SOFT ROBOTICS mGrip Parallel Kit User manual

QUICK START GUIDE

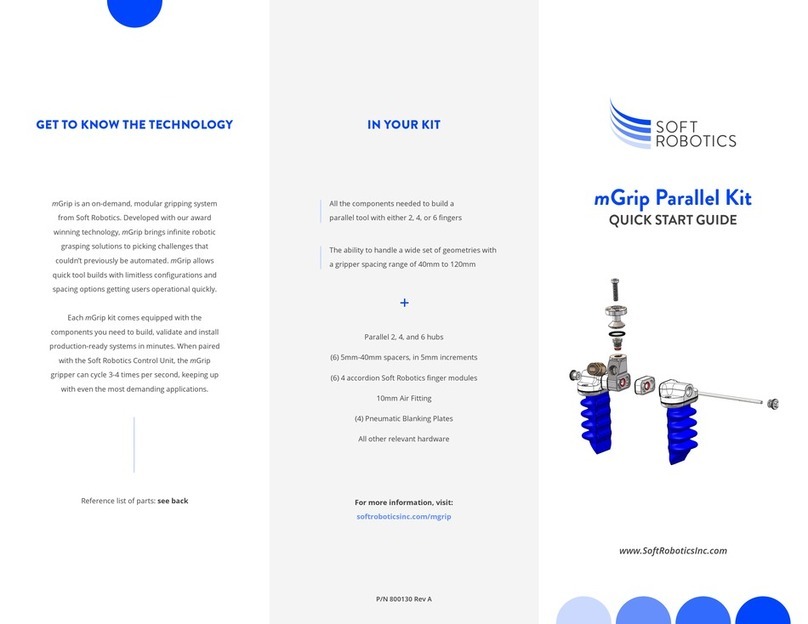

IN YOUR KIT

All the components needed to build a

parallel tool with either 2, 4, or 6 ngers

The ability to handle a wide set of geometries with

a gripper spacing range of 40mm to 120mm

Parallel 2, 4, and 6 hubs

(6) 5mm-40mm spacers, in 5mm increments

(6) 4 accordion Soft Robotics nger modules

10mm Air Fitting

(4) Pneumatic Blanking Plates

All other relevant hardware

For more information, visit:

softroboticsinc.com/mgrip

P/N 800130 Rev A

www.SoftRoboticsInc.com

mGrip Parallel Kit

SOF T

ROBOTIC

S

GET TO KNOW THE TECHNOLOGY

mGrip is an on-demand, modular gripping system

from Soft Robotics. Developed with our award

winning technology, mGrip brings innite robotic

grasping solutions to picking challenges that

couldn’t previously be automated. mGrip allows

quick tool builds with limitless congurations and

spacing options getting users operational quickly.

Each mGrip kit comes equipped with the

components you need to build, validate and install

production-ready systems in minutes. When paired

with the Soft Robotics Control Unit, the mGrip

gripper can cycle 3-4 times per second, keeping up

with even the most demanding applications.

Reference list of parts: see back

QUICK START GUIDE

IN YOUR KIT

All the components needed to build a

parallel tool with either 2, 4, or 6 ngers

The ability to handle a wide set of geometries with

a gripper spacing range of 40mm to 120mm

Parallel 2, 4, and 6 hubs

(6) 5mm-40mm spacers, in 5mm increments

(6) 4 accordion Soft Robotics nger modules

10mm Air Fitting

(4) Pneumatic Blanking Plates

All other relevant hardware

For more information, visit:

softroboticsinc.com/mgrip

P/N 800130 Rev A

www.SoftRoboticsInc.com

mGrip Parallel Kit

SOF T

ROBOTIC

S

GET TO KNOW THE TECHNOLOGY

mGrip is an on-demand, modular gripping system

from Soft Robotics. Developed with our award

winning technology, mGrip brings innite robotic

grasping solutions to picking challenges that

couldn’t previously be automated. mGrip allows

quick tool builds with limitless congurations and

spacing options getting users operational quickly.

Each mGrip kit comes equipped with the

components you need to build, validate and install

production-ready systems in minutes. When paired

with the Soft Robotics Control Unit, the mGrip

gripper can cycle 3-4 times per second, keeping up

with even the most demanding applications.

Reference list of parts: see back

PARALLEL KIT SPACER AND TIE ROD CHART

Grip Spacing (mm)

40

50

60

70

80

90

100

110

120

Blanking Plate

0

5

10

15

20

25

30

35

40

-

85

95

105

115

125

135

145

155

165

35

Spacer (mm) Tie Rod (mm)

3

7

Insert the M6 Screw to attach

Robot Adapter through Parallel

Hub. Torque this screw to 5Nm.

Use the M4 Hex Nut to be tightened

onto Tie Rod (after Anti-Seize applied)

and then used to attached Finger

Module and Spacer (if required) to hub.

Note: Use the tie rod and spacer chart (located on the right panel of this guide) to identify

which tie rod is best for your gripper.We recommend using food-safe anti-seize lubricant when

torquing tie-rods. We recommend Anti-Seize gel onto Tie Rod before M4 Hex Nut is installed.

Note: We recommend Anti-Seize gel

onto M6 screw before installation.

Note: Fingers can be mounted

directly to the hub if spacers are

not being used. Note: We recommend Anti-Seize gel onto

Tie Rod before M4 Cap Nut installation.

11

Repeat steps 5 through 10 to

secure other Spacers and Finger

Modules to the Parallel Hub

(for Parallel 4 and Parallel 6 EOATs)

4

8

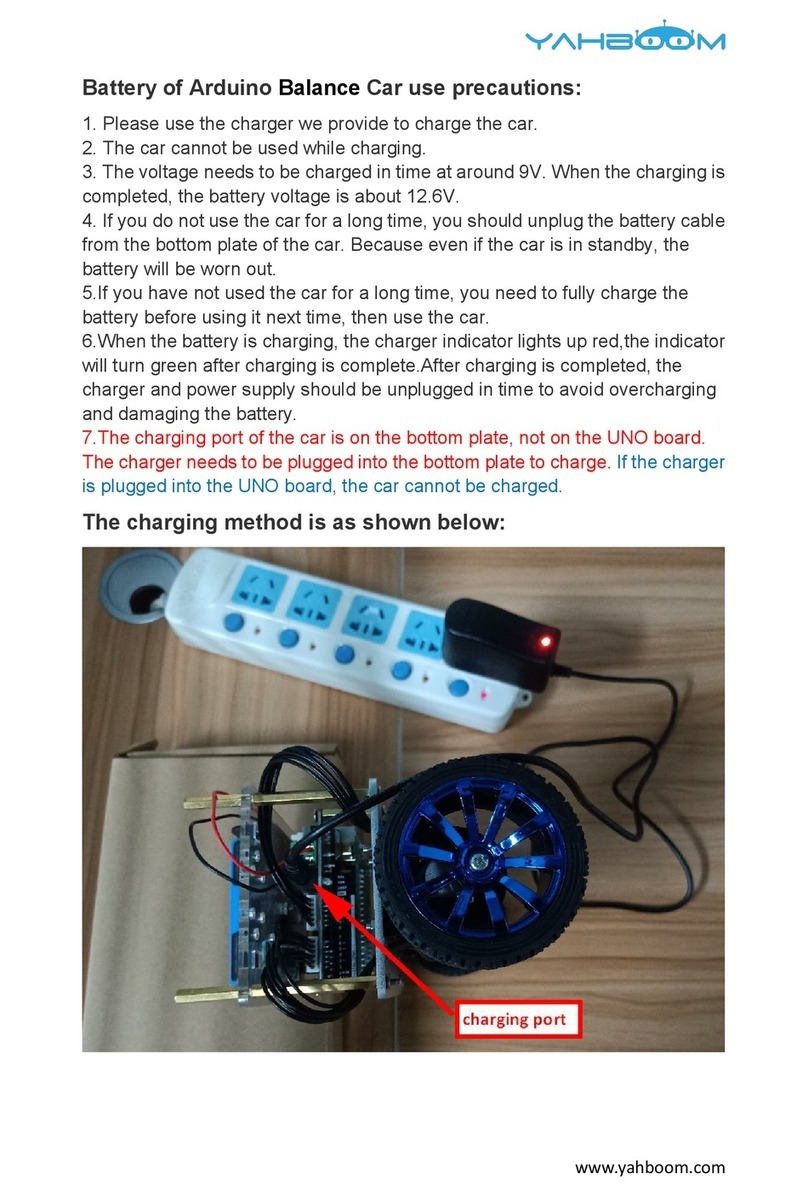

Ensure O-Rings are installed

on the Parallel Hub and did not

come loose during shipping.

Install the second Spacer, if

required, onto the opposite side

of the Parallel Hub by passing

the tie rod through the center of

the spacer and pressing rmly

against the Parallel Hub.

Install the Air Fitting onto

the desired Parallel Hub.

Torque to 6Nm.

Install the desired Spacer

onto the Parallel Hub (if

required) by aligning the

features and pressing rmly.

Install the second Finger

Module onto Spacer and

through the tie rod.

1 5 9

2

Install the Robot Adapter

onto the Parallel Hub.

6

Install Finger Module onto

the Spacer by aligning

features and pressing rmly.

10

Install an M4 Sealing Cap

Nut onto the end of the tie

rod to secure the Spacers

and Finger Modules in place.

Torque Hex Nut to 2.2Nm.

PARALLEL KIT SPACER AND TIE ROD CHART

Grip Spacing (mm)

40

50

60

70

80

90

100

110

120

Blanking Plate

0

5

10

15

20

25

30

35

40

-

85

95

105

115

125

135

145

155

165

35

Spacer (mm) Tie Rod (mm)

3

7

Insert the M6 Screw to attach

Robot Adapter through Parallel

Hub. Torque this screw to 5Nm.

Use the M4 Hex Nut to be tightened

onto Tie Rod (after Anti-Seize applied)

and then used to attached Finger

Module and Spacer (if required) to hub.

Note: Use the tie rod and spacer chart (located on the right panel of this guide) to identify

which tie rod is best for your gripper.We recommend using food-safe anti-seize lubricant when

torquing tie-rods. We recommend Anti-Seize gel onto Tie Rod before M4 Hex Nut is installed.

Note: We recommend Anti-Seize gel

onto M6 screw before installation.

Note: Fingers can be mounted

directly to the hub if spacers are

not being used. Note: We recommend Anti-Seize gel onto

Tie Rod before M4 Cap Nut installation.

11

Repeat steps 5 through 10 to

secure other Spacers and Finger

Modules to the Parallel Hub

(for Parallel 4 and Parallel 6 EOATs)

4

8

Ensure O-Rings are installed

on the Parallel Hub and did not

come loose during shipping.

Install the second Spacer, if

required, onto the opposite side

of the Parallel Hub by passing

the tie rod through the center of

the spacer and pressing rmly

against the Parallel Hub.

Install the Air Fitting onto

the desired Parallel Hub.

Torque to 6Nm.

Install the desired Spacer

onto the Parallel Hub (if

required) by aligning the

features and pressing rmly.

Install the second Finger

Module onto Spacer and

through the tie rod.

1 5 9

2

Install the Robot Adapter

onto the Parallel Hub.

6

Install Finger Module onto

the Spacer by aligning

features and pressing rmly.

10

Install an M4 Sealing Cap

Nut onto the end of the tie

rod to secure the Spacers

and Finger Modules in place.

Torque Hex Nut to 2.2Nm.

PARALLEL KIT SPACER AND TIE ROD CHART

Grip Spacing (mm)

40

50

60

70

80

90

100

110

120

Blanking Plate

0

5

10

15

20

25

30

35

40

-

85

95

105

115

125

135

145

155

165

35

Spacer (mm) Tie Rod (mm)

3

7

Insert the M6 Screw to attach

Robot Adapter through Parallel

Hub. Torque this screw to 5Nm.

Use the M4 Hex Nut to be tightened

onto Tie Rod (after Anti-Seize applied)

and then used to attached Finger

Module and Spacer (if required) to hub.

Note: Use the tie rod and spacer chart (located on the right panel of this guide) to identify

which tie rod is best for your gripper.We recommend using food-safe anti-seize lubricant when

torquing tie-rods. We recommend Anti-Seize gel onto Tie Rod before M4 Hex Nut is installed.

Note: We recommend Anti-Seize gel

onto M6 screw before installation.

Note: Fingers can be mounted

directly to the hub if spacers are

not being used. Note: We recommend Anti-Seize gel onto

Tie Rod before M4 Cap Nut installation.

11

Repeat steps 5 through 10 to

secure other Spacers and Finger

Modules to the Parallel Hub

(for Parallel 4 and Parallel 6 EOATs)

4

8

Ensure O-Rings are installed

on the Parallel Hub and did not

come loose during shipping.

Install the second Spacer, if

required, onto the opposite side

of the Parallel Hub by passing

the tie rod through the center of

the spacer and pressing rmly

against the Parallel Hub.

Install the Air Fitting onto

the desired Parallel Hub.

Torque to 6Nm.

Install the desired Spacer

onto the Parallel Hub (if

required) by aligning the

features and pressing rmly.

Install the second Finger

Module onto Spacer and

through the tie rod.

1 5 9

2

Install the Robot Adapter

onto the Parallel Hub.

6

Install Finger Module onto

the Spacer by aligning

features and pressing rmly.

10

Install an M4 Sealing Cap

Nut onto the end of the tie

rod to secure the Spacers

and Finger Modules in place.

Torque Hex Nut to 2.2Nm.

QUICK START GUIDE

IN YOUR KIT

All the components needed to build a

parallel tool with either 2, 4, or 6 ngers

The ability to handle a wide set of geometries with

a gripper spacing range of 40mm to 120mm

Parallel 2, 4, and 6 hubs

(6) 5mm-40mm spacers, in 5mm increments

(6) 4 accordion Soft Robotics nger modules

10mm Air Fitting

(4) Pneumatic Blanking Plates

All other relevant hardware

For more information, visit:

softroboticsinc.com/mgrip

P/N 800130 Rev A

www.SoftRoboticsInc.com

mGrip Parallel Kit

SOF T

ROBOTIC

S

GET TO KNOW THE TECHNOLOGY

mGrip is an on-demand, modular gripping system

from Soft Robotics. Developed with our award

winning technology, mGrip brings innite robotic

grasping solutions to picking challenges that

couldn’t previously be automated. mGrip allows

quick tool builds with limitless congurations and

spacing options getting users operational quickly.

Each mGrip kit comes equipped with the

components you need to build, validate and install

production-ready systems in minutes. When paired

with the Soft Robotics Control Unit, the mGrip

gripper can cycle 3-4 times per second, keeping up

with even the most demanding applications.

Reference list of parts: see back

Other SOFT ROBOTICS Robotics manuals