SMK P100 User manual

Page 16

Operator’s Safety

and Service Manual

Cordless Sprayer

Model: P100

SMK Industries Inc

12839 Carpenter Trail

Carlisle, IA 50047 Email: john.00@smksprayers.com

Phone: 515-202-0052 Web: www.smksprayers.com

Page 1

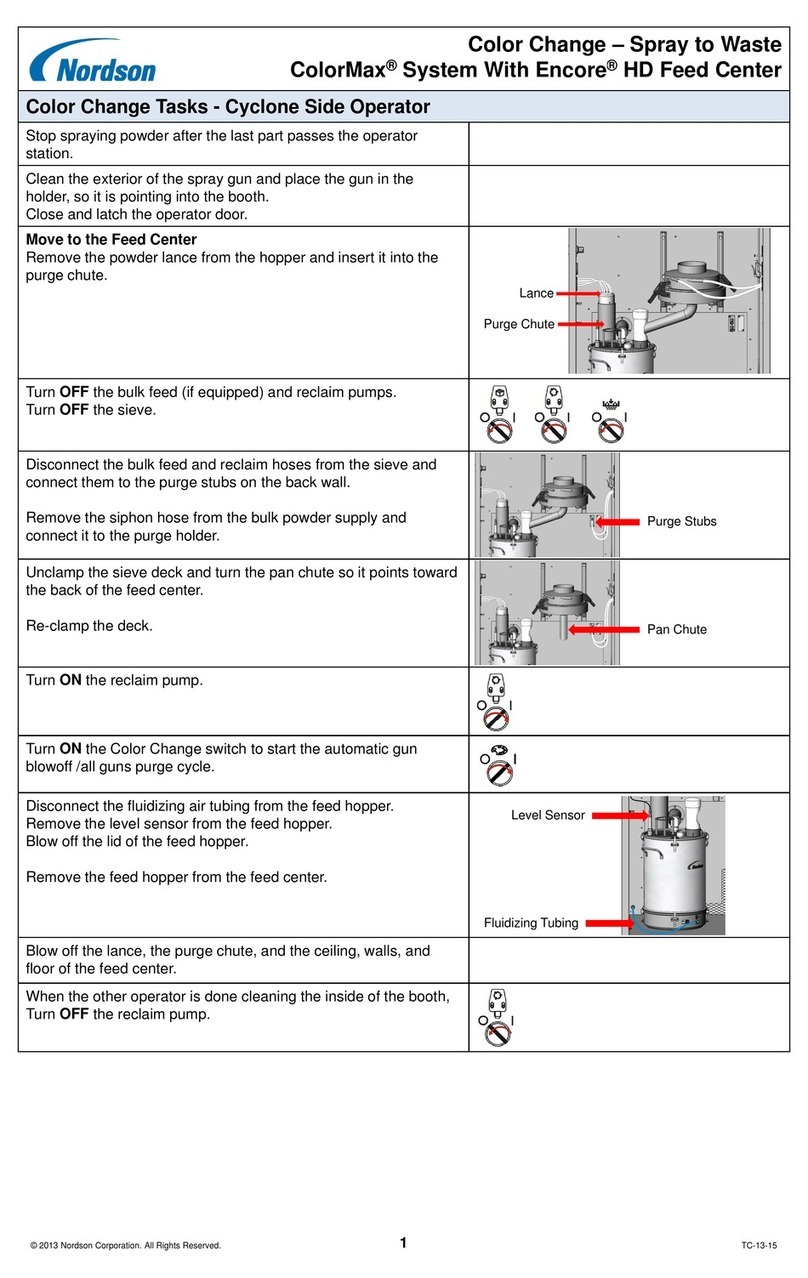

INTRODUCTION

You have purchased a quality SMK product, proudly made

in the USA. If you use and maintain your SMK product for

what it is intended, you will enjoy many years of safe,

reliable service.

The SMK “P100” portable sprayer utilizes the popular

SHURflo® pump technology. SHURflo® pumps provide

industry standard Viton® valves and Santoprene®

diaphragms and DeWalt rechargeable 12V –18V batteries.

SMK reserves the right to make changes to this manual without notice

Table of Contents

Safety Information 3

Introduction 3

Safety Precautions 4-5

Warranty 6

Proof of purchase 7

Warranty card 7

Specifications 7

Operation 8

Introduction 8

Before operating the sprayer 8

Contents of carton 8

Contents illustration 9

Assembly 10-11

Operating the sprayer 12

Clean up 12

Chemical compatibility 13

Troubleshooting 14

Maintenance 15

Service 15

Replacement parts 15

Page 2

Page 15

Maintenance

Maintenance of the unit is normally not required with the

exception of thoroughly cleaning the entire unit, by flushing

the internal components (see clean up on page 11) and

cleaning the exterior of the case, after each use.

Service

C A U T I O N

Service on this unit both within and after the warranty

period should be performed only by an authorized service

center. To find the service center nearest you Call 1-515-

953-9967

Replacement Parts

For a list of replaceable parts, please call 515-953-9967 for

assistance.

Page 14

Safety Information

Introduction

This Safety Alert Symbol is used to call attention to

items or operations which may be dangerous to those

operating or working with this equipment. The symbol can

be found throughout this manual and on the unit. Please

read these warning and cautions carefully before

attempting to operate the unit. Make sure every individual

who operates or works with this equipment is familiar with

all safety precautions.

W A R N I N G

GENERAL WARNING: Indicates information important to

the proper operation of the equipment. Failure to observe

may result in damage to the equipment and/ or severe

bodily injury or death.

C A U T I O N

GENERAL CAUTION: Indicates information important to

the proper operation of the equipment. Failure to observe

may result in damage to the equipment.

REFERENCES: For details on safety rules and regulations in the United States, contact

your local Occupational Safety and Health Administration (OSHA) office. Equipment

operated in other countries must be operated and serviced in accordance and

compliance with any an all safety requirements of that country. The publication of these

safety precautions is done for your information. SMK does not by the publication of these

precautions, imply or in any way represent that these are the sum of all dangers present

near SMK equipment. If you are operating SMK equipment, it is your responsibility to

insure that such operation is in full accordance with all applicable safety requirements

and codes. All requirements of the United States Federal Occupational Safety and

Health Administration Act must be me when operated in areas that are under the

jurisdiction of that United States Department.

Safety Decals

Carefully read and follow all safety decals. Keep them in good condition. If decals

become damaged, replace as required. Decals are available from authorized distributors.

Page 3

Safety Precautions

W A R N I N G

Before attempting to operate the unit, read and

understand all safety precautions and warnings.

Do Not use this unit in a combustive environment.

Do not use the unit when tired, ill, or under the

influence of alcohol, drugs or medication.

Inspect unit before each use for loose, broken,

cracked, split, or damaged parts. Do Not operate the

unit with loose or damaged component parts.

Always wear safety glasses or goggles that are

marked with ANSI Z87

Use only in daylight or good artificial light.

Never use unit without the proper factory authorized

accessories attached. When using the unit, ensure

that the sprayer discharge hose is securely

attached.

Do not use Acetone, Laquers, Laquer thinners, or

Acetate in this unit. These are flammable liquids and

will also permanently damage the internal

components of the sprayers pump.

Do not modify the unit

Use approved batteries only

Page 4

Trouble shooting

SPRAYER WILL NOT START

If battery is properly seated and fully charged

If On/Off switch is in the off position

If fuse is blown

SPRAYER WILL NOT PRIME

If pickup tube or discharge hose for restrictions

If you are out of product

For properly charged battery

For vacuum leak in pickup tube

SPRAYER OUTPUT VOLUME REDUCED

If pickup tube or discharge hose for restrictions

Sprayer wand and wand tip for restrictions

Material is too high in viscosity

Material is too cold

EXCESSIVE VIBRATION ON SPRAYER

For foreign debris on sprayer assembly or bucket

For loose hardware on sprayer assembly

Page 13

Chemical Compatibility

Refer to the following website for a chemical compatibility

chart to ensure that the material you wish to spray is

compatible with the pump components (EPDM,

Santoprene® and Polypropolene).

www.shurflo.com/pdf/industry/CCChart.pdf

C A U T I O N

IT IS YOUR RESPONSIBILITY TO ENSURE THAT THE

MATERIAL YOU ARE SPRAYING IS COMPATIBLE

WITH THE PUMPS COMPONENTS.

Page 12

C A U T I O N

Due to the nature of this unit, it is imperative the unit

is properly cleaned and flushed using the

appropriate fluids as recommended by the chemical/

compound manufacturer. Failure to clean the unit

after each use will result in the failure of the unit and

will result in loss of warranty coverage.

Do not assume fluid compatibility. If the fluid is

improperly matched to the pumps elastomers, a leak

or damage to the pump may occur. Be certain that

the material being sprayed is compatible with Viton®

Santoprene®, and Polypropolyne.

Attempting to spray liquids below the manufactures

recommended temperatures may affect the sprayers

ability to adequately perform. Low temperatures

may affect your materials viscosity.

Do not leave material in unit in between uses

Do not submerge or expose to excessive moisture

Page 5

Warranty

C A U T I O N

DO NOT ATTEMPT TO SERVICE THE UNIT BY REMOVING

THE COVER. REMOVAL OF THE UNIT COVER WILL VOID

THE WARRANTY. CALL THE SERVICE CENTER.

SMK Industries warrants this product to be free from

material or workmanship defects for a period of one year

from the date of manufacture. Alternatively, one year from

purchase, not to exceed two years from date of

manufacture.

Warranty does not apply when:

Unit is not used within the guidelines of this

manual.

Product or Parts are used or installed outside

the SMK authorized service center.

Incompatible fluids are used.

Misuse or Abuse.

Improper or inadequate cleaning of unit after

use.

In the event you need to utilize this warranty, the product or

part must be returned for examination, postage prepaid,

direct to the SMK Industries service center as instructed by

calling 515-953-9967. Proof of purchase date and an

explanation of the claim must accompany the

merchandise. If inspection discloses a defect, SMK will

either repair or replace the product with like equipment at

SMK’s expense. If no defect is found during the

inspection, or if the defect resulted from causes not within

the scope of SMK’s limited warranty, then the user must

assume all costs incurred returning and/or storing the

product.

All products and parts will be tested using SMK testing

criteria. Units found to be damaged, altered or otherwise

mistreated will not be covered under this warranty. Units

found not to be defective are subject to charges to be paid

by the returnee

Page 6

Operating the Sprayer

Keeping all safety and operating measures in mind You are

now ready to begin spraying. By squeezing the trigger

handle you will activate the sprayer to begin “priming” the

pump.

The pump is self priming and will not be damaged by

running dry. Priming time will vary depending on the fluid

viscosity and temperature. Priming should only take a few

seconds, depending on the material. Be certain the fluid

being pumped is compatible with the pump materials,

Viton®, Santoprene® and Polypropylene. For a partial list

of compatible fluids see appendix A. If it is not listed or you

are unsure, contact your chemical supplier. The pump is

intended for continuous or intermittent duty when the

proper operating criteria are met.

NOTE: “Intermittent Duty” is defined as; operated and/or

frequently started within a period of time that would cause

the motor to reach its maximum thermal limits. Once the

maximum thermal limit is obtained, a thermal breaker

switch will interrupt operation until the motor cools down to

normal operating temperature, then it will automatically

reset and resume operation.

Pump may cycle on and off at varying intervals depending

on viscosity and temperature of the material being sprayed.

Clean up

C A U T I O N

As with any type of sprayer, this unit will not function

satisfactorily if the unit is not clean. Thoroughly clean the

sprayer after EACH use by completely flushing the unit,

including all hoses and wand. The cleaning agent should be

whatever is recommended by the manufacturer of the material

that you are spraying. Pump the cleaning agent through the

sprayer until all traces of the previously sprayed material has

been removed from the unit.

Page 11pe

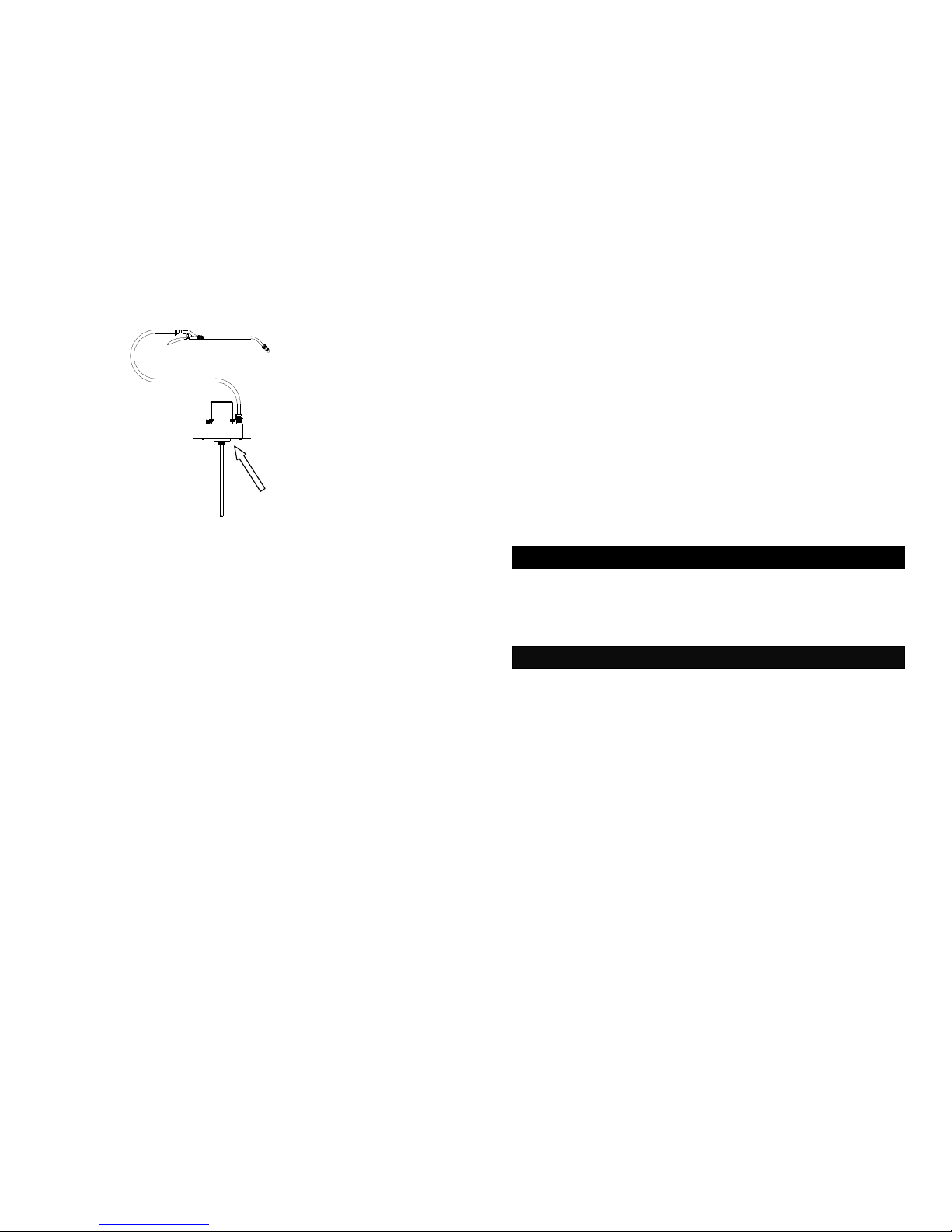

1. Slide the 3 inch diameter by ½ inch thick Foam Gasket over

the plastic inlet tube onto the metal fitting.

2. Remove the spout cover from the 5 Gallon Bucket of material

that you intend to spray.

3. Set the Sprayer unit on top of the Bucket by guiding the inlet

tube into the pouring spout of the bucket lid.

4. Set the Power Switch to the off position

5. Insert the Battery into the receptacle, when fully inserted it will

contact the Sprayer housing.

6. Rotate the Pump Handle towards the inlet side of the housing.

7. Raise the Bucket Handle up to the Sprayer handle into one of

the sets of notches.

8. Rotate the Sprayer and Bucket Handles together until it cams

over to a locked position.

9. Check the sprayer trigger handle to make sure the lever is not

locked in the open/ on position.

10. Turn on The Power Switch.

11. Adjust the Speed Control to the desired output.

12. You are now ready to begin spraying your material.

Page 10

SMK shall in no event be liable for death, injuries to

persons or property or for incidental, contingent, special or

consequential damages of any kind by the reason of use or

sale of any defective product or part. This limited warranty

covers units distributed in the United States of America

only.

This limited warranty is in lieu of all other warranties,

expressed or implied, and no other person is authorized to

give any other warranty or assume obligation or liability on

behalf of SMK Industries, Inc.

Products and parts must be flushed free of all fluids prior to

returning to SMK for warranty inspection.

PROOF OF PURCHASE

Please retain your dated sales receipt as proof of purchase

to validate the warranty period.

SPECIFICATIONS

Integral pump SHURflo® Model: SLV10-XA41

Pump motor voltage 12 Volt

Chassis Powder coated steel

Trigger Chapin®brand

Wand Chapin®brand

Wand tips Chapin®brand

Approved batteries Dewalt®12V –18V

or Interstate® brand 12V- 18V

Page 7

ration

Before Operating your Sprayer

W A R N I N G

Carefully read through this entire manual before attempting

to use your new product. Pay close attention to the safety

alerts symbols, warnings and cautions.

Contents of Carton

Contents of Carton include:

1. Cordless sprayer assembly

2. Sprayer trigger with hose

3. Wand extension tube

4. Suction tube

5. Owners manual

6. product warranty and registration card

7. adjustable cone spray tip

8. .50 fan spray tip

9. ½” thick foam bucket gasket

Battery and bucket not included

Examine all parts to ensure that everything is accounted

for and no damage has occurred during shipment. Any

damaged or missing part must be replaced before

attempting to use this product.

Page 8

Assembly

To prepare the unit for operation, assemble the sprayer as

follows:

13. Attach the Sprayer Hose assembly to the Garden Hose Thread

Fitting located on the side of the Sprayer housing.

14. Attach the Inlet Tube to the fitting located on the bottom of the

Sprayer housing.

Page 9

Table of contents

Other SMK Paint Sprayer manuals