Smokeeter SE 10 User manual

Electronic Air Cleaner

MODEL SE 10

OWNER’S MANUAL

To Place an Order Call ACS, Inc. @(800) 878-5030

1

POWER REQUIREMENTS

115 VAC, 60 Hz,

.9 Amps Max.

POWER CORD

10' 16 ga. with molded

grounded plug

POWER CONSUMPTION

104 Watts (Max.)

AIR HANDLING CAPACITY

90 to 250 CFM

WEIGHT

HANGING................27 lbs (10 KG)

SHIPPING................32 lbs (12 KG)

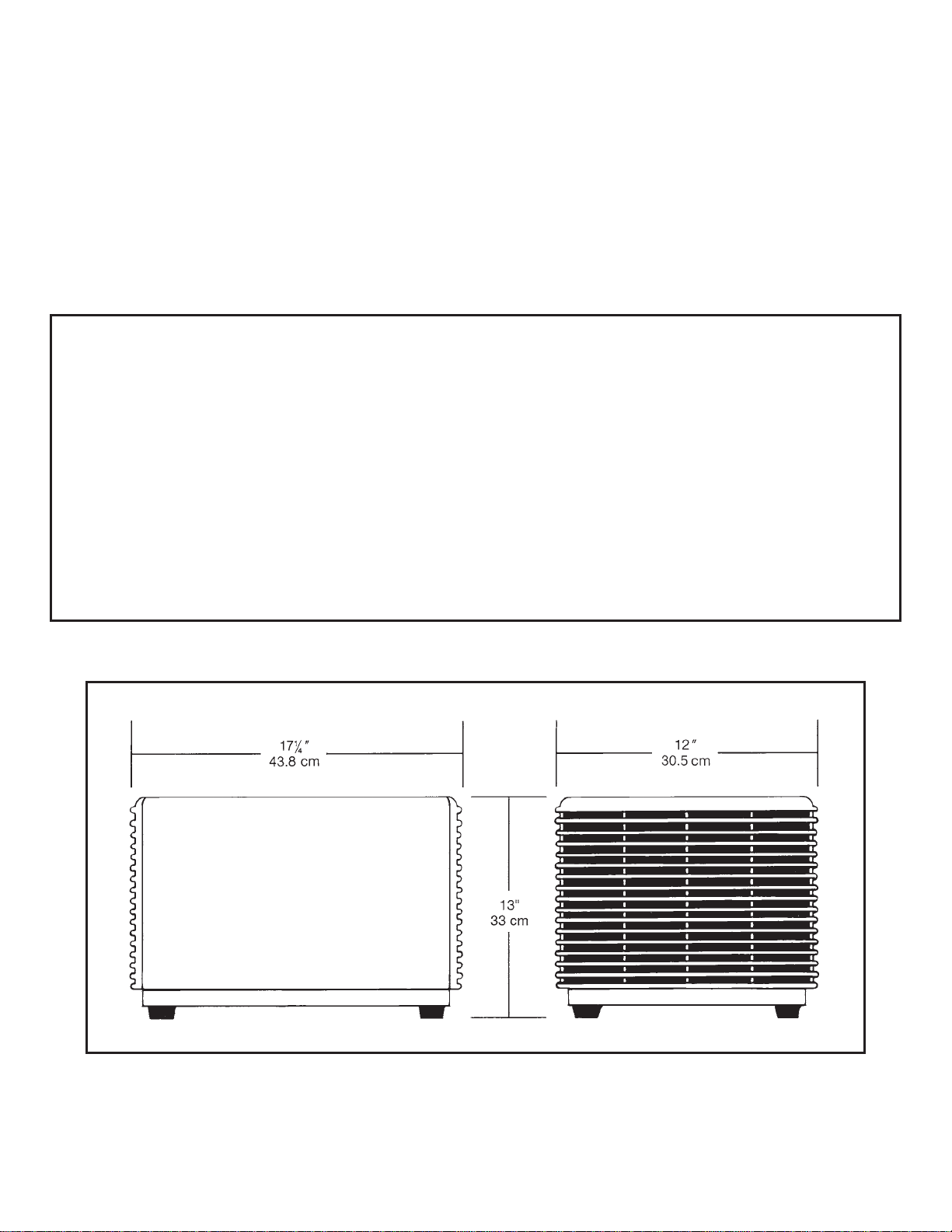

DIMENSIONS

Height Width Length

13" 12" 171⁄4"

(33 cm) (30.5 cm) (43.8 cm)

SPECIFICATIONS

MODEL SE 10

2

MODEL SE 10

TABLE OF CONTENTS

SECTION PAGE

I. Introduction 3

II. Inspection of Equipment 3

Ill. How Your SMOKEETER/CRYSTAL-AIRE Operates 3

IV. Installation 4

V. Operation 4

VI. Cleaning 5

THE FOLLOWING INFORMATION IS PROVIDED

FOR TRAINED SERVICE PERSONNEL ONLY

VII. Periodic Maintenance and Troubleshooting 6

VIll. Replacement Parts 8

IX. Illustrated Parts 10

Unicell Assembly 12

Wiring Diagrams 13

IMPORTANT NOTICE

BEFORE OPERATION, PLEASE REMOVE ALL PACKING MATERIAL FROM

INSIDE UNIT. THIS CAN INCLUDE MARKED TIE DOWN SCREWS,

CARDBOARD, STYROFOAM AND PLASTIC WRAP ON CARBON FILTER.

MODELS VARY IN MATERIAL USED.

3

I. INTRODUCTION

Your new air cleaner is the most advanced product of

its type on the market today and will provide a safer,

healthier environment. As you begin its operation, we

would like to remind you of a few important facts.

First, we appreciate your business, and because we

appreciate your business, we have manufactured an air

cleaner engineered to rigid specifications, incor-

porating the latest technological advances. It is built

using the best materials available and is subjected to

rigorous quality control checks. A warranty backs

every air cleaner that leaves our factory.

Second, like any piece of equipment, your air cleaner

needs periodic maintenance. Properly cared for, it will

operate at peak efficiency for many years to come.

Finally, while we hope you never have any problems,

United Air Specialists, Inc. (UAS) is always ready to

lend assistance through our factory-trained sales-

people. Should you need information or service, con-

tact your local salesperson or the Customer Service

Department at United Air Specialists, Inc., 4440 Creek

Road, Cincinnati, Ohio 45242, 1-800-252-4647.

II. INSPECTION OF EQUIPMENT

Upon receipt of your SMOKEETER/CRYSTAL-

AIRE, check for any shipping damage. A damaged

carton indicates that the equipment may have

received rough handling during shipping that may

have caused internal damage. Notify your delivery

carrier and enter a claim if any damage is found.

Before operating unit, remove all packing material

including carbon afterfilter, packaging and unicell

shipping screws.

III. HOW YOUR SMOKEETER/

CRYSTAL-AIRE OPERATES

The air mover draws air through the ionizer. As par-

ticles pass through the ionizer section, they are given

an intense positive charge. These charged particles

are then collected on cell plates. The clean air is

redistributed into the room through an outlet diffuser.

An activated carbon afterfilter helps control odors

in the air.

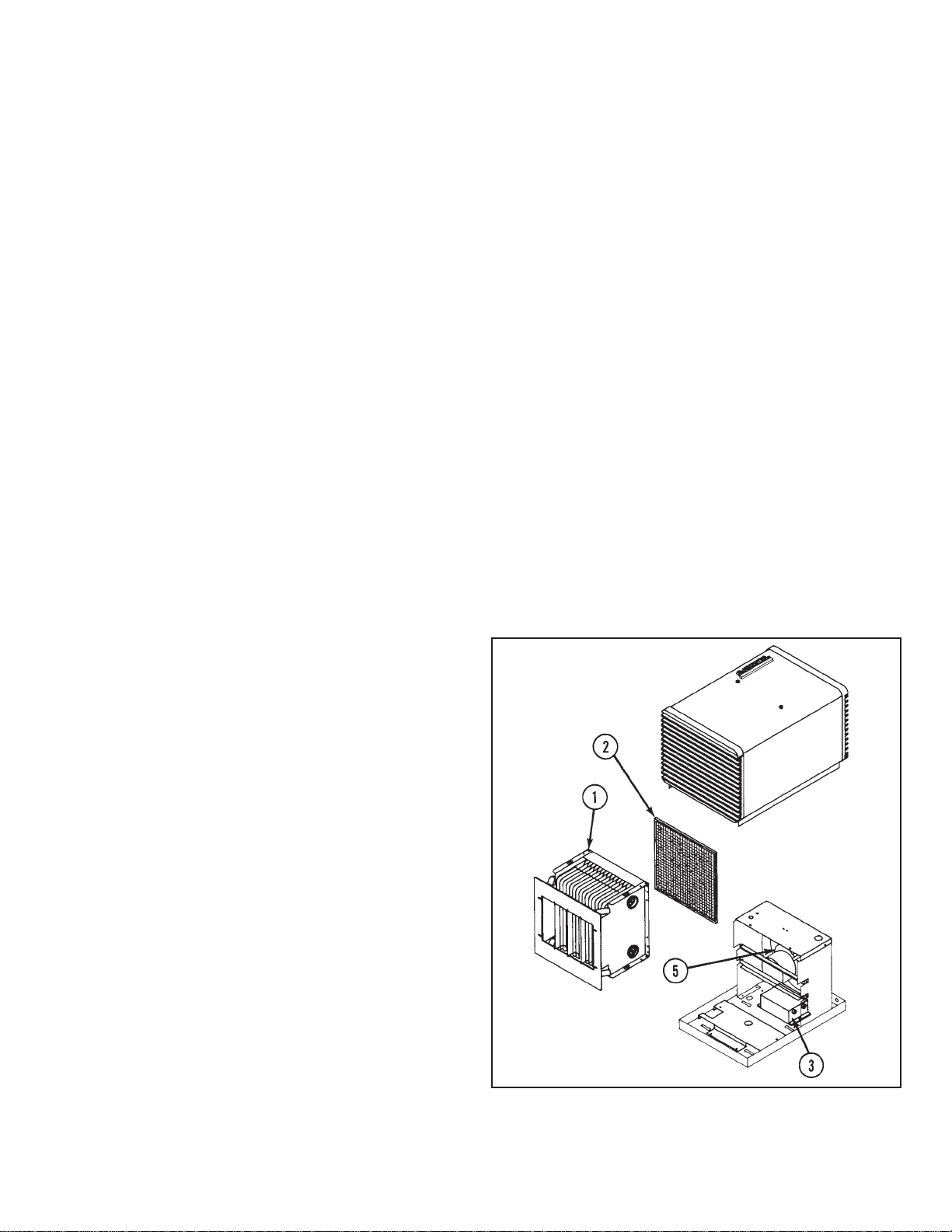

COMPONENTS MAKE IT WORK

(See Figure 1)

1. UNICELL is comprised of the ionizing section and

the collecting section. The ionizing section is made

of fine tungsten wires supported between metal

plates. When high voltage is applied to these

parts, a “corona” field is generated, imparting a

high voltage charge on particles that pass through

it.

The collection section is made up of a series of flat

metal plates. These plates act like a magnet and at-

tract the charged particles, removing them from the

air. The plates are alternately charged positive and

ground. The positive plates repel the particles while

the ground plates attract them, yielding a very high

efficiency.

2. ACTIVATED CARBON AFTERFILTER helps remove

odors in the air.

3. POWER PACK is a dual high voltage supply. It sup-

plies 12,000 volts DC to the ionizer and 6,000 volts

DC to the collection cell.

4. SOLID-STATE SPEED CONTROL (not shown) allows

airflow adjustment.

5. AIR MOVER is a three blade fan designed for quiet

operation. The motor features an automatic reset

thermal protector.

FIGURE 1

4

FIGURE 2

IV. INSTALLATION

NOTE: This product has been designed specifically

for commercial and residential applications

such as offices, conference rooms, cafeteria

and living areas. United Air Specialists

assumes no responsibility for those applica-

tions unlike the aforementioned.

The SMOKEETER/CRYSTAL-AIRE is designed to

draw the contaminated air through the unit and

exhaust clean air back into the room. The clean

air is used to push contaminated air around the

room to the inlet of the unit. Directions of air

patterns and proper placement of the unit should

be established by your local SMOKEETER/

CRYSTAL-AIRE distributor or by United Air

Specialists, Inc.

The SMOKEETER/CRYSTAL-AIRE can be installed

by:

1. Placing on desk, file cabinet or other stable surface.

2. Mounting on a wall.

CAUTION: Power connection — The power cord

on this product should be used in con-

nection with a properly-sized and

appropriately located 115 VAC ground-

ed outlet receptacle. No alteration of

the power cord should be attempted

nor should extension cords be used.

To reduce the risk of electric shock,

this equipment has a grounding-type

plug that has a third (grounding) pin.

This plug will only fit into a grounding-

type power outlet. If the plug does not

fit into the outlet, contact qualified

personnel to install the proper outlet.

Do not alter the plug in any way.

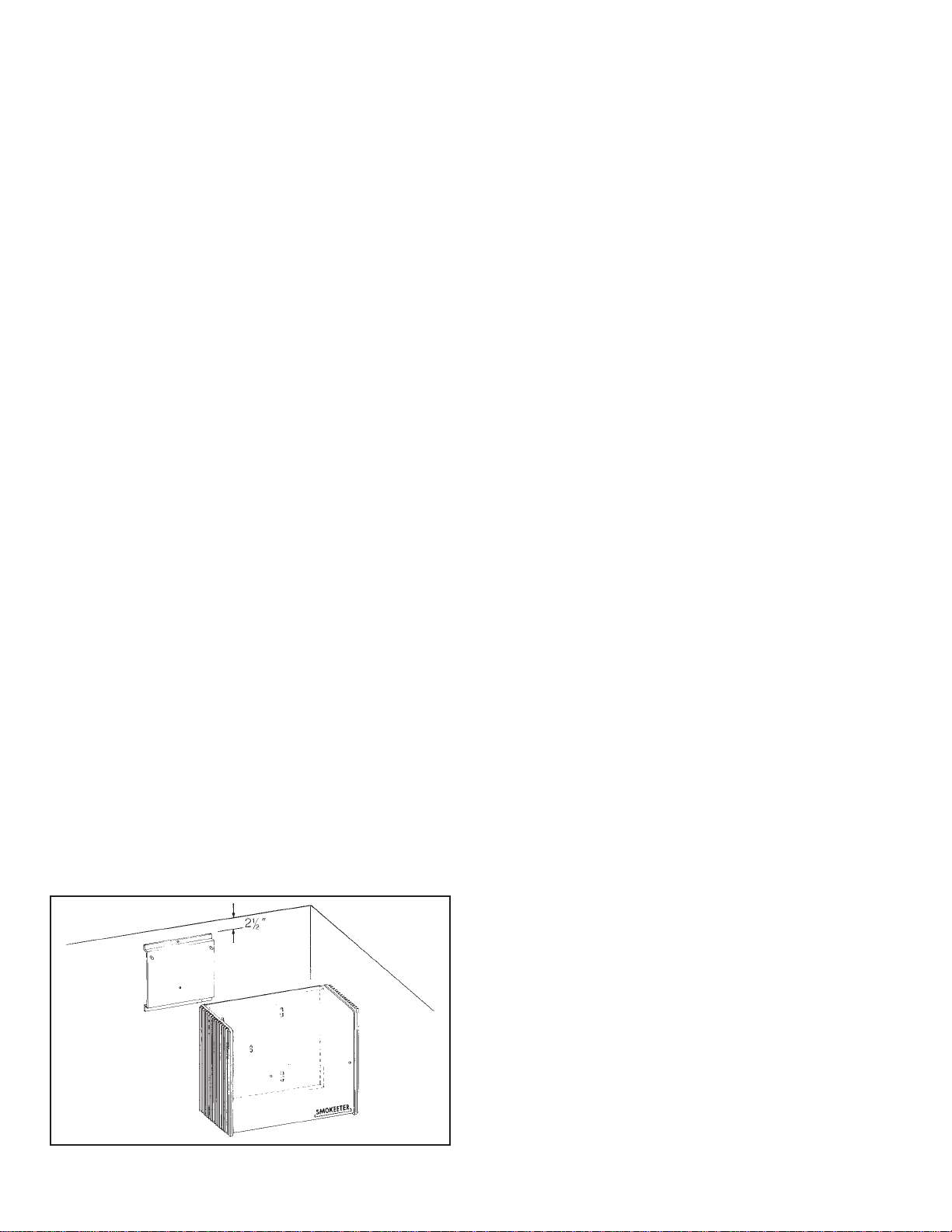

WALL MOUNTING OPTION

Awall mounting bracket is provided for mounting

the unit on walls.

Securely attach the wall mounting bracket against

the wall, allowing 21⁄2" from the ceiling for clearance

of the unit (see Figure 2).

WARNING: Use fasteners and anchoring devices that

will ensure support of the 27 pound unit.

After the mounting bracket is attached, remove the

unicell assembly from the cabinet to facilitate

handling and lighten the weight (see Removing

Components — page 5).

Slide the keyhole slots in the unit base over the

studs on the wall bracket and allow the base to drop

into place, resting on the studs. Using the screw

provided with the unit, secure the base to the moun-

ting bracket.

The SMOKEETER/CRYSTAL-AIRE should now be

tested for secure support.

Reinstall the components and attach the cabinet.

Plug the unit into a grounded 115 volt AC outlet.

REVERSING AIRFLOW

The unit is shipped to you ready for installation

in a left-to-right airflow configuration. If a right-

to-left airflow is desirable, simply turn unit 180°

(unit will be upside down). Remove plastic logo and

place upright in same position (logo is now located in

upper left).

V. OPERATION

For best results and to assure maximum air quality,

your SMOKEETER/CRYSTAL-AIRE should be

started before the air becomes contaminated. An

indicator lamp on the unit is illuminated during

normal operation of both the power pack and the

unicell and will dim when the unicell requires

servicing. A solid-state speed control switch allows

you to adjust the fan speed. If you notice a decrease

in cleaning efficiency, increase the fan speed to

increase the unit’s effectiveness.

FOR YOUR INFORMATION — Each SMOKEETER/

CRYSTAL-AIRE has been thoroughly tested prior to

shipment from the factory. Even so, there may

be some initial arcing of the components at start

up. The noise should cease after a few minutes

of operation.

5

VI. CLEANING

CAUTION: Servicing this product for purposes other

than routine cleaning of the collection com-

ponents (unicell) should be performed by

trained authorized service personnel. Any

effort to exceed this service by non-quali-

fied personnel may lead to bodily injury

and/or equipment failure.

This section is defined for cleaning and periodic main-

tenance. The internal components must be removed

prior to cleaning.

CAUTION: The unit should be inspected frequently

and dirt removed to prevent excessive

accumulation which may result in flashover

or fire damage. An electrical interlock is

provided for protection — do not defeat its

purpose.

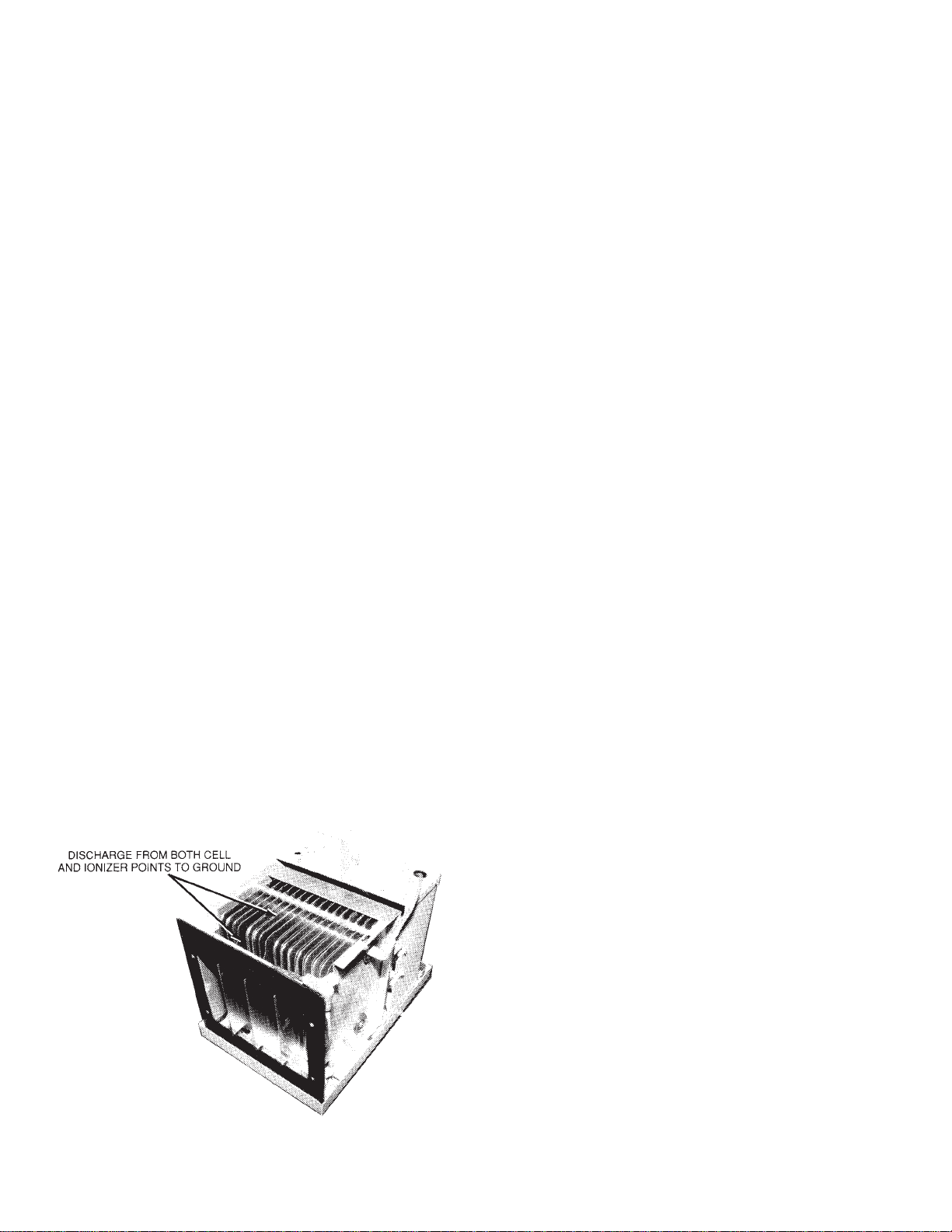

HOW TO REMOVE COMPONENTS

1. Turn off the SMOKEETER/CRYSTAL-AIRE.

•Loosen the two knobs and lift cabinet wrapper.

Wait approximately 15 seconds to allow for any

residual high voltage to bleed off.

•For added safety, manually discharge the unicell

in the following manner. Place the blade of a

common screwdriver (with insulated handle)

across the ionizer wire and ionizer fin. Next,

place the screwdriver blade between any two

cell plates. This will remove any residual charge

that may not have bled off. Disconnect high volt-

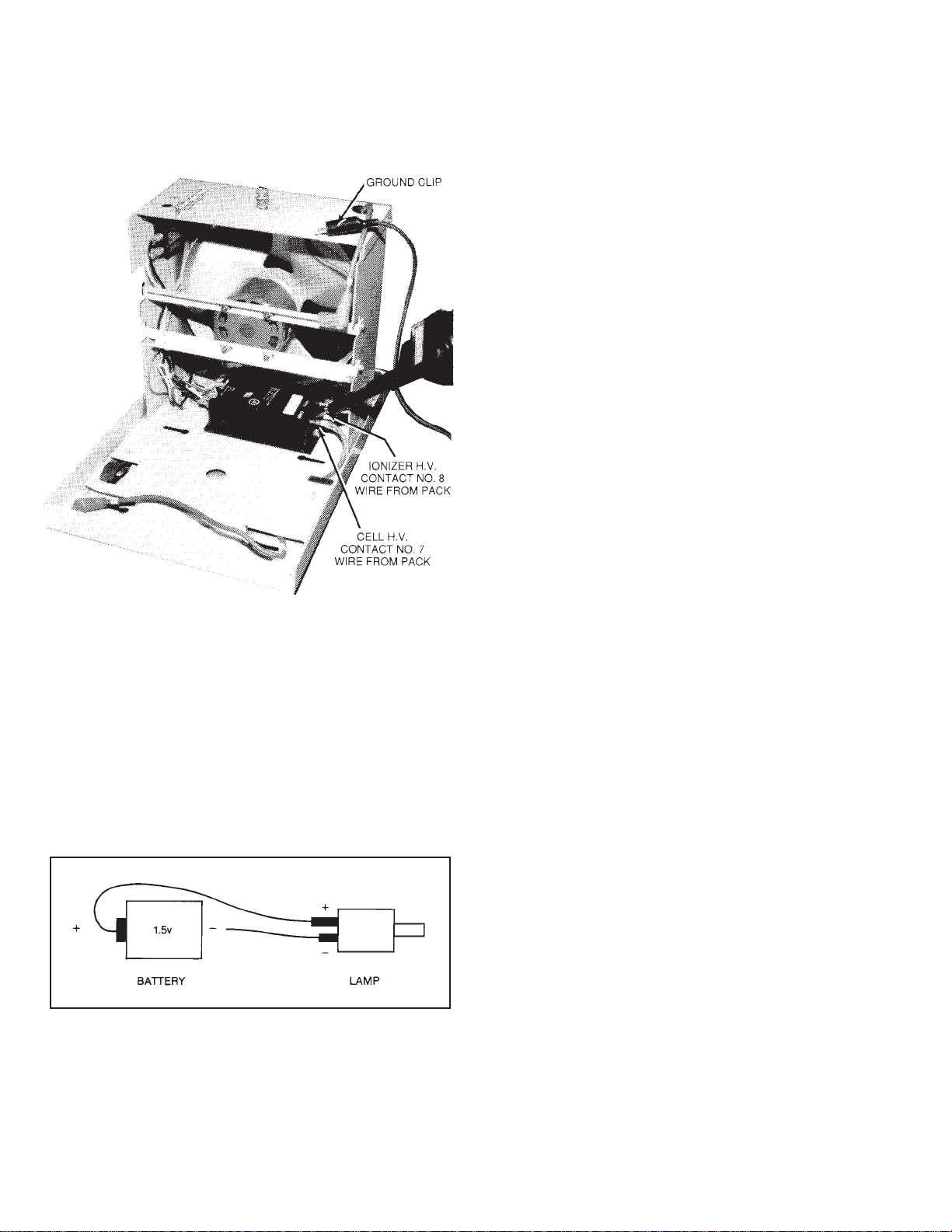

age wires (see Figure 3).

2. Remove the carbon afterfilter by sliding from the

track.

3. Slide the unicell from the cabinet.

CLEANING

Major cleaning is confined to the unicell and the inside

cabinet. The unicell and cabinet should be cleaned

periodically to assure continued efficiency. Cleaning

may be required from once a month to once every four

months depending on the air quality.

NOTE: The carbon filter cannot be cleaned and

needs to be replaced once every six to 12

months.

1. The unicell can be cleaned by soaking in a hot solution

of SMOKEETER/CRYSTAL-AIRE brand detergent for

30-60 minutes. If possible, agitate the solution to aid

in dirt removal. If agitation is not possible, soaking time

should be increased.

CAUTION: Do not use temperature exceeding 160°F

and do not steam clean as this may cause

permanent damage to the unicell. If deter-

gent other than SMOKEETER/CRYSTAL-

AIRE is used, care must be taken to assure

that it contains an aluminum inhibitor so

that it does not attack the aluminum com-

ponents. Be sure to follow manufacturer’s

cleaning instructions.

2. Remove the components from the detergent bath

and immediately flush away any residue and rinse

thoroughly with hot water. Shake off excess water

and let components dry for 30-60 minutes. Set the

cell so that its plates are in a vertical position for

drainage.

3. Vacuum clean the interior of the cabinet and clean

off all electrical connections before reinstalling the

components.

4. Clean the outside cabinet and inlet/outlet grilles by

wiping down with a lint free soft cloth and a suitable

household cleaner, (i.e. Mr. Clean, 409, etc.)

5. Reinstall the components.

6. Attach high voltage wires.

7. Reinstall cabinet wrapper.

8. Plug in and turn on unit.

FIGURE 3

6

VII. PERIODIC MAINTENANCE AND

TROUBLESHOOTING

The following sections are for the use of trained service

personnel only.

WARNING — THE FOLLOWING PROCEDURES WILL

EXPOSE HAZARDOUS LIVE AND MOVING PARTS. DIS-

CONNECT AIR CLEANER BEFORE PROCEEDING.

All SMOKEETER/CRYSTAL-AIRE air cleaners are

manufactured to give years of trouble-free

performance. As with any piece of equipment,

however, breakdowns can occur. Due to the

simplicity of design, breakdowns are restricted to

these components:

— the air mover*

— the power pack

— unicell

— speed control switch

— safety switch

— indicator lamp

This section covers the troubleshooting procedure and

a guide which will enable you to determine the cause of

most problems. Refer to Section VIII for replacement

parts.

*This model is equipped with a permanently lubricated

motor and no further oiling is required.

COMPONENT FUNCTION

1. Power Pack — the electrical circuit is designed

around the power pack which contains the necessary

components to convert 115 Volts, single-phase, 60

hertz to the high voltage DC required for the unicell.

2. Unicell Ionizing Section — the ionizing section

supports four tungsten wires charged positive to a

nominal 11,000 volts DC. The baffle plates parallel to

the wire are at ground potential. Its function is to

electrically charge the contaminated particles as

they pass through it.

3. Unicell Collecting Section — the collecting section

consists of alternately charged plates. Plates are

alternately charged with a nominal 5,500 volts DC

positive. The field between the plates forces the

charged particles to the ground plates and removes

them from the airstream.

4. Air Mover — the air mover draws in contaminated

air and exhausts clean air through the outlet.

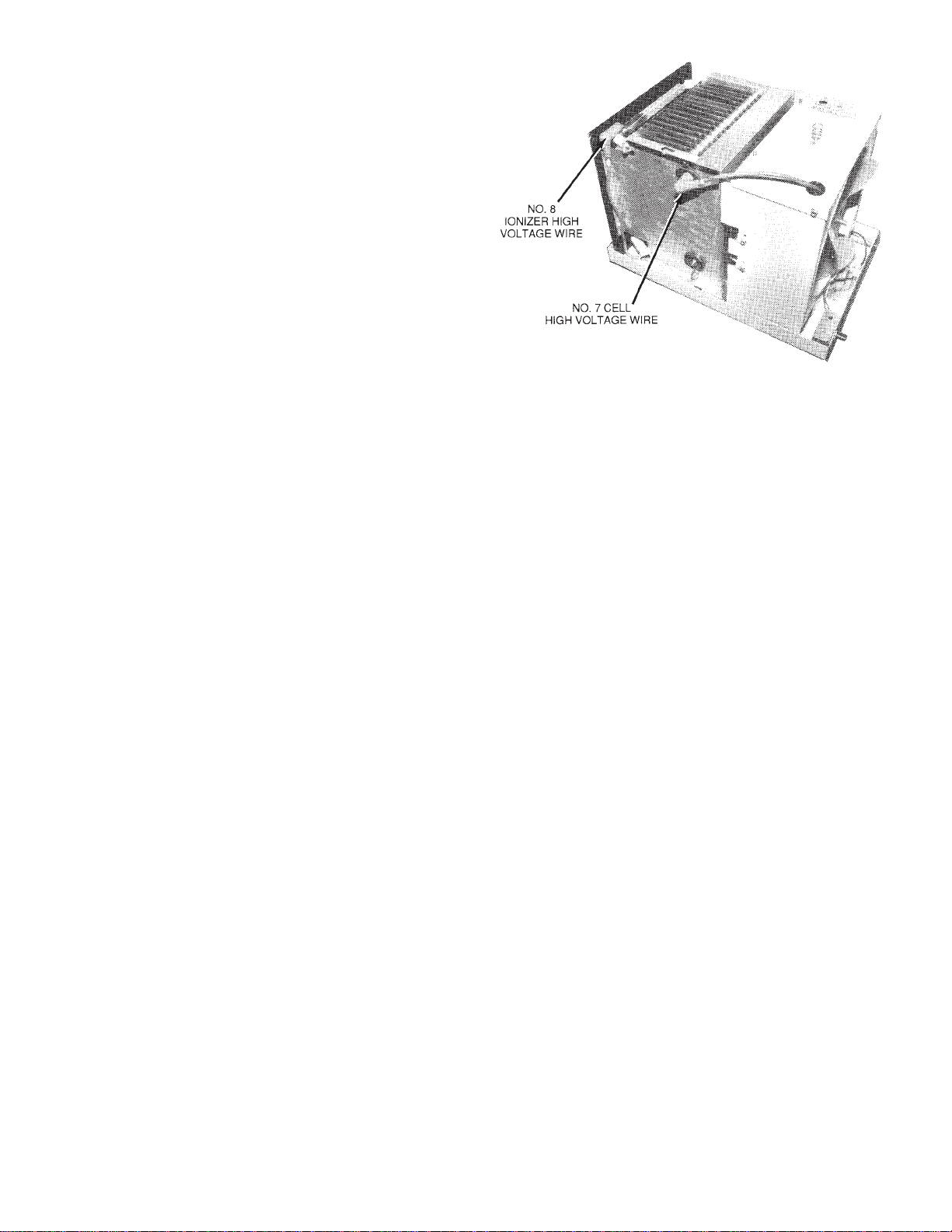

HOW THE HIGH VOLTAGE IS SUPPLIED TO THE

COMPONENTS

The power pack supplies high voltage DC to the

ionizing and collecting sections of the unicell by the

use of high voltage lead wires. Two separate terminals

are used on the output side of the pack. Terminal #8

supplies nominal 11,000 volts DC positive to the ionizer.

Terminal #7 supplies 5,500 volts DC to the cell (see

Figure 4).

TOOLS REQUIRED FOR TROUBLESHOOTING

—Screwdriver — (common type) 8" or longer with in-

sulated handle.

—Volt-Ohm Meter — for measuring low voltage input

(115 VAC), continuity (OHMS) and low voltage DC.

—High Voltage Probe (DC) positive polarity — for

checking the high voltage power supply (minimum

range from 0 to 15 KV DC).

HOW TO MEASURE HIGH VOLTAGE

For accurately measuring the high voltage, a 0 to 15 KV

minimum scale high voltage probe capable of mea-

suring positive polarity is required.

FIGURE 4

7

MEASURING UNICELL IONIZER VOLTAGE

(See Figure 5)

1. Turn the unit off and remove the cabinet. This will

disengage the safety interlock.

2. Connect the ground clip of the positive polarity

probe to the base unit.

CAUTION: Always ground the high voltage probe to

a solid ground connection on the base

unit.

MEASURING UNICELL COLLECTOR VOLTAGE

(See Figure 6)

1. Connect the ground clip of the positive polarity

probe to the base unit.

2. Engage the safety interlock switch and measure the

collector high voltage by placing the probe’s tip on

one of the charged plates. The voltage reading

should be 5.0 to 6.0 KV DC.

3. Turn unit speed control switch on and cautiously

engage the safety interlock switch by depressing

the button.

CAUTION: Be sure to disengage safety interlock

switch after measuring voltages.

4. Place the probe’s tip on the ionizer and measure

the positive DC voltage. The voltage should read

10.0 to 11.0 KV DC.

•If measurements are abnormal, refer to the

troubleshooting guide for cause and correction.

•If measurements are abnormal, refer to the

troubleshooting guide for cause and correction.

CHECKING THE POWER PACK OUTPUT

(See Figure 7)

1. Remove unicell from the cabinet.

2. Engage the safety interlock switch and measure the

output from the ionizer terminal of the power pack

by placing the probe’s tip on the ionizer high voltage

contact.

•Output reading without the unicell should read 11.0

to 13.0 KV DC positive.

FIGURE 5

FIGURE 6

8

3. To measure the collection cell output voltage, place

the probe’s tip on the cell high voltage contact.

•Output without the unicell should read 5.0 to 6.5 KV

DC positive.

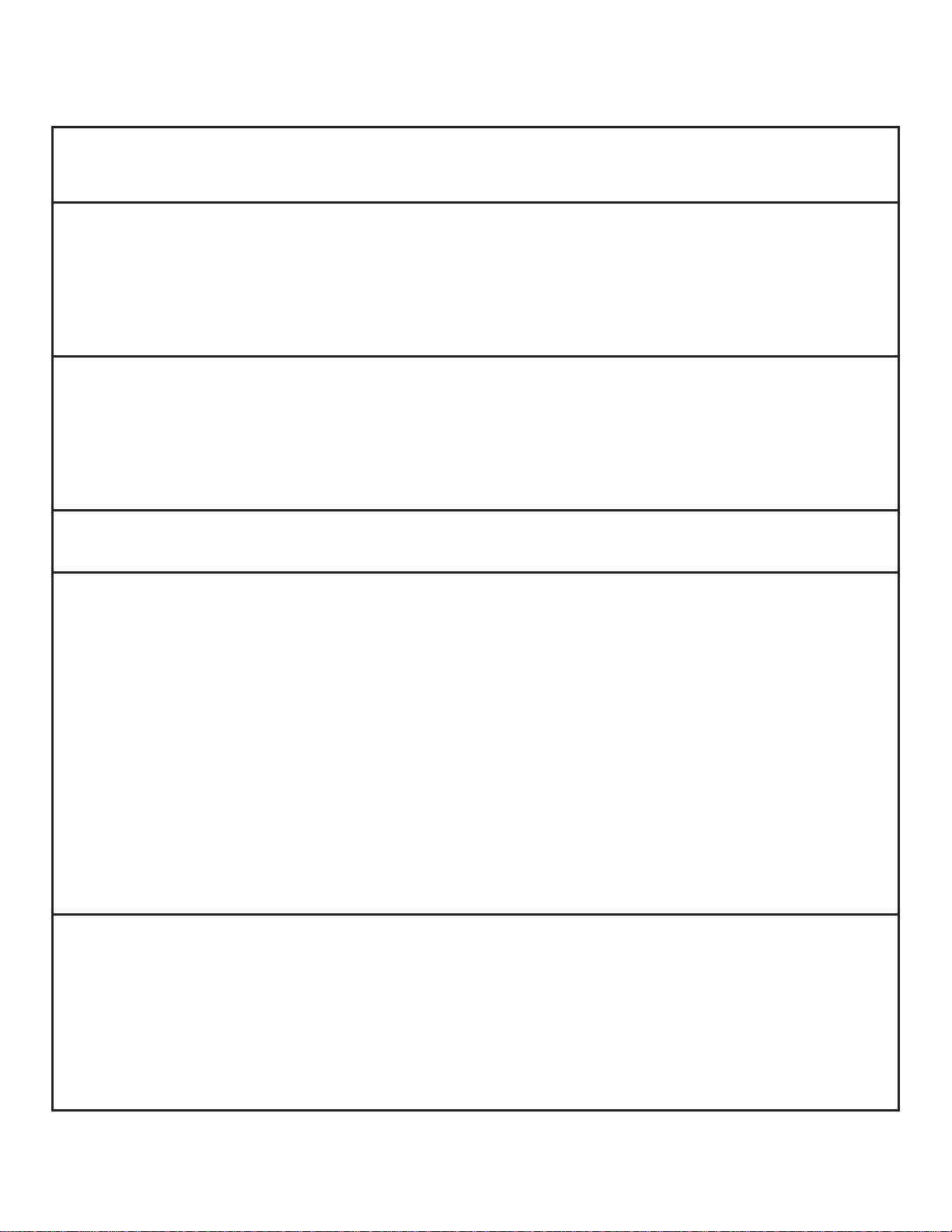

CHECKING LAMP VOLTAGE

1. Check power supply output lamp output by con-

necting a good 2 volt lamp.

2. Check lamp operation with 1.5 volt battery as

shown in Figure 8.

VIII.REPLACEMENT PARTS

Replacement parts can be ordered from your local

distributor or from UAS. To order parts from UAS,

call or write:

UNITED AIR SPECIALISTS, INC.

4440 CREEK ROAD

CINCINNATI, OHIO 45242

1-800-551-5401

ATTN: SMOKEETER/CRYSTAL-AIRE

CUSTOMER SERVICE

The following information will be required for prompt

service:

1. Unit Model No. on bottom of base unit at air

mover end.

2. Unit Serial No. on bottom of base unit at air mover

end.

3. Part No. of part (see Section IX, Illustrated Parts).

When returning a defective part under warranty, you

must call UAS for a customer return authorization

number. This number should appear on the package

that is being returned. With this control number, we can

assure you will receive prompt service. You can also

return defective parts to your local distributor.

FIGURE 7

FIGURE 8

9

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

A. Control switch on, 1. Defective lamp. 1. Replace lamp.

indicator lamp off, 2. Faulty connection to lamp. 2. Check connection to lamp.

air mover operates. 3. Loss of high voltage. 3. Check power pack.

B. Control switch on, 1. Air mover faulty. 1. Replace air mover.

indicator lamp on, 2. Foreign object locking 2. Clean foreign object from

air mover does not air mover. air mover.

operate. 3. Faulty control switch. 3. Replace control switch.

4. Connector not properly 4. Check connection at

connected (at control control switch.

switch).

C. Control switch on, 1. Unit is not plugged in. 1. Plug unit into 115 VAC

air mover and lamp off. receptacle.

2. Safety interlock switch 2. Engage safety interlock

not engaged. switch.

3. Safety interlock switch 3. Replace safety interlock

defective. switch.

4. Control switch defective. 4. Replace control switch.

D. Air mover operates on 1. Control switch defective. 1. Replace control switch.

low or high speed only.

E. Poor air quality. 1. Unicell dirty. 1. Clean unicell.

2. Unicell malfunctioning. 2. Check unicell for:

a. Foreign matter between

plates

b. Ionizer wire loose or

broken

c. Defects in insulators

3. Unicell installed 3. Install unicell as shown

backwards or upside in Figure 1.

down.

4. High voltage contacts 4. Clean high voltage

dirty. contacts.

5. Unit being operated on 5. Increase air mover speed.

too low a speed.

6. Placement of unit not 6. Contact your local

creating a good air distributor or United Air

pattern. Specialists.

F. High voltage output 1. Loss of input 115 VAC. 1. Determine loss of input

low or zero. voltage.

2. Unicell malfunctioning. 2. Check unicell for:

a. Foreign matter between

plates

b. Ionizer wire loose or

broken

c. Defects in insulators

3. Power pack defective. 3. Replace power pack.

*Refer to Wiring Diagram and Illustrated Parts

10

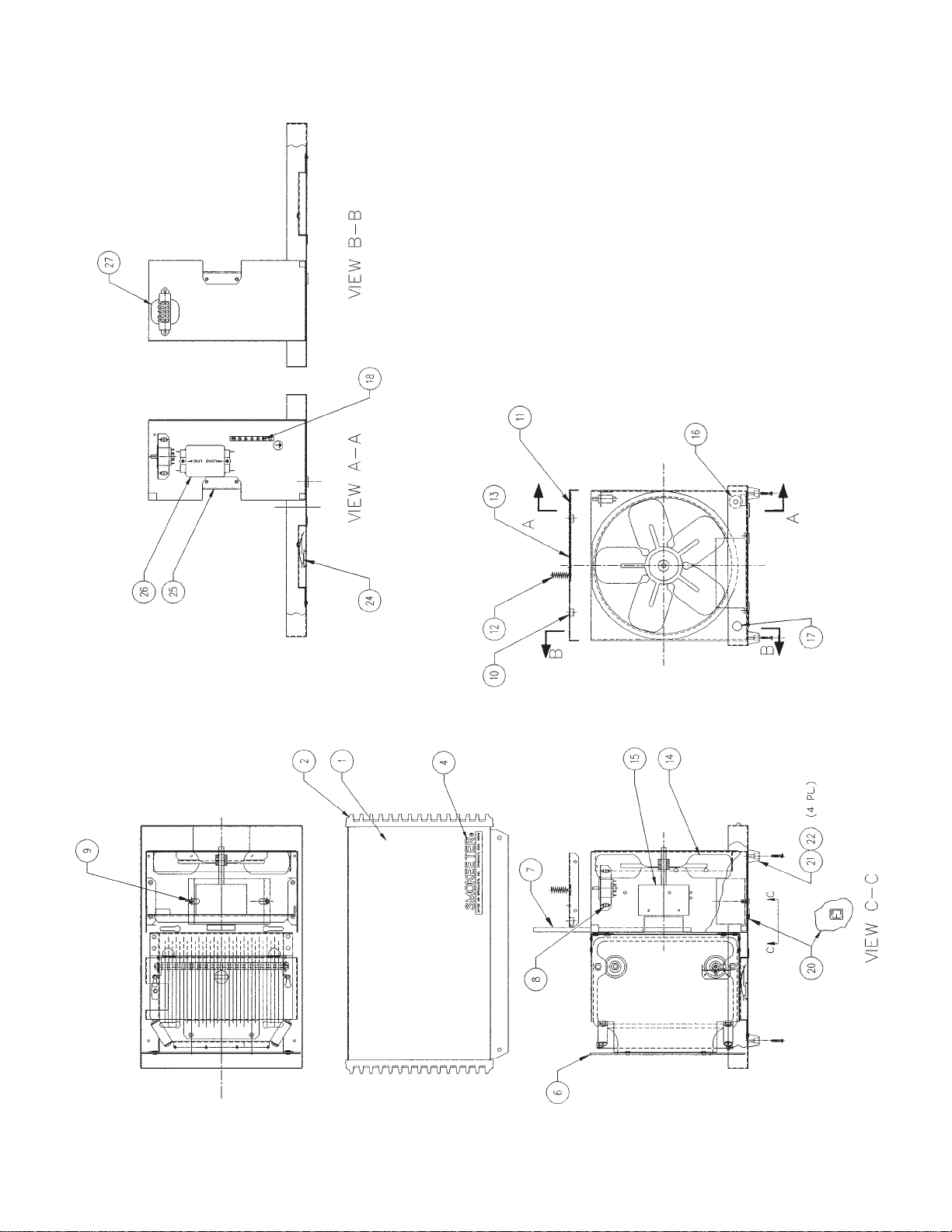

IX. ILLUSTRATED PARTS

11

SE 10 REPLACEMENT PARTS

ITEM NO. PART NO. DESCRIPTION QTY.

1CHOOSE 1 10-8878 WRAPPER, OYSTER 1

10-3048 WRAPPER, WOODGRAIN 1

2CHOOSE 1 33-0136 GRILLE, OYSTER 2

33-0146 GRILLE, BLACK 2

3CHOOSE 1 30-0589 KNOB, OYSTER 2

30-0588 KNOB, BLACK 2

4CHOOSE 1 41-1026 SMOKEETER LOGO, OYSTER 1

41-1130 SMOKEETER LOGO, WOODGRAIN 1

41-1246 CRYSTAL-AIRE LOGO, OYSTER 1

41-1247 CRYSTAL-AIRE LOGO, WOODGRAIN 1

510-2735 PRE-FILTER SCREEN 1

602-2723 UNICELL 1

733-0154 CARBON FILTER 1

820-2841 INTERLOCK SWITCH 1

9CHOOSE 1 21-1219 POWER PACK, 90-130V 1

21-1246 POWER PACK, 200-250V 1

10 30-0537 TINNERMAN NUT 2

11 36-0072 LEAF SPRING, INTERLOCK ACTUATOR 1

12 36-0014 CONTACT SPRING, COIL 1

13 10-3491 FAN COVER 1

14 32-0156 ALUMINUM PROPELLER 1

15 02-2625 MOTOR ASSEMBLY 1

16 20-1314 LED INDICATOR 1

17 CHOOSE 1 03-1513 SPEED CONTROL (VARIABLE SPEED UNITS) 1

20-1421 ROCKER SWITCH (2-SPEED UNITS) 1

18 20-1368 GROUNDBUS 1

19 20-2922 CORD, 10' GREY 1

20 20-2921 IEC 320 CONNECTOR 1

21 30-1735 SCREW, SELF-TAPPING, #10-32X3/4 1

22 39-0286 FOOT, MOLDED 1

23 RESERVED

24 03-1535 CONTACT SPRING 1

25 10-9347 MOTOR BRACKET 1

26 OPTIONAL 25-0229 EMI FILTER 1

27 230 V UNITS 21-1255 TRANSFORMER, 23OV-12OV, IEC APPROVED 1

28 NOT SHOWN 03-0862 HIGH VOLTAGE WIRE KIT 1

12

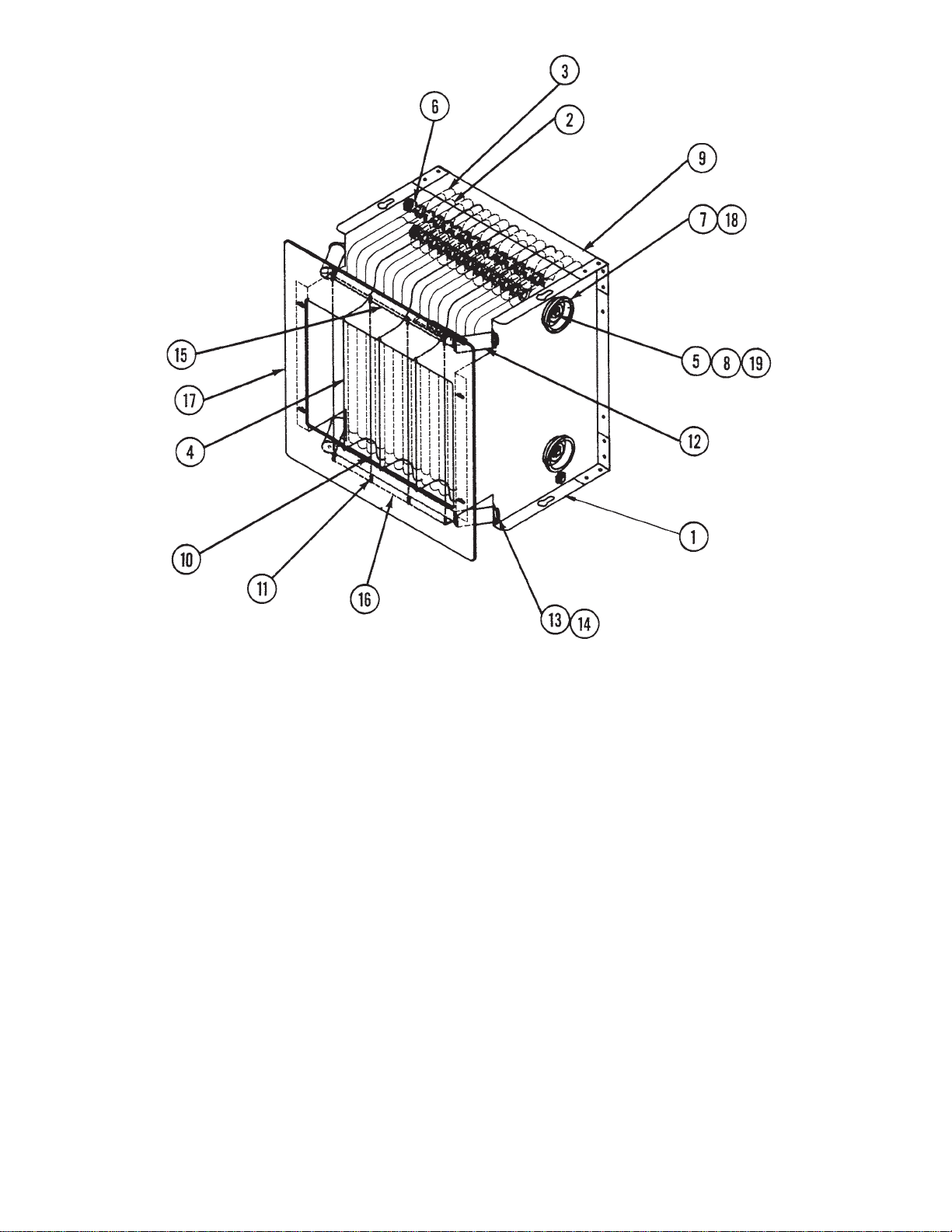

SE 10 UNICELL ASSEMBLY

02-2723

ITEM PART

NO. NO. DESCRIPTION QTY.

110-2780 END PLATE 2

210-0946 CELL PLATE, NARROW 16

310-0944 CELL PLATE, WIDE 12

410-2805 IONIZER GROUND PLATE 3

535-0072 CELL ROD 8-15/16" LG 4

635-0067 CELL SPACER 62

737-0008 CELL INSULATOR, DISK 4

830-0449 HEX NUT-1/4-20 8

910-2811 CORNER ANGLE 2

10 02-2721 IONIZER WIRE ASSEMBLY 4

11 36-0037 IONIZER WIRE SPRING 8

12 37-0013 INSULATOR (CERAMIC) 4

13 30-0039 LOCKWASHER #8 INT TOOTH 8

14 30-0119 SCR, PAN HD 8-32x5/16 LG 8

15 18-0795 IONIZER RAIL (TOP, WITH H.V. CONTACT) 1

16 10-2786 IONIZER RAIL (BOTTOM) 1

17 37-0064 UNICELL MASK 1

18 30-0283 CELL SPACER WASHER 4

19 20-1312 TERMINAL, CELL 1

20 20-1313 TERMINAL, IONIZER 1

*To convert cell with “spark plug” type H.V. connections to current H.V. connections, order kit

#03-1595.

13

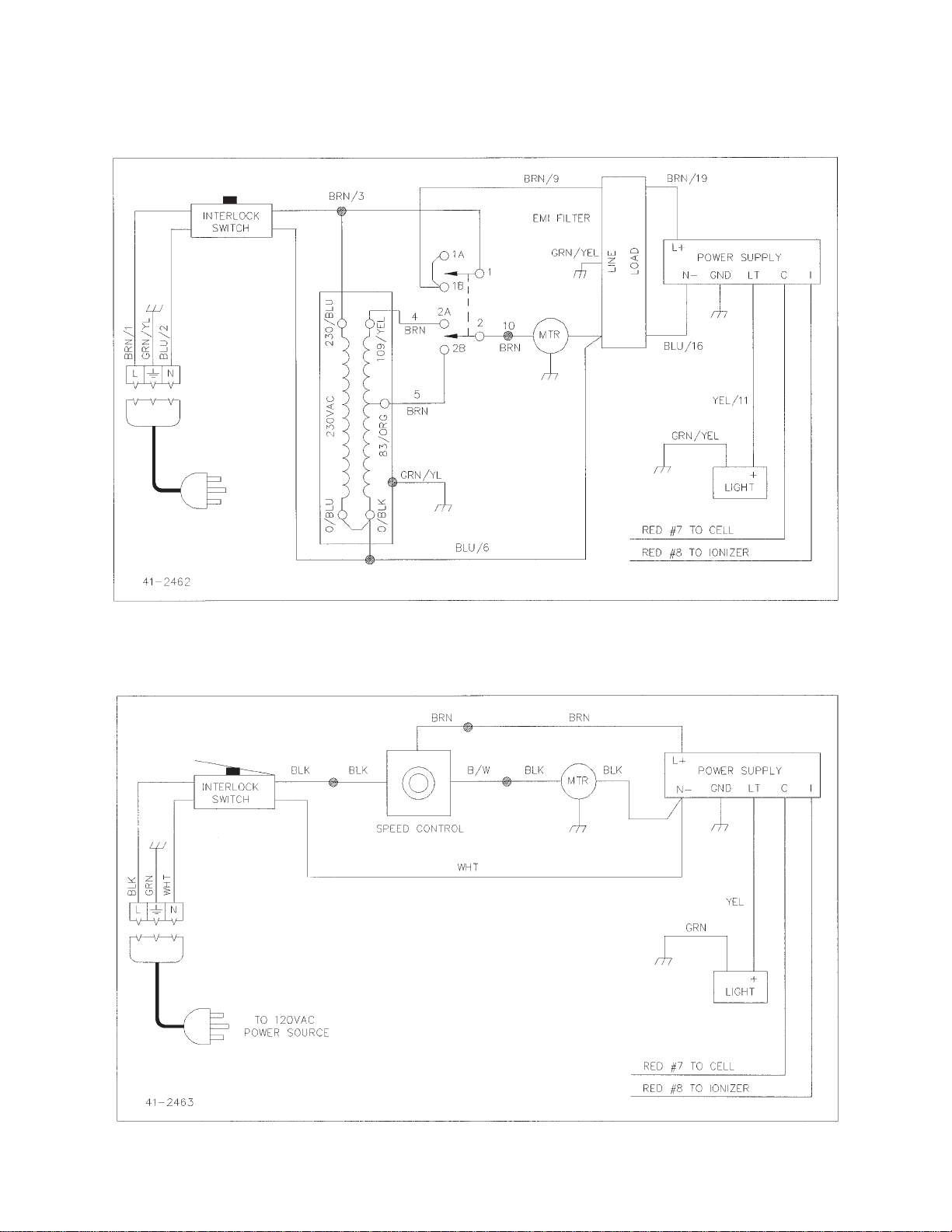

WIRING DIAGRAMS

SE 10 230 VAC, 2-Speed

SE 10 120 VAC,Variable Speed

To Place an order contact ACS, Inc. @ (800) 878-5030

UNITED AIR SPECIALISTS, INC,

LIMITED WARRANTY

UAS warrants all equipment manufactured and sold by UAS against defective parts and

workmanship for one year from date of shipment to Purchaser, except that commercial or

nonindustrial air cleaners (other than engineered systems) are warranted for three years from such

date. This warranty is subject to the limitations in UAS’ standard terms and conditions provided to

Purchaser. Any unauthorized repairs or modifications or abnormal use or misuse of equipment will

void all warranties. In no case will UAS’ responsibility or warranty extend to equipment not

manufactured by UAS.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES,

WHETHER WRITTEN, ORAL OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NONINFRINGEMENT.

As Purchaser’s exclusive remedy for any defects in the equipment, UAS will exchange or repair any

defective parts during the warranty period, provided such parts are returned, prepaid, to UAS’factory.

The obligation of UAS is limited to furnishing replacement parts F.O.B. UAS’ factory or making repairs

at UAS’ factory of any parts which are determined, upon inspection by UAS, to be defective. UAS

is not responsible for labor or transportation charges for the removal, reshipment or reinstallation of

the parts.

IN NO EVENT WILLUAS BE RESPONSIBLE FORANY SPECIALOR CONSEQUENTIAL DAMAGES.

PRINTED IN USA

Part No. 44-2454

8/97

Table of contents

Other Smokeeter Air Cleaner manuals

Popular Air Cleaner manuals by other brands

EcoWays

EcoWays GENESIS Pro manual

Klarwind

Klarwind Klarwind-500s user manual

LUCCI Air

LUCCI Air ALLO manual

Deltech Fitness

Deltech Fitness PYRAMID 8000 Installation, operating and maintenance manual

Suntec Wellness

Suntec Wellness Klimatronic AirCare 200 instruction manual

Heaven Fresh

Heaven Fresh HF 86 instruction manual