This document can not be reproduced or released without the Sodikart authorization.

MAN.SIG.EN.02

04/2014 5

USE SPARE PARTS OF SODI ORIGIN

User maintenance guide

1.1 - Recap of all warnings included in this

manual

Chapter: Assembly

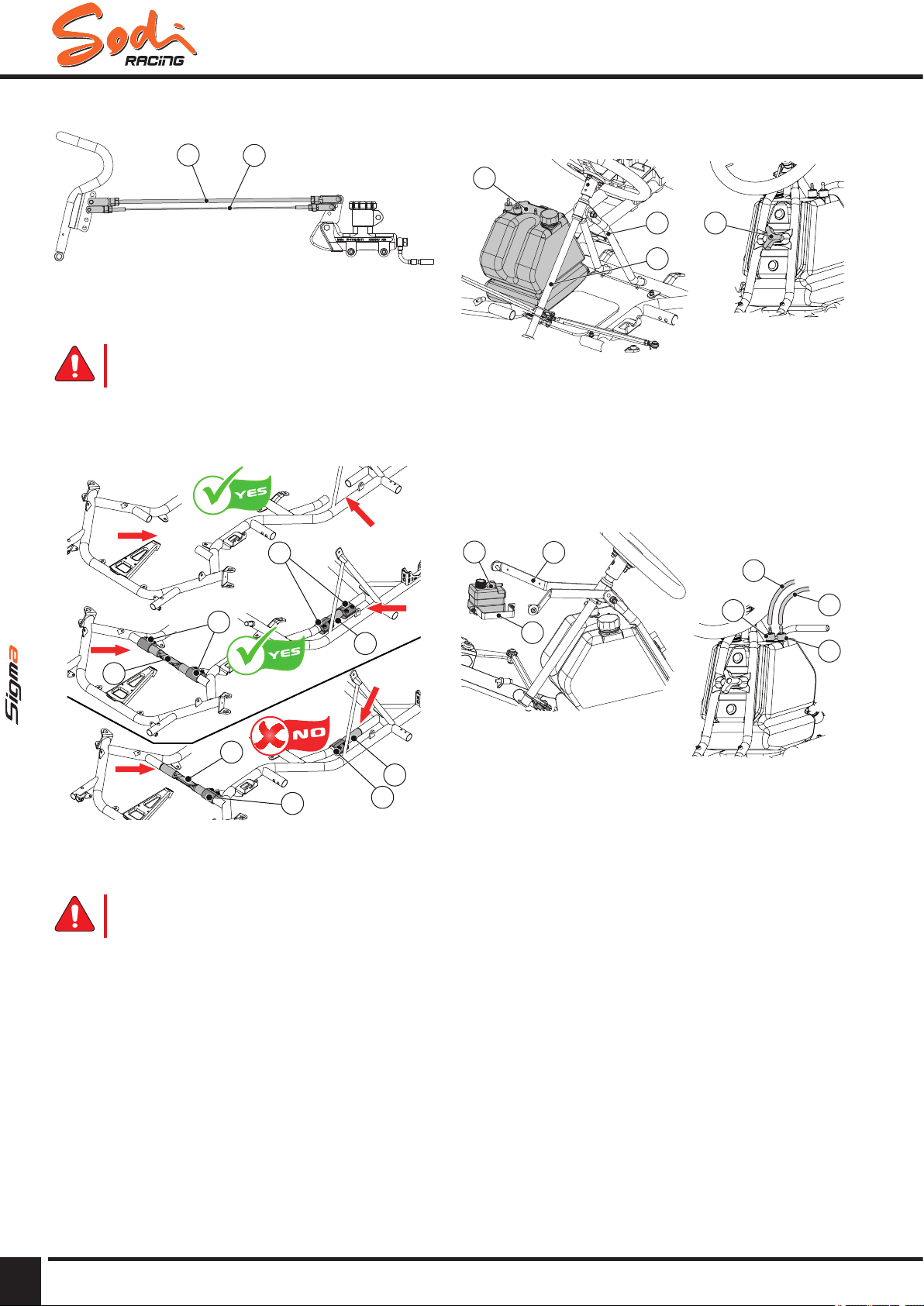

►A bad assembly or a bad adjustment of the steering

system can lead to accidents. Systematically

check the tightening of the system and its

adjustment./ Page 9

►Always t the safety cable clips (1) under the staples

of the brake rod (2)./ Page 10

►Always attach the stabilisers to the frame with a

sleeve at each side./ Page 10

Chapter: Commissioning

►Your kart can only be driven on a track approved by

CIK/FIA, or your local federation and by a driver who

is in possession of a valid membership card of the

kart’s federation of his own country./ Page 17

►For your safety and the safety of other pilots, strictly

follow the above instructions: not doing so may lead

to severe, even fatal injuries./ Page 17

Chapter: Adjustments

►Never drive with badly tightened wheels: it may lead

to severe, even fatal injuries./ Page 23

►Make sure that each ball joint penetrates at least 5

threads in the tie rods./ Page 23

►Badly tightened wheels may lead to severe, even

fatal injuries./ Page 24

►Check the hub key (5) is correctly

positioned./ Page 24

►Never position the hubs beyond the maximum

allowed width: it may lead to severe or even fatal

injuries./ Page 24

►The brake system is a key safety item of the kart.

Regularly check all its components./ Page 25

►In case of doubt, do not drive before xing the

problem./ Page 25

►Bad maintenance of the brakes can lead to severe,

even fatal injuries./ Page 25

►Never repair a break system on your own; return it

to your local dealer./ Page 25

Chapter: Maintenance

►The Super Blue brake uid has been designed for

racing use and is used exclusively for this purpose

(forbidden on open road)./ Page 26

►Use brake uid DOT4 only. Using another brake

uid could cause leaks and failure of the brake

system./ Page 26

►Check the pads for wear before every start-

up./ Page 27

►Never drive with excessively worn pads (minimum

thickness for the D18 4-piston calipers (front):

4mm)./ Page 27

►The brake is an essential safety element. If the

braking system is defective or you have the slightest

doubt, do not put the kart in service./ Page 27

►Never drive with excessively worn pads (minimum

thickness of pads for D24 4-piston calipers (rear): 6

mm)./ Page 27

►The brake is an essential safety element. Do not put

the kart in operation if the break system is faulty or if

you have a doubt./ Page 28

►Faulty braking system may lead to a serious or even

fatal injury./ Page 28

►Check connexions of hoses, no leak./ Page 28

►Use brake uid DOT 4 only./ Page 28

►An air bubble in the brake system can lead to a

partial or total lost of brakes and may lead to a

serious or even fatal injury./ Page 29

►Leaks in the brake system may lead to a serious or

even fatal injury./ Page 29

►Moisture in the brake uid may cause vapour lock

and a sudden loss of braking power, may lead to a

serious or even fatal injury./ Page 29

►Use brake uid DOT 4 only/ Page 29

►Test the brake after each bleed./ Page 29

►Do not use any cleaning product that could damage

the seals. A brake uid leak could appear, causing a

serious or fatal accident./ Page 33

►If WD-40 or a similar cleaning product is splashed

on the brake disc or calliper, braking will be less

efcient or possibly totally ineffective for a few

revolutions. This could cause a serious or fatal

accident./ Page 37

►Do not apply WD-40 or other cleaning products to

the brake pump./ Page 37

►Change all damaged rims. A damaged rim may lead

to a loss of tyre or loss of pressure and may lead to

a serious or even fatal injury./ Page 38

►Check the tyre wear daily. Worn or damaged tyres

may lead to a serious or even fatal injury./ Page 38

►Never run with worn or damaged tyres: a burst

of tyre may lead to a serious or even fatal

injury./ Page 38

►Always blow up tyre with the pressure

recommended by the manufacturer./ Page 38

►Cold tyres have a reduced adherence, and increase

the loss of control of the kart. This may lead to a

serious or even fatal injury./ Page 38

►Too much grip reduces the stability of the kart under

impact, and lead to a tendency to go on two wheels.

It also increases the risk of riding over./ Page 38

►Store tyres in an appropriate area to prevent re

hazard./ Page 38

►Never inate above 4 bars: there is a risk of severe

injury due to potential failure of the rim. / Page 38

►Spray cleaning product on brake pads or brake

caliper may reduce the braking ability partially or

totally, and can lead to a serious accident./ Page 40