SNEED Coding Solutions SNEED PACK CS-5OTS User manual

SNEED CODING SOLUTIONS | WWW.SNEEDCODING.COM

CS-5OTS USER GUIDE

2

www.sneedcoding.com | (833)926-3464 | support@sneedcoding.com

Thank you for your purchase of the SNEED-PACK CS-50TS top and side belt driven carton

sealer. In this manual you will find the basic operating and maintenance procedures to ensure

your success with the CS-50TS. Please read the manual carefully before operating the

equipment.

Safety Precautions

Keep hands clear of any moving parts while the case sealer is in

operation and always power down prior to inspection. Failure to do

so may cause bodily harm.

Risk of electric shock, make sure the machine is properly grounded

before use.

.

Do not alter the mechanical or electrical systems. Any changes

could result in malfunction or injury.

Always turn off power to the case sealer when changing the tape

roll or performing maintenance.

3

www.sneedcoding.com | (833)926-3464 | support@sneedcoding.com

Contents

Specifications ................................................................................................................................................ 4

Component Diagram..................................................................................................................................... 5

Setting up the Case Sealer ............................................................................................................................ 6

Adjusting the Deck Height ........................................................................................................................ 6

Installing the Roller Tables........................................................................................................................ 7

Adjusting for your Carton Dimensions...................................................................................................... 8

Installing the Tape..................................................................................................................................... 9

Adjusting the Tape Position .................................................................................................................... 10

Setting the Tape Tension ........................................................................................................................ 10

Common Issues ...........................................................................................................................................11

Circuit Diagram ...........................................................................................................................................12

Exploded Parts Diagrams ............................................................................................................................13

Main Body & Lift Mechanism.................................................................................................................. 13

Parts List..............................................................................................................................................14

Drive / Conveyance System .................................................................................................................... 17

Parts List..............................................................................................................................................18

Tape Head ............................................................................................................................................... 20

Parts List..............................................................................................................................................20

6

www.sneedcoding.com | (833)926-3464 | support@sneedcoding.com

Setting up the Case Sealer

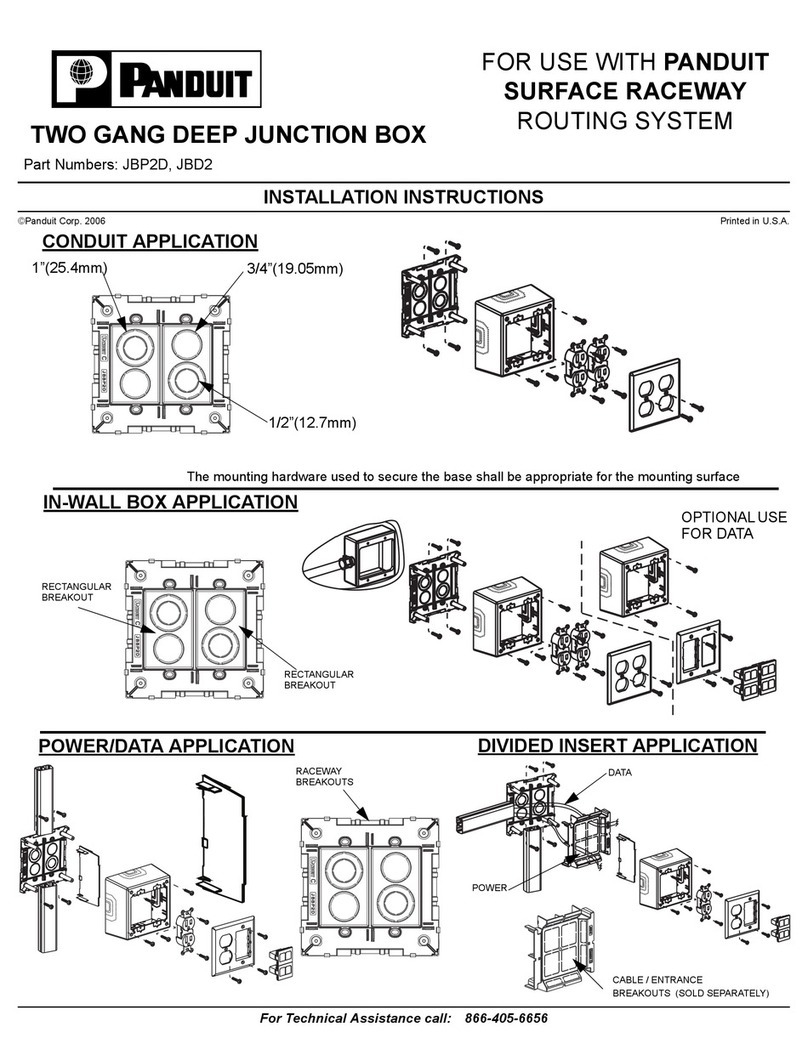

Adjusting the Deck Height

Figure 1

1. Begin by lifting the case sealer to the desired height with a pallet fork, dolly, or jack and

secure it safely in place.

2. Loosen the “adjustment bolts” on each leg and allow the “Height adjustment Insert” to drop

the floor.

3. Tighten the adjustment bolts and repeat these steps for each leg.

4. Once you have tightened all of the legs remove the lifting device holding the case sealer

in place.

Always consider safety and never lay down underneath the case sealer while

adjusting the legs.

Leg

Height Adjustment inserts

Adjustment bolts

Wheel Brake

Castor

Lock Nut

7

www.sneedcoding.com | (833)926-3464 | support@sneedcoding.com

Installing the Roller Tables

1. The fasteners (nuts) to attach the roller tables are already tightened onto their

corresponding bolt and will need to be removed first. *Only remove the first of two

fasteners (nuts)

2. Once the fasteners are removed place the roller tables onto the bolts and tighten them in

place.

fasteners

8

www.sneedcoding.com | (833)926-3464 | support@sneedcoding.com

Adjusting for your Carton Dimensions.

Figure 3

1. To set the case sealer to fit the dimensions of your carton/case use the adjustments shown

in Figure 3.

2. The adjustment handles will be installed backwards for shipping, remove them using the

included 10mm wrench and reinstall.

Carton width adjustment

Carton height adjustment

9

www.sneedcoding.com | (833)926-3464 | support@sneedcoding.com

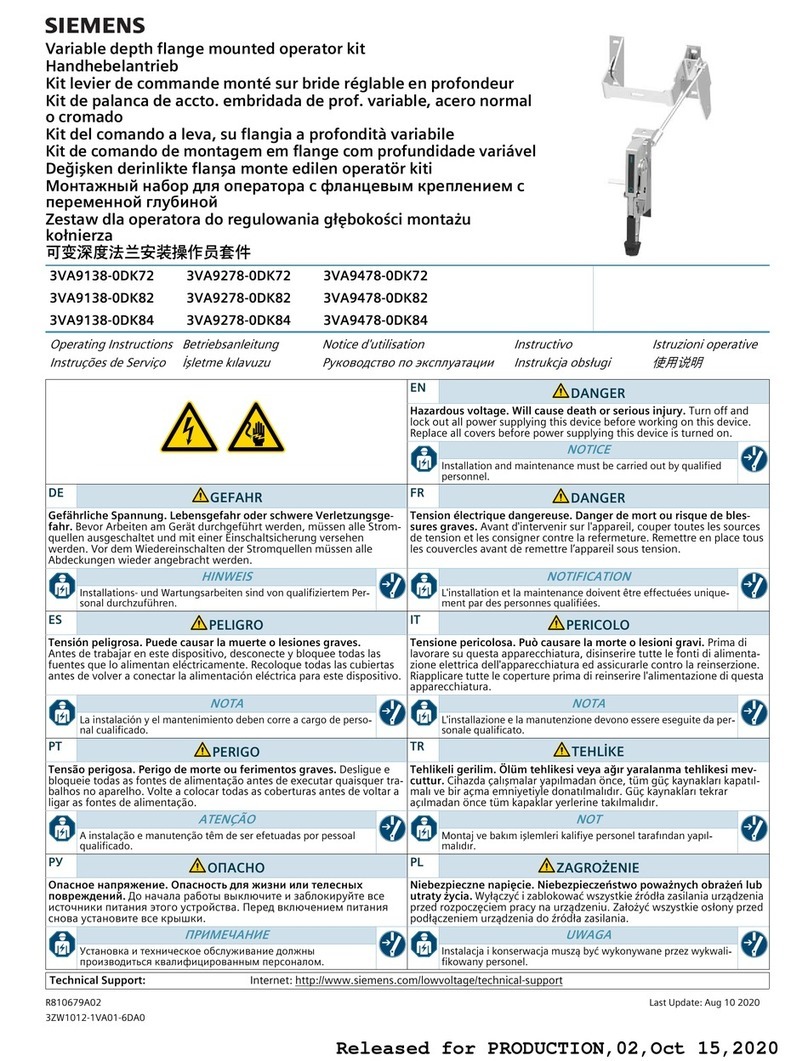

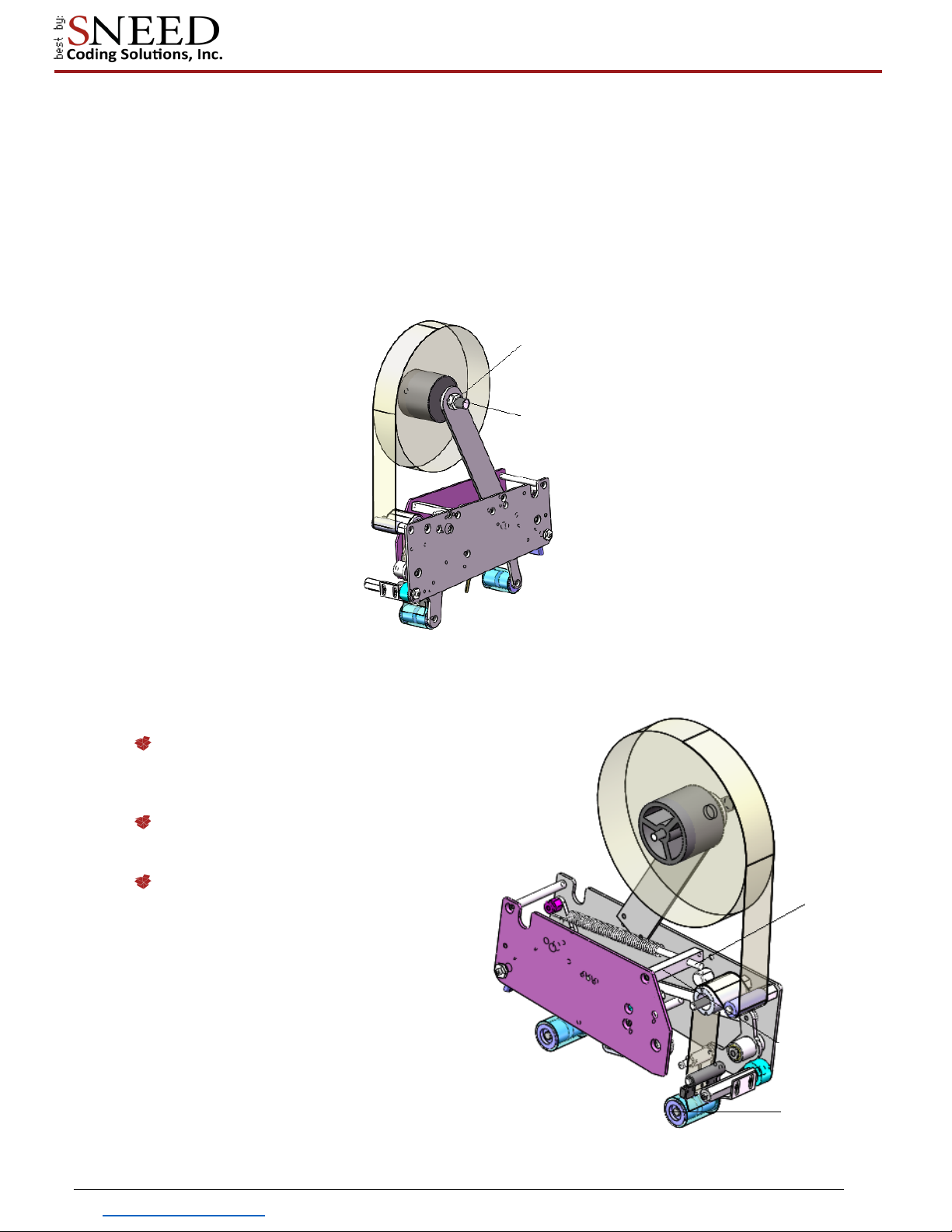

Installing the Tape

1. Begin by attaching the tape arms to each tape head using the included screws. (top and

bottom)

2. Next Install the tape onto the tape wheel so that when you pull the tape down the adhesive

side is facing outward.

3. Now guide the tape under the first guide roller, over the one-way roller, and through the

clip just above the last guide roller. The red line in figure 5 shows the tape path.

Figure 5

Tape roll

Adhesive face

Guide roller

One -way roller

Adhesive face

Guide wheel

Adhesive face

Adhesive face

10

www.sneedcoding.com | (833)926-3464 | support@sneedcoding.com

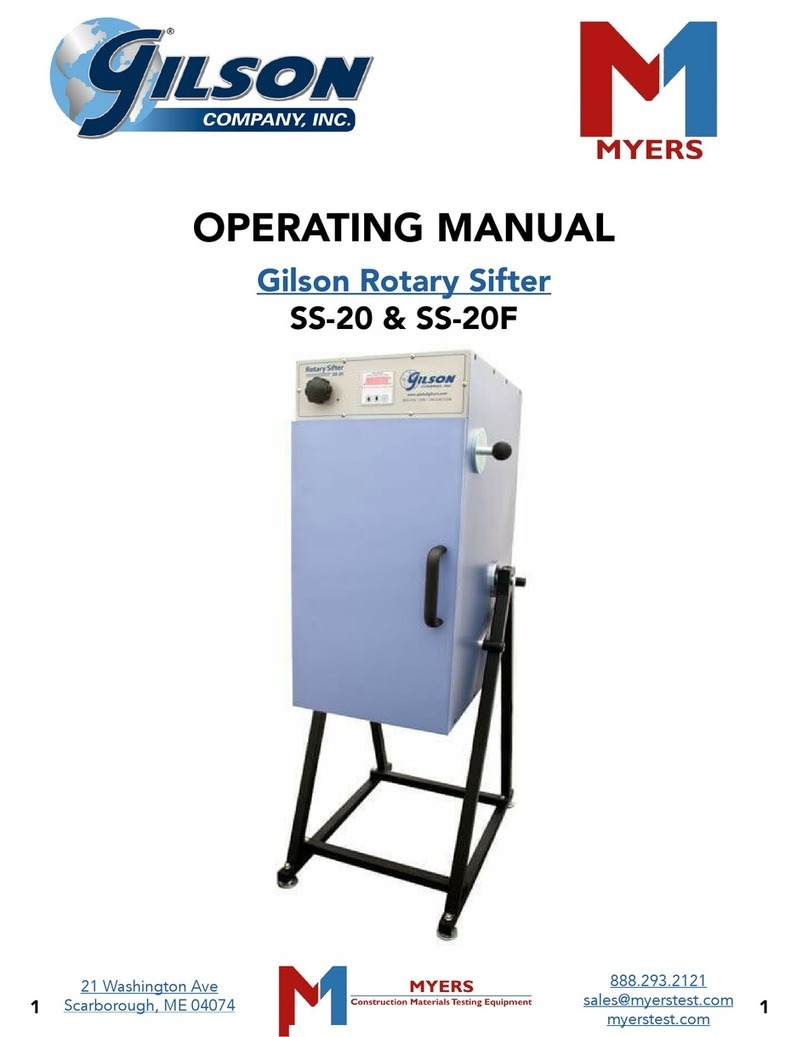

Adjusting the Tape Position

If you find that your tape is not lining up with the center of the box seems you can use the M18

nut shown in figure 6 to reposition the tape.

1. Remove the tape roll.

2. Loosen the nut.

3. Thread the tape spindle in or out to move the tape to the left or right on the arm.

4. Tighten the M18 nut into place when you have set the desired position.

Figure 6

Setting the Tape Tension

M18 Nut

Tape positioning bolt

The tape applicators will come to

you already adjusted. You may

find that over time the tension

needs to be adjusted.

To loosen or tighten the tension

of the tape applicators use the

nut on the end of the tension rod.

Turn the nut right to tighten the

spring and to the left to loosen.

Tension Rod

Tape applicator /

roller

11

www.sneedcoding.com | (833)926-3464 | support@sneedcoding.com

Common Issues

Issue

Cause

Solution

Tape does not cut

The tape head blade is dull or

jammed

1.Remove the tape jam.

2.Wipe clean any accumulated

adhesive from the tape head

with 90% isopropyl alcohol.

3.Sharpen or replace the tape

blade.

The tape has been cut but only

applied to a section of the case/

carton

The Tape head is likely jammed

1.Remove the Jam

2.Check to see if any parts of

the tape head have come loose.

The box is sealed but the flaps

are loose

1.The main tension spring is too

loose

2.the height adjustment is set

too high.

1.Tighten the nut on the tension

rod. This will stiffen the tape

applicators (pg10 / fig7)

The carton gets stuck halfway

through

The main tension springs are

too tight causing the tape

applicators to pinch the box in

place

Loosen the tension spring by

backing out the nut on the

tension rod (Pg10/Fig 7)

The tape is retracting or coming

loose from the rollers

Check to see if the one-way

tape roller is spinning both

ways.

Replace if needed

18

www.sneedcoding.com | (833)926-3464 | support@sneedcoding.com

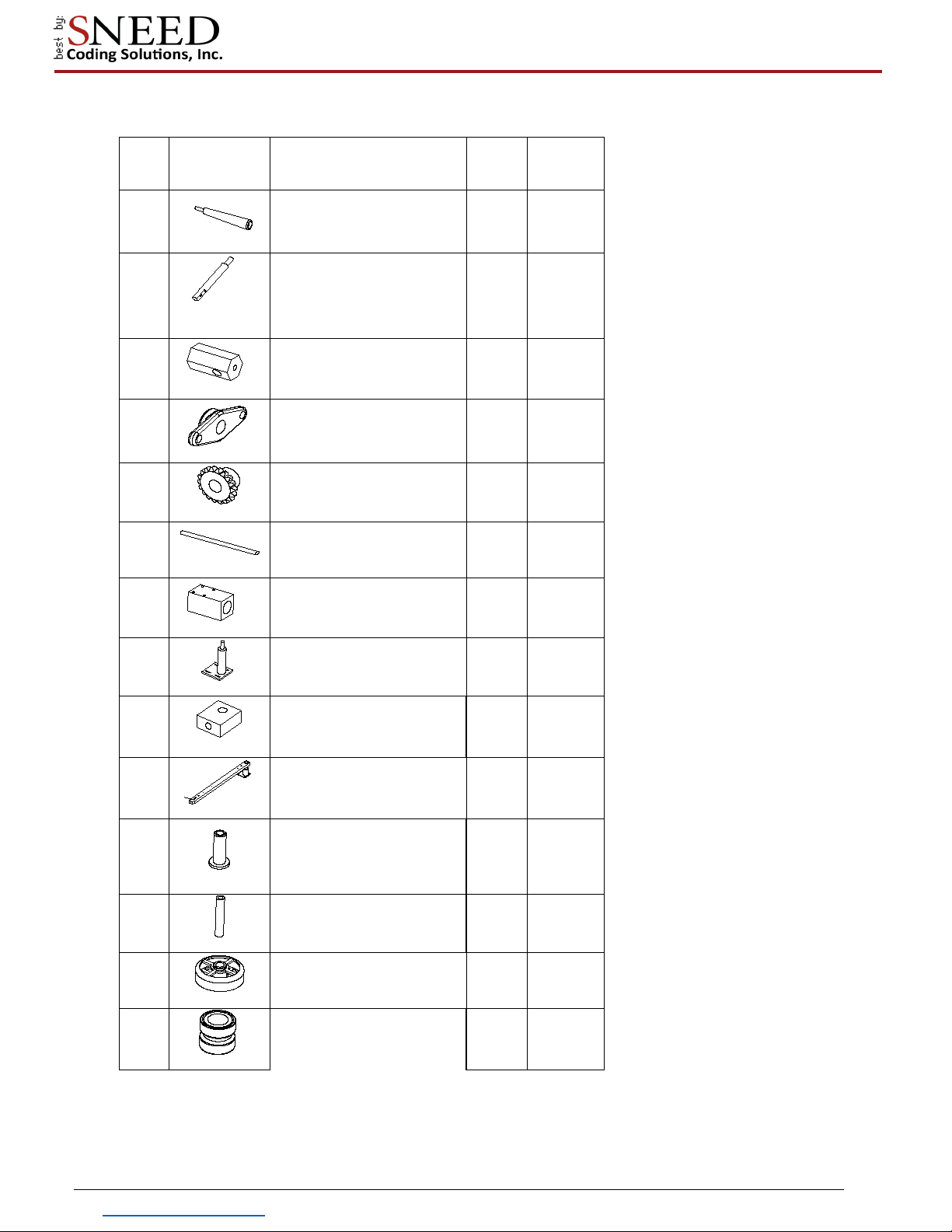

Parts List

ON DRAW DESCRIPTION QTY MEMO

1

handle 2

2

handle setting shaft 2

3

handle setting 2

4

unit bearing assembly 4

5

chain wheel 2

6

screw rod 2

7 Sliding base 4

8

bracket 4

9

adjusting slider 2

10

bracket 2

11

pin roll

2

12

pin roll 20

13 supporting roller 40

14

driven wheel 4

Table of contents

Other SNEED Coding Solutions Industrial Equipment manuals