Software House RM 4000 Series Instruction Manual

1

RM xx-4000 Series Readers

Quick Start

Installation Guide

Version F1

Document Part Number UM-209

June 2012

OVERVIEW This guide provides quick start installation and connection information for RM xx-4000

Series Readers.

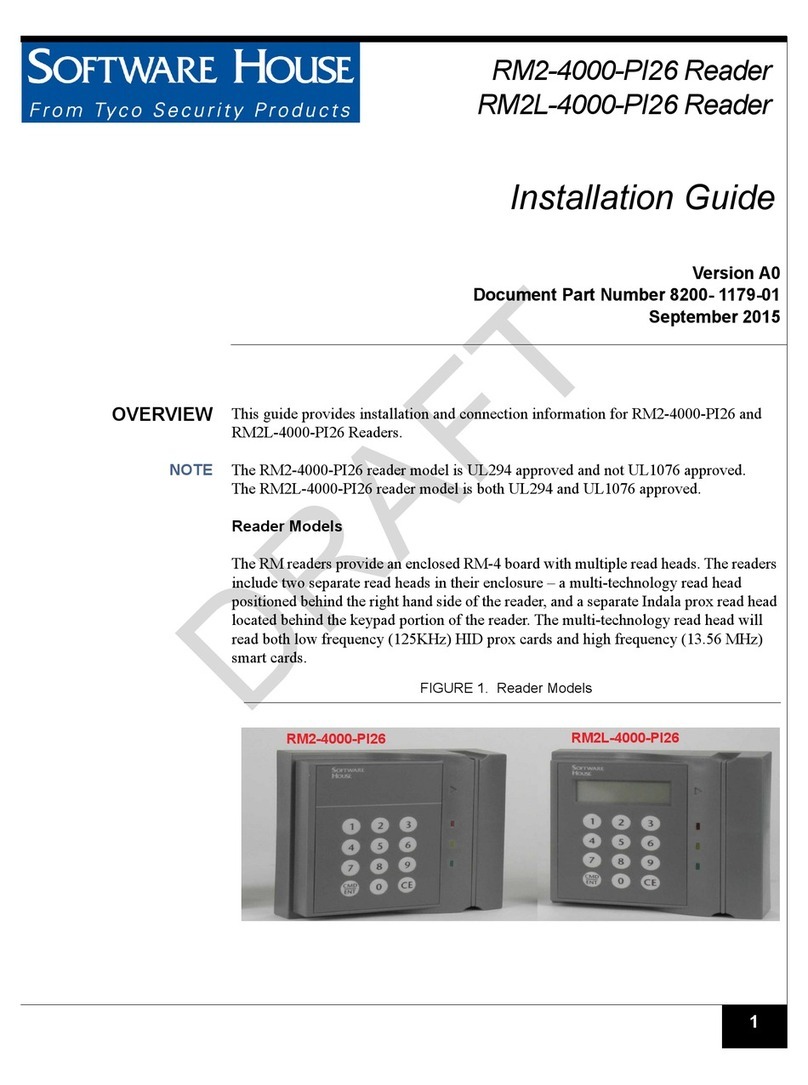

Reader Models

RM 1-4000, RM 2-4000, and RM 2L-4000 readers provide an enclosed RM-4 board

and attached multi-technology read head.

Figure 1 illustrates the RM xx-4000 Series Reader Models:

FIGURE 1. RM xx-4000 Series Reader Models

RM2-4000 RM1-4000 RM2L-4000

Overview

2

Table 1 lists the RM xx-4000 models and part numbers.

Supported

Technologies and Card

Formats

The RM Multi-Technology reader offers enhanced security through encryption and is

compatible with major card formats, including ISO 14443 A/B serial number, ISO

15693 serial number, iCLASS® serial number, MIFARE®, DESFire®, FIPS 201 PIV-II

and most 125 KHz formats (HID and CASI ProxLite).

The RM Multi-Technology reader includes a RoHS compliant RM-4 board in the RM

housing and provides the same features and functionality as the Software House Multi-

Technology Reader, including the ability to “flash” new card protocols or formats

directly to the reader.

NOTE UL has not evaluated the ability to “flash” new card protocols or formats directly to the reader.

The RM Multi-Technology reader can be used to transition from a proximity system to a

more advanced smart card system gradually over time, or to maintain the existing

proximity card system while moving selected personnel to smart cards.

NOTE UL has not evaluated Smart Card technology with this unit.

NOTE UL has evaluated the Wiegand Proximity (26-bit only) card format for this unit.

TABLE 1. RM xx-4000 Series Part Numbers

RM xx-4000 Model RM xx-4000 P.N.

RM1 - Without keypad or LCD;

with built-in RM-4 DS interface board

RM1-4000

RM2 - With keypad;

with built-in RM-4 DS interface board

RM2-4000

RM2L - With keypad and LCD;

with built-in RM-4 DS interface board

RM2L-4000

Overview

3

Model RMxx-4000

Proximity

(125 KHz) Formats

Supported

NOTE Not all features have been evaluated by UL.

Model RMxx-4000

Smart Card

(13.56 MHz) Formats

Supported

NOTE Not all features have been evaluated by UL.

TABLE 2. Proximity (125 KHz) Formats Supported

Proximity (125 KHz) Formats

Supported

As Shipped: Default Mode

(On)

HID® 26 Bit Yes

HID® Corporate 1000 Yes

HID® 36 Bit Wiegand Yes

HID® 37 Bit Wiegand Yes

Other HID® Pass-through Formats Yes

Deister Prox SmartFrame® Yes

(GE) Casi Rusco ProxLite Yes

Kantech ioProx No

TABLE 3. Smart Card (13.56 MHz) Formats Supported

Smart Card (13.56 MHz) Formats

Supported Enabled by Default?

MiFARE® Sector No

MiFARE® Serial number, 32 Bit Yes

MiFARE® Serial number, 56 Bit Yes

MiFARE® Plus Serial number, 56 Bit Yes

MiFARE® DesFire Serial number, 56 Bit No

MiFARE® DesFire® EV1 Serial number, 56 Bit No

iCLASS® ISO 15693 Serial number, 64 Bit Yes

* PIV, TWIC, CAC, FASC-N Read Yes* (200-bit output)

* PIV-I, 128 Bit, GUID Yes* (if 200-bit output is enabled)

* PIV-C, 128 Bit, GUID Yes* (if 200-bit output is enabled)

* Refers to cards issued under the U.S. Government Smart Card Initiative, HSPD-12.

Features

4

FEATURES Universal compatibility with most 125 KHz Prox (including all HID® Prox

formats), all ISO 15693, and ISO 14443A credentials (badges, disk tags and key

fobs). Reads both 125 KHz and 13.56 MHz credentials in the same reader.

Electrical protection (reverse polarity diode protection on power lines).

Data lines: high-speed transient voltage suppressor diodes.

IP65-rated sealed electronics for deployment in both interior and exterior

environments.

Beep-on-card defaults to ON.

Approved by U.S. GSA for FIPS 201

PIV-I Support - The reader supports reading of a PIV-I (PIV-Interoperable) card.

With a PIV-I card, the Agency code, System code and Credential number are all set

to 9s. The reader senses this and outputs the full UUID (Universally Unique

Identifier), which is a 128-bit long number. The firmware only supports PIV-I when

the 200-bit FASC-N output is selected.

PIV-C Support - The reader supports reading of a PIV-C (PIV-Credential) card.

CAC 5.5 Support - The firmware supports reading the new CAC card from

Oberthur, v5.5 and outputs the FASC-N according to the firmware FASC-N setting.

MIFARE 7-byte CSN Support - The reader firmware will be able to distinguish

between a legacy MIFARE Classic card and a “next-generation” MIFARE classic

card. The next generation MIFARE cards have a unique 7-byte serial number, not 4-

byte. When presented to a reader, the next-gen card causes the reader to output a 56-

bit CSN. Older cards still output a 32-bit CSN.

NOTE Not all features have been evaluated by UL.

Features

5

Controller Communications

Wiegand

Locally Flashable via RS485

Open Standards Compliance

ISO 14443A

ISO 14443B

ISO 15693

Configure Using Program Card

Pass-through - Default setting that allows the reader to send all data on the card.

Fixed length - Reader can be configured to output a fixed length by padding or truncating

data on the card.

(26-bit, 32-bit, 35-bit, 37-bit, 64-bit)

CASI ProxLite

44-bit pass-through

MIFARE sectors

Select a sector (0-15)

Customize encryption keys

Specify data format (number of bits output)

Enable PIN-on Smart Card functionality

FIPS 201 PIV-II

Customize FASC-N Weigand BCD output

75-bit

128-bit

200-bit (default)

Customize the HMAC by changing the site key

Output HMAC

Output expiration date

Features

6

Specifications

The following specifications apply to all RM xx-4000 series readers:

Data Cable: Recommended data cable is Belden #9841or equivalent. The maximum

length is 4000 feet (1212 meters) between the controller and the RM xx-4000 reader.

Power Wiring: Recommended power wiring is Belden #8461/8442 twisted pair.

Maximum length depends on the wire gauge. RM xx-4000 readers can be powered

from a local power supply.

Temperature:

Indoor: 32° F to 120° F (0° C to 49° C)

Outdoor: -31° F to 151° F (-35 ° C to 66° C)

- Reader Display: 14° F to 151° F (-10° C to 66° C)

- Display with Heater: -4° F to 151° F (-20° C to 66° C)

RM xx-4000 Series Readers

Table 4 shows the power requirements for RM xx-4000 series readers.

Reader power to be supplied from power limited output of a Listed control unit or

from a separately-supplied UL Listed, access control (UL294) or burglar alarm

(UL603), power-limited power source with 4-hour standby capability.

TABLE 4. RM xx-4000 Series Reader Power Supply Requirements

RM xx-4000 Series

Reader Type Model #s Power Requirements:

12 VDC

Without Keypad or LCD RM1-4000 300 mA Max

With Keypad RM2-4000 300 mA Max

With Keypad and LCD RM2L-4000 300 mA Max

Installation

7

Standards RMxx-4000 series readers are Underwriters Laboratories Inc. (UL), Listed to Standard

UL 294, Access Control System Units, Fifth Edition.

RM2L-4000 series readers are Underwriters Laboratories Inc. (UL), Listed to Standard

UL 1076.

RMxx-4000 series readers must be wired in accordance with the National Electrical

Code (ANSI/NFPA 70), local codes, and the authorities having jurisdiction.

INSTALLATION To install an RM xx-4000 series reader, perform these steps:

1. Install the RM mount plate

2. Wire the components

3. Connect and ground the cable shields on the reader bus.

(Refer to TAB 2010-15 “RM Reader ESD Protection Guidelines.”)

4. Set the RM-4 (reader) address

5. Install the ARM-1 relay boards (optional)

6. Install the heater kit. (optional)

7. Mount the RM standard housing on the RM mount plate using the Software House

security screwdriver (Part number 132-183).

Install the RM Mount

Plate

Figure 2 shows the RM standard housing, mount plate, and gasket. All RM xx-4000

series readers conform to the same housing, mount plate, and gasket dimensions.

FIGURE 2. Standard Housing and Mount Plate

Standard Housing

Standard mount plate

Housing

screws

Gasket

Requires a security screwdriver

Installation

8

Figure 3 shows the RM mount plate dimensions.

FIGURE 3. RM Mount Plate Dimensions

This device has been approved for outdoor use when properly installed with RM

Heater Kit Installation (P.N. 130-915) and the supplied gasket material. Position

the gasket with the RM mount plate so that the mounting holes are properly

aligned. Ensure that the gasket is placed between the mounting surface and

mating surface of the RM mount plate. Fasten the RM mount plate to the

mounting surface with the gasket material in between. Install the gasket so that

no gaps or wrinkles are present.

The RM mount plate contains eight mounting holes. However, you do not have to

use all eight holes; usually any four of the eight holes are adequate. The

mounting holes are 0.156” and provide clearance for 6-32 flat head counter sunk

bolts or screws.

Wiring

access

1.29"

.83"

2.47"

3.66"

2.73"

1.54"

5.45"

4.94"

4.11"

1.82"

3.92"

3.64"

8 mounting holes

.0.156" Thru, 0.280” Countersink

RM xx-4000 Series Reader Setup

10

Wiring the Inputs,

Outputs, Reader Bus

Figure 5 shows RM-4 P1 and P5 wiring.

FIGURE 5. RM-4 Wiring Requirements

NOTES 1. SW3-7 and SW3-8 refer to the Beeper on the RM-4.

2. P3 BEEP refers to the Beeper on the read head, if it exists. There is no Beeper on the

RM xx-4000 read heads. Some third-party readers that are connected to a standalone

RM-4 have beepers.

RM XX-4000 SERIES

READER SETUP

TO SET UP AN RM XX-4000 SERIES READER

1. Set the Reader Address Switch, SW1 (a 16 position rotary switch, see Figure 5), to a

number from one to eight. Each Reader along the bus must have a unique address.

2. The SW3-1, SW3-2, SW3-3, and SW3-6 Configuration Switches are factory preset

for the RM xx-4000 readers, as shown in Figure 6 .

3. Note that you can override SW3-4, SW3-5, SW3-7 and SW3-8 if desired.

To properly terminate an RS-485 line, only the last unit on the bus should have

SW3-5 in the On (closed) position.

RM xx-4000 Series Reader Setup

11

RM xx-4000 Pre-wired Reader Connections

The RM xx-4000 Reader is pre-wired, as shown in Figure 6.

FIGURE 6. RM-4 xx-4000 Reader pre-Wired Connections

NOTE The following P3 Reader pins are not used on the RM xx-4000 readers:

RS-485 TXD/RXD +

RS-485 TXD/RXD –

BEEP

RM xx-4000 Series Reader Setup

12

Table 5 indicates the wiring for units with keypads.

TABLE 5. Wiring for Units with Keypads

J2 Pin Function

1 Col 3

2 Col 2

3 Col 1

4 Col 0

5 Row 3

6 Row 2

7 Row 1

8 Row 0

123

456

789

0CE

CMD

ENT

C3 C2 C1

R3

R2

R1

R0

Note: On a 3 x 4

matrix keypad,

Pin 4 (C0) is not

used.

RM xx-4000 Series Reader Setup

13

Grounding and

Shielding

Single RM Reader

1. When connecting a single RM reader to the reader bus, use twisted pair, shielded

minimum 24 AWG cable. Attach the shield at the controller end.

(Refer to TAB 2010-15 “RM Reader ESD Protection Guidelines.”)

2. Attach a local earth ground (18 or 22 gauge) wire to the J5 component on the RM

reader.

Multiple RM Bus Devices

When wiring an RM reader to a bus with multiple devices, such as other RM-4s, I/8s, or

R/8s:

1. Attach the shields along the bus together (insulate each connection). Snip off the

shield wire at the end of the bus. See Figure 7.

2. Attach the shield to the ground at only one point – at the ground stud inside the

controller

3. Attach a local earth ground (18 or 22 gauge) wire to the J5 component on the RM

reader.

FIGURE 7. Reader Shield Wiring

Setting Module

Address and

EOL Termination

To set the module address, set SW1 (16 position rotary switch) to a number from one to

eight. Every RM xx-4000 series reader on a bus must have a unique address.

To set RS-485 EOL (End of Line) termination, set SW3-5 to the On (closed) position if

the module is the last unit on the bus. If the module is not the last unit on the bus,

SW3-5 should be Off (open).

RS-485 connector on a reader

Knockout

Twist shield wires together and insulate

(do not ground)

Ground stud

(bus configuration)

Shield wire

Enclosure/cabinet

Shield wire Snip off shield

wire at end of

bus

RM xx-4000 Series Reader Setup

14

Figure 8 shows how to connect ARM-1 relay modules to the RM-4 outputs and how to

wire NO (Normally Open) and NC (Normally Closed) supervised inputs.

FIGURE 8. RM-4 Input/Output Connections

NOTE Maximum distance from P5 to the ARM-1 is 25 feet.

Maximum distance from P5 to the inputs is 2000 feet.

Locate the 1Kresistors for the NO and NC supervised inputs as close as possible

to the switch.

To comply with UL requirements, use shielded, minimum 22 AWG stranded,

twisted pair cable.

RM xx-4000 Series Reader Setup

15

Installing the ARM-1

Relay Module

Two ARM-1 relay components can be connected to the RM xx-4000 series reader

through the P5 connector (Table 6 ).

RM P5-1 is the common (+12 VDC) pin for either ARM-1.

RM P5-2 is the output drive (GND) for the first relay.

RM P5-3 is the output drive (GND) for the second relay.

Installing the Heater

(optional)

RM xx-4000 readers require a heater kit (Model C130-915) when installed outdoors in

an environment where temperatures may drop below 40° F (5° C).

The Model C130-915 heater kit contains the following parts:

Part number C130-915A is supplied without a transformer. A UL Listed Class 2

transformer rated output 12 VAC, 40 VA is required for proper installation.

TABLE 6. ARM-1 Wiring

Module (131-192) Wiring

ARM-1 Relay ARM P2-1 to RM P5-1

ARM P2-2 to RM P5-2

ARM-2 Relay ARM P2-1 to RM P5-1

ARM P2-2 to RM P5-3

TABLE 7. Heater Parts

Quantity Description

1 Transformer 12 VAC 40VA

2 Heater Strips

1 Thermostat (turns on at 40 ° F)

3 Wire nuts

2 6-32 x 1/4” screws to mount thermostat to RM plate.

RM xx-4000 Series Reader Setup

16

Figure 9 shows how to wire the RM heater kit.

FIGURE 9. RM Heater Kit Wiring

Figure 10 shows the location of the heater strips and thermostat on the RM mount plate.

.

FIGURE 10. RM Installation

Applying Heater Strips

To apply heater strips:

1. Clean the attachment surface of the RM mount plate with a solvent such as alcohol

(use all required precautions when handling solvents).

2. Carefully remove the release film from the adhesive.

3. Locate the heater on the clean surface of the RM mount plate exactly as shown in

Figure 10

RM xx-4000 Series Reader Setup

17

4. Gently roll the heater strip in place to remove air bubbles.

5. For maximum adhesion, do not apply pressure to the heater strips for 72 hours.

NOTE Air gaps or bubbles under the heater cause localized overheating and possible heater

burnout. Also, application of adhesives at temperatures below 50° F is not

recommended.

Installing the Thermostat

To install the thermostat:

1. Fasten the thermostat to the RM mount plate with the body of the device facing the

junction box and the face sitting flat against the RM mount plate surface.

2. With the back (or outside) surface facing up, align the thermostat such that the screw

holes of the thermostat allow for the 6-32 x 1/4” screws to secure the device to the

RM mount plate.

3. Use two (Quantity 2) 6-32 x 1/4” screws to mount the thermostat to the RM mount

Plate. Tighten the screws allowing the thermostat to be sufficiently secured to the

RM mount plate. Do not over tighten the screws.

Requirements and

Specifications

Table 8 lists the power requirements and operating specifications of the RM-4

board.

TABLE 8. Power Requirements and Operating Specifications

NOTE Specifications have not been evaluated by UL.

Requirement Specification

RM-4 Power requirements +12 VDC

175 mA without reader and relays

Maximum input (with full load) +12 VDC

550 mA maximum with reader and relays

Relay contact power limits Up to 30 VAC/DC, 3.3 A maximum

Reader LED output control 4.0 VDC to 5.25 VDC, 20 mA maximum

Reader port output voltage 5 VDC

or

12 VDC

Reader port output maximum

current

300 mA (at 5V or 12V)

Testing RM xx-4000 Readers

18

TESTING RM XX-4000

READERS

To test RM xx-4000 series readers:

1. Properly configure Readers, Inputs, and Outputs using the C•CURE Administration

application and put the reader Online.

2. Measure the supply voltage to the RM-4.

The voltage can be measured between pin 1 (+12 VDC supply) and pin 4 (ground)

on the P4 connector. The voltage must be +12 VDC (+/-5%).

3. Check the RM xx-4000 reader address setting.

The RM xx-4000 reader must be set to an unused address, between 1 and 8, when

connected to the apC or iSTAR. Use rotary switch SW1 to set the reader address.

4. Check the RM-4 for communications to the controller by observing LED2 and

LED3.

5. Check the supervised inputs. Configure the inputs on the controller using the

C•CURE Administration application.

With no switches or resistors connected to the supervised input 1 and 2 lines, the

C•CURE Monitoring application should report inputs as “Open Loop”. When you

connect the 1,000-ohm resistor to the input terminals, the C• CURE Monitoring

application should report that the input as “Deactivated”. Supervised inputs #1 is

found at pins 4 and 5 of P5. Supervised input #2 is found at pins 6 and 7 of P5.

6. Check the outputs.

The outputs can be functionally tested by using the “momentary activate” feature in

the C• CURE Monitoring application. When the outputs are momentarily activated,

the signal will change state for a few seconds.

7. Check the reader interface.

The reader interface can only be tested by presenting a card with the appropriate

technology to the reader. Reading a card will cause the display to show “Access

Granted” or “Access Denied,” depending on the clearance of the card.

Configuration Notes

19

CONFIGURATION

NOTES

The change to the default reader settings requires the use of special program cards that

are available from the Software House Applications Department. Program cards are

used to set a specific MIFARE read key and change other settings including card

technologies to be read.

To program a card reader, follow these steps:

1. Power cycle the reader.

2. Present the .INI card. The reader’s internal amber LED turns off within the read head

compartment to indicate the reader is ready for the first program card.

3. Present the first program card. The amber LED turns on solid.

4. If there are more program cards, repeat steps 2 and 3 until you have presented the

necessary number of program cards.

5. The reader is configured for the specified option(s) and is ready for use.

For more information about programming a card reader, refer to the PDF document

entitled SWH Readers Program Card Use posted on the Software House Member

Center.

Amber LED

Flash Upgrade Notes

20

FLASH UPGRADE

NOTES

In some cases the reader may require a new firmware revision to enable new features or

card formats that are not included in a previous revision.

To upgrade the reader, you need to obtain the new firmware file from Software House,

and then connect to the reader through a local RS485 connection, using terminals 9 and

10.

In most cases you can use a RS485-to-USB device, or a RS232-to-RS485 converter to

connect the PC to the reader. Once a physical connection is established, double-click on

the firmware update utility, which is a self-running executable. A typical flash upgrade

takes about 2 minutes per reader.

For more information about upgrading the firmware revision, refer to the PDF

document entitled SWH Readers Download Firmware to Reader posted on the Software

House Member Center.

This manual suits for next models

3

Table of contents

Other Software House Card Reader manuals

Software House

Software House SWH-4100 User manual

Software House

Software House RM2-4000-PI26 User manual

Software House

Software House iSTAR Edge Datasheet

Software House

Software House SWH-4000 User manual

Software House

Software House SWH-4000 User manual

Software House

Software House SWH-400 Series User manual

Popular Card Reader manuals by other brands

Advanced Card Systems

Advanced Card Systems ACR3901T-W1 Reference manual

IDTECH

IDTECH VP3300 OEM user manual

Magtek

Magtek DynaPro Mini Installation and operation manual

RCI

RCI Easy Read-Prox 9321 installation instructions

Nayax

Nayax VPOS Touch user manual

Feig Electronic

Feig Electronic OBID classic-pro ID CPR.03.20-CD manual