Snap Fresh BBT-JOZ57C User manual

CORDLESS DRILL

User Manual

BBT-JOZ57C

geprufte

Sicherheit

Read all safety rules and instructions carefully before operating this tool.

+1 833 635 0955

Please scan the QR CODE for more services.

CONTENTS

Contents..................................................................................................................................................................................2

.......................................................................................................................................................................................

Safety instructions ....................................................................................................................................................4-7

3

.............................................................................................................................................7-8Machine information

............................................................................................................................................................................8-11

.......................................................................................................................................................................

.....................................................................................................................................................................

...................................................................................................................................................................

..............................................................................................................................................................................

12-13

13

13

14

Environment

Warranty

Maintenance

Operation

Assembly

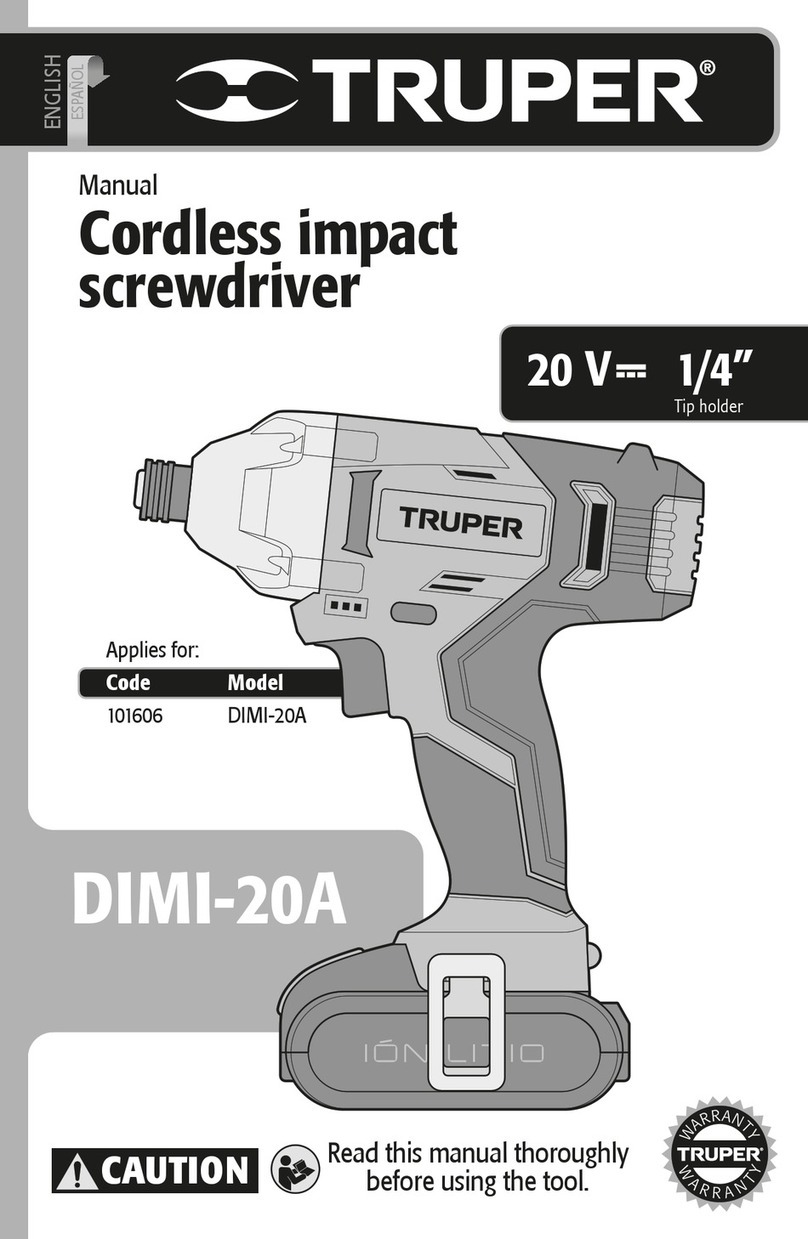

Symbols

2

Read the user manual.

Denotes risk of personal injury, loss

of life or damage to the tool in case of

non-observance of the instructions

in this manual.

Risk of electric shock.

Variable electronic speed.

Rotation, left/right.

Do not use in rain.

Indoor use only.

Class II machine - Double insulation

You don’t need any earthed plug.

Time-lag miniature fuse-link.

Max temperature 450C.

Do not throw the battery into fire.

Do not throw the battery into water.

Separate collection for Li-ion battery.

SYMBOLS

The following symbols are used in the user manual or on the product:

3

SAFETY INSTRUCTIONS

Read the enclosed safety warnings, the additional safety warnings and the instructions. Failure to

follow the safety warnings and the instructions may result in electric shock, fire and/or serious

injury. Save the safety warnings and the instructions for future reference.

GENERAL POWER TOOL SAFETY WARNINGS

WARNING! Read all safety warnings and all instructions. Failure to follow the warning and

instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) Work area safety

.

.

.

.

.

.

.

.

.

Keep the work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

Keep children and bystanders away while operating a power tool. Distractions can cause you to

lose control.

2) Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets

will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords

increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoidable, use a residual current device (RCD)

protected supply. Use a RCD to reduces the risk of electric shock.

4

.

.

3) Personal safety

Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in serious personal injury.

Use personal protective equipment. Always wear eye protection

.

Protective equipment such as

dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions

will reduce personal injuries.

.

Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power

source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger

on the switch or energising power tools that have the switch on invites accidents.

5

.

.

.

.

Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

If devices are provided for the connection of dust extraction and collection facilities, ensure these

are connected and properly used. Use of dust collection can reduce dust related hazards.

.

Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore

tool safety principles. A careless action can cause severe injury within a fraction of a second.

.

.

.

.

.

.

.

4) Power tool use and care

Do not force the power tool. Use the correct power tool for your application. The correct power

tool will do the job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or the battery pack from the power tool before

making any adjustments, changing accessories, or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool accidentally.

Store idle power tools out of the reach of children and do not allow persons unfamiliar with the

power tool or these instructions to operate the power tool. Power tools are dangerous in the hands

of untrained users.

Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and

any other condition that may affect the power tool’s operation. If damaged, have the power tool

repaired before use. Many accidents are caused by poorly maintained power tools.

Keep cutting tools sharp andclean. Properly maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking

into account the working conditions and the work to be performed. Use of the power tool for

operations different from those intended could result in a hazardous situation.

.

Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles

and grasping surfaces do not allow for safe handling and control of the tool in unexpected

situations.

.

.

.

5) Battery tool use and care

Recharge only with the charger specified by the manufacturer. A charger that is suitable for one

type of battery pack may create a risk of fire when used with another battery pack.

Use power tools only with specifically designated battery packs. Use of any other battery packs

may create a risk of injury and fire.

When the battery pack is not in use, keep it away from other metal objects, like paper clips, coins,

keys, nails, screws or other small metal objects that can make a connection from one terminal to

another. Shorting the battery terminals together may cause burns or a

fi

re.

.

Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact

accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid

ejected from the battery may cause irritation or burns.

ADDITIONAL SAFETY WARNINGS FOR DRILLS AND SCREW DRIVERS

•

•

Wear ear protectors when impact drilling. Noise exposure can cause hearing loss.

•Hold the power tool by insulated gripping surfaces, when performing an operation where the

cutting accessory may contact hidden wiring. Cutting accessory contacting a “live” wire may make

exposed metal parts of the power tool “live” and could give the operator an electric shock.

•Brace the tool properly before use This tool produces a high output torque and without properly

bracing the tool during operation, loss of control may occur resulting in personal injury.

SAFETY INSTRUCTIONS WHEN USING LONG DRILL BITS.

•Never operate at higher speed than the maximum speed rating of the drill bit. At higher speeds,

the bit is likely to bend if allowed to rotate freely without contacting the workpiece, resulting in

personal injury.

•Always start drilling at low speed and with the bit tip in contact with the workpiece. At higher

speeds, the bit is likely to bend if allowed to rotate freely without contacting the workpiece,

resulting in personal injury.

•Apply pressure only in direct line with the bit and do not apply excessive pressure. Bits can bend

causing breakage or lose of control, resulting in personal injury.

6

.

Do not use a battery pack or tool that is damaged or modified. Damaged or modified batteries may

exhibit unpredictable behavior resulting in fire, explosion or risk of injury.

.

Do not expose a battery pack or tool to fire or excessive temperature. Exposure to fire or

temperature above 130 °C may cause an explosion. NOTE The temperature „130 °C“ can be replaced by

the temperature „265 °F“.

.

Follow all charging instructions and do not charge the battery pack or tool outside the temperature

range specified in the instructions. Charging improperly or at temperatures outside the specified

range may damage the battery and increase the risk of fire.

6) Service

Have your power tool serviced by a qualified repair person using only identical replacement

parts. This will ensure that the safety of the power tool is maintained.

•

Never service damaged battery packs. Service of battery packs should only be performed by the

manufacturer or authorized service providers.

•

•

SAFETY WARNINGS FOR BATTERY

Do not open the battery. Danger of shortcircuiting.

Protect the battery against heat, e. g., against continuous intense sunlight, fire, water, and moisture.

Danger of explosion.

•

•

•

In case of damage and improper use of the battery, vapors may be emitted. Ventilate the area

and seek medical help in case of complaints. The vapors can irritate the respiratory system.

Use the battery only in conjunction with your SnapFresh product. This measure alone protects the

battery against dangerous overload.

The battery can be damaged by pointed objects such as nails or screwdrivers or by force applied

externally. An internal short circuit can occur and the battery can burn, smoke, explode or overheat.

Drill safety warnings

MACHINE INFORMATION

Intended use

This cordless drill is intended for driving in and loosening screws as well as for drilling in wood,

metal and plastic.

7

SAFETY WARNINGS FOR CHARGER

Intended use

Charge only BBT-DC20A and BBT-DC40A type rechargeable Battery packs with the charger. Other

types of batteries may burst to cause personal injury and damage.

•

•

•

•

The appliance is not to be used by persons (including children) with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction.

Children being supervised not to play with the appliance.

Do not recharge non-rechargeable batteries!

During charging, batteries must be placed in the well ventilated area!

Electrical safety

Always check that the voltage of the power supply corresponds to the voltage on the rating

plate.

• Do not use the machine if the mains cable or the mains plug is damaged.

• Only use extension cables that are suitable for the power rating of the machine with a minimum

thickness of 1.5mm . If you use an extension cable reel, always fully unroll the cable.

2

TECHNICAL SPECIFICATIONS

Model No. BBT-JOZ57C

Rated voltage 20V

Chuck capacity φ10 mm

No load speed

Position 1:

Position 2:

0-400 /min

0-1400 /min

Weight 0.9 kg

Sound pressure level LPA

65.4dB(A), K=3dB(A)

Sound power level L WA

76.4 dB(A), K=3dB(A)

Model Number BBT-DC20A

Battery type Lithium-ion

Voltage 20V

Capacity 2.0 Ah

Recommended charger BBT-YFT20V

Weight 0.3 kg

Model Number BBT-YFT20V

Charger input 100-120V~60Hz 65W

Charger output 21V 2.5A

Charging time 2Ah battery 60 minutes

Charging time 4Ah battery 120 minutes

Recommended batteries BBT-DC20A, BBT-DC40A

Weight 0.36 kg

Hand-arm vibration a

h,D

(Drilling into metal) 0.893 m/s

2

K=1.5 m/s

2

8

•

•

Only use the following batteries of the SnapFresh

power 20V battery platform. Using any other batteries

could cause serious injury or damage the tool.

BBT-DC20A 20V, 2Ah Lithium-ion

BBT-DC40A 20V, 4Ah Lithium-ion

The following charger of the can be used to charge these batteries.

BBT-YFT20V Quick charger

The batteries of the SnapFresh power 20V battery platform are interchangeable with all the SnapFresh

power 20V battery platform tools.

Vibration level

The vibration emission level stated in this instruction manual has been measured. It may be used to

compare one tool with another and as a preliminary assessment of exposure to vibration when using

the tool for the applications mentioned

.

Using the tool for different applications, or with different or poorly maintained accessories, may

significantly increase the exposure level.

The times when the tool is switched off or when it is running but not actually doing the job, may

significantly reduce the exposure level.

Protect yourself against the effects of vibration by maintaining the tool and its accessories, keeping

your hands warm, and organizing your work patterns.

9

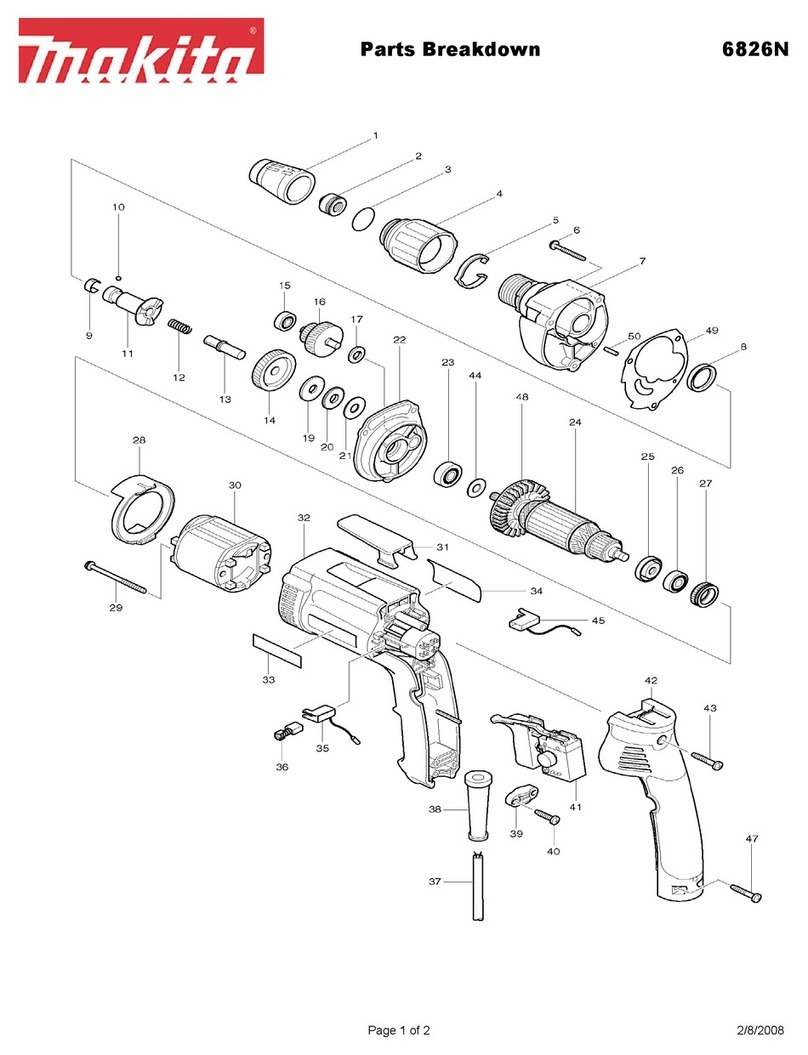

ASSEMBLY

A

B C

3

2

3

2

4

1

9

8

6

7

5

1

2

2

13

12

11

10

10

10

Before any work on the power tool, remove the battery.

The battery must be charged before first use.

DESCRIPTION

The numbers in the text refer to the diagrams on page 9.

Inserting the battery into the machine (Fig. B)

Ensure that the exterior of the battery is clean and dry before connecting to the charger or

machine.

Insert the battery (2) into the base of the machine

as shown in Fig. B.

Push the battery further forward until it clicks into place.

•

•

Removing the battery from the machine (Fig. B)

Push the battery to unlock button (3)

Pull the battery out of the machine like shown in Fig. B.

•

•

Checking the battery charging status (Fig. C)

• To check the battery charge status, push the button (11) on battery shortly.

•

The battery has 3 lights indicating the charge level, the more lights that burn, the more charge the

battery has left.

•

When the lights are not burning it means the battery is empty and must be charged immediately.

1. Machine

2. Battery

3. Battery unlock button

4. Work light

5. On / off switch

6. Torque adjustment ring

7. Chuck

8. Gear selection switch

9. Direction switch

10. Charger LED indicators

11. Battery LED indicators button

12. Battery LED indicators

13. Charger

Fitting and removing drills or screwdriver bits (Fig. A) The drill chuck (7) is suitable for drills and

screwdriver bits with round shaft as well as hexagonal shaft.

Hold the machine firmly with one hand.

Open the drill chuck (7) by rotating the chuck with your other hand in clockwise direction until it is

opened far enough for the bit to slide in.

Insert the shaft of the drill or screwdriver bit.

11

•

•

•

•

Charging the battery with the charger (Fig. C)

Take the battery (2) off from the machine.

Turn the battery (2) to upside down position and slide it onto the charger (13) as shown in Fig. C.

Push the battery until it is fully pushed into the slot.

Plug the charger plug into an electrical outlet and wait for a while. The LED indicators

(10)

on the

charger(13) will lighten up and show the charger status.

The charger has 2 LED indicators (10) which indicate the status of the charging process:

Red LED Status Green LED status Charger status

Off Off No power

Off On

Standby mode:

-No battery is

inserted or,

-Battery inserted

but charging has

finished

On Off Battery charging in

progress

• Fully charging the 2Ah battery may take up to 60 minutes.

•

•

•

•

Tighten the drill chuck again by firmly rotating the chuck (7) counterclockwise.

•

Check if the bit is centered well by shortly activating the machine´s on/off switch.

•

Fully charging the 4Ah battery may take up to 120 minutes.

After the battery is fully charged remove the charger plug from the outlet and remove the battery

from the charger.

When the machine is not being used over a longer period of time it is best to store the battery

in charged condition.

Adjusting the gears (Fig.A)

•

•

The machine has 2 drill speeds, which can be adjusted by sliding the gear switch (8) forward or

backwards. The number on the gear switch (8) shows which position is chosen.

The on/off switch (5) is used for activating the machine and adjusting rotation speed.

Position 1: For slow drilling, large drilling diameter or screw driving. The machine has high power

at a low speed.

Position 2: For fast drilling or small drilling diameter.

•

•

Adjusting the direction of rotation (Fig. A)

Switching the machine on and off (Fig. A)

Set the direction switch (9) to position in order to drive screws or to use it for drilling.

in order to remove screws.

Set the direction switch (9) to position

12

OPERATION

Never switch gears when the motor is running, this will damage your machine.

Never put switch in the middle between both positions, this will damage your machine.

•Pressing the on/off switch (5) will activate the machine, the further the switch is being pushed,

the faster the drill will turn.

•Releasing the on/off switch (5) will stop the machine.

• Move the direction reversing switch (9) to the middle position to lock the movement of the on/off

switch.

The machine has 21 different torque settings and a special drill mode to set the power being

transmitted to the chuck. By rotating the torque adjustment ring (6), screws can be driven to a

predetermined depth, which is ideal for repetitive work. The higher the number, the more torque will

be transmitted.

Adjusting the torque (Fig. A)

•Select a low setting for small screws or soft work material.

•Select a high setting for large screws, hard work materials and when removing screws.

•You should preferably choose a setting as low as possible when driving screws. Select a higher

setting if the motor slips before the screw is fully tightened.

•For drilling, turn the torque adjustment ring (6) to the setting for drilling (

it counterclockwise.

) by fully turning

13

MAINTENANCE

Before cleaning and maintenance, always switch off the machine and remove the battery pack

from the machine.

Clean the machine casings regularly with a soft cloth, preferably after each use. Make sure that the

ventilation openings are free of dust and dirt. Remove very persistent dirt using a soft cloth moist-

ened with soapsuds. Do not use any solvents such as gasoline, alcohol, ammonia, etc. Chemicals

such as these will damage the synthetic components.

ENVIRONMENT

Faulty and/or discarded electrical or electronic apparatus have to be collected at the

appropriate recycling locations.

Ensure that the direction switch (9) is always set to during drilling.

The machine is equipped with electronic overload protection function. When the machine

gets overloaded it will shut down automatically. When this happens, please wait for a few

seconds to let the overload protection reset itself.

14

If a defect arises and a valid claim is received within the Warranty Period, at its option, Babytec

will either 1) repair the defect at no charge, using new or refurbished replacement parts, or 2)

replace the product with a new product that is at least functionally equivalent to the original product,

or provide a store credit in the amount of the purchase price of the original product. A replacement

product or part, including a part installed in accordance with instructions product by Babytec,

assumes the remaining warranty of the original product. When a product or part is exchanged, any

replacement item becomes your property and the replaced item becomes Babytec’s property. When

a store credit is given, the original product must be returned to Babytec and becomes Babytec’s

property. To obtain warranty service, e-mail Babytec Warranty Service at support@snapfresh-

tools.com.Please be prepared to describe the product that needs service and the nature of the

problem.

WARRANTY

Ningbo Babytec Technology Co., Ltd (Hereinafter referred to as Babytec) warrants this product

against defects in materials and/or workmanship under normal use for a period of ONE (1) YEAR

from the date of purchase by the original purchaser (’Warranty Period’).

The following circumstances are excluded from this guarantee:

• Repairs and or alterations have been made or attempted to the machine by unauthorized service

centers;

• Normal wear and tear;

• The tool has been abused, misused or improperly maintained;

• Non-original spare parts have been used.

Allrightsreservedby Ningbo Babytec Technology Co.,Ltd

(Monday - Friday 9 a.m. - 5 p.m. EST 6 a.m. - 2 p.m. PST)

+1 833 635 0955

Table of contents

Other Snap Fresh Power Screwdriver manuals