SNE FAP-VBO Series User manual

FAP-VBO Series Operating Directions

New Environmental International Limited

www.hksne.com

SNE®FAP/CAP-VBO Series

Ventiduct Bacteria & Odor Elimination

Air Purification System

Operation Manual

FAP-VBO Series Operating Directions

New Environmental International Limited

www.hksne.com

Thank you for purchasing the SNE®FAP/CAP-VBO Series Ventiduct Bacteria &

Odor Elimination Purification System We are confident this system will provide you

a fresh, clean, odor free and healthy air environment.

NOTE:

Please take time to read the attached Manual and should be adhered to while

operating this system.

SNE®FAP/CAP-VBO can purify the odors in the air by multiple catalytic complex

purifying. It can effectively sterilize and decompose to eliminate the odors from

garbage, sewage, kitchen lampblack & cooking , VOC, fishy, smoke, paint, ink and

glue….etc.

Application:

Sewage Water Treatment Pools, Kitchen Cooking, Dumping Ground, Seafood, Print ,

Sewage Pumping, Garbage Treatment, Storage Stations, Print, Biochemistry, Painting,

Petrochemical and Dyeing. Grease Trap Rooms…etc. from the ventilation duct.

prevent the outdoor air from being polluted and guarantee people’s life quality and

health.

FAP-VBO Specifications:

Model

UV

Length

(mm)

Blower

Volume

(m3/h)

Power Supply

Consumption

(w)

FAP-VBO-300DZ

2×11”/287

< 1,000

100-250V/AC/50-60Hz

12w × 2

FAP-VBO-500DZ

2×14”/356

1,000-2,500

100-250V/AC/50-60Hz

15w × 2

FAP-VBO-600DZ

2×17”/436

2,500-3,500

100-250V/AC/50-60Hz

20w × 2

FAP-VBO-700DZ

2×21”/540

3,500-5,000

100-250V/AC/50-60Hz

25w × 2

FAP-VBO Series Operating Directions

New Environmental International Limited

www.hksne.com

Remarks:

1, All the FAP designed is double tube type.

2, Voltage:AC/100-250V/50Hz/60Hz.

3, According to the airflow and pollution, Type selected can be

done.

4, The panel has power switch, Power and MCI unit operation

indication LED.

SNE®MCITM Technology has been Tested and Certified by the

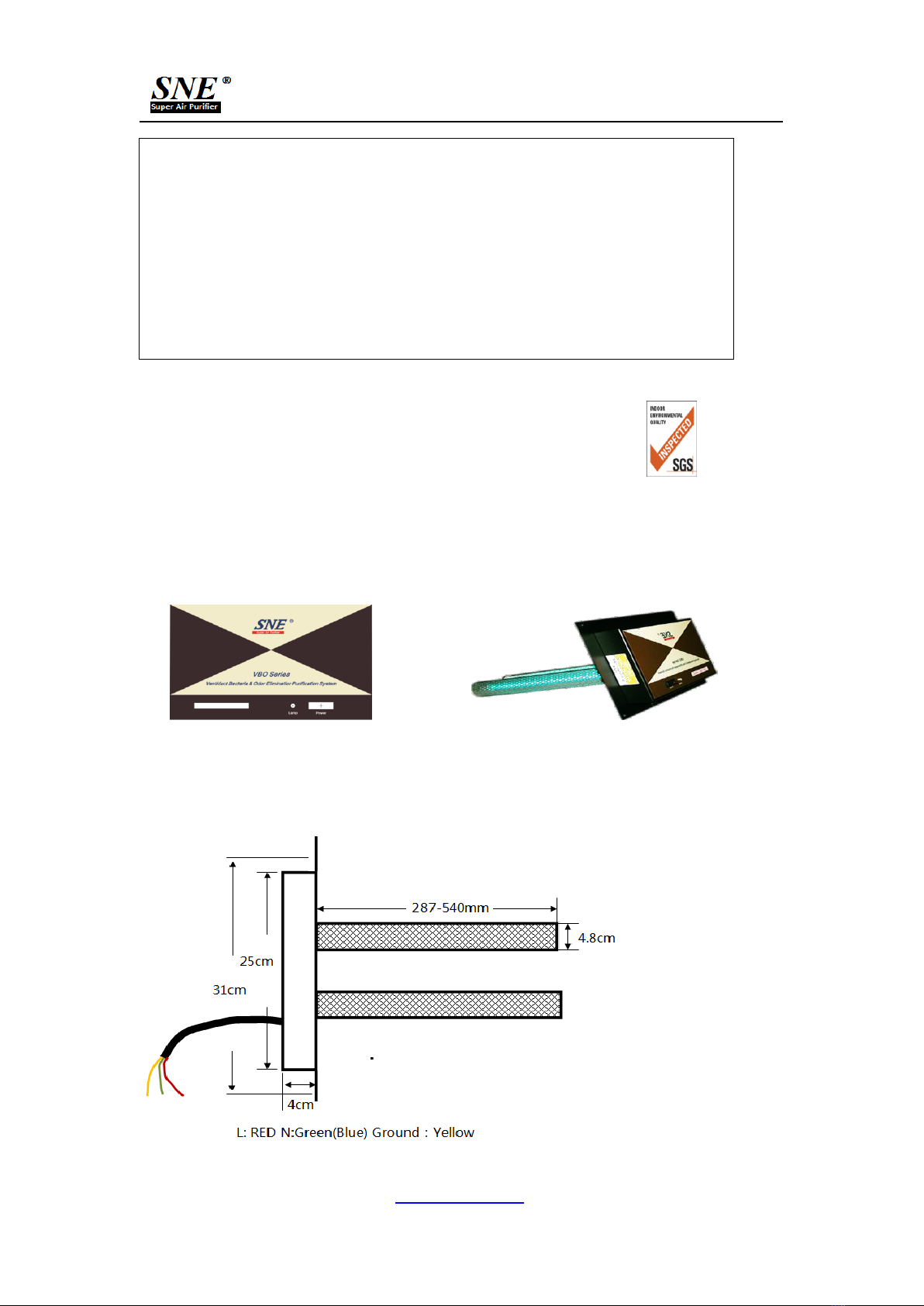

Figure-1 FAP-VBO Panel Diagrams Figure-2 FAP-VBO-700DZ Photo

Figure-3 FAP-VBO Size Diagrams

FAP-VBO Series Operating Directions

New Environmental International Limited

www.hksne.com

FAP-VBO Instruction:

1, Advanced power control: it has self-adaptive functions, which can extend the

length of validity of quartz tube. It has temperature, short circuit, and over current

protection. It also has the SMT technology, which is stable, reliable, and energy-

-saving.

2, LED instruction: Red: power on. Blue: double UV quartz tube working. Either

one of the tubes Not working, the Blue off.

3, VBO Power AC/100-250V/50H-60Hz. Power supply should be linked to air blower

power. That is, when the kitchen blower is operating, the VBO is on. When the

kitchen blower is off, so is the VBO. It is beneficial to extend the VBO quartz tube

life length.

4, Advanced power control: it has self-adaptive functions, which can extend the

length of validity of quartz tube. It has temperature, short circuit, and over current

protection. It also has the SMT technology, which is stable, reliable, and energy-

-saving.

5, LED instruction: Red: power on. Blue: double UV quartz tube working. Either one

of the tubes Not working, the Blue off.

6, VBO Power AC/100-250V/50H-60Hz. Power supply should be linked to air blower

power. That is, when the kitchen blower is operating, the VBO is on. When the

kitchen blower is off, so is the VBO. It is beneficial to extend the VBO quartz tube life

length.

7, Configuration can be set by referring to the wind range, odor pollution degree,

wind selection, and sample test. VBO can be used in parallel. Due to the fact that

ventilation tube purification is not recyclable and the pollutant is disposable to be let

out, customers should use more large types and increase the amount of the

products.

8, If the gas contain oil, VBO must be installation to the oil filter after.

9, When it is used in the Kitchen, the installment position should be in the ventilation

duct which is right behind the exhaust equipment(e.g., EP or stainless oil filter) in

order to avoid the oil pollution or high temperature. when the degreasing equipment

does not work. Multiple VBOs could be cross-installed on both sides of the

ventilation duct.

FAP-VBO Series Operating Directions

New Environmental International Limited

www.hksne.com

10, VBO Can be used many VBO models to installing and operation parallel according

the requirements. It can be to promote the purification effects.

FAP-VBO Installment:

--The installment position should be at the beginning end of the ventilation duct. The

ventilation duct should be long(>8m)enough to extend the purification time.

--Take to dismantle of the UV probe’s protecting membrane.

--Installation to the ventilation duct.

--The UV Probe Ø =4.8cm, Installing hole can be cut >5.5cm (Figure-4).

---Use 4 X 0.5cm screws to fix the ventilation duct. (Figure-4 Install Ø 0=0.6cm)

---Detail. Please look the FAP Installation DVD or Installation Figure.

WARNING!!!

Never look directly the UV light tube. It may cause blindness.

UV Probe Replacement:

Probe = (UV tube + Catalytic net cover)

1, After 2-3 years of normal use, or 1.5 years of continuous use, the UV Probe will

need replaced.

2, “Off” the power or unplug from the power supply.

3, Unscrew the 2 units X “A” 4 units Ø 1 =0.4 cm (Figure-4, A: Fixed and Connected

probe with the electrical box fitting).

4, Unscrew the 2 units X “C” 4 units Ø 2=0.4 cm (Figure-4).

5, Remove end connectors by gently pulling away from probe ends.

6, Re-assemble and check for the FAP-VBO.

This manual suits for next models

10

Other SNE Air Cleaner manuals