ii

TI 32P01J10-01EN

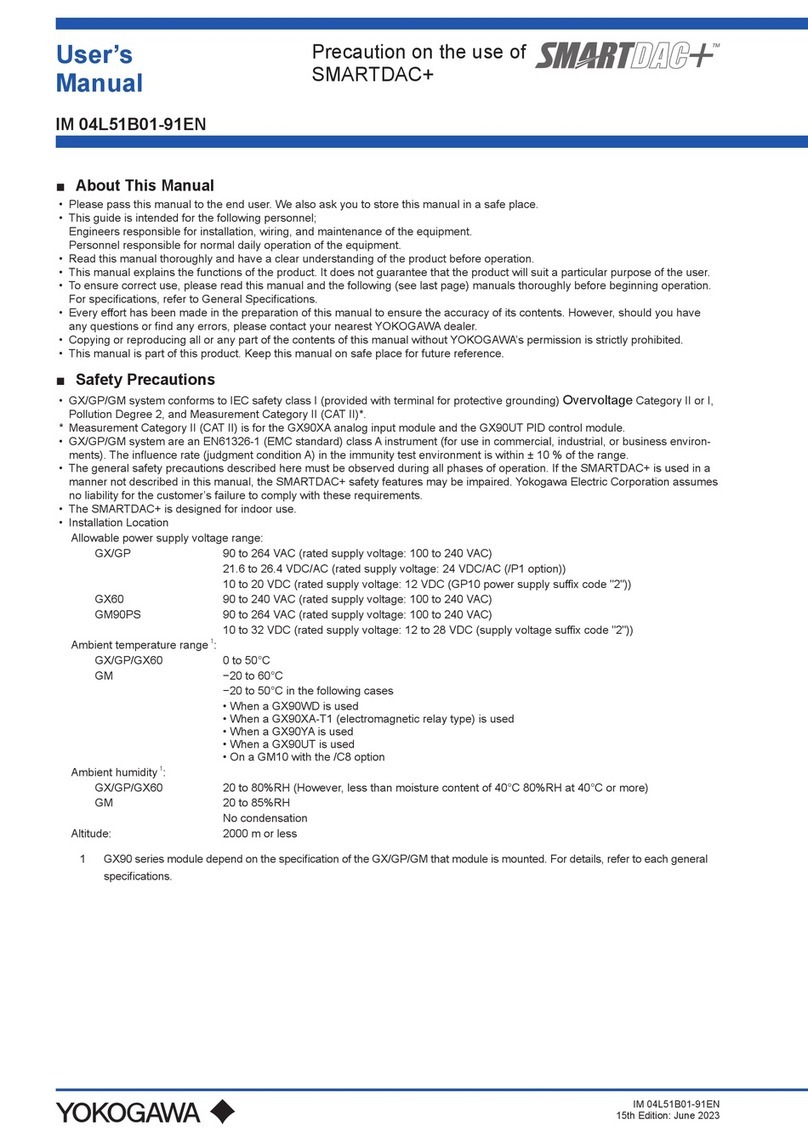

Safety Precautions

Safety, Protection, and Modication of the Product

• In order to protect the system controlled by the product and the product itself and ensure

safe operation, observe the safety precautions described in this Technical Information

and the User’s Manuals. We assume no liability for safety if users fail to observe these

instructions when operating the product.

• If this product is used in a manner not specied in this Technical Information, the protection

provided by this product may be impaired.

• If any protection or safety circuit is required for the system controlled by the product or for

the product itself, prepare it separately.

• Be sure to use the spare parts approved by Yokogawa Electric Corporation (hereafter

simply referred to as YOKOGAWA) when replacing parts or consumables.

• Do not use the accessories (Power supply cord set, etc.) that came with the product for any

other products.

• Modication of the product is strictly prohibited.

• The following symbols are used in the product and this Technical Information to indicate that

there are precautions for safety:

Indicates that caution is required. This symbol for the Product indicates the possibility of

dangers such as electric shock on personnel and equipment, and also indicates that the

user must refer to the User’s Manuals for necessary actions. In the User’s Manuals, this

symbol is used together with a word “CAUTION” or “WARNING” at the locations where

precautions for avoiding dangers are described

Indicates that caution is required for hot surface. Note that the devices with this symbol

become hot. The risk of burn injury or some damages exists if the devices are touched or

contacted.

Identies a protective conductor terminal. Before using the Product, you must ground the

protective conductor terminal to avoid electric shock

Identies a functional grounding terminal. A terminal marked “FG” also has the same

function. This terminal is used for grounding other than protective grounding. Before

using the Product, you must ground this terminal.

Indicates an AC supply.

Indicates a DC supply.

Indicates the ON state. The state of a power on/o switch and others is indicated.

Indicates the OFF state. The state of a power on/o switch and others is indicated.

Oct. 5, 2018-00