8

PRE-OPERATION CHECKLIST for SNAPPER PRO

21” STEEL DECK COMMERCIAL WALK BEHIND MOWERS

The manufacturer has completed initial adjustments and performed operational tests prior to shipping the

machine. Due to the possible effects of shipping, handling and storage, it is intended for all of the following

items to be verified and necessary final adjustments to be made at time of setup. It remains good practice and

is strongly recommended that all the items also be checked prior to placing the machine into service. It is very

important that setup is verified and all operational tests completed and results are acceptable. After completing

this form, sign and retain for future reference.

SET-UP (Details on Pages 1 through 6 of this Instruction)

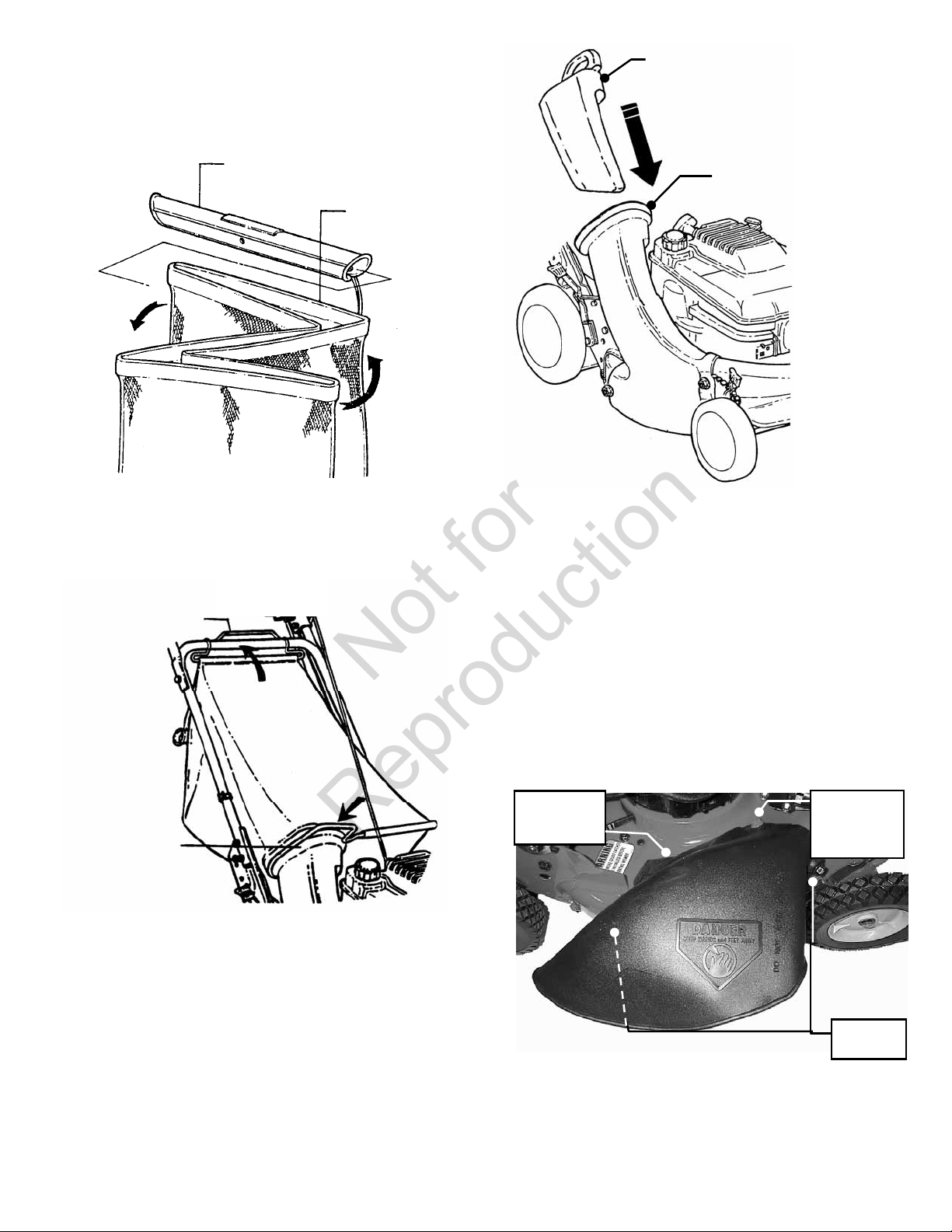

_____ FOAM SHIPPING BLOCK removed from cutting blade.

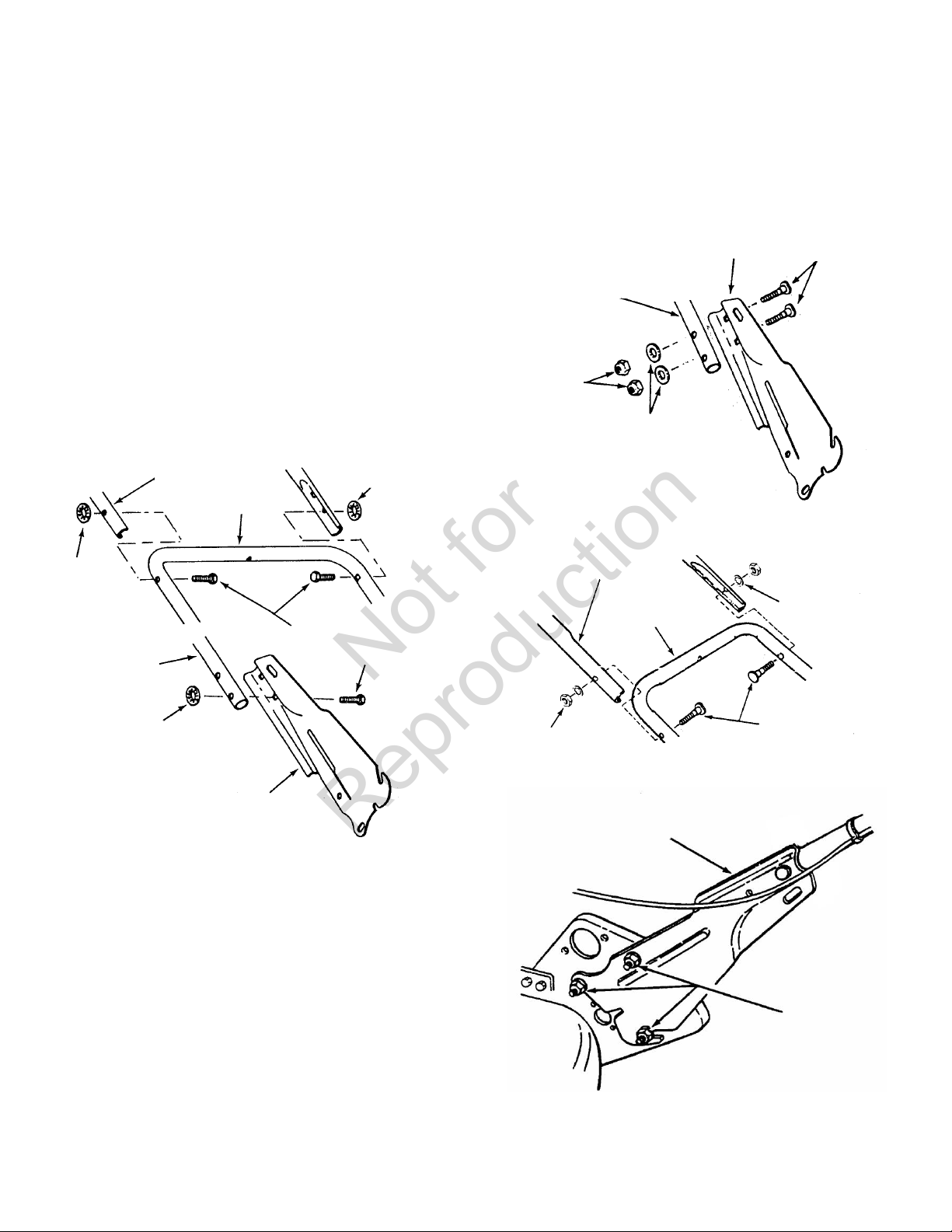

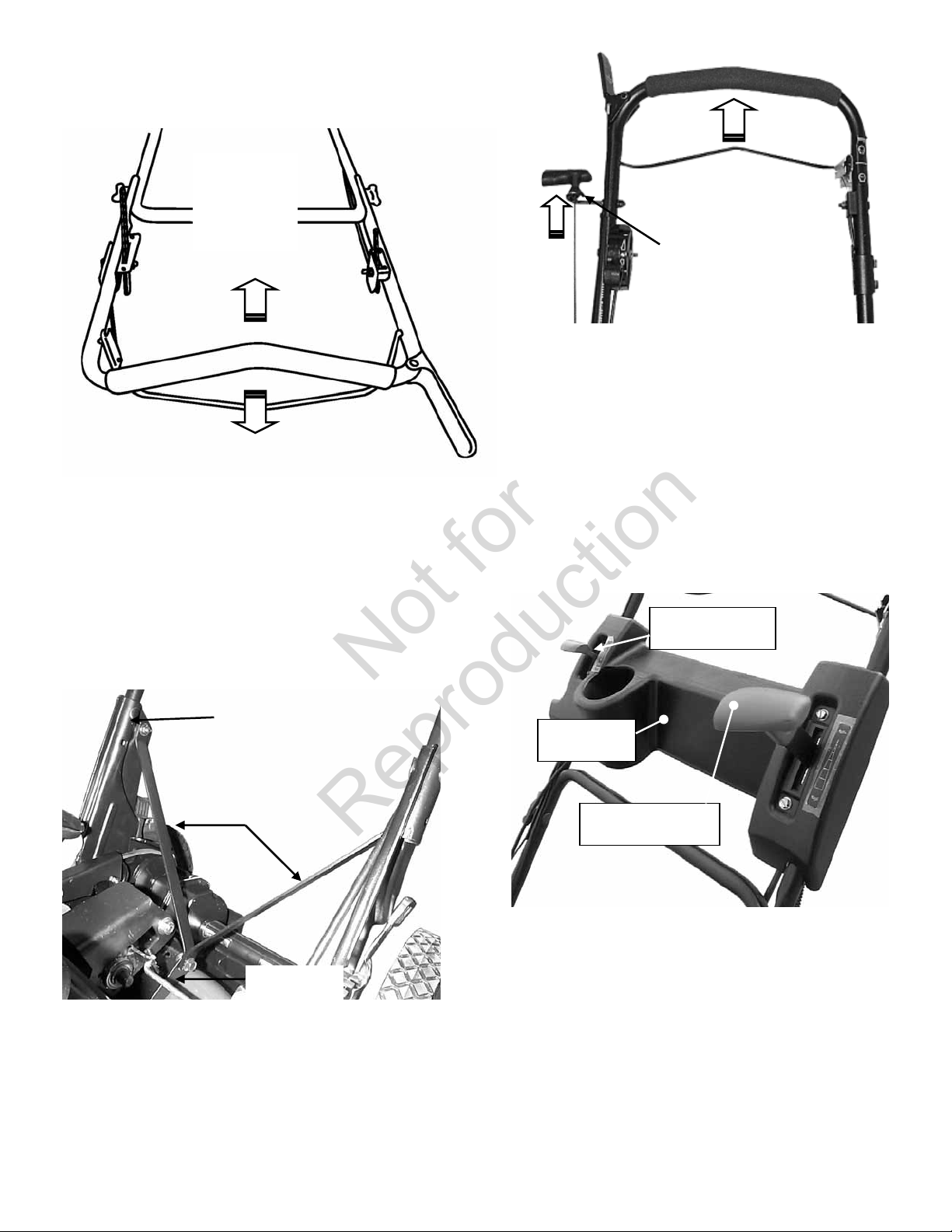

_____ UPPER HANDLE & LOWER HANDLE secured in place and hardware tightened securely.

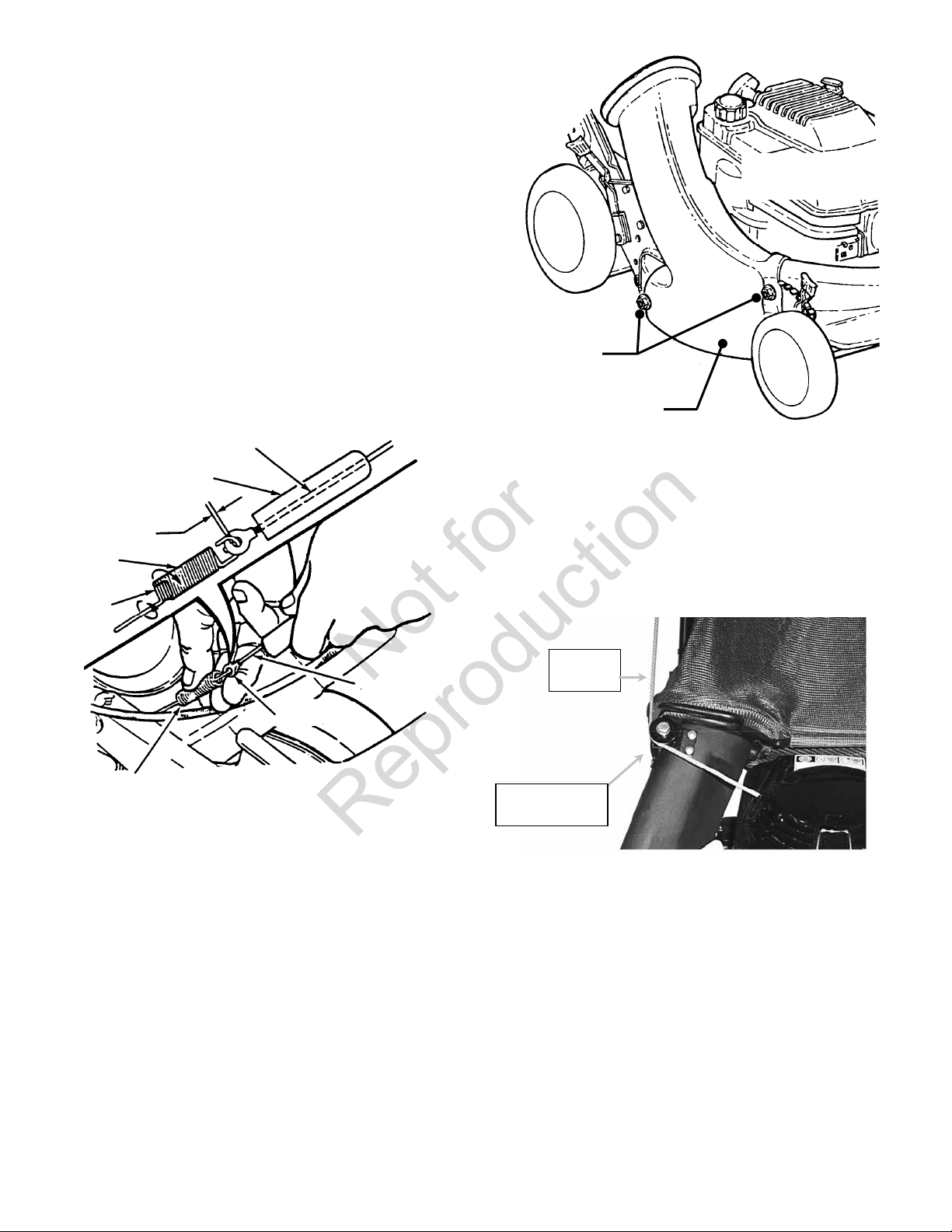

_____ RECOIL ROPE hooked into rope guide on handle.

_____ OPERATOR CONSOLE installed, engine speed and ground speed handles installed.

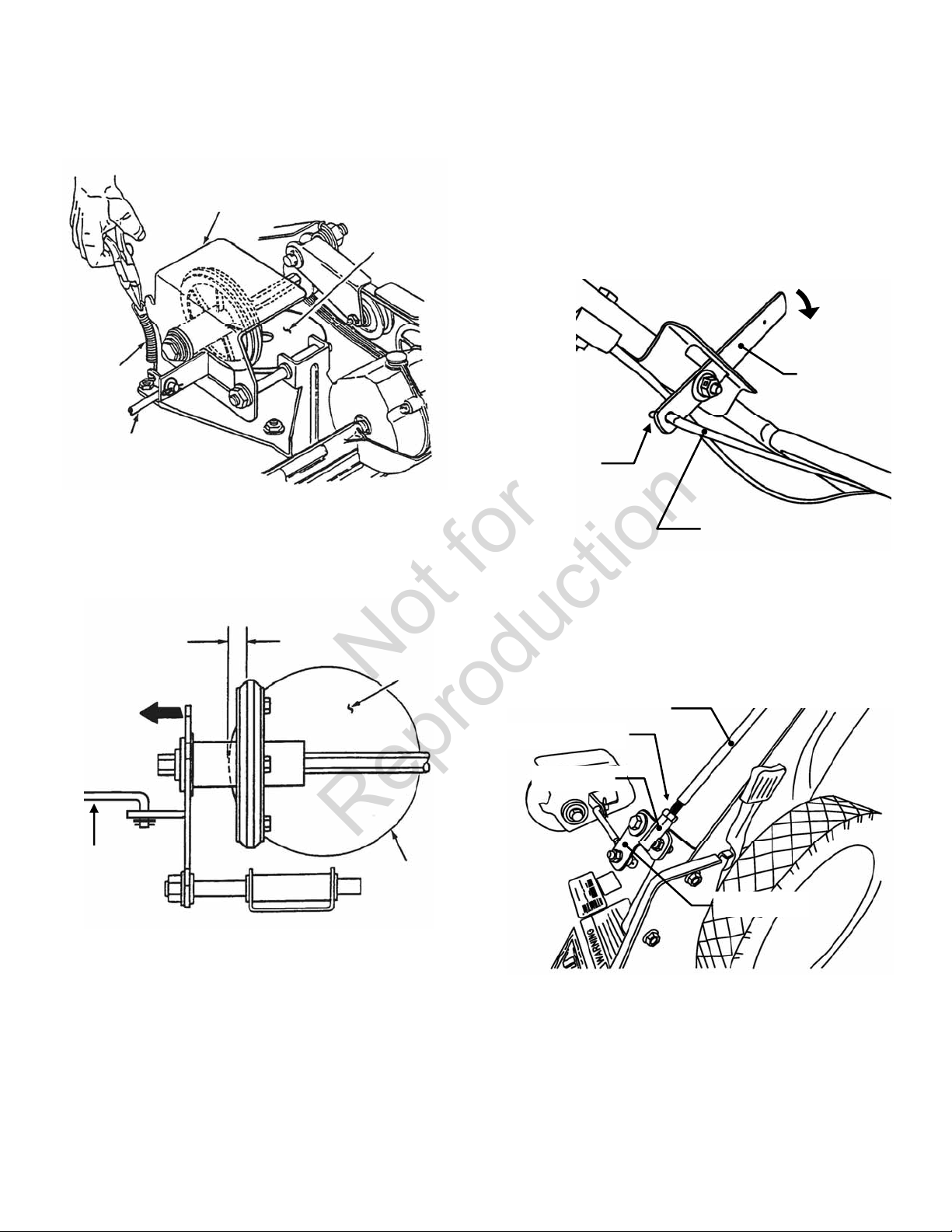

_____ DRIVE ASSEMBLY COMPONENTS installed and adjusted correctly.

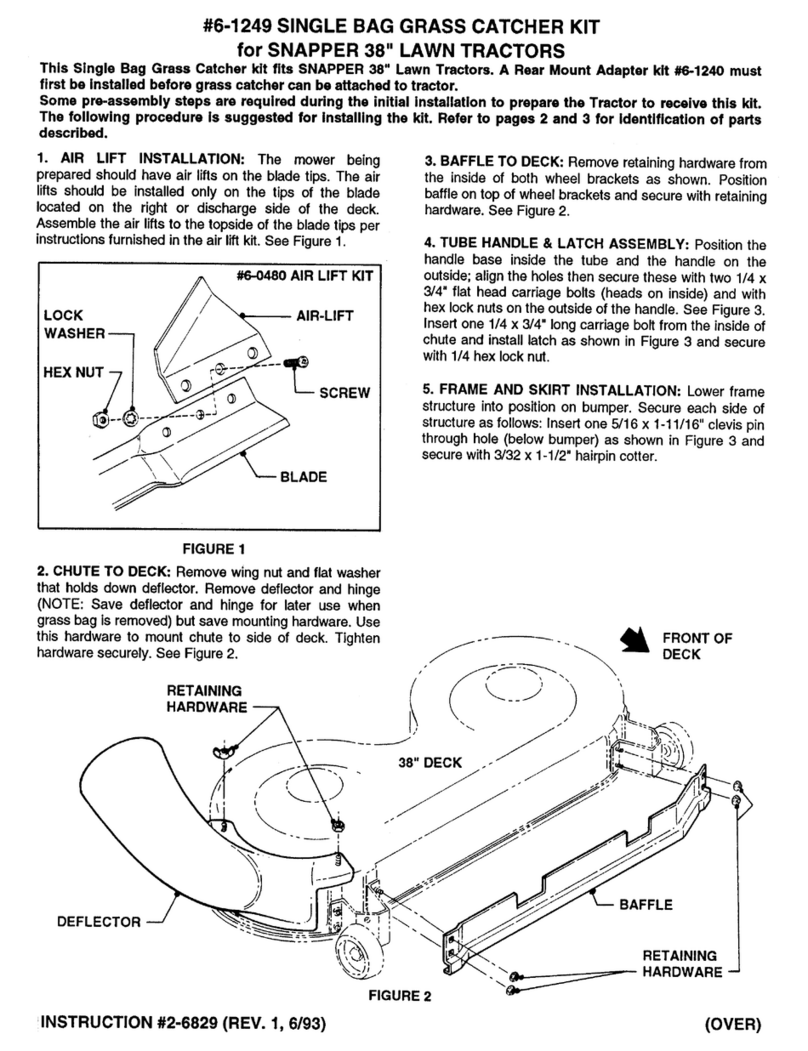

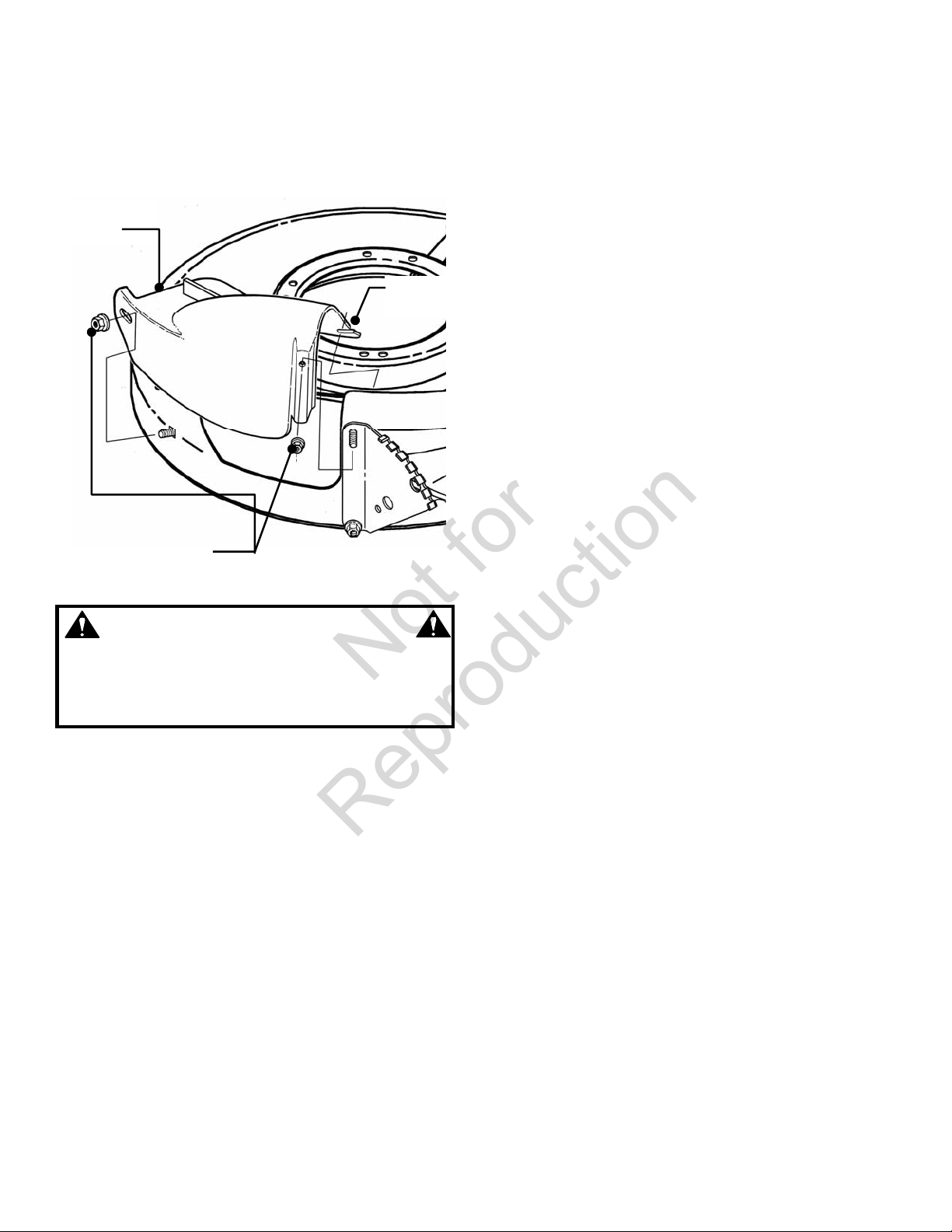

_____ SIDE CHUTE, RECYCLING COVER or GRASS BAG installed correctly on mower.

_____ BLADE retaining bolt(s) checked and tighten securely. (40 ft. lbs. recommended.)

LUBRICATION

_____ ENGINE OIL added to bring level up to full mark on 4-cycle engines (Refer to Engine Manual).

_____ OIL mixed with FUEL in specified ratio (2 Cycle Engines Only).

_____ DIFFERENTIAL grease checked and added if needed.

OPERATIONAL TEST

_____ ENGINE started, engine control settings checked and adjusted as needed.

_____ WHEEL DRIVE checked for proper operation and adjusted as needed.

_____ DRIVE DISC adjustment checked and made.

_____ GROUND SPEED control checked.

CPSC (Consumer Product Safety Commission) COMPLIANCE TEST

_____ BLADE CONTROL stops engine when released.

CONSUMER INFORMATION

Purchase Date ___________________ Model _______________________ Serial No. _______________________

Retailers Name ___________________________________ Signature ____________________________________

Address _____________________________________ City ____________________ State _______ Zip ______

MOWER WILL BE USED COMMERCIALLY? ______ YES______ NO

Purchaser’s Name _________________________________ Signature ____________________________________

Address ____________________________________ City ____________________ State _______ Zip _______

IMPORTANT: This form is to be retained for future reference regarding Warranty, proof of purchase, traceability

for product recall or service, etc.

INSTRUCTION No. 7103223 (Rev. ‘-’, 3/18/2009)