Aerotech VascuLathe ACS Series User manual

Other Aerotech Industrial Equipment manuals

Aerotech

Aerotech PRO115LM User manual

Aerotech

Aerotech ATX115SL User manual

Aerotech

Aerotech WaferMaxT Series User manual

Aerotech

Aerotech AGS15000HL Series User manual

Aerotech

Aerotech HexGen HEX500-350HL User manual

Aerotech

Aerotech ANT130LZS Series User manual

Aerotech

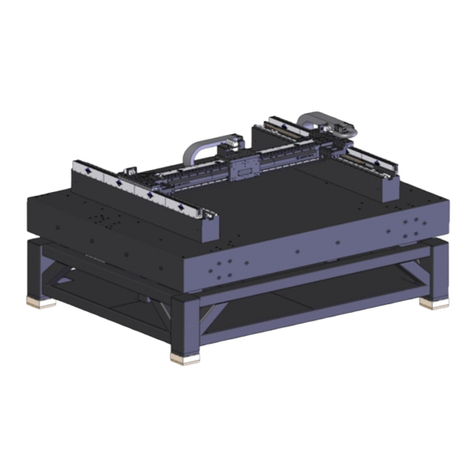

Aerotech PlanarDL-100XY Series User manual

Aerotech

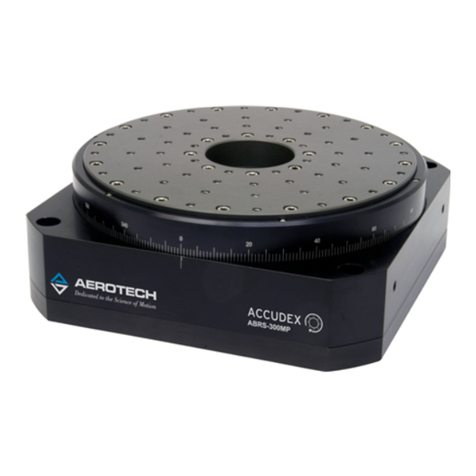

Aerotech ABRS Series User manual

Aerotech

Aerotech ACS LP Series User manual

Aerotech

Aerotech TM3 User manual

Aerotech

Aerotech PRO560LM Series User manual

Aerotech

Aerotech ABL1500 Series User manual

Aerotech

Aerotech FiberMax HP Series User manual

Aerotech

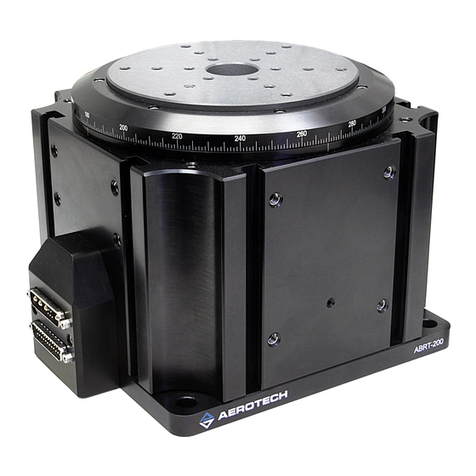

Aerotech ABRX User manual

Aerotech

Aerotech HexGen HEX300-230HL User manual

Aerotech

Aerotech PRO165LM Series User manual

Aerotech

Aerotech ASR1300 User manual

Aerotech

Aerotech PRO165SV Series User manual

Aerotech

Aerotech PRO280SL Series User manual

Aerotech

Aerotech ALAR-XP Series User manual