Snug Cottage Hardware Borglocks BL3400 User manual

ϭ

Code Change Key

for Recoding

BL3400 & 3430DKO-ECP

Parts List, Installation Guide, & Maintenance

Instructions

Before you begin installation, please consult your local building code and/or pool code to ensure this product

is suitable for your application. Periodic maintenance and testing to ensure proper operation is recommended.

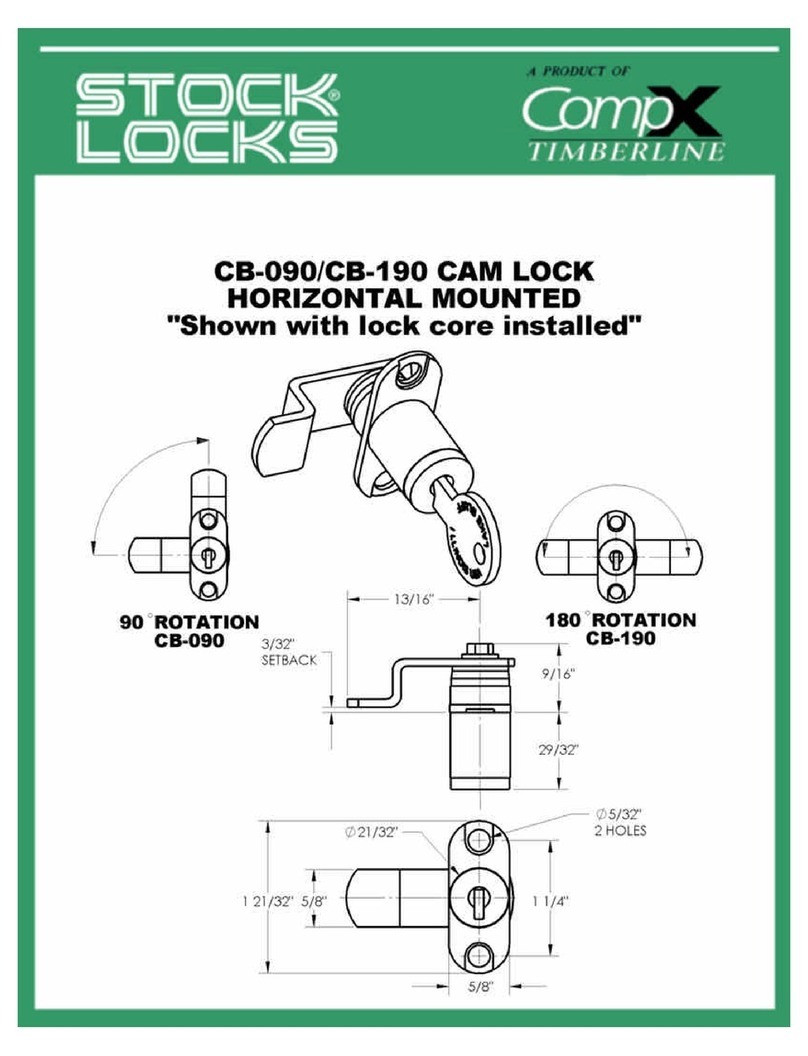

Parts List:

Factory Pre-set

Code Card

Tweezers x 1

Spare Tumblers

2 x coded

2 x blank

Euro cylinder with 2 keys for

BL3400 & BL3430DKO-ECP

models

Gate Jamb Striker

(1) Socket Machine Screw Plug x 2

(2) Socket Machine Screw x 2

(3) Spacer x 2

(4) Latch Bolt Finishing Insert x 1

Allen Wrench x 2

1 @ 3mm for Key Pack

1 @ 2.5mm for Latch Bolt Adjusting

Ϯ

Code Change

Key for Recoding

These instructions should be thoroughly explained and left with the owner of the lock for reference by

them or other service personnel at a later date.

Before commencing installation, check that all parts listed above are accounted for and the lock is working

correctly. Press the code into the lock, as per the code card provided and then turn the knob….it should turn

easily and return under spring pressure. If you intend to change the code, you can do this now or after the lock

is installed, see “How to Change your Code” for more details.

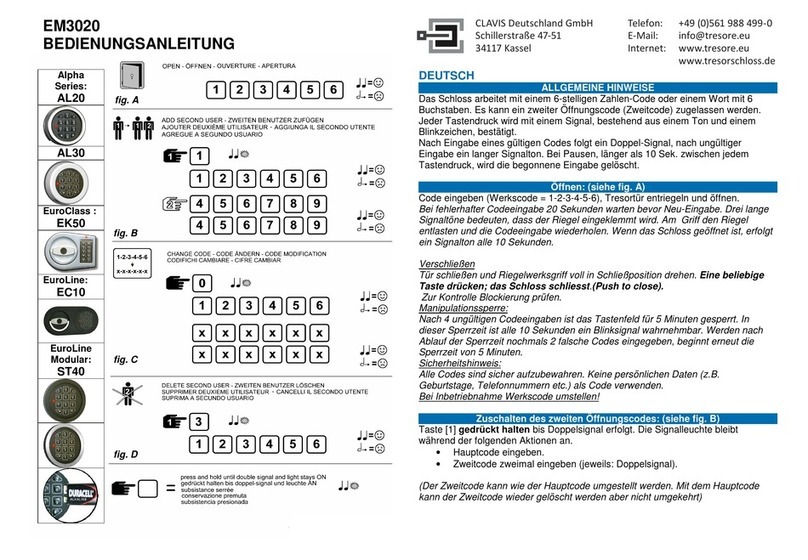

How to Change your Code:

The BL3400 and BL3430DKO-ECP models are equipped with the EasicodePro (ECP) code changing system

which allows quick and convenient code changes while the lock is still installed on the gate or door. Please

read the directions below and/or visit www.snugcottagehardware.com and look under Borg Locks for a “how

to” video which effectively shows the process.

In order to change the code you must know the existing code and all changes should be done with the gate

or door in the open position. Please refer to the code card provided with the lock for the factory set code. We

encourage you to take your time to ensure you press the new code correctly and to write down any changes

you make for reference later.

1.Open the gate or door, then enter the existing code into the keypad without turning the handle

2.Using the Code Change Key – Insert into the hole on the “*” button. Fully push in and hold in until you

reach step five (5).

3.Press the “C” button to clear the existing code.

4.Enter the new code.

5.Release the code change key from the hole in the “*” button

6.Press the “C” button to set the new code

7.The new code is now set and ready for use.

8.Before closing the gate or door – check that the new code is working five (5) times and that the latch

bolt is withdrawing correctly each time.

Please note: If a mistake is made while entering a new code (with the “*” button pressed) the “C” button can

be pressed which will cancel any buttons that have been pressed and you can start again.

Please note: You can either increase the number of digits in your code to 6-7 or reduce your code to 3-4 digits.

Numbers and letters may only be part of the code once – you cannot use any number more than once. (i.e

the code “1234” would be acceptable to use, while”1224” would not)

YZŽĚĞƚĂŬĞƐLJŽƵƚŽ,Žǁ

ƚŽŚĂŶŐĞLJŽƵƌŽĚĞǀŝĚĞŽ

ϯ

&ŝŐƵƌĞϭ

DĂĐŚŝŶĞ ^ĐƌĞǁƐ >ŽĐĂƚŝŽŶ

'ƌƵď^ĐƌĞǁ>ŽĐĂƚŝŽŶ

Deactivating the on the Door Code Change Function:

In the event where you know you will never need to change the code of the lock or in cases where you

wouldn’t want someone else to change the code without your knowledge, it is possible to disable the “on the

door” code changing feature.

Using the “on the door code change” deactivation plug supplied with each lock, insert it into the hole on the

back of the push button keypad with the red indicating arrow (just below X) – see diagram below. Ensure that

the domed part of the deactivation plug is facing out toward you when you insert it.

Please note that if the “on the door code change” deactivation plug is fitted to the back of the push button

keypad, the code will not be able to be changed as described previously in these instructions. If at a later date

the “on the door code change” function is required, the keypad will need to be removed from the lock body

and the deactivation plug removed.

How to Change the Handing of your Lock:

These locks can be installed either left or right by simply changing the hand of the lock. The BL3430DKO-ECP

can be made left or right by simply loosening the machine screw inside the tip of the latch bolt. Once loosened

twist/turn the tip of the latch bolt until the radiused edge is facing the appropriate way. While the same is true

for the BL3400DKO-ECP additionally it may be necessary to uninstall the key pads from the lock body and

switch them. See details for each style lock below.

BL3400DKO-ECP (single sided keypad):

xUse a 3mm Allen wrench to remove the

two (2) machine screws from the lever

handle only side of the lock. The machine

screws bolt through the lock body and

attach the back of keypad on the opposite

side. Switch the locations of each the lever

handle side and the keypad side and re-

install.

xNow change the handle position on the

keypad side by taking out the grey rubber

cover from the handle (use of a safety pin is

best) and revealing the grub screw.

Uninstall the grub screw using a 2.5mm

allen wrench, rotate the handle 180

degrees and re-install.

Continued next page

ϰ

BL3430DKO-ECP (double sided keypad):

xIt is not necessary to change the location of the keypads on the 3430 double sided model unless you

feel it may be defeated from the outside if you leave the machine screw heads exposed.

xIf so, use a 3mm Allen wrench to remove the two (2) machine screws from the keypad of the lock. The

machine screws bolt through the lock body and attach to the back of the opposing keypad on the

other side. Switch the locations of each keypad and re-install.

xNow change the handle position on the keypad side by taking out the grey rubber cover from the

handle (use of a safety pin is best) and revealing the grub screw. Uninstall the grub screw using a 2.5mm

allen wrench, rotate the handle 180 degrees and re-install.

BL3400 & BL3430DKO-ECP (both lock styles):

xIn addition to changing keypad sides on the lock body you may also

need to change the latch bolt handing. Using a 3mm allen wrench,

simply loosen the machine screw inside the tip of the latch bolt by

turning it counter clockwise until the tip can be twisted. Once loosened

twist/turn the tip of the latch bolt until the radiused edge is facing the

appropriate way. See latch bolt adjustment details below for further

details.

Adjusting the Latch Bolt Projection:

The length of the latch bolt on the BL3400 series can be adjusted from 2 3/8”

to 3 1/8” (65-80mm). The latch comes pre-set at 2 3/8” (65mm) and cannot

be shortened any further. Use a 3mm allen wrench inserted into the tip of the

latch bolt projection and turn counter clockwise to loosen. (pictured right in

figure 2)

Increasing and Decreasing the Length:

xInsert the 3mm Allen Wrench provided into the hole (see figure 1 & 2)

into the end of the latch bolt and rotate counter clockwise until the tip

of the bolt will twist/turn.

xTurn the tip of the latch bolt counter clockwise to lengthen or

clockwise to shorten the projection. The range of adjustment is 5/8” or

16mm.

xOnce the latch bolt is in the desired position, align the ball pin head

with the opening on the latch (pictured right in figure 3)

xRe-insert the 3mm Allen Wrench (see figure 1 & 2) and tighten the Allen

screw by rotating clockwise until snug. DO NOT OVER TIGHTEN

xIt may be necessary to adjust this position in the future so please

explain this to the owner and leave these instructions.

&ŝŐƵƌĞϮ

&ŝŐƵƌĞϯ

ĂůůWŝŶ,ĞĂĚ

ϱ

&ŝŐƵƌĞϰ

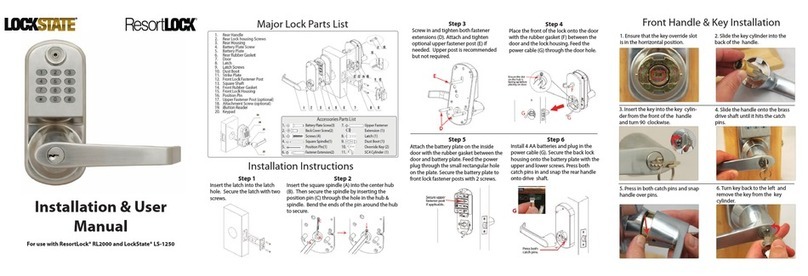

Installation instructions:

1.Establish the handing required for your lock installation and change if necessary following the

instructions above in “How to Change the Handing of your Lock”.

2.Enter the code and test the lock several times to ensure proper operation before proceeding.

3.Establish the position of the lock body on the gate frame/stile and using the provided drilling template,

mark the centers of both the 35/64”(14mm) holes and 51/64”(20mm) hole. Please note there is both an outside

and inside drilling template.

4.Drill the holes using the appropriate bits. Keep in mind that the 51/64”(20mm) goes all the way through

but the 35/64”(14mm) hole is for

the outside of the frame/stile only.

The hole on the inside of the

frame/stile is to be 11/32”(8.5mm).

The difference allows the head of

the “Socket Machine Screw” to

pass through the outside and

catch the inside wall of the gate

frame/stile.

5.Install the “Latch Bolt Finishing

Insert” into the outside

51/64”(20mm) hole and ensure it is

snugly and properly placed. You

should hear it snap into place.

6.Guide the latch projection of the

lock through the 51/64”(20mm)

hole from the inside of the gate

frame.

7.Using the “Socket Machine Screws

(item 2) and the “Spacers” (item 3), bolt the lock body to the gate stile. Make them snug but do not

tighten yet. The spacers are necessary to keep the socket machine screws from interfering with the

internal working of the lock.

8.Test the operation of the lock several times before proceeding here as well. It may be necessary to

loosen the “Socket Machine Screws” and slightly adjust the position of the lock to achieve the best

operation.

9.Once satisfied, tighten the “Socket Machine Screws” and secure the lock in its final position on the gate.

10.Now that you know where the lock will sit you can turn your attention to the “Gate Jamb Striker”. The

striker is complete with a gate stop to stop the gate in its travel and ensure the latch bolt catches

consistently.

11.Hold the “Gate Jamb Striker” on the latch post with center of the latch bolt receiver slot near the latch

bolt projection from the lock. Centering the latch bolt vertically in the slot will allow for some movement

up or down should the need arise.

12.Once you have determined its proper position you can mark and drill the two (2) 35/64”(14mm) holes to

mount it.

13.Once the holes are drilled push the supplied “Nutserts” into the holes. Place the “Gate Jamb Striker”

over top aligning the square holes and ensuring the gate stop is positioned appropriately for your gate

thickness.

14.Install the machine screws though the “Gate Jamb Striker” and thread by hand into the “Nutserts”

previously placed in the post.

15.Tighten the Allen Screws with a 5mm Allen Wrench until tight.

ϲ

Snug Cottage Hardware

Marysville Michigan, USA and London, Ontario, Canada

1-800-637-5427

www.snugcottagehardware.com

&ŝŐƵƌĞϱ

ZĞĨĞƌƚŽdĂďůĞ

Spacing Requirements:

The BL3400/3430 has a 5/8” (16mm) adjustment(from 2 3/8” (60mm) to 3”

(79mm)) in its latch bolt projection so the minimum and maximum set-up

distance between the gate and the post has to change with varying

gate post (stile) thicknesses. Please refer to the table below for some of

the most common sizes. Plan your spacing somewhere in the middle of

the min. and max. to allow for adjustment either way down the road if

anything moves. In addition, we recommend the use of adjustable

hinges like our 3100’s to allow for even more and finite adjustment.

Maintenance Instructions

Monthly:

xClean the surface of the lock by spraying with a silicon based lubricant and wiping clean with a soft

cloth. Do NOT use an oil based spray like WD40 as this will attract dirt and debris.

Annually:

xRemove the lock from the door or gate and the keypads from the lock body.

xSpray all the fixing accessories and the latch with a silicon based lubricant.

xSpray the inside of the keypads through the tumbler holes at the back and spray the lock body

thoroughly with a silicon based lubricant.

xWipe to remove any excess lubricant from undesired surfaces.

xPush each of the buttons and rotate the knob several times to ensure that the lock is working smoothly

and the lubricant has penetrated the lock appropriately.

xThese procedures can be carried out as needed when lock is sticky or code is accepted intermittently.

If you experience any problems when installing or changing the code on this lock, please contact:

ŝƐƚĂŶĐĞĞƚǁĞĞŶ'ĂƚĞĂŶĚWŽƐƚ

'ĂƚĞWŽƐƚ^ŝnjĞ DŝŶŝŵƵŵ DĂdžŝŵƵŵ

ϭϯϴΗ ϭϲϮϱΗ;ϰϭŵŵͿ ϮϮϱΗ;ϱϳŵŵͿ

ϭϱϴΗ ϭϯϳϱΗ;ϯϱŵŵͿ ϮΗ;ϱϭŵŵͿ

ϮΗ ϭϮϱΗ;ϯϮŵŵͿ ϭϳϱΗ;ϰϱŵŵͿ

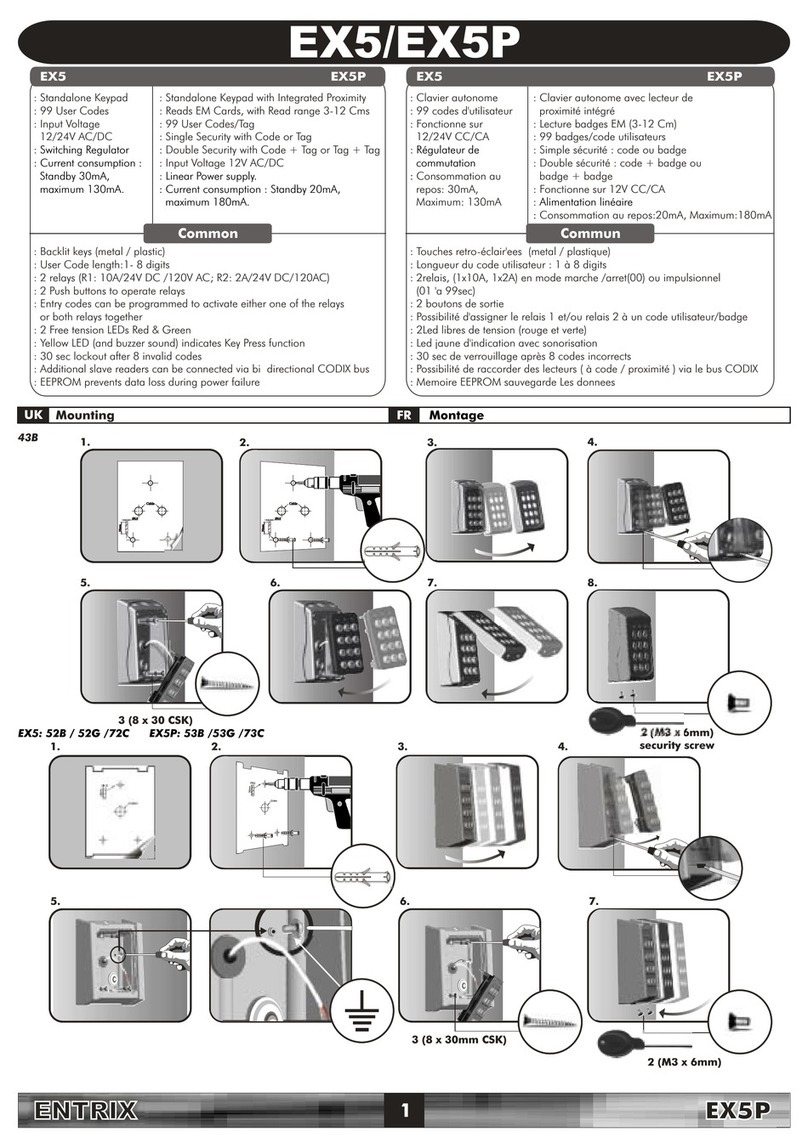

This manual suits for next models

1

Table of contents

Popular Lock manuals by other brands

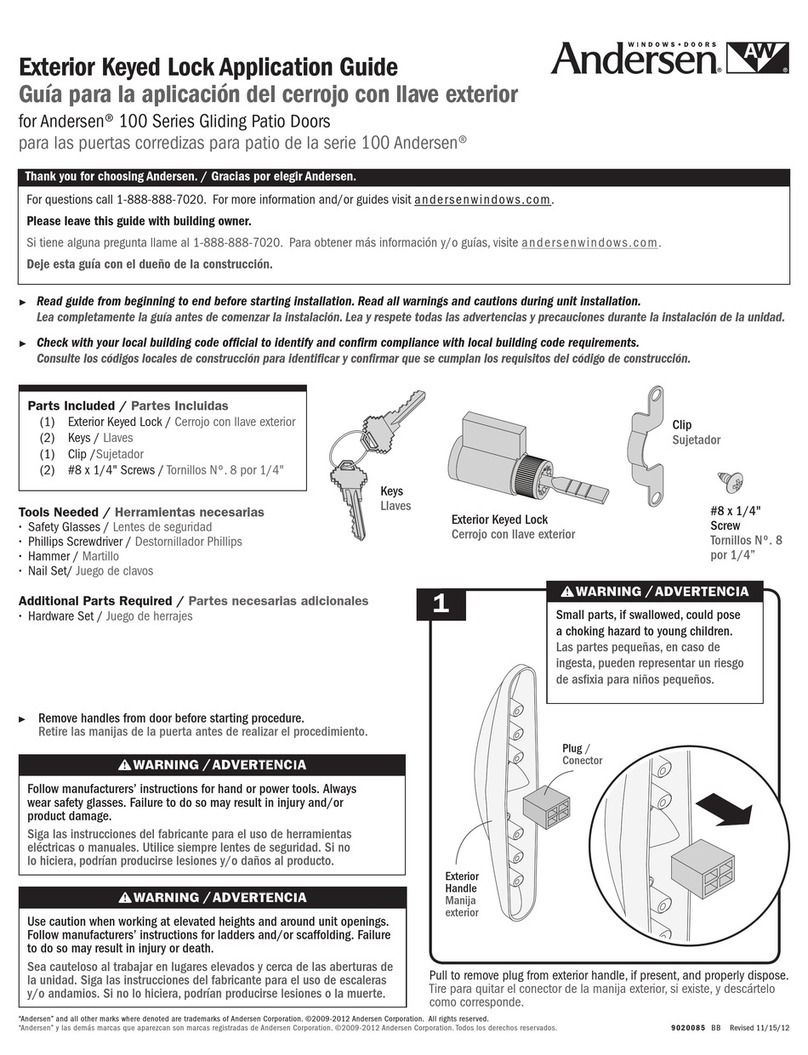

Andersen

Andersen 100 Series Application guide

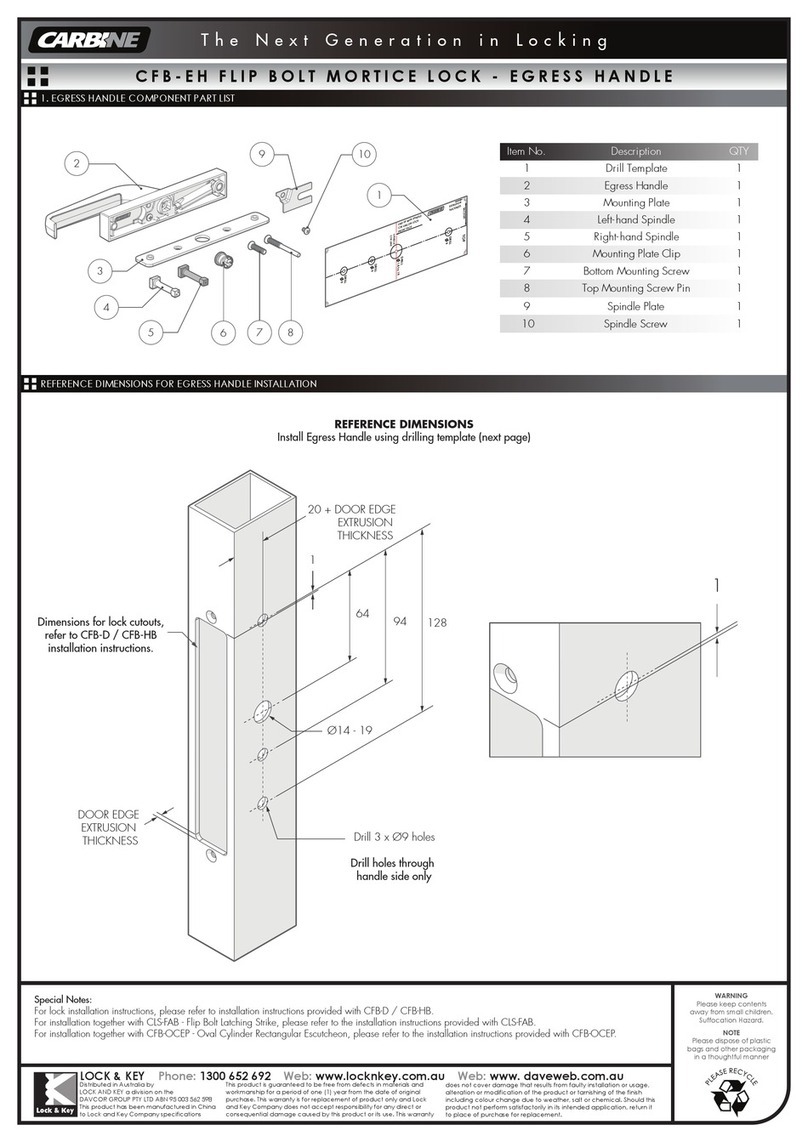

Carbine

Carbine CFB-EH manual

Burg Wächter

Burg Wächter 610/53 operating instructions

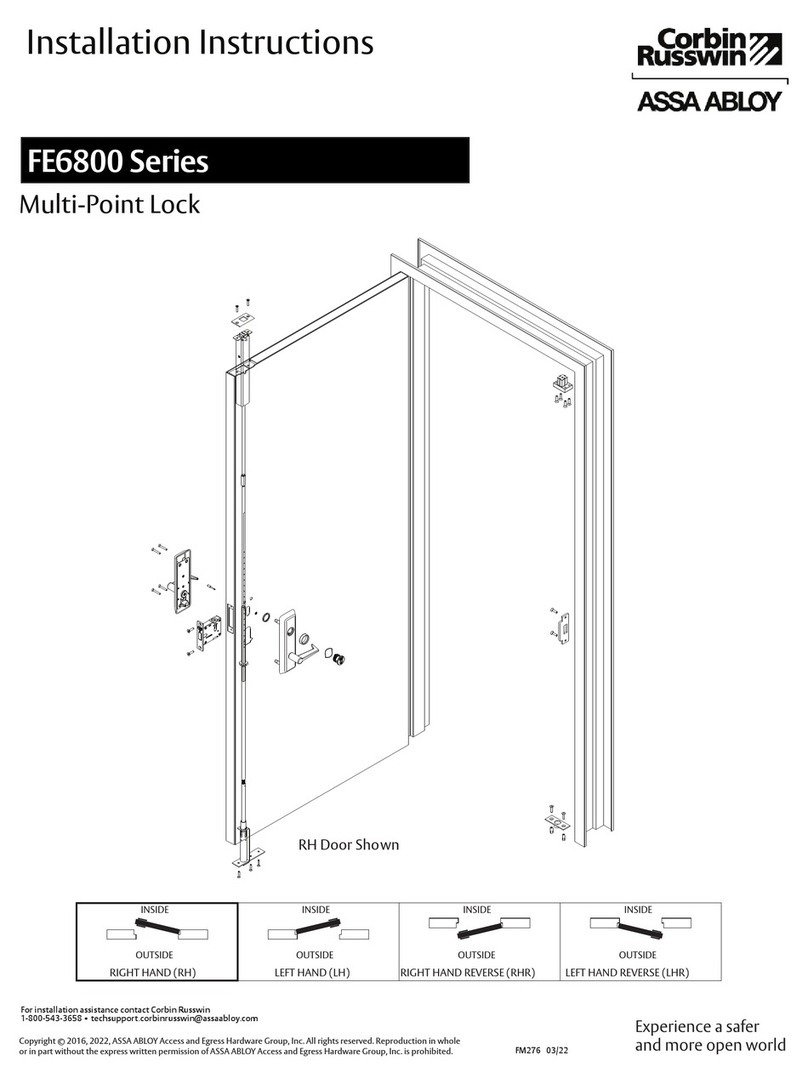

Assa Abloy

Assa Abloy Corbin Russwin FE6800 Series installation instructions

National Cabinet Lock

National Cabinet Lock C8102 Dimensional drawing

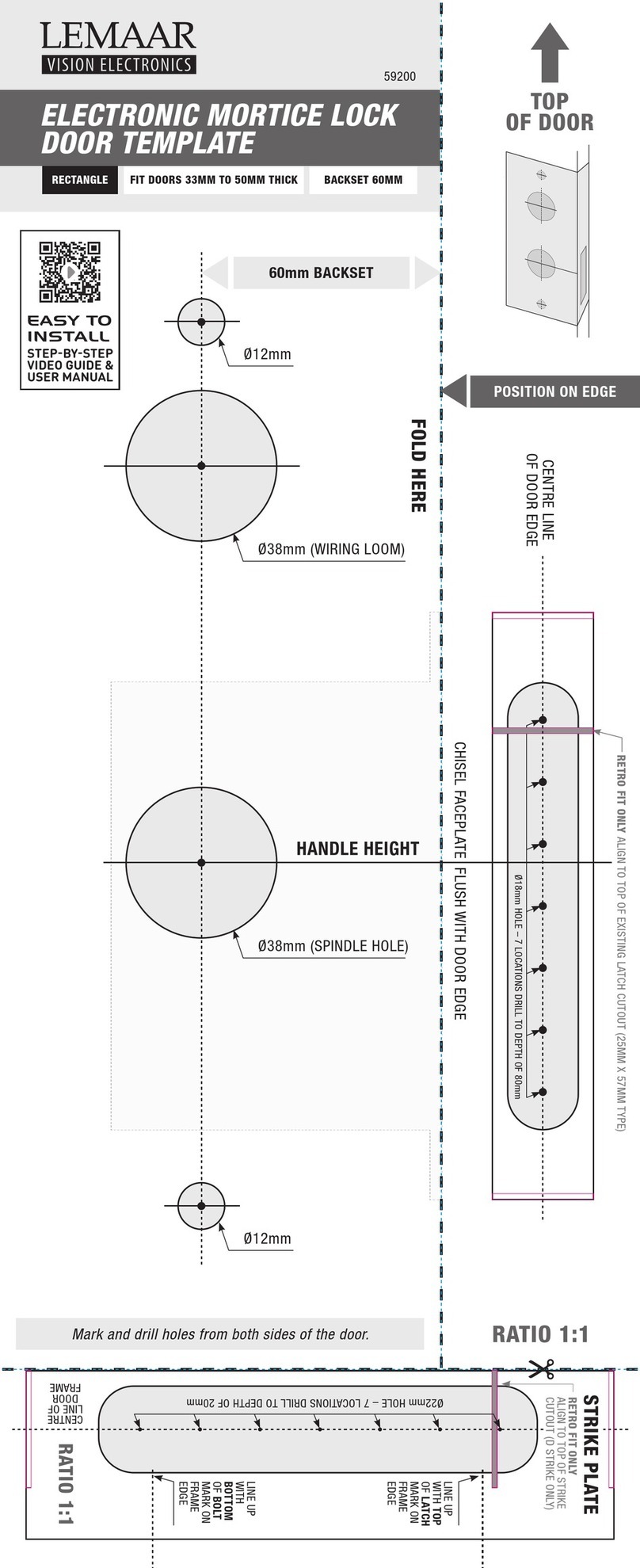

LEMAAR

LEMAAR 59200 quick start guide