And thank you again for putting

your trust in Smithy.

Customer Information

This manual should remain with your Smithy machine. If ownership changes, please

include the owner's manual with the machine.

Model # ________________________________________

Serial #_________________________________________

(on the back of the lathe bed)

Purchase date ___________________________________

Delivery date ____________________________________

Sales Technician__________________________________

1-1

Or Visit www.smithy.com

Chapter 2

Safety

Your workshop is only as safe as you make it. Take responsibility for the safety of all who

use or visit it. This list of rules is by no means complete, and remembers that common

sense is a must.

1. Know your machine. Read this manual thoroughly before attempting to operate your

lathe-mill-drill. Don't try to do more than you or your machine can handle. Understand

the hazards of operating a machine tool. In particular, remember never to change speeds

or setups until the machine is completely stopped, and never to operate it without first

rolling up your sleeves or tying them at your wrists.

2. Ground the machine. The Midas 1220 XL has a three conductor cord and a three

pronged grounding type receptacle. Never connect the power supply without properly

grounding the machine.

3. Remove all adjusting keys and wrenches from the machine before operating. A chuck

key or misplaced Allen wrench can be a safety hazard.

4. Keep your work area clean and organized. Cluttered work areas and benches invite

accidents. Have a place for everything and put everything in its place.

5. Keep children away from the machine while it is in use. Childproof your shop with

padlocks, master switches, and starter keys, or store the machine where children do not

have access to it.

6. Wear appropriate clothing. Avoid loose fitting clothes, gloves, neckties, or jewellery

that could get caught in moving parts. If you have long hair, tie it up or otherwise keep

it out of the machine.

7. Use safetyglasses, goggles, or a face shield at all times. Use glasses designed for

machinery operation; regular glasses will not do. Have extras for visitors. Know when to

wear a face mask and earplugs, as well.

8. Check for damaged parts. Make sure the machine will run properly before operating it.

9. Disconnect the machine before servicing and when changing accessories. Shut power

off before making changes, removing debris, or measuring your work. Don't reach over

the machine when it's operating. Keep you hands out of the way.

10. Avoid accidental starts. Turn the switch to Off before plugging in the machine.

11.Secure your work. Flying metal is dangerous. Loose work can also bind tools.

12. Use the recommended accessories. Understand how to use them beforetrying them

out.

2-1 For Assistance: Call Toll Free 1-800-476-4849

13. Use the correct tool for the job. Don't try to make a tool into something it isn't.

14. Keep your mind on your work.

Pay attention to these simple rules and you will spend many safe, enjoyable hours in your

workshop.

Remember: Your safety largely on your practices. Modifying your machine may void the

warranty and create potential hazards.

Safety

2-2

Or Visit www.smithy.com

Chapter 3

Knowing Your Machine

The Midas 1220 XL has a 3/4 hp, 110 V motor. The motor powers the lathe and millhead

through the main belt drive and the mill/drill belt drive.

Apositive lock clutch in front of the spindle pulley transfers power to either the lathe or

the mill. The clutch has three positions. To power the lathe, pull the clutch handle out. To

power the mill, push the clutch all the way in. The middle position is neutral. Always shift

the clutch with the motor turned off.

The Smithy can use V-belts or round polyurethane belts. The latter produce less dust and

is easier to change than standard V-belts.

The lathe runs at six speeds from 160 to 1600 rpm. To change lathe speeds, adjust the

belts in the main belt-drive system. This system uses three pulleys: the motor pulley,

floating idler pulley and spindle pulley.

To run the lathe at lower turning speeds, use two belts. Install one between the motor

and idler pulleys and the other between the idler and spindle pulleys. To increase the

speed, move the spindle belt in two more positions on the pulleys.

For higher ranges, use one long belt from the motor pulley directly to the spindle pulley.

You can adjust this belt to three different positions on the pulleys.

The millhead also has a belt-drive system. It uses only one belt, adjustable to either the

top or bottom position on the pulleys. These two positions, in conjunction with the main

belt drive, let you select 12 speeds ranging from 125 to 1600 rpm for milling or drilling.

3-1 For Assistance: Call Toll Free 1-800-476-4849

Chapter 4

Caring For Your Machine

The Midas 1220 XL is a delicate, precision tool with ground ways and hand-scraped

bearing surfaces under the table and carriage. Any rust spot or battering of the ways, any

chips or grit between close fitting parts, will affect the accuracy of this fine tool. Follow

these guidelines whenever you use your Smithy machine.

When you finish working, wipe machined surfaces with a clean, oily rag. Never leave the

machine without this thin film of protective oil over all parts that might rust, especially

ground finished parts.

Never lay wrenches, cutting tools, files, or other tools across the ways of your lathe. The

slightest dent or burr could impair its accuracy.

Before inserting collars, centers, adapters, or drawbar attachments in either the spindle

or tailstock spindle, wipe them with a clean, oily rag. Also wipe all internal surfaces

carefully with an oily rag on a ramrod. Chips or dirt on the centers or in the spindle nose

can scratch or mar surfaces and interfere with the assembled part's alignment.

Lubricate the machine beforeeach use (see Section 6.4)

4-1

Or Visit www.smithy.com

Chapter 5

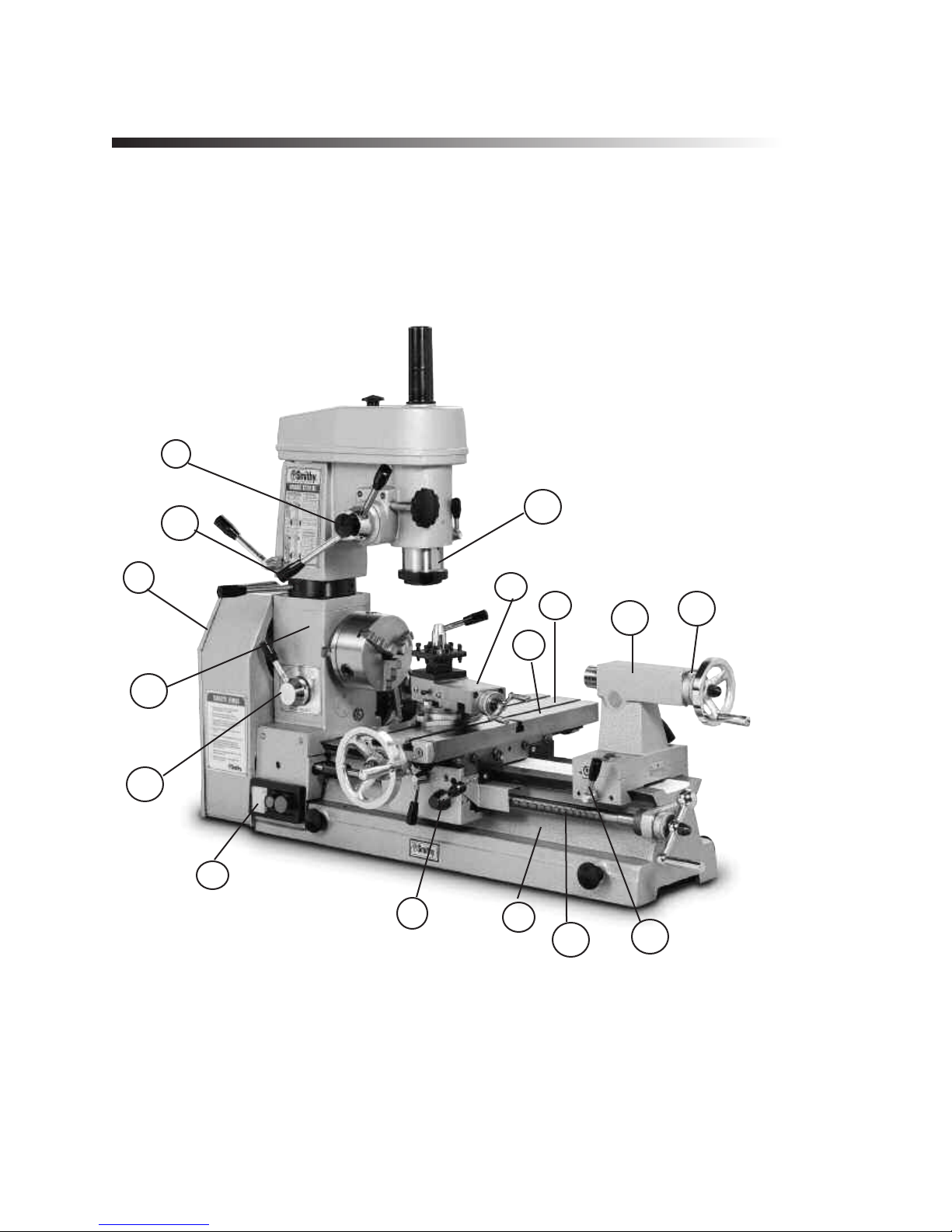

Basic Parts of the MI-1220 XL

To learn the operations of your machine, you have to know the names and functions of

its basic parts.

Figure 5.1 Basic parts of the MI-1220 XL

1.

Bed

-The Bed (Figure 5.1) is the machine's foundation. It is heavy, strong and built

for absolute rigidity. The two ways on the top are the tracks on which the carriage and

tailstock travel. To maintain an exact relationship between toolpoint and workpiece from

one end of the machine to the other

, the ways must be absolutely true and accurately

aligned to the line of centers and to one another.

5-1 For Assistance: Call Toll Free 1-800-476-4849

21

20

19

17

16

15

11

10

9

8

7

6

5

42

1

2.

Carriage

-The carriage consists of the saddle and apron. It moves by hand or power

along the bed, carrying the cross slides, compound rest, and toolpost. Its function is to

support the cutting tool rigidity and move it along the bed for different operations. It locks

into place by tightening the carriage lock under the cross slide handwheel.

3.

Change Gears

-The change gears cut different thread pitches. They also determine

the feed rate. Five change gears come installed on the machine; others are packed with

it.

Figure 5.2 Your machine arrives with this gear configuration. The C gear, behind B

meshes with D. Note the top two gears are permanent.

4.

Compound Rest

-Mounted on the cross slide, the compound rest swivels to any

angle horizontal to the lathe axis to produce bevels and tapers. Cutting tools fasten to a

toolpost on the compound rest. The calibrations on the front of the base are numbered

in degrees from 60 degree right to 60 degree left.

5.

Cross Slide

-The T-slotted cross slide (Figure 5.1 and 5.3) moves crosswise at 90

degree to the lathe axis by manual turning of the cross-feed screw hand-wheel. It also

serves as the milling table.

Figure 5.3 The cross slide moves laterally when you turn the cross slide handwheel.

Basic Parts of the MI-1220 XL

5-2

Or Visit www.smithy.com

Gib Adjustment

Screw

Cross Slide

Handwheel

Gib Adjustment

Screws

Saddle

Cross Slide

Lock

6.

Drill Press and Fine Feed Clutch

-Pushing in the drill-press clutch engages the fine

feed. To work the clutch, release the spring tension by rotating the drill-press handles

clockwise. Pull the clutch out to use it as a drill press or push it in to the fine feed. Use

the fine-feed handwheel to move the quill up and down.

7.

Forward / Off / Reverse Switch -

This is the main switch used to operate the

lathe. It is simply a forward / reverse switch for the motor. The motor turns counter

clockwise for normal lathe operation and clockwise for normal milling and drilling.

8.

Gearbox

-The gearbox (Figure 5.1 and 5.4) houses the belts that drive the spindle

and change gears for the powerfeed. Select the thread pitch (for threading) or the feed

rate (for turning) by changing the four change gears on the right side of the gear box.

Figure 5.4 The gearbox houses the belts and change gears.

9.

Half-nut Engagement Lever

-This lever, located on the apron, transmit power to

the carriage when rotated 90 degrees to the right.

10.

Half-nut Speed Selector

-The two-speed selector for powering the leadsrew is on

the front of the headstock. The leadscrew turns twice as fast in the II position as in the

Iposition.

11.

Headstock

-The headstock, which is secured to the bed, houses the gears that drive

the powerfeed and the taper bearings that secure the lathe spindle.

12.

Lathe Belt Tensione

r-To adjust the lathe belt (Figure 5.5), pull the tensioner

handle forwardto tighten the belt, back to loosen it.

5-3 For Assistance: Call Toll Free 1-800-476-4849

Midas 1220 XL Operator’s Manual

Figure 5.5 To adjust the tension on the lathe belt, move the tensioner handle forward or back.

13.

Lathe / Mill / Drill Clutch

-The lathe/mill/drill clutch (Figure 5.4) are inside the

gearbox. A three-position clutch, it transfers power to either the lathe or the mill, but not

to both at the same time. To engage it, rotate it slowly while pushing or pulling on the

clutch sleeve. Pulling it to the left runs the lathe, to the right (all the way in) runs the

mill/drill. The middle is neutral.

14.

Lathe Spindle

-The end of the lathe spindle face in the tailstock is the spindle nose.

The spindle nose, which has an MT4 taper, rotates the workpiece and drives lathe chucks

and other work holding devices. All attachments such as three and four jaw chucks bolt

to the spindle flange either directly or via an adapter plate.

15.

Leadscrew

-The leadscrew, which runs the length of the bed, moves the carriage

for lathe turning or thread cutting. It works both manually and under power. You can also

use it manually with the mill.

16.

Locks

-Locks on the cross slide (Figure 5.3) carriage (Figure 5.1), quill (Figure 5.6),

and tailstock (two), Figure 5.1 and 5.7, keep them from moving. During machining, lock

all lock except the one on the part you want to move.

Figure 5.6 The quill moves in and out of the millhead, carrying the spindle.

5-4

Or Visit www.smithy.com

Basic Parts of the MI-1220 XL

17.

Micrometer Dial Collars

-Just inside the handles of the tailstock (Figure5.1),

crossfeed (Figure 5.1), drill press (Figure 5.1), compound feed (Figure 5.1), and

leadscrew (Figure 5.1) there are collars calibrated in inches. The compound feed,

leadscrew, and crossfeed are calibrated in two thousandths, the tailstock in thousandths,

and the drill press in 40-thousandths.

These micrometer dial collars can move independently around the handle shafts. This

independent motion is called float. Floating dials on the cross slide, tailstock, and

leadscrew let you zero the collars at any point and read the feed travel from that point

on the dial for added accuracy.

18.

Mill Belt Tensioner -

To adjust the mill belt (Figure 5.7), swing the roller assembly

to the front and place the belt on the back of the roller. Loosen the roller assembly and

slide it back and forth in its slot.

Figure 5.7 With the millhead cover off, you can adjust the mill-belt tension.

19.

Millhead Height Adjustment

-Unlock the mill-head lock and place the height

adjustment handle in one of the three holes in the black collar. Turn the collar to raise

and lower the millhead.

20.

Mill Spindle

-The mill spindle (Figure 5.7) attaches to the quill, which moves in and

out of the head. The quill lock keeps the quill still when you install or remove tools from

it and while milling horizontally. Usually, tools fit into collets that attach through the

spindle via drawbars.

21.

Tailstock

-The tailstock, which provides right-end support for the work, moves

along the bed and can stop at any point. It has an MT3 taper and holds centers, drills,

reamers, taps and other tools. To move the tailstock spindle, turn the tailstock hand

wheel.

To offset the tailstock, adjust the two base-locking bolts (Figure 5.8). To offset to the left,

loosen the left adjusting bolt and tighten the right. To offset to the right, loosen the right

adjusting bolt and tighten the left.

5-5 For Assistance: Call Toll Free 1-800-476-4849

Midas 1220 XL Operator’s Manual

Table of contents

Other Smithy Lathe manuals

Popular Lathe manuals by other brands

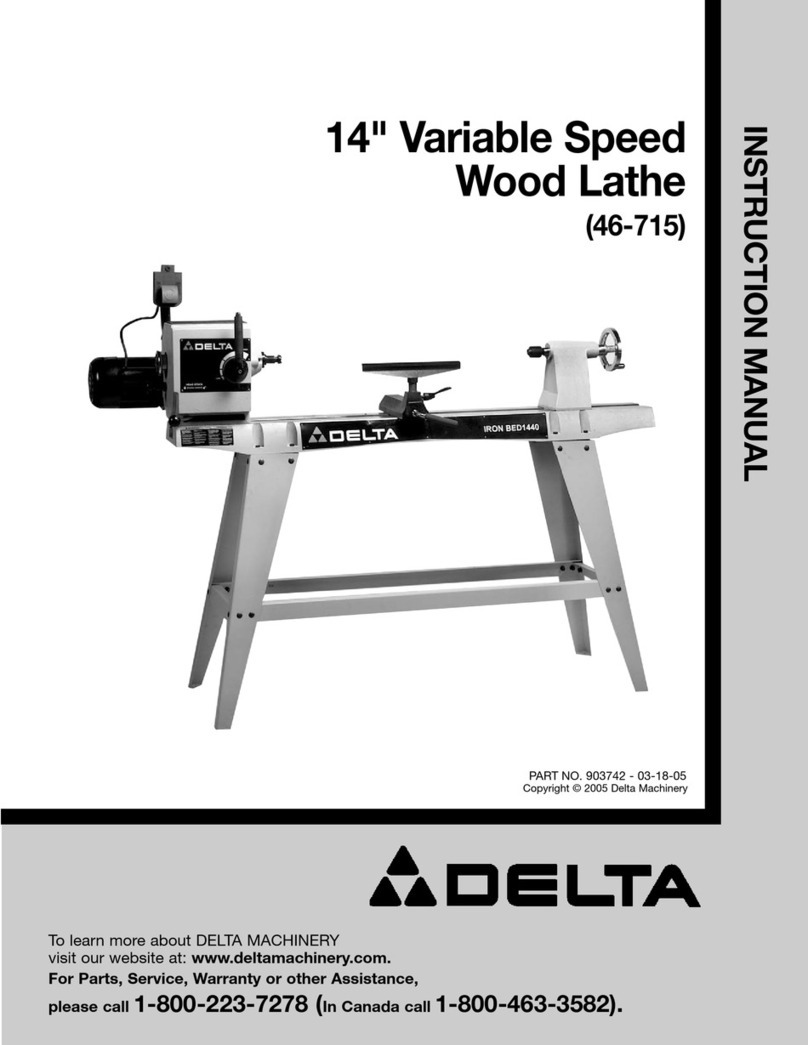

Delta

Delta 46-715 instruction manual

Oneway

Oneway 3008 instructions

LNS

LNS QUICK LOAD SERVO S3 Troubleshooting and Spare Parts Manual

Little Machine Shop

Little Machine Shop Mini Lathe user guide

Jet

Jet E-1440VS Operating instructions and parts manual

Central Machinery

Central Machinery 65044 Set up and operating instructions