SAFETY

BEFORE ATTEMPTING ANY PROCEDURE IN THIS

BOOK, READ AND UNDERSTAND ALL THE SAFETY

INFORMATION CONTAINED IN THIS SECTION. IN

ADDITION, ENSURE ALL INDIVIDUALS WORKING

WITH YOU ARE ALSO FAMILIAR WITH THESE

SAFETY PRECAUTIONS.

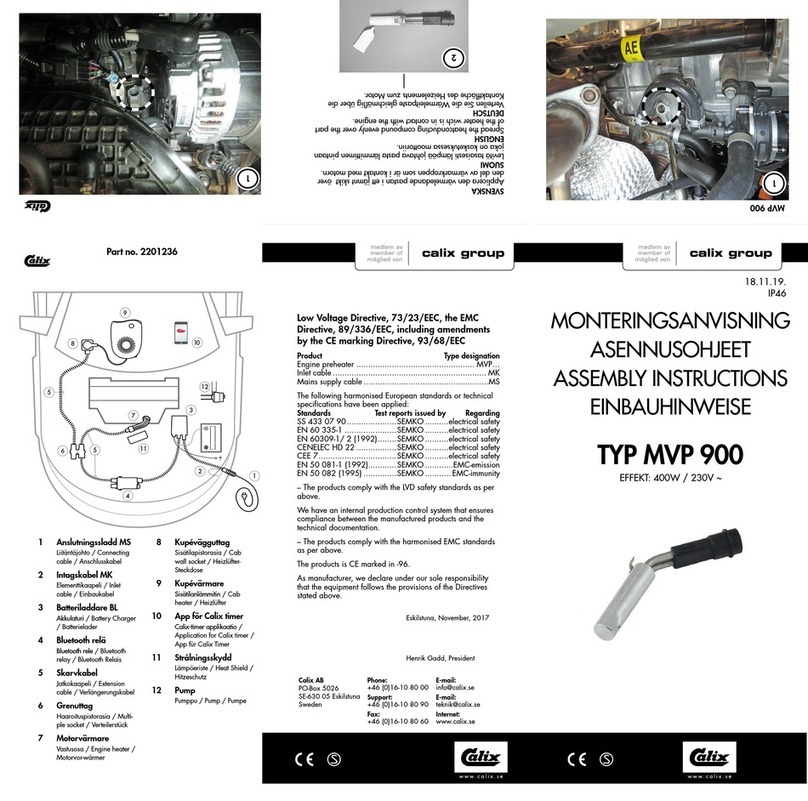

For your safety Warning and Information Decals have

been placed on this product to remind the operator

to take safety precautions. It is important that these

decals are in place and are legible before operation

begins. New decals can be obtained from Sno-Way or

your local dealer.

REMEMBER The careful operator is the best

operator. Most accidents are caused by human error.

Certain precautions must be observed to prevent the

possibility of injury to operator or bystanders and/or

damage to equipment.

NEVER operate Plow when under the influence of

alcohol, drugs or other medications that could hamper

your judgement and reactions. An accident may result in

serious injury or death to other persons or yourself.

ALWAYS operate vehicle in a well-ventilated area. The

carbon monoxide in exhaust gas is highly toxic and can

cause serious injury or death.

NEVER allow hands, hair or clothing to get near any

moving parts such as fan blades, belts and pulleys. Never

wear neckties or loose clothing when working on the

vehicle.

NEVER

wear wrist watches, rings or other jewelry when

working on the vehicle or individual equipment. These

things can catch on moving parts or cause an electrical

short circuit that could result in serious personal injury.

ALWAYS wear safety goggles when working on the

vehicle to protect your eyes from battery acid, gasoline,

and dust or dirt from flying off of moving engine parts.

ALWAYS be aware of and avoid contact with hot

surfaces such as engine, radiator, and hoses.

ALWAYS wear safety glasses with side shields when

striking metal against metal! In addition, it is

recommended that a softer (non-chipable) metal material

be used to cushion the blow. Failure to heed could result

in serious injury to the eye(s) or other parts of the body.

NEVER allow children or unauthorized person to

operate this unit.

NEVER exceed 45 m.p.h. when snow plow is attached

to vehicle. Braking distances may be reduced and

handling characteristics may be impaired at speeds

above 45 m.p.h.

ALWAYS lock the vehicle when unattended to prevent

unauthorized operation of the plow.

ALWAYS check the job site for terrain hazards,

obstructions and people.

NEVER exceed 10 m.p.h. when plowing. Excessive

speed may cause serious injury and damage of

equipment and property if an unseen obstacle is

encountered while plowing.

ALWAYS position blade so it does not block path of

headlamps beam. Do not change blade positions while

traveling. An incorrect plow position blocking headlamp

beam may result in an accident.

ALWAYS check surrounding area for hazardous

obstacles before operating this unit.

ALWAYS inspect the unit periodically for defects. Parts

that are broken, missing or plainly worn must be replaced

immediately. The unit, or any part of it should not be

altered without prior written approval of the manufacturer.

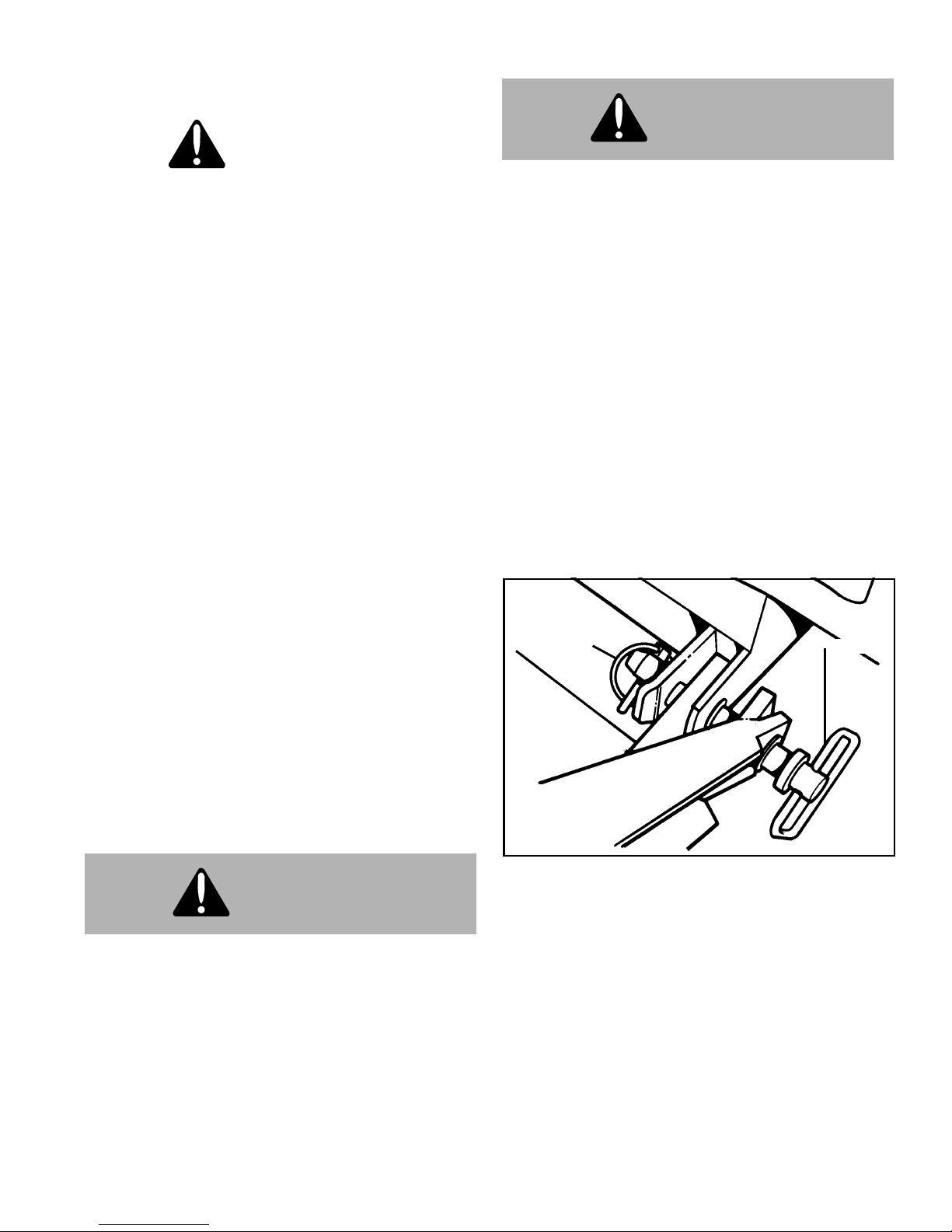

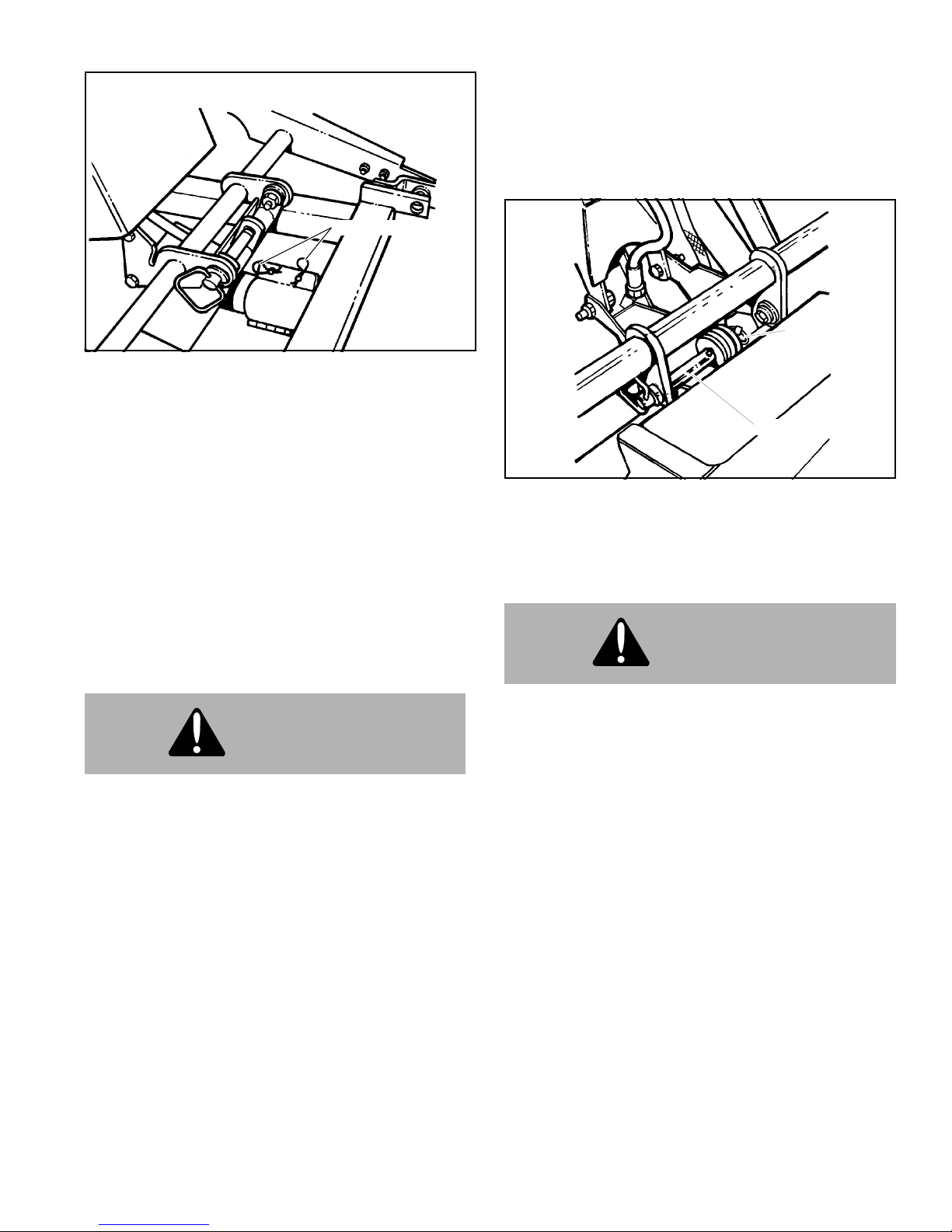

ALWAYS insert the cylinder lock when plow is not in

use. If the cylinder lock is not installed, the plow blade

could inadvertently drop and cause serious injury.

ALWAYS shut off the vehicle engine, place the

transmission in Neutral or Park, turn the ignition switch to

the “OFF” position and firmly apply the parking brake of

the vehicle before attaching or detaching the blade from

the vehicle or when making adjustments to the blade.

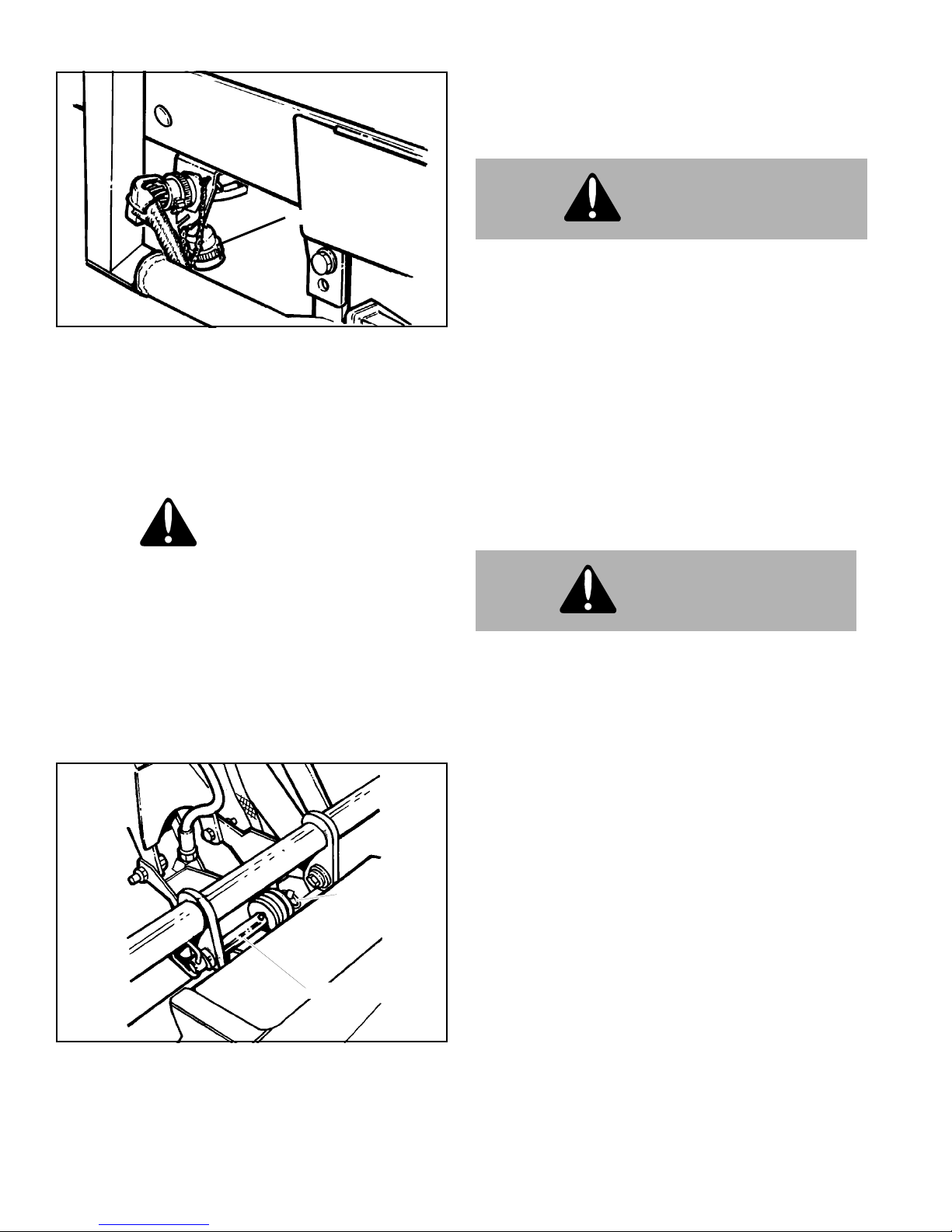

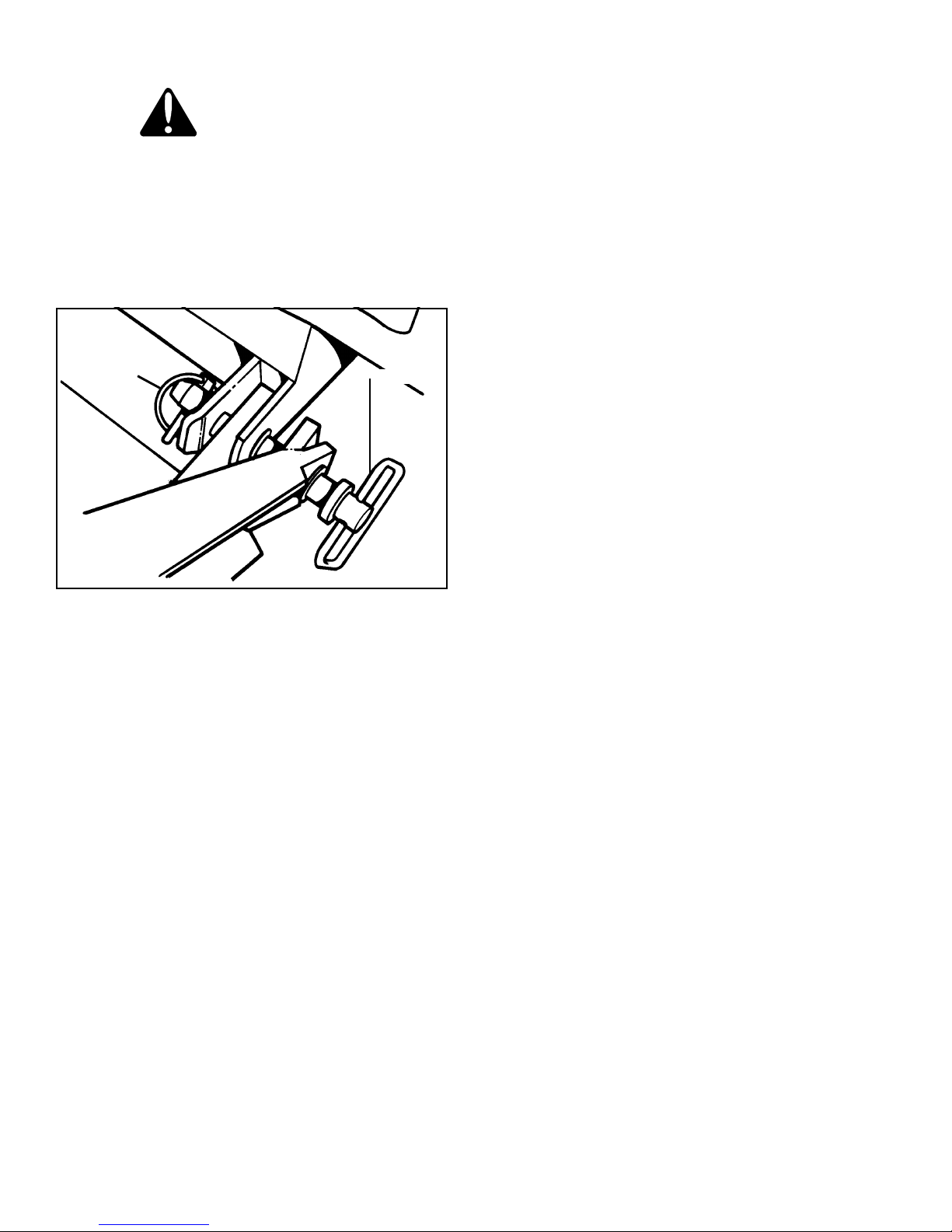

ALWAYS inspect lift system bolts and pins whenever

attaching or detaching the plow, and before traveling.

Worn or damaged components could result in the plow

dropping to the pavement while driving, causing an

accident.

ALWAYS keep hands and feet clear of blade and

A-Frame when attaching or detaching plow.

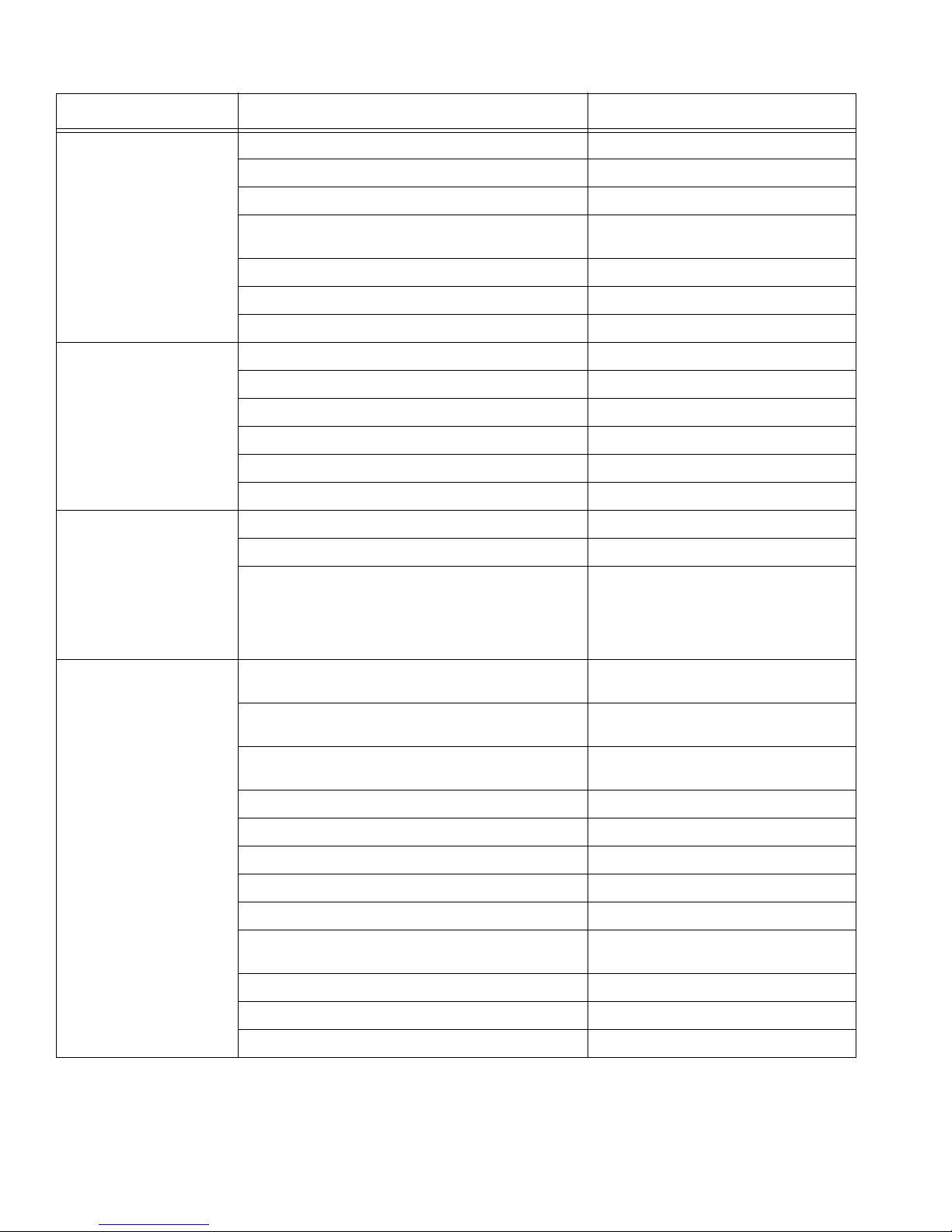

NEVER place fingers in A-frame or mount lug holes to

check alignment when attaching snow plow. Sudden

motion of the plow could severely injure a finger.

NEVER stand between the vehicle and blade or directly

in front of blade when it is being raised, lowered or

angled. Clearance between vehicle and blade decreases

as blade is operated and serious injury or death can

result from blade striking a body or dropping on hands or

feet.

NEVER work on the vehicle without having a fully

serviced fire extinguisher available. A 5 lb or larger CO2

or dry chemical unit specified for gasoline, chemical or

electrical fires, is recommended.

NEVER smoke while working on the vehicle. Gasoline

and battery acid vapors are extremely flammable and

explosive.

NEVER use your hands to search for hydraulic fluid

leaks; escaping fluid under pressure can be invisible and

can penetrate the skin and cause a serious injury! If any

fluid is injected into the skin, see a doctor at once!

Injected fluid MUST BE surgically removed by a doctor

familiar with this type of injury or gangrene may result.

REMEMBER it is the owner’s responsibility for

communicating information on the safe use and

proper maintenance of this machine.

3