Translation of the original instructions

© 2020 all rights reserved to Festo SE & Co. KG

1 Applicable Documents

All available documents for the product èwww.festo.com/sp.

2 Safety

2.1 Safety instructions

– Take into consideration the ambient conditions at the location of use.

– Only use the product in original status without unauthorised modifications.

– Observe labelling on the product.

– Store the product in a cool, dry, UV-protected and corrosion-protected envir-

onment. Ensure that storage times are kept to a minimum.

– Prior to mounting, installation and maintenance work: Switch off compressed

air supply and secure it from being switched back on.

– Observe tightening torques. Unless otherwise specified, the tolerance

is±20%.

2.2 Intended Use

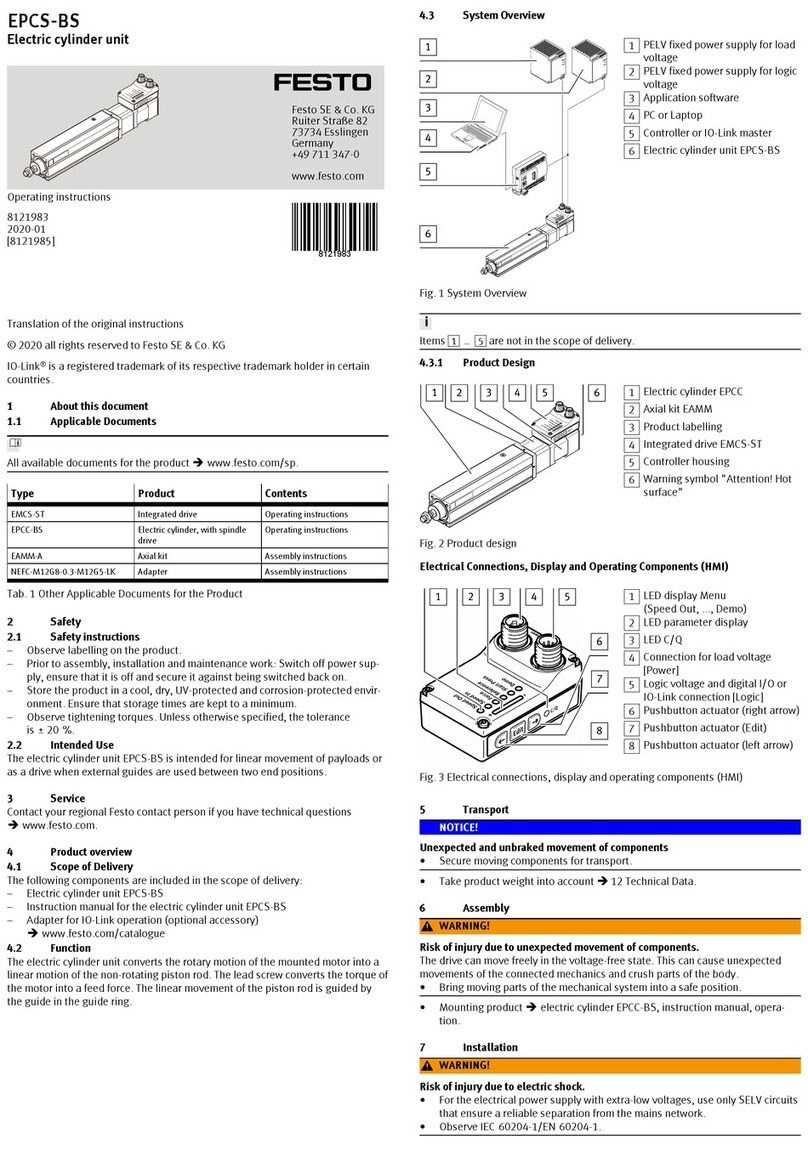

The stopper cylinder DFST is designed for use as a retractable fixed stop in order

to reach defined holding positions with transported material (e.g. on mounting or

sorting systems). The DFST sorts the stationary transported material in buffer

zones.

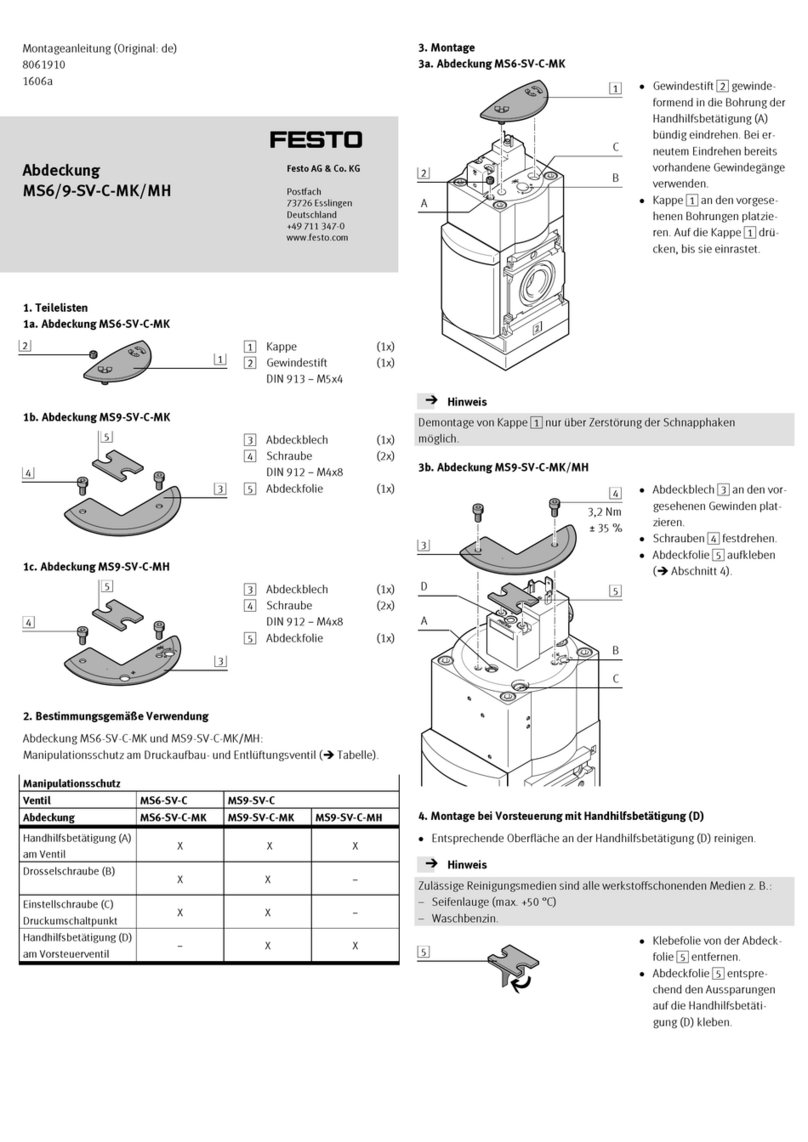

Fig. 1 Stopping transported material

2.3 Foreseeable misuse

With DFST-...-L: the toggle lever must not be overrun in the stop direction by the

transported material when the lever locking mechanism is active. Otherwise the

transported material will damage the locking mechanism.

2.4 Training of qualified personnel

Installation, commissioning, maintenance and disassembly should only be con-

ducted by qualified personnel.

The skilled personnel must be familiar with the installation of pneumatic control

systems.

3 Further information

– Accessories èwww.festo.com/catalogue.

– Spare parts èwww.festo.com/spareparts.

4 Service

Contact your regional Festo contact person if you have technical questions

èwww.festo.com.

5 Product overview

5.1 Function

The stopper cylinder DFST is a double-acting cylinder. The piston rod is extended

with the toggle lever mechanism by pressurising the supply port 1. The toggle

lever gently stops the incoming transported material with the integrated shock

absorber. The piston rod is retracted by pressurising the supply port 2. The

stopper cylinder with spring return (not applicable for DFST-...-D/DL) can also be

set to single-acting. This is done by screwing a silencer into the supply port 1.

This makes sense if reduced extension velocities are sufficient.

Lever Locking Mechanism

With the stopper cylinder DFST-..-L with a factory-installed lever locking mechan-

ism, the toggle lever locks into its end position. When the stopper cylinder is

retracted, the toggle lever locking mechanism is automatically deactivated.

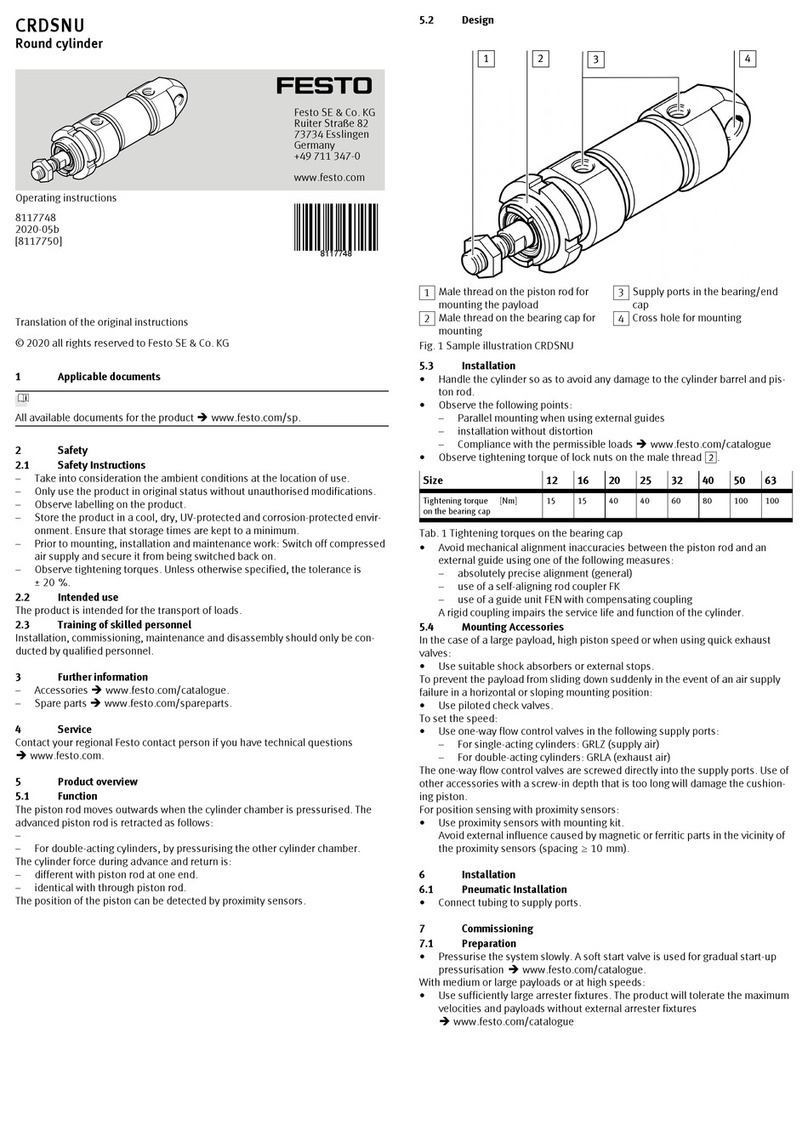

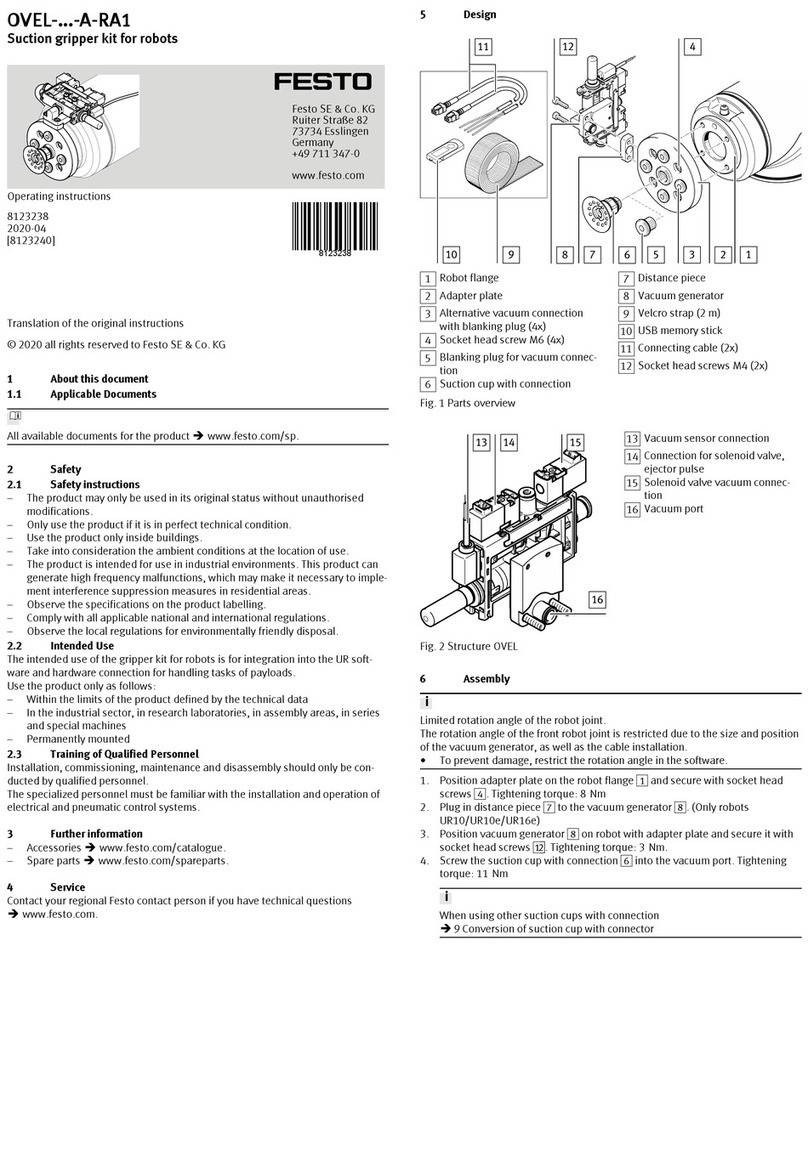

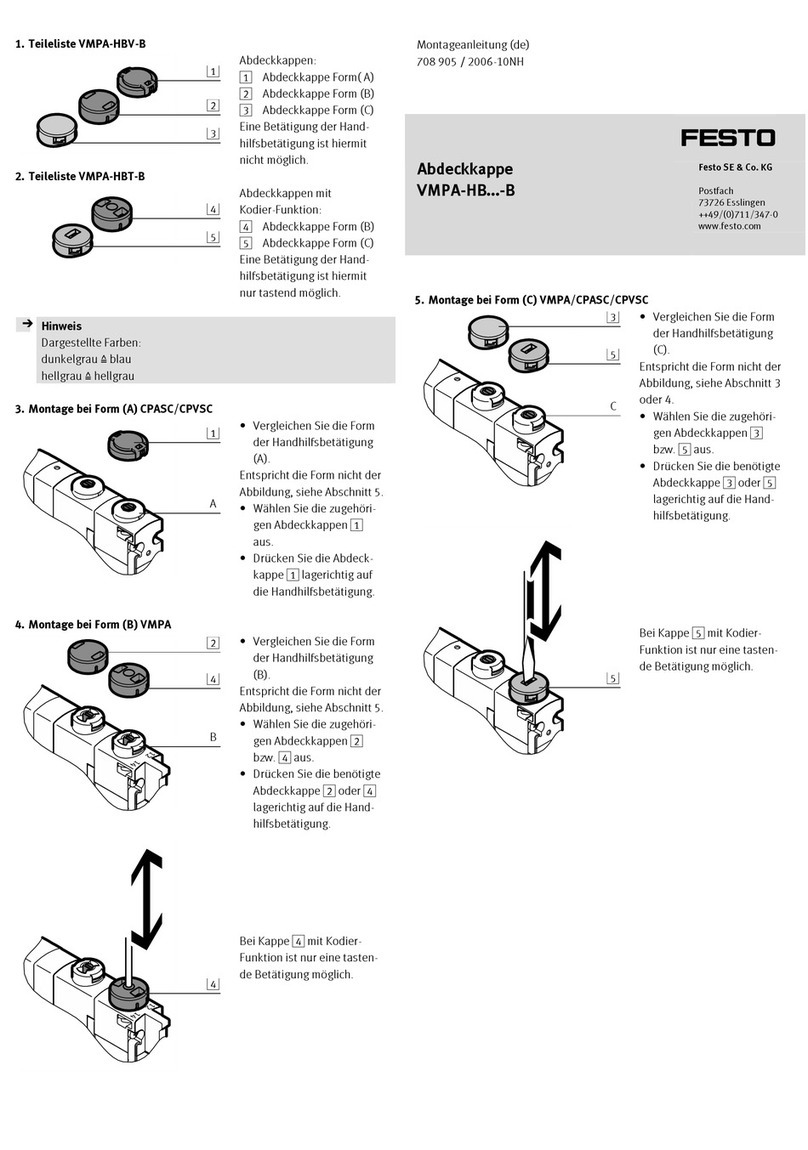

5.2 Structure

1Supply port (extending, 2x)

2Supply port (retracting, 2x)

3Guide rod for protection against

rotation

4Piston rod

5Detent for knurled nut

6Roller toggle lever

7Stop roller

8Thread for inductive proximity

sensor (2x)

9Lever locking mechanism (option-

al)

10 Knurled nut for setting the cush-

ioning

11 Stop for lever locking mechanism

12 Hole for mounting toggle lever

deactivation mechanism

13 Through-hole for mounting (4x)

14 Slot for proximity sensor (6x)

Fig. 2 Product design

8123248

DFST-32-...-G2

Stopper cylinder

8123248

2020-01

[8123250]

Instructions| Operating

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com