Smoke Guard 2100 Manual

Doc #2102, Rev 2 1

Operation & Maintenance Manual

for Model 2100 Fire+Smoke systems from Smoke Guard, Inc.

287 N. Maple Grove - Boise, ID 83704

Phone: (800) 574-0330 Fax: (208) 639-7851

E-Mail: info@smokeguard.com

Website: http://www.smokeguard.com

Call your local Smoke Guard distributor

for answers to questions about your system

Doc #2102, Rev 2 2

Table of Contents

Table of Contents 2

Introduction 3

The responsibilities of the building owner 4

Testing frequency ....................................................... 4

Alterations and additions ............................................. 4

System acceptance testing........................................... 4

Operation 5

What makes up the Model 2100 Smoke Guard system..... 5

How the Smoke Guard system works ............................ 6

What to do if the curtain has deployed .......................... 7

Maintenance/Testing 8

Before you test........................................................... 8

Functional test and visual inspection ............................. 9

Record Keeping 10

Why keep records?.....................................................10

What records should you keep? ...................................10

Mandatory Semi-Annual Cycle Test 11

Appendix: Troubleshooting a System Fault 12

System fault annunciation...........................................12

Clearing a system fault ...............................................12

M2100 Status LED interpretations ................................13

Notes on status LED interpretations .............................14

Recommended corrective action ..................................14

Doc #2102, Rev 2 3

Introduction

This is the official operation, maintenance, and testing manual for the Model

2100 Smoke and Model 2100 Fire+Smoke curtains from Smoke Guard, Inc.

NOTE: Read this entire manual before operating, maintaining or testing your

Smoke Guard system.

The Smoke Guard Model 2100 Fire+Smoke system is a code compliant, 2

hour (120 minute), Fire Endurance rated curtain and complies with the UL

10D standard. It is also rated to UL 1784 according to the requirements of

smoke and draft control assemblies defined in NFPA 105.

The M2100 is designed to be installed into the building structure with the

main housing located at ceiling level and guides mounted to each wall of the

opening to be protected. The main housing contains a smoke or fire rated

curtain stored around a curtain tube. During normal operation and under

alarm conditions, the curtain unwinds from the tube towards the floor.

Guides at each side maintain pressure sealing. The descent of the curtain is

normally regulated by a DC motor at an average of at least 6 inches per

second. The curtain will also deploy entirely by gravity in the event of power

loss. The M2100 controller will interface with a smoke detector or fire alarm

circuit. The controller also controls the DC motor, which deploy and retract

the curtain. Battery backup power ensures operation in the event of AC

power loss.

As with other components of your fire protection system, periodic

maintenance is required. The building owner must inspect and test each

Smoke Guard unit at least once every six months. Failure to properly test

and maintain your Smoke Guard unit could result in death or serious injury in

the event of a fire.

Doc #2102, Rev 2 4

The responsibilities of the building owner

The Smoke Guard system is considered “connected equipment” as defined in

NFPA 72. As such, the owner or designated representative shall be

responsible for inspecting, functional testing, recording of tests, and

maintaining the system. Delegation of responsibility shall be in writing, with

a copy made available to the authority having jurisdiction under the

provisions of the building code and local ordinances.

Testing frequency

Visual inspection, functional testing, and maintenance described in this

manual must be performed and recorded at intervals not longer than six

months, more frequently where required by the authority having jurisdiction.

Alterations and additions

Visual inspection shall ensure that there are no changes that would affect

equipment performance—such as building modifications, occupancy hazards,

and environmental effects. Smoke Guard recognized personnel must

perform any alterations or additions to your system.

System acceptance testing

Acceptance tests shall be performed after system components are added or

deleted, after any modification, repair, or adjustment to the system hardware

or wiring.

Doc #2102, Rev 2 5

Operation

The following topics explain the function of your M2100 Smoke Guard

system.

What makes up the Model 2100 Smoke Guard system

Housing: The housing consists of curtain assembly mounted within a steel

housing with tubular motor and drive components.

Guide system: The curtain is captured vertically on both sides by guides.

Guides can be mounted on a wall face, recessed into pockets or mounted

within an opening jamb. The curtain deploys within a continuous vertical slot

in each guide.

Curtain: The curtain is made of a smoke-rated or fire+smoke-rated fabric

and is equipped with a bottom bar to seal the curtain at the floor.

Controller: The main controller houses terminal blocks to receive main

power, a 24Vdc power supply, controller PCA, batteries and terminal blocks

to interface with curtain and building connections. It also contains a user

interface PCA, which has three indicator LEDs, and a test deploy switch. The

system is powered by an input source supplying 100-240VAC 50/60Hz. A

24VDC power supply provides power for the entire curtain system. Two 12V

sealed lead-acid batteries provide power should the primary power be lost.

An optional dual system controller configuration contains an additional

controller PCA and terminals to control a second independent curtain system.

Door activation switches: Optional door activation switches, located on the

right as occupants approach the curtain from either side, allow occupants to

rewind the curtain temporarily by pressing the switch.

Keyed test-deploy switch. An optional keyed wall switch simulates an

alarm condition and is provided to facilitate testing. (NOTE: There is also a

test-deploy switch on the main controller near the user-interface LEDs.)

NOTE: The smoke detector or other initiating device is part of the building

smoke and fire alarm system and NOT a component of the Smoke Guard

system. However, it is an essential component, vital to the proper operation

of the system and all other connected equipment. The smoke detecting

system must therefore be inspected, tested, and properly maintained in

accordance with the equipment manufacturer’s guidelines as well as the

requirements of the authorities having jurisdiction. Emergency power to the

smoke detector should be maintained in accordance with NFPA 70.

Doc #2102, Rev 2 6

How the Smoke Guard system works

Ready: The system connects to an auxiliary relay in the smoke detector

located nearby. The curtain is rolled up and concealed within the housing.

Alarm: When the local smoke detector goes into alarm, the curtain deploys,

stopping when it reaches the floor. A bottom bar along the bottom of the

curtain creates a seal at the floor when the curtain is fully deployed.

Deployed: When the unit is deployed, it remains deployed until the smoke

detector clears. The curtain may bow slightly in or out due to differential

pressure.

Optional door activation switch: For units equipped with these switches,

someone requiring passage through an opening where the curtain is

deployed can press this switch (mounted to the right side of the curtain as

approached from either side) and the curtain retracts temporarily. The

curtain then re-deploys if alarm conditions still exist; otherwise, the curtain

retracts fully and remains in ready mode.

Retract: The curtain retracts automatically when the smoke detector clears.

(Pressing the optional curtain retract switch retracts the curtain only

temporarily while an alarm condition exists.)

Input/output signal monitoring: The controller monitors the integrity of

various subsystems. If the controller should detect any anomalies during

operation an audible alarm will sound and reports the problem via three

status LEDS on the outside of the controller.

Status LED flash code—LED flash patterns visible from the outside of the

control box identify the system fault. Refer to the appendix in this document

“Appendix: Troubleshooting a System Fault” at the end of this document to

determine the fault and appropriate corrective action.

If the issue cannot be resolved, notify an authorized service representative or

contact Smoke Guard at 800-574-0330.

Doc #2102, Rev 2 7

What to do if the curtain has deployed

The curtain should only deploy if the smoke detector goes into alarm. If

equipped with an optional door activation switch, press the switch to rewind

the curtain temporarily. If alarm conditions continue to exist, the curtain re-

deploys. After the smoke detector clears, the curtain retracts automatically.

If the unit loses power for a period exceeding the capacity of the integral

battery backup system (approximately 15 hours) the curtain will remain

deployed until main power is restored.

If a unit deploys during a fire, notify Smoke Guard (800-574-0330) for a free

service visit.

Doc #2102, Rev 2 8

Maintenance/Testing

The following topics cover the requirements for testing, inspecting, and

maintaining your Smoke Guard system.

Before you test

NOTE: These instructions assume that installation is complete and the

installer has conducted the tests specified in the installation manual to verify

proper installation.

Prior to testing, complete the following tasks:

Review the information regarding the system included in this manual.

Notify anyone who might receive an alarm.

Notify building occupants.

Doc #2102, Rev 2 9

Functional test and visual inspection

A functional test involves triggering the local smoke detector, observing the

deployment of the system, and retracting the curtain. Locate the service

record at the back of this manual and fill it out as you proceed. You are

responsible for reporting any required adjustments to Smoke Guard or the

distributor who installed the unit.

1. Locate the status LEDs on the outside of the control box and verify

that the system is in standby state by the presence of one

continuously-lit, green LED. (If all LEDs flash sequentially, the system

is running a normal system check.)

2. Activate the smoke detector or other initiating device connected to the

unit per manufacturer’s recommendations.

3. Observe curtain deployment to ensure smooth motion. If motion is

jerky, check the guides for obstruction.

4. While deployed, verify that there is one continuously-lit, green LED on

the control box indicating successful deployment.

5. Visually inspect the curtain assembly for damage to the curtain

material or bottom bar at the floor. If any damage is present,

immediately contact Smoke Guard or local distributor for repair

procedures.

6. Retract the curtain by clearing the smoke detector.

7. Observe curtain retraction to ensure smooth motion.

8. Again, verify that the system is in standby state by the presence of

one solid green LED. (If all LEDs flash sequentially, the system is

running a normal system check.)

If there is an optional door activation switch:

9. Activate the smoke detector a second time to deploy the system.

10. Press the door activation switch. The curtain should retract, pause,

and re-deploy.

11. If present, press the other door activation switch. The curtain should

retract, pause, and re-deploy.

12. Verify that the system is in standby state by the presence of one solid

green LED. (If all LEDs flash sequentially, the system is running a

normal system check.)

13. Retract the curtain by clearing the smoke detector.

Doc #2102, Rev 2 10

Record Keeping

The following topics explain how to maintain a record of the tests that you

perform on your Smoke Guard system:

Why keep records?

What records should be kept?

Why keep records?

According to NFPA 72 (2002 edition), the building owner is responsible for

keeping the maintenance and testing record for the life safety devices in their

building. Records should be kept available for examination by any authority

having jurisdiction upon request.

What records should you keep?

A permanent record of all inspections, testing, and maintenance shall be

retained by the building owner, including all the information below:

test date

name of person performing inspection, maintenance, and/or tests

functional test of smoke detectors signaling the system per NFPA 72

location of M2100

any modifications or alterations made to the system

name and signature of the tester

11

Mandatory Semi-Annual Cycle Test

12

Appendix: Troubleshooting a System Fault

If the curtain fully deploys on its own (fall-by-gravity) this indicates that it

has completely lost power: main power is off and the battery backup voltage

has dropped below a critical threshold. If the controller is emitting a steady

audible alarm the system is in a fault state. Refer to the sections below.

System fault annunciation

If one of the system-monitored input/output signals becomes abnormal, the

control module enters a fault state, warning that system functionality may be

compromised. The controller will emit a steady audible alarm. Further

information is displayed through flashing LED patterns viewed from the right

side of the controller. All flashing LED patterns are provided below as well as

recommended corrective action.

Clearing a system fault

Clear a system fault by pressing, with a small probe, the test deploy switch

located on the front of the controller adjacent to the indicator LEDs. Pressing

the test deploy switch once will silence the audible alarm and the system will

remain in a fault state. In order to clear a system fault, first correct the

problem (see “Recommended Correct Action” page 14) and then press the

test deploy switch again to attempt to clear the fault. If successful, the fault

is cleared and the system remains in the ready state. If the problem

persists, the system will continue to indicate the error with the audible alarm

and the flashing LED pattern. If the audible alarm is silenced but the fault is

not cleared the audible alarm will be reactivated after 4 hours to remind

personnel that the problem persists.

Dual System Controller Configuration

The Dual System Controller contains two independent control systems within

one housing with connections to control two independent curtains. There is a

shared common power supply but otherwise the systems function separately.

There is an indicator LED/test deploy switch interface for each system. The

troubleshooting procedures below apply equally to each system.

13

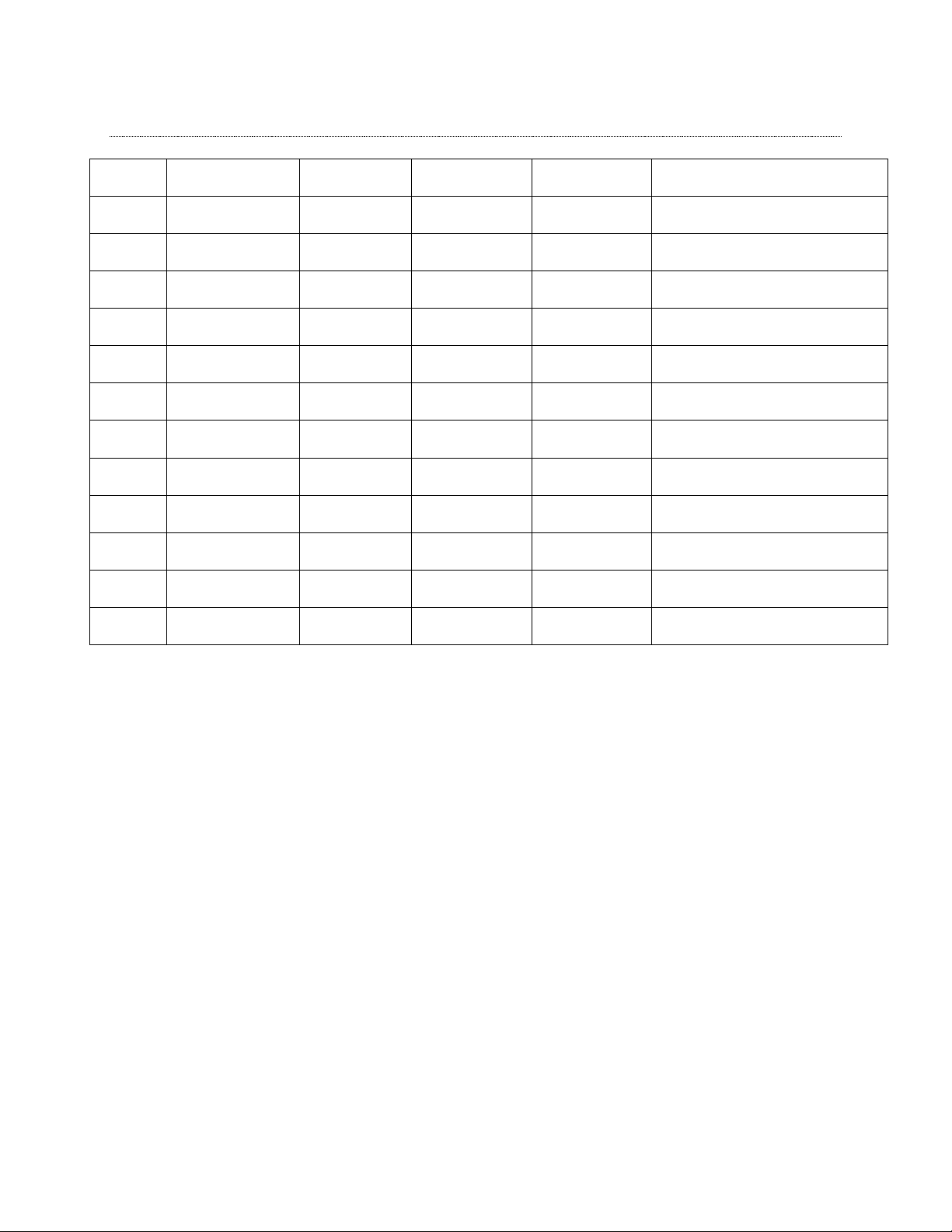

M2100 Status LED interpretations

State

Description

GREEN

Status

YELLOW

Fault Code

RED

Trouble

Notes

Normal 1

System OK

ON

OFF

OFF

System fully functional.

Normal 2

Power on/ Self-

Test active

Sequential

Flash

Sequential Flash

Sequential Flash

Approximately 12 seconds to

complete.

Normal 3

System in

calibration

1-Blink on .5

S Off 5 S

1-Blink on .5 S

Off 5 S

OFF

Normal 4

LAS active

1

1-Blink on .5 S

Off 5 S

OFF

Normal operation with Full

deploy.

Normal 5

No AC, battery

active

1-Blink on .5

S Off 5 S

OFF

1-Blink on .5 S

Off 5 S

Low voltage power supply or main

power off, running on battery.

Error 1

Battery Health

Low/Critical

OFF

1-Blink on .5 S

Off 5 S

ON

Battery low or controller charging

problem.

Error 2

Out of calibration

OFF

2-Blink on .5 S

Off 5 S

ON

If error occurs on power-up then

out of calibration.

Error 3

LAS open circuit

OFF

3-Blink on .5 S

Off 5 S

ON

No EOL detected.

Error 4

Moving timeout

OFF

4-Blink on .5 S

Off 5 S

ON

Motor, controller or limit switch

problem.

Error 5

Motor over-

current

OFF

5-Blink on .5 S

Off 5 S

ON

Motor stopped due to excessive

current draw.

Error 6

Edge Sensor fault

OFF

6-Blink on .5 S

Off 5 S

ON

NOT IMPLEMENTED

Error 7

Braking fault

OFF

7-Blink on .5 S

Off 5 S

ON

Curtain will fall by gravity due to

failed braking action.

14

Notes on status LED interpretations

1. System status LED (green) is normally on solid and changes to blink

once per 5 seconds when running on the battery.

2. Fault LED (yellow): Blinks for fault conditions when the RED led # 2 is

on solid. This LED will be off and then blink on for brief periods (1/2

second for the number of times indicated). It will then repeat this

sequence after a delay of 5 seconds in between.

Recommended corrective action

Error 1—battery health is low: Verify battery electrical connectors are

secure within the controller housing. Replace batteries if faulty (combined

battery voltage measures less than 24.5VDC).

Error 2—out of calibration: If the system has not been calibrated, this

error will appear at power-up. Perform a calibration to clear the fault.

Error 3—local alarm system open circuit: The local alarm system,

whether a smoke detector or fire alarm, requires an end-of-line (EOL) diode,

provided by Smoke Guard, installed at the normally open contacts of the

device. This error will occur if the diode is not connected or is faulty, or if the

wiring between the diode and controller is interrupted.

Error 4—moving up or down timeout: Indicates that movement was not

detected when the system was deploying or retracting. Ensure that the

curtain is not blocked or jammed. If it is observed that the curtain did

actually move, it is likely that the motor position sensor is faulty. If no

movement is observed, then there is potentially a faulty motor or controller.

Notify the local distributor or Smoke Guard at 800-574-0330.

Error 5—motor overcurrent: The motor has drawn an excessive amount

of current. Check system alignment and blockage. This could also represent

faulty motor or wiring. Notify the local distributor or Smoke Guard.

Error 6—edge sensor fault: Currently not implemented.

Error 7—braking fault: The controller uses the motor to hold the curtain in

the retracted position. If the controller determines that the curtain has

moved downward while it was supposed to be retracted, it assumes the

braking action of the motor has failed. If the problem persists then notify

the local distributor or Smoke Guard.

15

16

Table of contents

Other Smoke Guard Firefighting Equipment manuals