Table of Contents, Continued

Section 6—Installation, Continued

Mechanical Installation of the Glue Regulator, Gauge, and Gauge Protector................................ 6-19

FillingInstructions........................................................................................................................ 6-19

InstallationInstructions............................................................................................................... 6-19

Mechanical Installation of the Glue Filter ............................................................................................ 6-21

Installation of the Glue-Pressure Relief System.................................................................................. 6-21

Installing the Air Supply ...................................................................................................................................... 6-22

Installing the Hot-Melt Interface ........................................................................................................................ 6-23

Installing the Dump Valve................................................................................................................................... 6-24

Mode 1 ........................................................................................................................................................ 6-24

Mode 2 ........................................................................................................................................................ 6-24

Installing the JP2000 Jam Preventer.................................................................................................................. 6-25

Section 7—Initial Setup................................................................................................................................................. 7-1

Introduction ............................................................................................................................................................ 7-1

Glue Delivery System .......................................................................................................................................... 7-1

Air Pressure Settings................................................................................................................................. 7-1

Glue Pressure Settings.............................................................................................................................. 7-2

Glue Application System..................................................................................................................................... 7-2

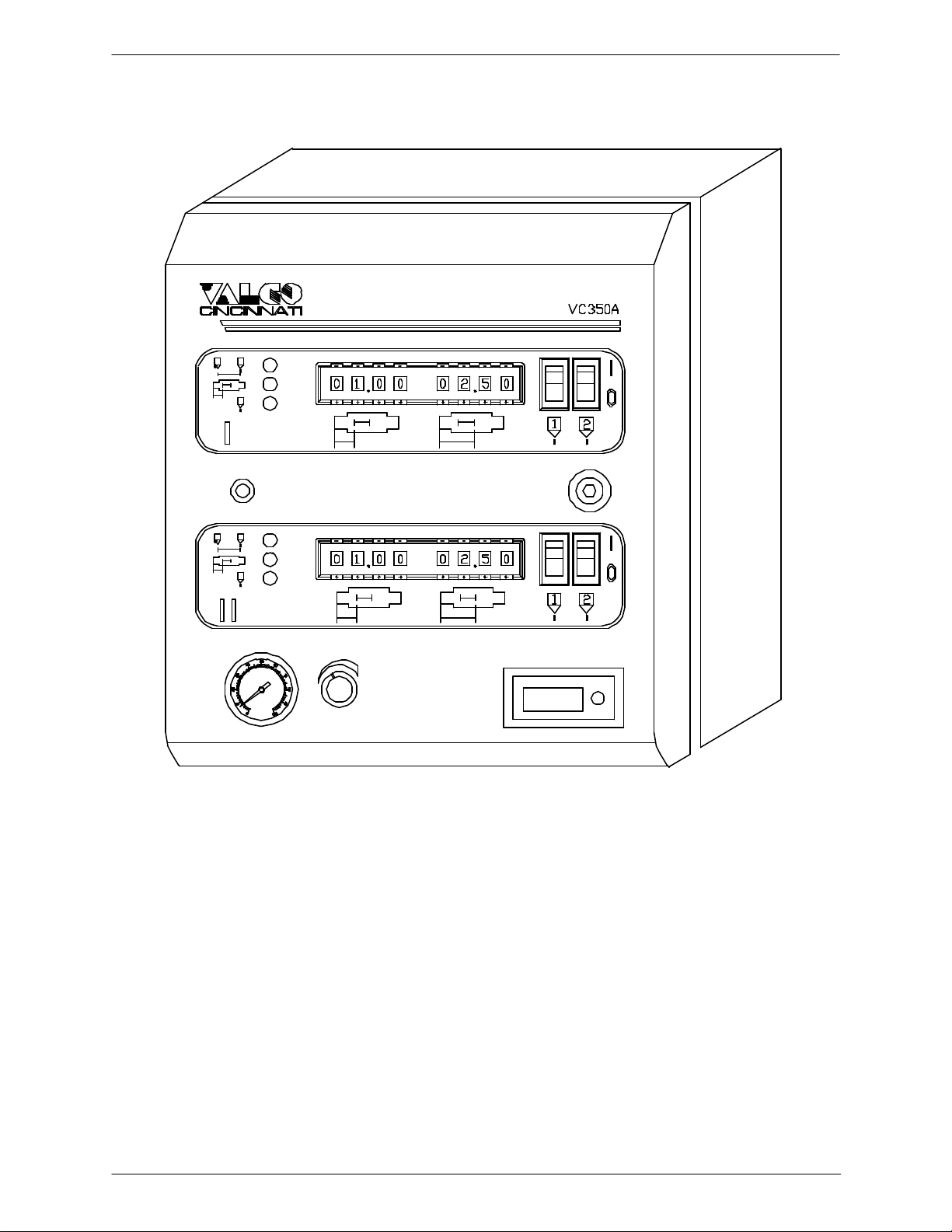

VC350A Control................................................................................................................................................... 7-2

Example of Adjusting the Ratio Compensation .................................................................................. 7-4

On/Off Compensation Theory of Operation .................................................................................................... 7-4

Hot-MeltAdjustments .......................................................................................................................................... 7-6

Motor Stop/Motor Idle Jumper............................................................................................................... 7-7

Idle Speed Adjustments ........................................................................................................................... 7-7

Calibration Potentiometer........................................................................................................................ 7-8

Torque Potentiometer............................................................................................................................... 7-8

IR Compensation Potentiometer............................................................................................................. 7-9

Minimum-Speed Potentiometer.............................................................................................................. 7-10

Maximum-Speed Potentiometer............................................................................................................. 7-10

Deceleration/Acceleration Potentiometers ............................................................................................ 7-11

Section 8—Operation ..................................................................................................................................................... 8-1

Introduction ............................................................................................................................................................ 8-1

JobSetup................................................................................................................................................................. 8-1

Fluid-Flow Control (EPC) ................................................................................................................................... 8-3

Section 9—Maintenance................................................................................................................................................ 9-1

Introduction ............................................................................................................................................................ 9-1

System Shutdown .................................................................................................................................................. 9-1

System Lubrication ............................................................................................................................................... 9-1

Adhesive System Flush ........................................................................................................................................ 9-1

In-Line Glue Filters .............................................................................................................................................. 9-1

Lubricating the Air-Line ...................................................................................................................................... 9-2

Repairing the 3-Way Air Solenoid Valve ......................................................................................................... 9-2

Repairing the 366 Glue Valve............................................................................................................................. 9-2

Disassembly ............................................................................................................................................... 9-2

Assembly .................................................................................................................................................... 9-3

Repairing the 08 Glue Valve............................................................................................................................... 9-4

Disassembly ............................................................................................................................................... 9-4

Assembly .................................................................................................................................................... 9-6

Repairing the Fluid Regulator............................................................................................................................. 9-8

Disassembly ............................................................................................................................................... 9-8

Assembly .................................................................................................................................................... 9-8

Cleaning the EPC Solenoid Valve ..................................................................................................................... 9-10

Disassembly ............................................................................................................................................... 9-10

Assembly .................................................................................................................................................... 9-10