EX260-TF2Z167EN

Page 1 of 2

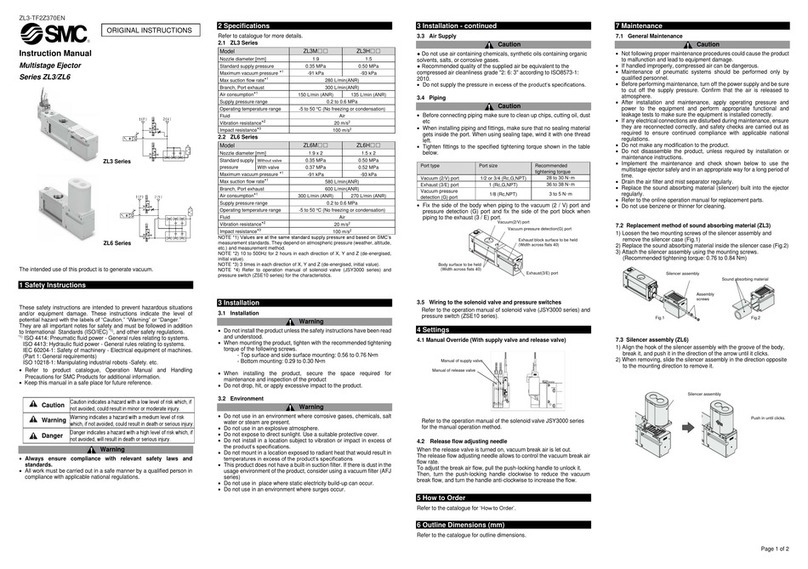

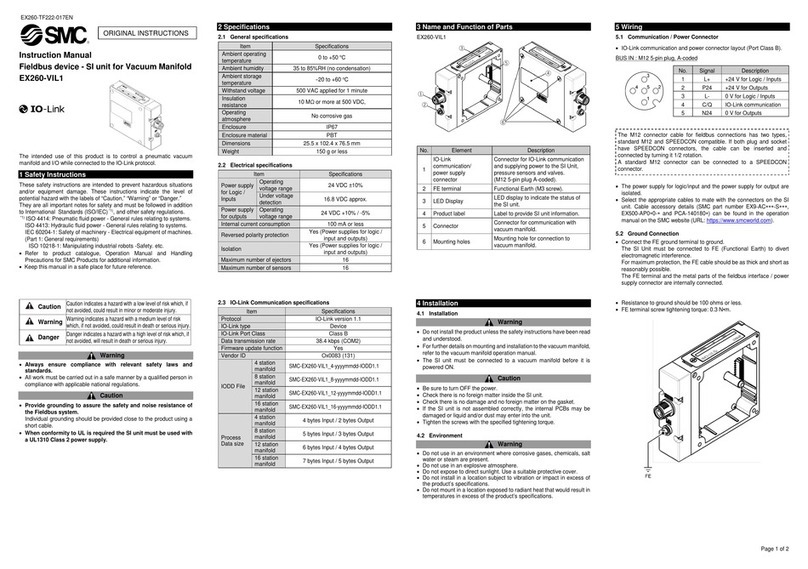

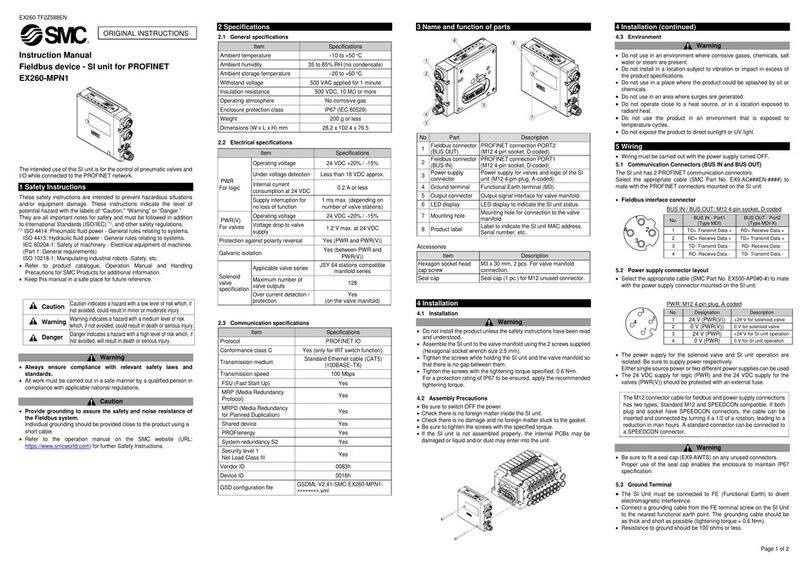

Instruction Manual

Fieldbus device - SI unit for PROFINET

EX260-SPN1 / SPN2 / SPN3 / SPN4

The intended use of this SI unit is for the control of pneumatic valves

and I/O while connected to the PROFINET network.

1 Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)*1), and other safety regulations.

*1) ISO 4414: Pneumatic fluid power - General rules relating to systems.

ISO 4413: Hydraulic fluid power - General rules relating to systems.

IEC 60204-1: Safety of machinery - Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Manipulating industrial robots -Safety. etc.

•Refer to product catalogue, Operation Manual and Handling

Precautions for SMC Products for additional information.

•Keep this manual in a safe place for future reference.

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Warning

•Always ensure compliance with relevant safety laws and

standards.

•All work must be carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

Caution

•Provide grounding to assure the safety and noise resistance of

the Fieldbus system.

Individual grounding should be provided close to the product using a

short cable.

•When conformity to UL is required the SI unit must be used with

a UL1310 Class 2 power supply.

2 Specifications

2.1 General specifications

35 to 85%RH (No condensate)

Ambient storage temperature

500 VAC applied for 1 minute

2.2 Electrical specifications

2.3 Communication specifications

Protocol

PROFINET IO (PROFINET RT)

(specification version 2.3)

Transmission medium

Standard Ethernet cable (CAT5)

(100BASE

-

TX)

Number of

outputs

32 outputs

16 outputs

Class C (only for IRT switch function)

Applicable function

FSU (Fast Start Up)

MRP (Media Redundancy Protocol)

Configuration file

GSD file (download from the SMC

website)

3 Name and function of parts

1

Fieldbus connector

(BUS OUT)

PROFINET connection PORT2

(M12 4-pin socket, D-coded)

2

Fieldbus connector

(BUS IN)

PROFINET connection PORT 1

(M12 4-pin socket, D-coded)

3

Power supply for valves and operation of SI

unit (M12 5-pin plug, A-coded)

Output signal interface for valve manifold

Bus status specific and SI unit status LED’s

7 Mounting hole

Mounting hole for connection to the valve

manifold

4 Installation

4.1 Installation Warning

•Do not install the product unless the safety instructions have been

read and understood.

•General instructions on installation and maintenance

Connect the valve manifold to the SI unit.

•Assembly and disassembly of the SI unit

4.2 Replacement of the SI unit

•Remove the M3 hexagon screws from the SI unit and release the SI

unit from the valve manifold.

•Replace the SI unit.

•Tighten the screws with the specified tightening torque. (0.6 N•m)

4 Installation (continued)

4.3 Assembly Precautions

•Be sure to switch off the power.

•Check there is no foreign matter inside the SI unit.

•Check there is no damage and no foreign matter stuck to the gasket.

•Be sure to tighten the screws with the specified torque.

•If the SI unit is not assembled properly, the internal PCBs may be

damaged or liquid and/or dust may enter into the unit.

4.4 Connecting Cables

Select the appropriate cables to mate with the connectors mounted on

the SI unit.

•Fieldbus interface connector layout

-pin socket, D-coded (SPEEDCON)

: M12 4-pin socket, D-coded (SPEEDCON)

•Power supply connector layout

M12 4-pin plug, A-coded (SPEEDCON)

+24 V for SI unit operation

0 V for SI unit operation

•The power supply for the solenoid valve and SI unit operation are

isolated. Be sure to supply power respectively.

Either single source power or two different power supplies can be

used.

NOTE

When conformity to UL is required the SI unit must be used with a

UL1310 Class 2 power supply.

The M12 connector cable for fieldbus and power supply connections

has two types, Standard M12 and SPEEDCON compatible. If both

plug and socket have SPEEDCON connectors, the cable can be

inserted and connected by turning it a 1/2 of a rotation, leading to a

reduction in man hours.

A standard connector can be connected to a SPEEDCON connector.

Warning

•Be sure to fit a seal cap (EX9-AWTS) on any unused connectors.

Proper use of the seal cap enables the enclosure to maintain IP67

specification.

4.5 Ground Terminal

•Connect the ground terminal to ground.

•Individual grounding should be provided close to the product with a

short cable to assure the safety and noise resistance of the Fieldbus

system.

•Resistance to ground should be 100 ohms or less.

4.6 Environment Warning

•Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

•Do not install in a location subject to vibration or impact in excess of

the product’s specifications.

Power supply

voltage range

/ current

consumption

Controller power supply

21.6 to 26.4 VDC

0.1 A max.

Solenoid valve power

supply

2.0 A or less, according

to the solenoid valve

Solenoid

valve

specification

Output

type

PNP (negative common)

/ source

NPN (positive common) /

sink

Output condition at the time

of communication error

Connected load

surge voltage

suppressor of 24 VDC

and 1.0 W or less