SMORACY BEAST 3680 User manual

THE 3680 BEASTTHE 3680 BEAST

THE 3680 BEASTTHE 3680 BEAST

THE 3680 BEAST®

RECYCLER

MODEL 3680

OPERATING & PARTS MANUAL

“BUILT WITH QUALITY AND DESIGN FIRST”

Model No: __________________

Serial No: XXXX

WorkOrderNo. XXXXX

Manual Date: XX/XX

Engine Make: _________________

Serial No: ________________

Clutch Make: _________________

Model: __________________

S/N: ___________________

36803680

36803680

3680

ATTENTION:

Dependingonwhatreplacementpartsyouare

ordering,wewillneedthefollowinginformation:

RECYCLER COMPONENTS

SerialNumber

ModelNumberofRecycler

ENGINE COMPONENTS

EngineSize

EngineSerialNumber

EngineSpec.Number

CLUTCH COMPONENTS

NameofManufacturer

SerialNumber

BOM# ofClutch

(seechecksheet) MANUFACTUREDBY

SMORACY, LLC

6750 Millbrook Road

REMUS,MICHIGAN,USA49340

PHONE:(989)561-2270OR561-2272

TOLLFREEINUSA 800/952-0178

FAX: (989) 561-2273~SALESDEPT.

FAX:(989)561-5343 ~ PARTS/SERVICE

E-MAIL:www.banditchippers.com

WARNING

!

ADVERTENCIA

!

Breathing diesel engine

exhaust exposes you to

chemicals known to the

State of California to cause

cancer and birth defects or

other reproductive harm.

• Always start and

operate the engine in a

well-ventilated area.

• If in an enclosed area,

vent the exhaust to the

outside.

• Do not modify or tamper

with the exhaust system.

• Do not idle the engine

except as necessary.

For more information go to:

www.P65warnings.ca.gov/diesel

Respirar gases de escape de

motores diesel le expone a

quÍmicos conocidos por el estado

de California como causales de

cáncer y defectos congénitos u

otros daños reproductivos.

Para mayor informaciÓn visite:

www.P65warnings.ca.gov/diesel

• Siempre encienda y opere el

motor en áreas bien ventiladas.

• Si está en un área cerrada,

ventile escape hacia el exterior.

• No modifi que ni altere el

sistema de escape.

• No deje el motor en ralentÍa no

ser que sea necesario.

SPW-46 8/18

SPW-47 8/18

Cancer and

Reproductive

Harm

WARNING

!

ADVERTENCIA

!

Cáncer y daño

reproductivo

www.P65warnings.ca.gov

CALIFORNIA PROPOSITION 65

I have inspected this equipment and nd it in correct working condition. To the best of my knowledge, the customer and

his/her personnel are aware of, and agree to the above procedures.

Signed: ________________________________________________________________________ Date: ______________

(Dealer Representative)

The equipment has been thoroughly checked by the above named dealer representative, and I am satised with his/her

instructions. I have also read, understand, and agree to reverse side of page.

Signed: ________________________________________________________________________ Date: ______________

(Customer)

IT IS VERY IMPORTANT THAT THIS FORM IS FILLED OUT COMPLETELY & ACCURATELY. IF WE CANNOT READ THE

PURCHASER’S INFORMATION OR IT IS INCORRECT, OUR CUSTOMER LIST WILL NOT BE ACCURATE.

IMPORTANT - THIS FORM MUST BE RETURNED TO THE

CUSTOMER DATA DEPARTMENT WITHIN TEN (10)

DAYS IN ORDER TO VALIDATE WARRANTY

Customer Data Department

6750 Millbrook Road

Remus, MI, USA 49340

Phone: (800) 952-0178 in USA

Phone: (989) 561-2270

Fax: (989) 561-2273

E-mail: www.banditchippers.com

Copyright 2-08 FORM #WV-118

OWNERSHIP / WARRANTY VALIDATION FORM

(RECYCLER)

1. _______ Customer has been instructed and understands operation and all safety aspects of operating the equipment.

2. _______ Customer has been instructed and understands that everyone within 100 feet of machine must wear

personal safety equipment (i.e. hard hat, face shield, safety glasses, gloves, ear protection, etc.)

3. _______ Customer has been instructed and understands equipment maintenance schedules, procedures, and that it

is their responsibility to perform maintenance that includes periodic relief valve adjustments, retightening

all fasteners as needed, teeth replacement, especially clutch and belt adjustments, etc.

4. _______ Customer understands hazards of working under, and how to properly lock, the feed wheel in the up position.

5. _______ Customer has been instructed and understands that any machine operators must, always be located within easy

reachofcontrolsandshutdowndevices,andknowhowtouse,activate,andmaintainthereextinguishers.

6. _______ Customer has been instructed, understands, and agrees that all potential operators must use proper shut

downprocedures,checkforres,andremoveallpotentialrehazards.Alwayscleanoffandremoveall

ammabledebrissuchas:wood,mulch,oils,fuels,etc.fromanywherematerialscollect.

7. _______ Customer understands the purpose of and how to operate all the safety devices and guards and to never

attempt to override any safety devices or guards.

8. _______ Customer has been instructed and understands to always remove the ignition key, completely disconnect

battery from cables or by using the battery disconnect switch, and to wait for the cutterhead to come to a

completestop.Allowallthetimenecessaryforthecutterheadtocometoacomplete stop before performing

any type of service or maintenance procedures. Customer has been shown and understands the purpose of

thebeltshieldinspectionholeandtonotattemptanymaintenanceuntilbeltsarevisuallyconrmedtohave

come to a complete stop.

9. _______ Customer has been instructed and understands the operational, electrical, and radio devices on the

machine, and no one is to be within restricted area, around recycler, while it is running.

10. _______ Customer has reviewed and understands limited warranty, and all written and visual instructions.

11. _______ Customer has received, been advised, and understands the manuals, and the Safety/Service video supplied

withtherecycler.Avideoissuppliedforequipmentmodelsasavailable.

12._______AllDanger,WarningandOperationaldecalsareproperlydisplayedonequipmentandfullyunderstoodbycustomer.

13._______ Customerhasbeeninstructed,understands,andagreesthatallpotentialoperatorsmust:Seethesuppliedvideo,

beinstructedonalltheDanger,WarningandOperationaldecals,readthemanualandfollowtheprocedures.

PURCHASER / OWNER INFORMATION:

Company Name ______________________________________________ Contact Name _______________________

Mailing/StreetAddress________________________________________________City________________________

State __________________________ Zip Code ____________ Telephone Number ( ___ ) ____________________

E-mail _____________________________________ Recycler Model No. ___________ Serial No. ______________

DateRecyclerPutIntoService____________EngineMake&S/N_________________________________________

DEALER / SELLER INFORMATION:

Dealer/SellerName___________________________________________ContactName_______________________

Mailing/StreetAddress________________________________________________City________________________

State __________________________ Zip Code ____________ Telephone Number ( ___ ) ____________________

Copyright 9-02 FORM #Q-110

DATE PURCHASED: _________________

MODEL: ___________________________

SERIAL NUMBER: ___________________

DEALER NAME: ____________________

___________________________________

TO BE RETURNED AFTER THIRTY (30) DAYS OF OPERATION

Please return to: Customer Data Department

6750 Millbrook Road

Remus, MI 49340

PH: (800) 952-0178 in USA

PH: (989) 561-2270

FAX: (989) 561-2273

E-MAIL: www.banditchippers.com

RECYCLER QUALITY REPORT

All of the employees that build your equipment strive to manufacturer the very best quality product on the market.

We would appreciate your efforts in letting us know how we are doing.

We would like you to operate your machine for thirty (30) days and then ll out this questionnaire and mail it to us.

This will help us to keep producing a good product and improving our products through your recommendations.

1. Did your machine perform to your expectations? ____________________________________________

2. Was the machine delivered on schedule? __________________________________________________

3. Was the paint color and nish to your satisfaction? __________________________________________

4. Was machine equipment as ordered? _____________________________________________________

5. Did all welds appear to be of high quality? _________________________________________________

6. Was the overall machine to your liking? ___________________________________________________

7. What problems have you experienced? ___________________________________________________

8. Have any components regularly loosened that caused problems? _______________________________

9. Does the hydraulic system seem to have adequate power for feeding wood into the recycler? ________

10. Is the machine manufactured to accommodate service in an adequate manner? If not, please explain:

___________________________________________________________________________________

11. General comments and/or suggestions: ___________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

12. Would you like to be contacted concerning more of our equipment? _____________________________

YOUR COMPANY:__________________________________

NAME: __________________________________________

ADDRESS: ______________________________________

CITY: ___________________________________________

STATE & ZIP: ____________________________________

PHONE: ( ______ ) ________________________________

E-MAIL: _________________________________________

Copyright 12/14 1 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680 TABLE OF CONTENTS

PAGE NO.

INTRODUCTION & WARRANTY............................................................... 2

SERIAL NUMBER LOCATION.................................................................. 6

SAFETY PROCEDURES.......................................................................... 7

SAFETY DECALS....................................................................................13

AUTOFEED SECTION..............................................................................19

RADIO/TETHER CONTROLS....................................................................26

EQUIPMENT SPECIFICATIONS............................................................... 30

CONTROLS/START-UP PROCEDURES.................................................... 36

TRANSPORTATION PROCEDURES......................................................... 45

MAINTENANCE ...................................................................................... 46

DAILY, WEEKLY, MONTHLY CHECKLIST........................................... 47

CUTTERHEAD SECTION................................................................... 50

CUTTERTEETH SECTION.................................................................. 53

SCREEN SECTION............................................................................ 58

AUGER SECTION..............................................................................59

INFEED SECTION..............................................................................62

BELT/CHAIN SECTION...................................................................... 63

TIRE WEAR SECTION....................................................................... 64

AXLE LUBRICATION......................................................................... 65

CLUTCH SECTION............................................................................ 66

PAINT AND APPEARANCE.................................................................66

DUST SUPPRESSION SYSTEM.........................................................67

TROUBLE SHOOTING....................................................................... 68

HYDRAULIC SECTION.......................................................................79

LUBRICATION & BOLT TORQUE CHARTS......................................... 82

ELECTRICAL SECTION..................................................................... 84

REPLACEMENT PARTS SECTION........................................................... 85

INFEED CONVEYOR COMPONENTS..................................................86

BASE COMPONENTS........................................................................88

HYDRAULIC TANK COMPONENTS.................................................... 90

FEEDWHEEL COMPONENTS.............................................................92

DUST SUPPRESSION COMPONENTS................................................94

CUTTERTEETH COMPONENTS..........................................................96

SCREEN COMPONENTS....................................................................98

SCREEN HOIST COMPONENTS........................................................100

ANVIL & CONCAVE GATE COMPONENTS.........................................102

DISCHARGE CONVEYOR COMPONENTS..........................................104

AUGER COMPONENTS.....................................................................108

HYDRAULIC COMPONENTS..............................................................110

FRAME & ACCESSORY COMPONENTS.............................................142

AIR BRAKE COMPONENTS...............................................................144

AXLE COMPONENTS........................................................................146

HUB GROUPS...................................................................................147

CONTROL BOX COMPONENTS.........................................................148

INDEX.....................................................................................................150

NOTE- ANY PART, PORTION, DESIGN, NUMBER, SPECIFICATION, AND/OR

DIMENSION IN THIS MANUAL IS SUBJECT TO CHANGE WITHOUT

NOTICE BY THE MANUFACTURER.

TABLE OF CONTENTS

Copyright 12/14 2 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680

INTRODUCTION

The purpose of this manual is to provide the user with specifications and procedures for the

operation, maintenance and repair of the Beast Recycler. As with any piece of equipment, safety

should always be a constant thought while the machine is being operated, serviced or stored. In order

tohighlightthis consideration,thematerial whichaddressessafety isproceededby thefollowingsignal

words:

Signal Word Likelihood of Occurrence Degree of Potential

Injury or Damage

DANGER

WARNING

CAUTION

NOTICE

Will occur if warning is ignored

Can occur if warning is ignored

Will or can occur if warning is ignored

Important, but not hazard related

Severe

Severe

MinortoSevere

Minor

The recycler is designed and manufactured in accordance with the latest machine industry standards.

This alone does not prevent injury. It is the operator’s responsibility to use good judgement and follow

the warnings and instructions as indicated in this manual.

Improperuseofthe recycler canresultin severe personal injury. Personnel usingtherecycler must be

qualified, trained and familiar with the operating procedures as defined in this manual.

It is the responsibility of the owner or employer to insure that the operator is trained and practices safe

operation while using and servicing the machine. It is also the owner’s responsibility to provide and

follow a regularly scheduled preventative maintenance and repair program on the recycler, using only

factory approved replacement parts. Any unapproved repairs or modifications may not only damage

the machine and its performance, but could result in severe personal injury. Consult the equipment

manufacturer!!!

Each machine is shipped with a manual, a customer’s check sheet on the recycler, any available parts

& service manuals on component parts not produced by this manufacturer, and service & safety video

tape. Additional copies of these manuals and check sheets can be purchased from the manufacturer,

or through the dealer. Engine parts, service and maintenance manuals MUST be purchased through

the engine manufacturer or their dealer.

NOTE - The producer of the Beast Recycler reserves the right to make any

modifications or revisions to the design or specifications of its machine

without advance notice. The producer also reserves the right to change

machine and part prices as needed without advance notice.

INTRODUCTION & WARRANTY

WARNING

WARNING

Copyright 12/14 6 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680

1. TopofTongue

2. InsidetheControl Cabinet

3. CurbSideBearing Pad

NOTE: Theengine information is locatedonthe

engine block. The clutch information is

locatedontheclutchplate.

1

INTRODUCTION & WARRANTY

3

2

TYPICAL RECYCLER SERIAL NUMBER

LOCATIONS

Machine directional instructions are described as “curbside” (radiator side of machine) and

“roadside” (clutch side of machine).

Copyright 12/14 7 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680

SAFETY PROCEDURES

SAFETY PROCEDURES

CHECK FOR FIRES, CLEAN OFF DEBRIS,

SWITCH OFF BATTERY

DO NOT leavethismachineunattendeduntilallpoten-

tial fire debris is removed, no fire or smoldering exists and battery is

switchedoff. Thedieselenginecreatesmanyhotspots,including

exhaustmanifoldandturbo. Removeallflammabledebris(wood,mulch,

oils,fuels,etc.)from:

• Engineturboandexhaust • Insidebeltshields

• Besideandaround engine • Insidecontrolcabinets

• Underengineandtanks • Anywherematerialscollect

DO NOT leavethismachineunattendeduntilallfirehazardsare

removed,hotspotsare cold and battery is disconnected.

ALWAYS keepseveraltypeA:B:Cfireextinguishersoperationalandon

thejobatall times.

SMORACY, LLC IS NOT RESPONSIBLE FOR FIRES CAUSED BY

FIRE HAZARDS LEFT TO SMOLDER AND BURN, OR IMPROPER

SHUTDOWN PROCEDURES.

WARNING

RESTRICTEDAREA

DO NOT approachwithin envelope oryouwill be injuredwhilemachineis operating.

DANGER

100ft.

(30.5m)

200ft.

(61.0m)

50 ft.

(15.2m)

RECYCLER DISCHARGE

Copyright 12/14 8 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680

The words Danger, Warning, Caution, and

Notice are used on the safety decals and throughout

this manual, to make you aware of the safety

procedures. Theseproceduresareveryimportant,read

andobey them.

YOUR SAFETY IS VERY IMPORTANT TO US!

Thismachine is equippedwithsafety decals, guards

anddesigns for yourprotection.

Don’t ever take the machine for granted, always be

cautiousandcareful when operatingyourequipment.

Read and follow all the instructions in your manual

thoroughly. Your safety is dependent on your

knowledgeofhowtooperateandmaintain thismachine.

You may obtain additional copies of this manual from

yourSmoracy,LLCDealer.

Beforeoperatingrecycler, you must haveallpotential

operators; read and understand manuals, decals, and

watchthe video tapeandfollowall recommendations.

Regardless of how hard a manufacturer tries to

produce a safe machine, accidents still happen.

Normally accidents are caused by people making

mistakes. They do not read the manual, they ignore

warningdecalsordo not uselockoutsprovidedfortheir

safety. This normally happens after the person has

become accustomed to the machinery. In the initial

start up and operation of the machinery, they are

cautious, they are very careful because they do not

understandthemachine.

Thisequipmentis intended forusebypersonnelwho

are experienced with similar equipment. Always

operate safely. It is also recommended that someone

else is present while operating or servicing in case an

accidentshouldoccur. Neveroperateanymachinewhile

underthe influence ofdrugsoralcohol.

Keep children, bystanders and animals clear of

workingarea. Neveroperate equipment thatisinneed

ofrepair or adjustment.

Before starting the machine, take a minute to check

a few things. The recycler should be in an area

restrictedfrompeoplepassingby. This area aroundthe

recycler must be free of all objects that can obstruct

your movement when working with the machine. The

machine should be checked for loose tools or foreign

objects,especiallyintheinfeedconveyorarea. Alltools

not in use should be secured in a tool box.

Operators must at all times be located within easy

reach of all feed control and shut-off devices when the

unitisrunning. Alsoalwaysbeobservantand prepared

toactivate controlstoprevent an accident.

Do Not wear torn or loose clothing it is more likely to

getcaughtinmovingmachineryparts. Keepsuchitems

as long hair, shirt sleeves, and shirt tails properly

contained. Avoid wearing necklaces, rings, watches,

andespeciallyneckties while operatingthismachinery.

Make sure the machine is in excellent condition, and

all the guards are in place, tight and secure.

Wearallpersonalprotection equipment andfollowall

safety standards per ANSI and OSHA instructions.

Examples of equipment: hard hat, safety glasses,

gloves, ear protection, etc. Do not wear gauntlet or

secured fit gloves. Always keep a fully charged

type A:B:C fire extinguisher with the machine while

operatingor servicing therecycler.

SAFETY PROCEDURES

SAFETY PROCEDURES

WARNING

DANGER

DANGER

Copyright 12/14 9 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680

NeverstandattheentrancetotheInfeedConveyoror

look over the Infeed Conveyor side panels. Never

attempt to manually dislodge material located on the

Infeed Conveyor while the machine is running. Never

raise Feedwheel Yoke and look inside, or look down

Infeed Conveyor while machine is working.

Entanglement in Infeed Conveyor can cause serious

injury. Stay away from the Infeed Conveyor during

operation. Ifthe conveyordriveisnot shutoffastalled

conveyor may restart unexpectedly as the obstruction

isremoved. Donot handfeedrawmaterialontoInfeed

Conveyor.

Avoid moving parts. Keep hands, feet, and clothing

away from power driven parts. Keep all guards and

shieldsin placeandproperly secured.

Stay away from the Feedwheel and Cutterhead

areas. Never stand close to the Feedwheel assembly

whilethemachineisrunning. Never attempt todowork

on a raised Feedwheel without making sure all safety

devicesaresecured. AlwaysengagethehydraulicYoke

Lock Bars, and use the Safety Chain to secure the

Feedwheel assembly to the Discharge Belt Conveyor

rest before replacing Cutterhead inserts or bodies.

Follow proper shutdown procedures before beginning

any type of maintenance to the Recycler.

Entanglement in the Discharge Belt Conveyor can

cause serious injury. Stay away from the conveyor

duringoperation. If theconveyordrive isnotshut offa

stalled conveyor may restart unexpectedly as the

obstruction is removed. Avoid the Discharge Belt

Conveyor area. Ejected material can cause serious

injury. Stay away! Stay clear of thrown and falling

objects. Take the following precautions to avoid

injuries from thrown and falling objects: Wear all

applicable safety equipment. Only properly protected

workers are allowed in “thrown object area”. All

machines in “thrown object area” must have overhead

protection. Machines used to load the recycler must

haveanenclosedcab. Donotleavecontrolsunattended

whilemachine isoperating. Locate therecycler asafe

distance from buildings, public roads and populated

areas.

NEVER sit, stand, lay, climb or ride anywhere

on this machine while it is running, operating, or in

transit. You will be injured.

To avoid damage to the Discharge Conveyor do not

movethemachinewiththeConveyorextended. Donot

foldor unfoldthe Conveyoron unevenground. Do not

cause abrupt stops when raising or lowering the

Conveyor. Do follow all operation, service and safety

guidelines. Dofollow thesesteps topurge airfrom the

hydraulic system every time the Conveyor is moved.

1)Placepressuregaugeindiagnosticportofvalvebank.

2) With Conveyor resting in fold or unfold position,

operatevalvetopositionitfurther in that direction. Hold

valve position for 4 to 5 seconds until gauge reaches

system pressure. 3) Repeat these steps for second

control valve. Now you may proceed to raise or lower

theConveyor. Do operate theConveyorfoldingactions

with the engine at idle. Do fold the Conveyor upper

section first, then the mid section. NEVER slam the

DischargeBelt Conveyorto arest.

It is very important after you have operated a new

machine for approximately an hour, shut down the

machineand recheckall nutsand bolts.It isnormal for

bolts to loosen once on a new piece of machinery. If

you tighten them now, there is a good possibility they

won’t loosen again. Certain bolts should be checked

periodically such as Cutterbody and Teeth bolts, etc.

fortorque and fit.

Most of the nuts used on the Smoracy, LLC

Recyclerareselflocking.After a nuthasbeenremoved

five times, it should be replaced to insure proper

tightness.

SAFETY PROCEDURES

SAFETY PROCEDURES

DANGER

DANGER

DANGER

NOTICE

DANGER

DANGER

WARNING

Copyright 12/14 10 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680 SAFETY PROCEDURES

SAFETY PROCEDURES

Neverusejumpercablesduringfreezingtemperatures.

Tow the machine inside and allow the battery time to

warm up. Explosion will occur with a frozen battery.

Never use jumper cables in a confined or unventilated

area. Battery acid fumes are explosive. Battery acid

cancause severe burns. Avoidcontact witheyes, skin

and clothing. Battery fumes are flammable and can

explode. Neverexpose an openflameorsparknearthe

battery. Keep all burning materials away from the

battery. Whenservicingthebattery,donotsmoke,shield

eyesand face. Servicein awellventilated area.

DO NOT GO NEAR HYDRAULIC LEAKS! High

pressure oil easily punctures skin causing serious

injury, gangrene,or death. DO NOTuse fingersor skin

to check for leaks. Lower load or relieve hydraulic

pressure before loosening fittings. Use a piece of

cardboardto find leaks. Neveruseyour bare hands.

In cold weather situations let your hydraulic system

idle for approximately 15 minutes to allow the system

towarmuptooperating temperature. Avoid burns from

fluid. Hotfluidunderpressure can causesevereburns.

Relieveallpressureinthe system before disconnecting

the lines, hoses or performing other work. Allow

system to cool down to ambient temperature before

opening any coolant or hydraulic oil system.

Inspectrawmaterialspileforprohibitedmaterials. The

following are examples of prohibited materials to be

avoided. Material and products containing toxic

substances, explosive or flammable materials

including chemicals, liquids, gases, pressurized

containers etc., tires, glass, heavy rigid plastic, sheet

metal, masonry, stone materials, and solid metals.

DO NOT operate this machine indoors! Exhaust

fumes can be fatal. Never refuel while the machine is

running or engine is hot. Never refuel in the shop or

building. Alwaysrefuel in awell ventilated area, away

from sparks or open flames, DO NOT SMOKE.

Extinguish all smoking materials. Wipe up all spilled

fuelbefore restartingthe engine. Donot fillabove 1/2”

(12.7 mm) from top of tank.

To obtain the most from the recycler, for the least

amount of cost, it is a good practice to set and follow a

scheduled preventative maintenance program. It will

eliminatemany possibleproblems anddown time.

Check laws and regulations. Know and obey all

federal,state,and local lawsand regulations thatapply

to your work situation and the transportation of a

machine this size.

Keep the machine in good condition. Be sure the

machineisingoodoperatingconditionandthatallsafety

devices,includingguards andshields are installedand

functioningproperly.Visuallyinspectthe machine daily

before starting the machine. Refer to the “Start-up

Procedures“. Make no modifications toyourequipment

unless specifically recommended or requested by

Smoracy,LLC.

Avoid power lines. Electrocution is possible if the

recycler touches a power line. Take the following

precautions. Position the recycler and any loading

equipmentatleast10feet(3meters) from electric lines.

If the machine contacts an electric line stay away from

themachine.

After engine is started, let the Cutterhead turn at the

lowest RPM’s possible. Listen for any type of noise

that is foreign. Any steel against steel noise is

foreign. Ifyouhearanoise,stoptheengineandfindthe

problem.

The machine was built with a maintenance door

enginedisableplugwhich disables theengineif it isnot

installed properly with the maintenance in the closed

position.Correctlyinstalledand maintained, theengine

will not start or it will shut off if the maintenance door

enginedisableplugis disconnected. The maintenance

doormustNEVERbeopenoropenedduring operation.

WARNING

DANGER

DANGER

DANGER

WARNING

DANGER

WARNING

WARNING

WARNNG

Copyright 12/14 11 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680 SAFETY PROCEDURES

SAFETY PROCEDURES

Never work under or around the Feedwheel without

first disengaging clutch, turning off engine, waiting for

the Cutterhead to come to a complete stop, turning

Battery Disconnect Switch off, and you must have the

ignitionkey inYOUR possession. Some maintenance

requires that you work under the Feedwheel while it is

in the raised position. The FeedwheelYoke assembly

isequipped withtwo safetydevices thatmust beput in

placebefore work commences.

1. Yoke Lock Bars:

Withthe engine running,clutch disengaged,andthe

Cutterhead completely stopped, raise the Feedwheel

Yoketo its maximum heightusing theFeedwheel Yoke

manual control valve. Then locate the Hydraulic Yoke

Lock valve and pull the lever. The Yoke Lock Bars

locatedon top ofthe Cutterheadhousing willextend or

engage.

2. Safety Chain:

Nowuse the SafetyChain attachedto the Discharge

Belt Conveyor rest and secure it to the lug located on

the right side of the Feedwheel Yoke. With the safety

devices in place lower the Feedwheel Yoke until it

contactstheYoke LockBarsand the SafetyChainpulls

tight. Disengage clutch, turn off engine, wait for the

Cutterhead to come to a complete stop, turn Battery

Disconnect Switch off, and you must have the ignition

keyinYOUR possession. Foradded safety itis a good

practice to use an additional log chain to help support

the Feedwheel Yoke to the conveyor rest. When all

safety devices are in place you may start performing

maintenanceto themachine.

Do Not feed this machine with the top feedwheel

pinned, blocked or secured in the open position.

Before you change the Screen in your Recycler

you must remember to never do any maintenance

work inside or around your Recycler without first

disengaging clutch, turning off engine, waiting for the

Cutterheadtocome to acomplete stop, turningBattery

Disconnect Switch off, and you must have the ignition

key in YOUR possession.

The Recycler is equipped with a remote controlled

electric lift to assist service person while changing the

screen. It is only to be used to assist in changing the

screen!!! Always follow the instructions in the lift

owners manual! Never attempt any maintenance or

serviceunless the equipmentis completely shutdown!

Never overload lift or its cable, it is only to be used to

handle the recycler screens (max. 300 lbs. or 136 kg)!

Always keep components 100% operational and

maintained:cable, hooks,wiring,connections,boltsand

nuts,controls, etc.! Always replace wireropeif it shows

kinks, frayed wires, broken or worn strands! Always

wear quality leather gloves when handling wire rope!

Always stay clear of wire rope, hooks, lift and screen

whileoperating! Always insure thatthe brake devicein

liftis operational andmaintained, beforeusing it!

FirstlowerwinchcabletoScreenarea,removewinch

hook stop block from winch hook. Hook winch up to

thebackofScreenand snug upthecable. Removethe

eight mounting bolts that hold the screen in place.

Remove Screen using winch. Clean ALL debris from

Screen mounting area, then install new Screen.

Reinsert clamp locks and bolts into Screen mounting

area. Lightlysnugupbolts then adjustScreen. Screen

mustALWAYSbeat least1/8” (3.2mm) minimum from

teeth. Whenfinaladjustment is completedtorquebolts

to376ft.-lbs(510Nm). Reinstallwinchstopblockbefore

reeling in winch cable. Stop block must pull tightly to

enginebase when winchoperation iscomplete.

Do not hand feed this machine! This machine is

designed to only be fed by a mechanical log loader.

Feeding material into this machine by hand is not

permitted or authorized. Severe injury or death can

result!

Do not run or operate this machine with any door/

compartment open. Door enclosures are guards, you

canbe injured ifopen during operation.

Donotopenthebeltshielddoorunlessengineand all

machinepartshavecompletelystopped moving. Open

thisdooronly to checkfor proper drivebelt tension. Do

not start or operate this machine unless door is

securely in place.

DANGER

DANGER

DANGER

WARNING

WARNING

Copyright 12/14 12 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680 SAFETY PROCEDURES

SAFETY PROCEDURES

Do not work on the machine if the engine is running

withtheclutch disengaged. Aclutchcan self-engageif

eitherthepilot or throw-outbearinghappens to seizeto

the main output shaft.

Remember, it should take most of yourstrengthto

engage the clutch. If the clutch engages easily, DO

NOT OPERATE this recycler until the clutch has been

adjusted.

TheclutchisanexpensivecomponentpartoftheBeast

Recycler. Itneedspropermaintenance(seemaintenance

section and manufacturers manual for detailed

information). The operator must take care in the

engagement and disengagement of the engine, RPM

should always be 800 to 900 RPM.

Check for fires, clean off debris, switch off battery.

Donot leave thismachine unattended untilall potential

firedebris isremoved, nofire or smolderingexists and

batteryisswitched off. Thedieselengine creates many

hot spots, including exhaust manifold and turbo.

Removeall flammable debris(wood, mulch, oils,fuels,

etc.)from: engineturboandexhaust,besideandaround

engine, under engine and tanks, inside belt shield,

insidecontrolcabinets,anywhere materials collect. Do

notleave this machineunattended untilall firehazards

are removed, hot spots are cold and battery is

disconnected. Always keep several type A:B:C fire

extinguishers on the job at all times. Smoracy, LLC is

not responsible for fires caused by fire hazards left to

smolderandburn, or impropershutdown procedures. Before transporting the machine: 1) Clean out any

existing material on the machine by allowing the

machineto operatefor severalminutes withoutfurther

loading. 2)Idle engine anddisengage clutch. 3)Make

sure that the feedwheel is in the lowered position.

4)Make sure all manual hydraulic control valvesare

in the off position. 5) Switch engine off and remove

ignition key. 6) Lock radiator debris screen in

transport position. 7) Stow remote cable controls

inside hydraulic compartment. 8) Lock compartment

doors. 9)Cleanoff all Debrisand potential firehazards

from the machine. Along with these procedures make

sure to follow all of the “transportation procedures “ in

that section.

The self activating fire extinguishers located in

variousplaceswill not stopyourmachine from burning.

They are there to help put out a fire that may start. If a

firegets going afteryou have leftthe machine,they will

beineffective. You mustcleanthedebrisawayfrom the

engineandotherhotareas before leaving themachine!

Itisyour responsibility toproperly maintain andtest the

extinguishersas instructed bythe directionsthat come

with the fire extinguisher. If you do not have that

informationcontactSmoracy,LLC.

FIRE WARNING!

Observe tire manufacture’s instructions. Do not

inflatetiresaboverecommendedpressure. Checktires

onadailybasisforlowpressure. Inflatetorecommended

pressure. Replaceany wheel withtire cuts,bubbles or

damagedrims.

The stabilizer is used to assist in truck hookup. It is

highly recommended that blocks are used under the

frame near the hitch to support the Recycler during

operation.

WARNING

DANGER

DANGER

DANGER

DANGER

Ifthemachine is equippedwith a screenhoist,do not

operate the hoist while the machine is running. Make

sure the screen hoist and all the components are in

goodworking orderbeforeoperating. Useextremecare

and safety when operating the screen hoist. Screen

hoist operation is a one person job. This means the

person who hooks the hoist to the screen is the same

person who operates the hoist. Make sure the screen

is securely attached to the screen hoist before lifting.

Donotexceedtheliftingcapabilitiesof the screen hoist.

This device is designed and authorized to lift screens

only! Beforeresumingmachineoperationortransporting

the machine, make sure the screen hoist and all

components are properly stored on the machine and

thescreen hoist disconnectswitch is inthe offposition.

Donotleavethemachineunattended,unlessthescreen

hoist disconnect switch is in the off position. Use only

themanufacturer’srecommendedfluidforthehoistpump.

WARNING

Copyright 12/14 13 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680 SAFETY DECALS

SAFETY DECALS

Safety Decals located on your Beast Recycler contain useful information to assist you in operating your

equipment safely. Some of the decals on your machine and their location are shown in this section.

It is very important that all decals remain in place and in good condition on your machine. Please follow the

careand instructions givenbelow:

1) You should use soap and water to keep your decals clean. Never use mineral spirits or

anyotherabrasive cleaners.

2) Replace immediately any missing or damaged decals. If decals are damaged or

removed it is the owner’s responsibility to replace them. The location the decal is going

to be applied to must be clean and dry, and at least 40° F (5°C) before applying decal.

3) When the need arises to replace a machine component with a decal attached, be sure

andreplace thedecal.

4) Replacement decals areavailable, and canbe purchased fromthe manufactureror

yourSmoracy,LLCDealer.

EXAMPLES:

NOTICE

DECALMAINTENANCEISTHE

RESPONSIBILITYOFTHEOWNEROFTHIS

MACHINE.KEEPDECALSLEGIBLE.DECALS

(ETC.)AREAVAILABLEINOTHERLANGUAGES.

CONTACT:PARTS DEPARTMENT

6750 MILLBROOK RD.

REMUS, MI 49340

PHONE (888) 748-6348

DANGER

DANGER

DANGER

FALLING OBJECTS - STAND CLEAR

STAY CLEAR - MOVING CONVEYOR

FLYING OBJECTS

STAY CLEAR

OR YOU WILL BE

INJURED!

Copyright 12/14 14 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680

DECAL LOCATIONS

IMPORTANT!!!!!!

ALTHOUGH LOCATIONSMAYVARY,ALLDECALS MUSTBE ONMACHINEDURING OPERATION

IFANYDECALS BECOMEDAMAGED, REPLACE IMMEDIATELY.

SAFETY DECALS

INSIDECONTROLCABINETS

DECALS

8,11,12,13,14,15,27,28,30,40,

65

INLAIDPLAQUES

26 344

38

16

49

41

46

39

51 48 33 42

122 31 29 15 45 7

50

63

818 47 37 36 18 40

40

34 35 46

21

19

38,43

32

24

46

ONREARBUMPER

BATTERYBOX

25,32

40 36 23 35 50 15 45

48

63

33 42 122 51 39 16 44 326

46 49 41

38

64

60,61

60,61

50

62

66

66

Copyright 12/14 15 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680

DECAL LOCATIONS

Modifications and/or additions of decals to this list will happen.

Consult recycler dealer or manufacturer for most current decal package.

*SOME DECALS ARE FOR OPTIONAL COMPONENTS

LOCATION NUMBERS DECAL NUMBERS DESCRIPTION

1. ID-33 3680 Recycler...

3. ID-43 Distributed By: Bandit Industries Inc...

Variety of locations INST-04 Arrow

Variety of locations INST-12 Grease DailyArrow

Variety of locations INST-16 Grease Weekly

7. INST-38 Avoid ProblemsAnd Equipment Damage...

8. INST-39 Oil Daily

9. *Optional INST-44 California Proposition65...

10. INST-45 For Parts And Service...

11. INST-47 Trouble ShootingMachine Problems...

12. INST-50 AvoidDamageToDischargeConveyor...

13. INST-51 Fire Warning!The SelfActivating...

14. INST-53 Hydraulic Oil......

15. INST-56 Avoid CostlyDowntime.....

64. INST-92 Air BrakeRelease

16. INST-97 Adjust Chain Tension......

66. INST-98 Adjust Chain Tension.......

17. N-02 Notice MaintainLubrication andHydraulics...

18. N-03 Notice Service Required Under...

19. N-05 Notice FrequentAdjustment...

20. N-06 Notice DecalMaintenance Is...

21. N-07 Notice TheClutch HandleShould Not...

22. N-08 Notice This MachineIs Covered...

23. N-14 Notice Do Not Start To Weld...

24. N-16 Notice 24 Volt Circuit

25. N-17 Notice Battery Disconnect......

26. N-20 Notice MaximumTowingSpeed55MPH

27. N-26 Notice Battery Disconnect Switch...

28. N-27 Set Feed To Match Material

29. N-28 In Line FuelFilter

65. N-30 Notice Must Wait 45 Seconds.......

SAFETY DECALS

Copyright 12/14 16 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680 SAFETY DECALS

DECAL LOCATIONS

IMPORTANT!!!!!!

ALTHOUGH LOCATIONSMAYVARY,ALLDECALS MUSTBE ONMACHINEDURING OPERATION

IFANYDECALS BECOMEDAMAGED, REPLACE IMMEDIATELY.

INSIDECONTROLCABINETS

DECALS

8,11,12,13,14,15,27,28,30,40

INLAIDPLAQUES

26 344

38

16

49

41

46

39

51 48 33 42

122 31 29 15 45 7

50

63

818 47 37 36 18 40

40

34 35 46

21

19

38,43

32

24

46

ONREARBUMPER

BATTERYBOX

25,32

40 36 23 35 50 15 45

63

33 42 122 51 39 16 44 326

46 49 41

38

64

60,61

60,61

48

62

62

66

66

Copyright 12/14 17 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680

LOCATION NUMBERS DECAL NUMBERS DESCRIPTION

30. W-01 Warning Do Not Go Near Leaks...

31. W-02 WarningCombustibleLiquid...

32. W-04 Warning Frozen Battery Will Cause...

33. W-08 Warning Wear Eye & Personal Protection...

34. W11 WarningDo Not Leave......

35. W-13 WarningCheck ForFires, CleanOff Debris...

36. W-14 Warning This Recycler Is Equipped With...

37. W-15 WarningDo NotOpen ThisDoor Unless...

38. D-02 Danger Moving Parts...

39. D-16 Danger DoNot Hand FeedThis Machine...

40. D-17 Danger DoNot Run OrOperate ThisMachine...

41. D-20 Danger FlyingObjectsStandClear...

42. D-23 Danger RestrictedAreaDo NotApproach...

43. D-24 Danger FallingObjectsStandClear...

44. D-25 DangerStayClear-MovingConveyor

45. D-26 Danger DoNot WorkUnder FeedWheel...

46. D-27 Danger Hydraulic ShutDown Switch

47. D-28 Danger DoNot Insert Fingers...

48. D-29 Danger NODo NotClimb OrReach...

49. D-30 Danger Do Not Sit, Stand, Lay, Climb...

50. D-31 Danger Never WorkUnderTopFeedWheel...

51. D-32 DangerAvoidInjuryOr Death...

52. D-34 Danger DoNot WorkUnderTop Wheel...

INL-501 InlaidPlaque-Feedwheel

INL-502 InlaidPlaque-Infeed

INL-503 InlaidPlaque -Yoke

INL-504 InlaidPlaque- Discharge

INL-505 InlaidPlaque - Stablizer

INL-506 InlaidPlaque-ConveyorFold

INL-507 Inlaid Plaque - Yoke Lock

INL-508 InlaidPlaque - Screen

INL-509 InlaidPlaque-Auger

60. OPEN OpenVinyl

61. CLOSED ClosedVinyl

62. Model 3680 Beast Vinyl

63. *Optional Magnet CautionStrong Magnet

DECAL LOCATIONS

Modifications and/or additions of decals to this list will happen.

Consult recycler dealer or manufacturer for most current decal package.

SAFETY DECALS

*SOME DECALS ARE FOR OPTIONAL COMPONENTS

Copyright 12/14 18 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680 SAFETY DECALS

Examplesofsomeprevious(oldstyle)decalsonSmoracy,LLCequipment

containingsafetyinformation. Thisinformationisalsocontainedinthe

current(newstyle) decals,intheoperatingmanual,andintheoperationsvideo.

CHECK FOR FIRES, CLEAN OFF DEBRIS

SWITCH OFF BATTERY

DONOTLEAVETHIS MACHINE UNATTENDED UNTILALLPOTENTIALFIRE

DEBRIS IS REMOVED, NO FIRE OR SMOLDERINGEXISTS AND

BATTERYIS SWITCHEDOFF.THE DIESELENGINECREATES

MANYHOT SPOTS, INCLUDINGEXHAUST MANIFOLDAND

TURBO. REMOVE ALL FLAMMABLE DEBRIS (WOOD,

MULCH,OILS, FUELS, ETC.)FROM...

• ENGINETURBO&EXHAUST

• BESIDE&AROUND ENGINE

• UNDERENGINE&TANKS

• INSIDEBELTCOWLS

• INSIDECONTROLCABINET’S

• ANYWHEREMATERIALSCOLLECT

DONOTLEAVETHISMACHINEUNATTENDEDUNTILALLFIREHAZARDSAREREMOVED,HOT

SPOTSARE COLDANDBATTERYISDISCONNECTED.

ALWAYSKEEPSEVERALTYPEA:B:CFIRE EXTINGUISHERS OPERATIONALANDONTHE JOB

ATALLTIMES.

SMORACY, LLC IS NOT RESPONSIBLE FOR FIRES CAUSED BY FIRE HAZARDS

LEFT TO SMOLDER & BURN, OR IMPROPER SHUTDOWN PROCEDURES.

THISMACHINE CAN CREATE

AHIGH FIRE HAZARD

THE OPERATOR OF THIS MACHINE IS

RESPONSIBLE FOR FIRE PROTECTION

•DO NOTALLOW FLAMMABLE MATERIALTO BUILD

UP ON OR AROUND THE MACHINE, ESPECIALLY ON

ENGINE TURBO OR NEAR ENGINE.

OPERATOR IS RESPONSIBLE TO CLEAN TURBO,

ENGINE, ETC. WHEN ENGINE IS SHUT DOWN.

ALWAYS KEEP OPERATIONAL FIRE EXTINGUISHERS

WITH MACHINE. ALWAYS TURN OFF ELECTRICAL

DISCONNECT WHEN ENGINE IS SHUT OFF ~

DISCONNECT IS LOCATEDAT THE BATTERYBOX.

DO NOT!! Climb or reach into the infeed

conveyor when the engine is running.

KEEPHANDSCLEAR

Table of contents

Popular Industrial Equipment manuals by other brands

Rittal

Rittal VX25 Blue e+ Assembly instructions

Festo

Festo DFST-32 G2 Series operating instructions

Delachaux

Delachaux Conductix-Wampfler 0314 Series installation manual

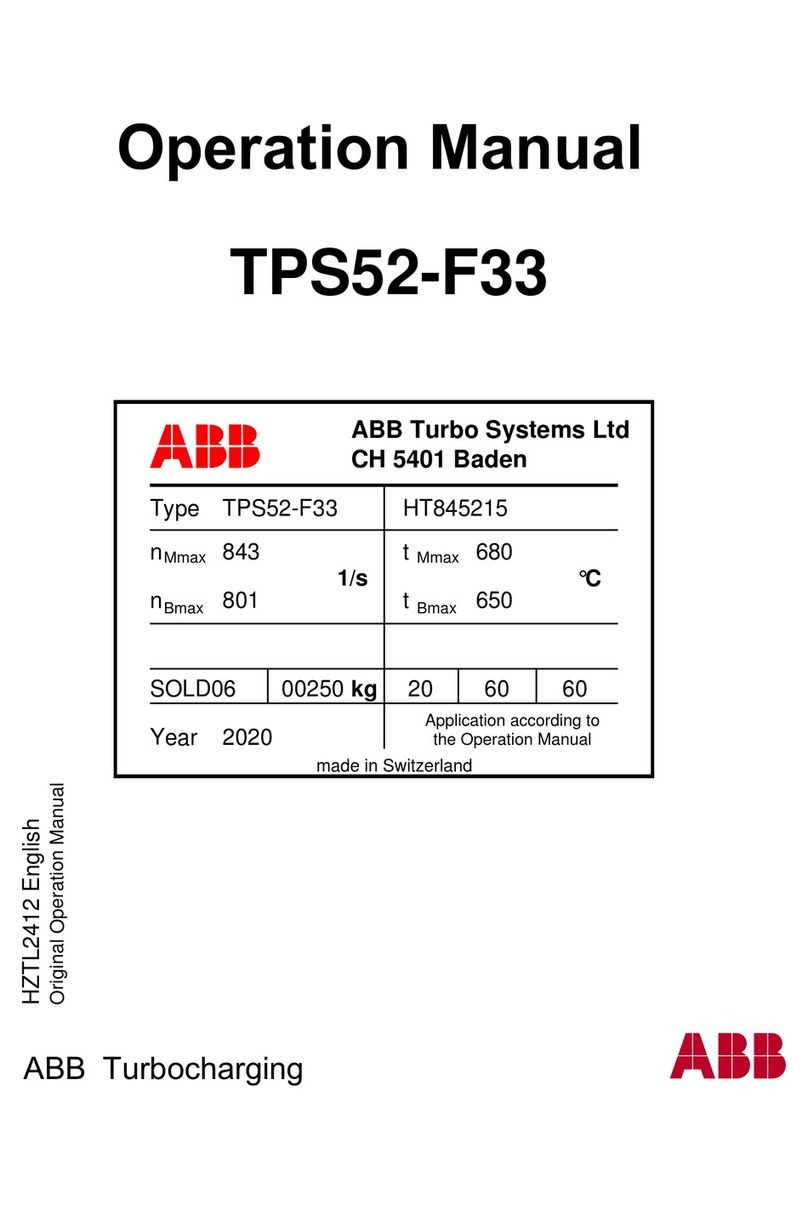

ABB

ABB HT845215 Operation manual

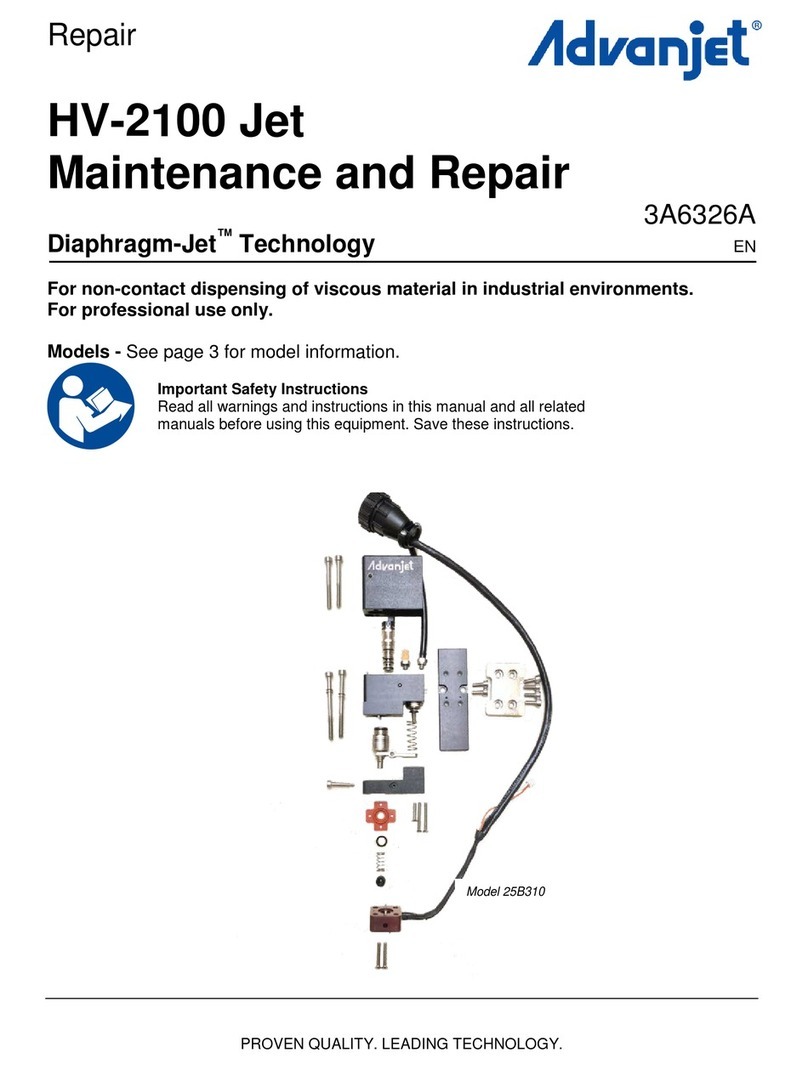

Advanjet

Advanjet HV-2100 Repair instructions

Dometic

Dometic SEASTAR POWER ASSIST PA1200-2HP Installation and user manual