TAKEDO - 3VF NXP USER MANUAL Release P09.1 dated 01-12-2017

9

1 – INTRODUCTION

The TAKEDO–3VF NXP is an inverter drive with built-in EMC filter and smoothing choke, responding to

Council Directives 3/89/CEE (electromagnetic compatibility) 336/73/CEE (low voltage equipment).

To ensure compliance with EN12015 regarding low frequency harmonics, a further 3% inductance is

required.

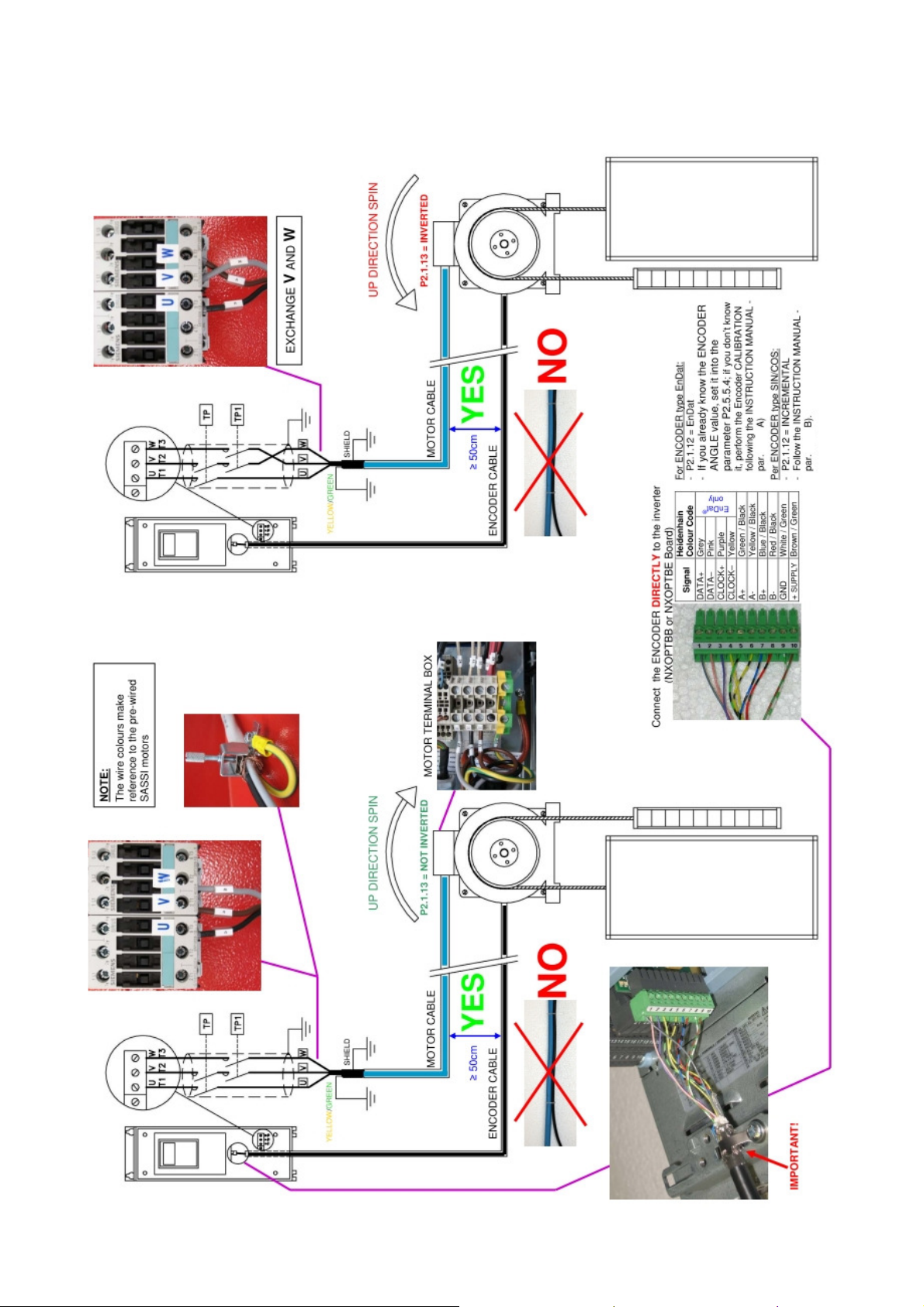

The drive can operate both in open loop and closed loop modes. For operation in closed loop mode, an

optional circuit board is required, and an encoder as described in the following pages.

This manual provides you with the necessary information about the starting up and operation of the NXP

frequency converter. You can find further information about application and installation in a lift control panel

in the ANNEX NXP FOR PANEL WIRING SPECIALISTS , available in electronic edition on our website:

www.sms.bo.it.

2 – SAFETY WARNINGS AND PRECAUTIONS

Full details are available in the original VACON manual (NXP range inverters) which can be consulted

at www.it.vacon.com.

Read this manual in its entirety before powering up the equipment, following the procedures step by step. In

detail, please read the following chapters carefully:

5.4 – ACTIVE FAULTS AND ALARMS

6 – ADJUSTMENT PROCEDURE

2.1 SAFETY WARNINGS

Follow the procedures indicated below with due care, so as to avoid any risk of serious accident.

1- The leakage current from the inverter to ground is greater than 30mA, and accordingly, the power

circuit must incorporate a differential circuit breaker with Id not less than 300mA, type B or type A

(type B is preferable). Under European directives, the ground connection must use a cable of not less

than 10 mm² section.

2- If the parameters used to program the drive are incorrect, the motor may rotate faster than synchronous

speed. Do not run the motor beyond its specified electrical and mechanical limits. The installer is

responsible for ensuring that movements are generated in conditions of safety, without exceeding

specified operating limits.

3- Risk of electrocution. Power up the inverter only with the front cover fitted. NEVER remove the cover

during operation. Before carrying out any operation on the equipment, isolate from the electrical power

supply and wait a few minutes for the internal capacitors to discharge.

4- The external braking resistor heats up during operation. Do not install it close to or in contact with

inflammable materials. To improve heat dissipation it is good practice to fix the resistor to a metal plate.

Ensure it is properly protected and cannot be touched.

5- The inverter must always be connected to the mains supply. In case of interruption wait 1 minute at

least before restoring the supply. TOO NEAR INSERTIONS OF THE MAINS CAN CAUSE A

PERMANENT DAMAGE OF THE INVERTER

2.2 PRECAUTIONS

Follow the procedures indicated in the manual with care so as to avoid the risk of damaging or destroying the

drive.

1- Do not connect the equipment to a voltage higher than the permissible input voltage. An excessive

voltage can cause irreparable damage to internal components.

2- Check the fan regularly: check the air flow is constant and remove and built-up dust.

3- To avoid the risk of damaging the drive in case it stays not working without power supply for a

long time, you should follow these precautions:

- If the inverter doesn’t work since several months, before starting the operation, regenerate the

bus capacitors powering up the drive at least for 1 hour preventing it can operate.

- If the inverter doesn’t work since one year or more, to regenerate the bus capacitors power up

the drive, preventing it can operate, for 1 hour at an input voltage less than 50% the rated

voltage, then for 1 hour at the rated input voltage.

4- Do not connect capacitors to the inverter outputs.

5- If the drive protection functions trip, do not reset the fault before having analysed and removed the

cause of the fault.

6- The lift system should be counterweighted at 50%, if counterweighted at 40% the current in up direction

with full load is greater and requires a larger capacity inverter to that normally necessary, with

consequent greater cost.

7- Use a drive having rated current equal to or greater than the motor rated current .

8- The braking resistor have to be connected between B+ and R-.

If connected between B+ and B-, the inverter will be permanently damaged.