Sola-Tecs F Series User manual

SOLA-TECS F

Assembly instructions

BJ 2019 …

SN 2917 …

F2000 | F3200 | F4000

MA 0302506 R00 2019-07

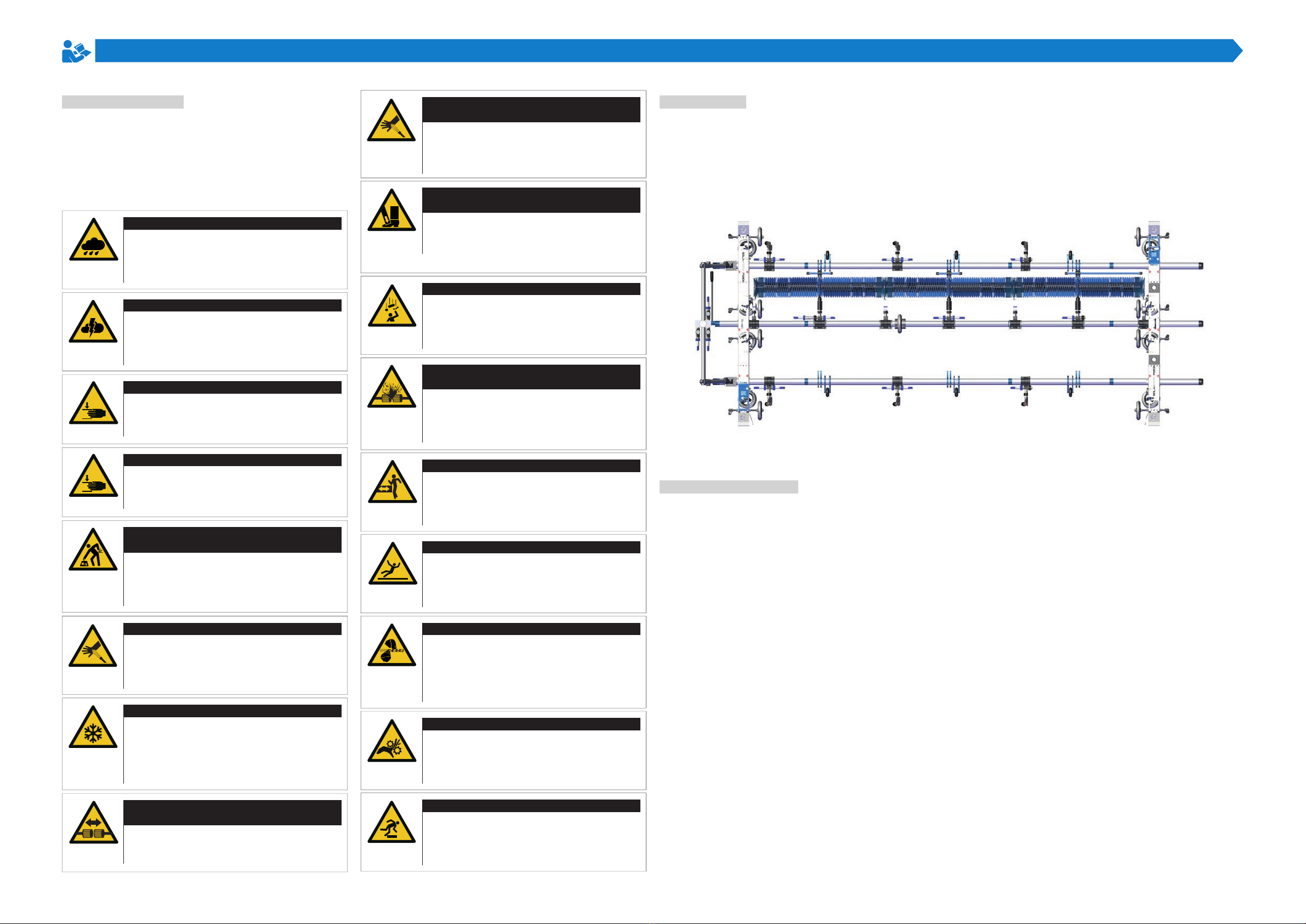

Overview

2

MA 0302506 R00 2019-07

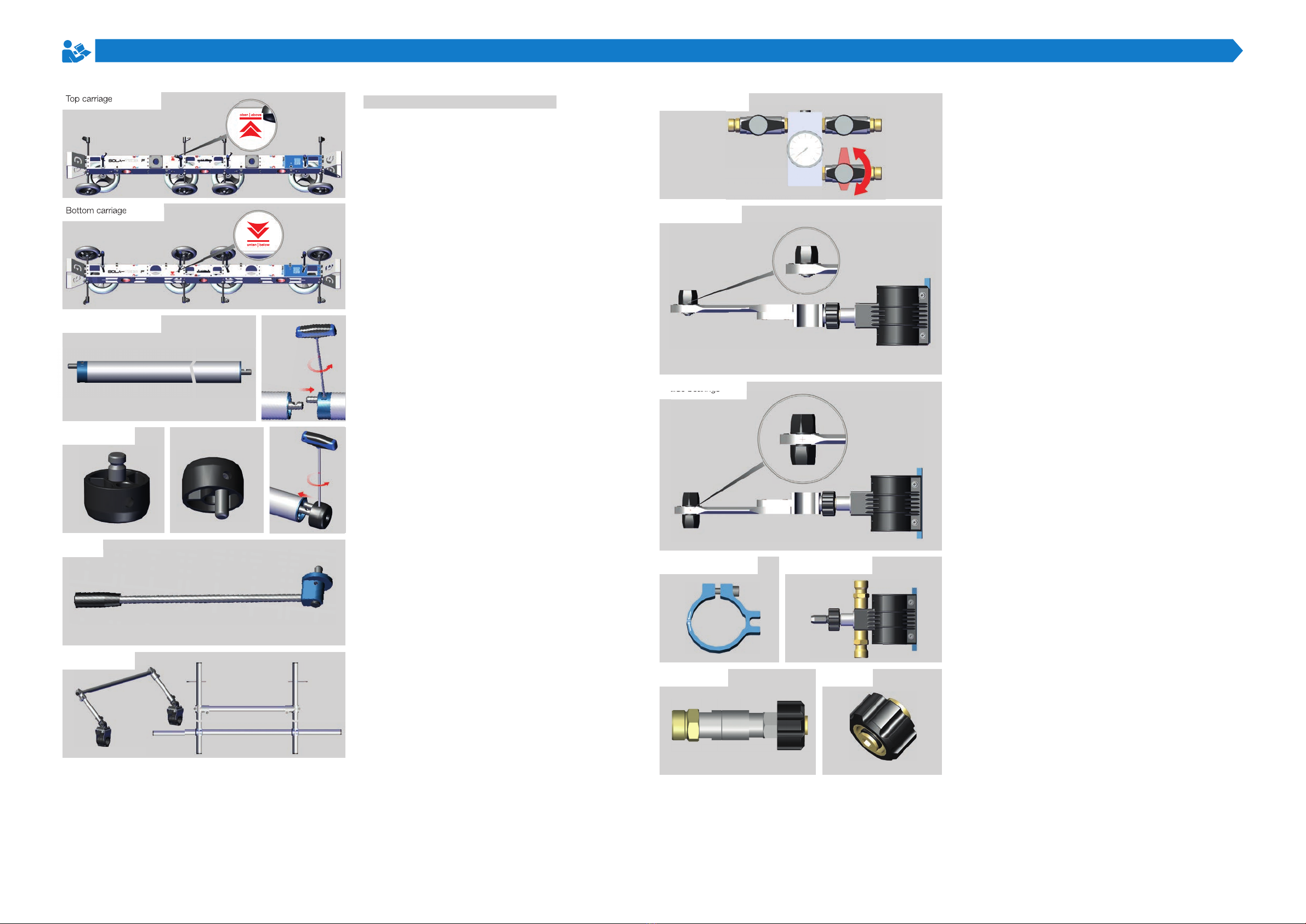

Component

11300 top carriage

21300 bottom carriage

3L1600 connecting tube element

L700 connecting tube element

L800 connecting tube element

4Velcro cable ties

5Active end cap

6Passive end cap

7Roll holder

8Brush stop

9SOLA-TECS F spray nozzle

0Guide bearings

Counterholder

Clamping element with connection

M22 x 1.5 plug

M22 x 1.5 swivel joint

Stop clamp

Relief roller

Top support frame

Bottom support frame

Water distributor

Passive lever

SOLA-TECS C 1000 - Hammer head

Brush roller left 100 mm

Brush roller right 100 mm

NW6 HD hose 2000 mm

NW8 HD hose 1000 mm

Distribution pipe 1500 mm

SOLA-TECS F 3.5 meter pull rope

SOLA-TECS F 6.5 meters pull rope

IQS standard sealing cap

Tool bag

3

MA 0302506 R00 2019-07

Introduction

It is IMPORTANT that you read these

operating instructions carefully READ CAREFULLY BEFORE USE

and KEEP FOR FUTURE REFERENCE.

Technical data

SOLA-TECS F BJ 2019 …

Seriennummer SN 2917 …

Space requirement Required floor space 5 m x 1.5 m

Required functional area min. 1 m x 1.5 m

Distance from floor to panel 150 mm

Work and maintenance stations Space required for assembly 8 m x 3 m

Working area 800 mm - 4000 mm

Movement space at workplaces min 5 m

Safety area in operating direction min. 1 m

Safety area around the operator 1 m

Bridgeable distance from panel to panel 400 mm

Weight and operating materials Weight min. 43 kg

Drive medium - water, ultrapure water

Cleaning substance - water, ultrapure water

Drive types and High water pressure

performance data High pressure max. 140 bar

Operating pressure 100 bar

Water consumption max. 3 L/min per

drive unit and 1.5 L/min per spray nozzle

Operating temperature 40 °C

Brush revolutions at diameter

160 mm – 700 rpm

Exagon socket - Size 5

Measuring tape - 5 Meter

Hose cutter

Exagon socket - Size 4

Exagon socket - Size 3

Exagon socket - Size 2,5

Exagon socket - Size 6

4

MA 0302506 R00 2019-07

Introduction

Safety instructions

Pay attention to the warning and safety instructions in

these operating instructions! This will protect you from

injuries.

AIn the case of bad weather, ensure that

appropriate protective clothing is worn.

This protects you from illness due to

hypothermia.

WARNING

Hazard due to bad weather

AAvoid using the machine during

thunderstorms.

This protects you from injury caused by

lightning and from hypothermia.

WARNING

Hazard due to thunderstorms

AWear gloves during disassembly.

This protects your skin from abrasions and

pinching.

WARNING

Risk of injury during disassembly

AWear gloves during assembly.

This protects your skin from abrasions and

pinching.

WARNING

Risk of injury during assembly

AMake sure to lift the machine ergonomically.

This protects you from injuries caused by

straining your back.

WARNING

Risk of injury when lifting heavy parts

ACheck all high-pressure hoses and

connections for damage.

This protects you from injuries caused by

intense water jets.

WARNING

Risk of injury due to damage

ADo not allow the machine to freeze. This

can cause damage to the high-pressure

components.

This protects you from injuries caused by

intense water jets.

WARNING

Verletzungsgefahr durch Beschädigungen

AAlways tighten joints and check thoroughly.

This protects you from injuries caused by

uncontrolled ying parts.

WARNING

Risk of injury due to incorrect assembly or

installation

ACheck that all high-pressure connections

have been installed properly.

This protects you from injuries caused by

intense water jets.

WARNING

Risk of injury due to incorrect assembly or

installation

ACheck that the machine is positioned

correctly.

This protects you from injuries caused by the

machine falling down.

WARNING

Risk of injury due to falling machine

ACheck the area to be cleaned for parts that

can fall off.

This protects you from injuries caused by

falling parts.

WARNING

Risk of injury due to falling parts

ADo not operate the machine above the

specied maximum operating pressure.

This protects you from injuries caused by

uncontrolled ying parts.

WARNING

Risk of injury due to excessive operating

pressure

AStart and stop the machine only via the

stopcock.

This protects you from injuries caused by the

machine starting suddenly and accidentally.

WARNING

Risk of injury due to sudden start

ACheck if there is anything on your tread that

could encourage slipping.

This protects you from injuries caused by

falling.

WARNING

Risk of injury due to slippery tread

AAvoid working on the machine near the

rotating parts with long hair protected.

This protects you from injuries caused by your

hair getting caught in the machine.

WARNING

Risk of injury due to moving parts

AAvoid touching the machine near the

rotating parts.

This protects you from injuries caused by

pinching.

WARNING

Risk of injury due to moving parts

Intended use

The SOLA-TECS F system is intended for cleaning photo-

voltaic panels in the commercial sector. The photovoltaic

panels must be mounted on an elevation. The photovoltaic

panel must be at least 150 mm from the ground.

Structure and function

The SOLA-TECS F system consists of a carrier system on

two carriages. Brush rollers are mounted on these carriages,

which are driven by high-pressure water.

The carrier system consists of two opposite carriages con-

nected by three connecting tubes. Wheels are attached to

the carriages. The wheels have two functions: They enable

rolling over the photovoltaic panels and secure the carrier

system from slipping.

Brush rollers are mounted on the central connecting tube for

cleaning work and propulsion. The brush rollers work across

the entire width of the carrier system and are rotated by a

high-pressure water turbine. After the drive, the water used

is fed into the brush roller and spray nozzles. Here the water

is used to moisten, clean and rinse the photovoltaic surface.

The central connecting tube can swivel 180° using a lever

together with the mounted brush rollers to clean the photo-

voltaic panels in both directions up to the edge.

The system has additional spray nozzles for if the photo-

voltaic frames are particularly dirty. The spray nozzles and

the brush rollers can be switched on or off independently of

each other via a water distributor.

The SOLA-TECS F system is pulled in the working direction

by two pull ropes attached to the carriage. The length of the

pull ropes can be adjusted to ensure correct posture.

ACheck your work area for bumps and

obstacles.

This protects you from injuries caused by

falling.

WARNING

Risk of injury due to falling

5

MA 0302506 R00 2019-07

Introduction

Components and their function

The top and bottom carriages are the drive units of the

carrier system. With them, the SOLA-TECS F system can

be rolled over the photovoltaic panels.

The settings for running behavior over the photovoltaic

panels can be adjusted on the carriage.

The connecting tubes of lengths 700 mm, 800 mm and

1600 mm are for connecting the carriages. The pipes are

connected via an active and passive coupling.

The active and passive end caps protect the tube ends

and joints on the carriage.

The passive lever is for the “swivel brush roller” func-

tion. It is mounted on the middle connecting tube (bottom

carriage).

The top and bottom support frames are the handles

for attaching the Sola-tecs F system to the photovoltaic

panels.

Top carriage

Bottom carriage

Connecting tube

End cap

Support frame

Lever

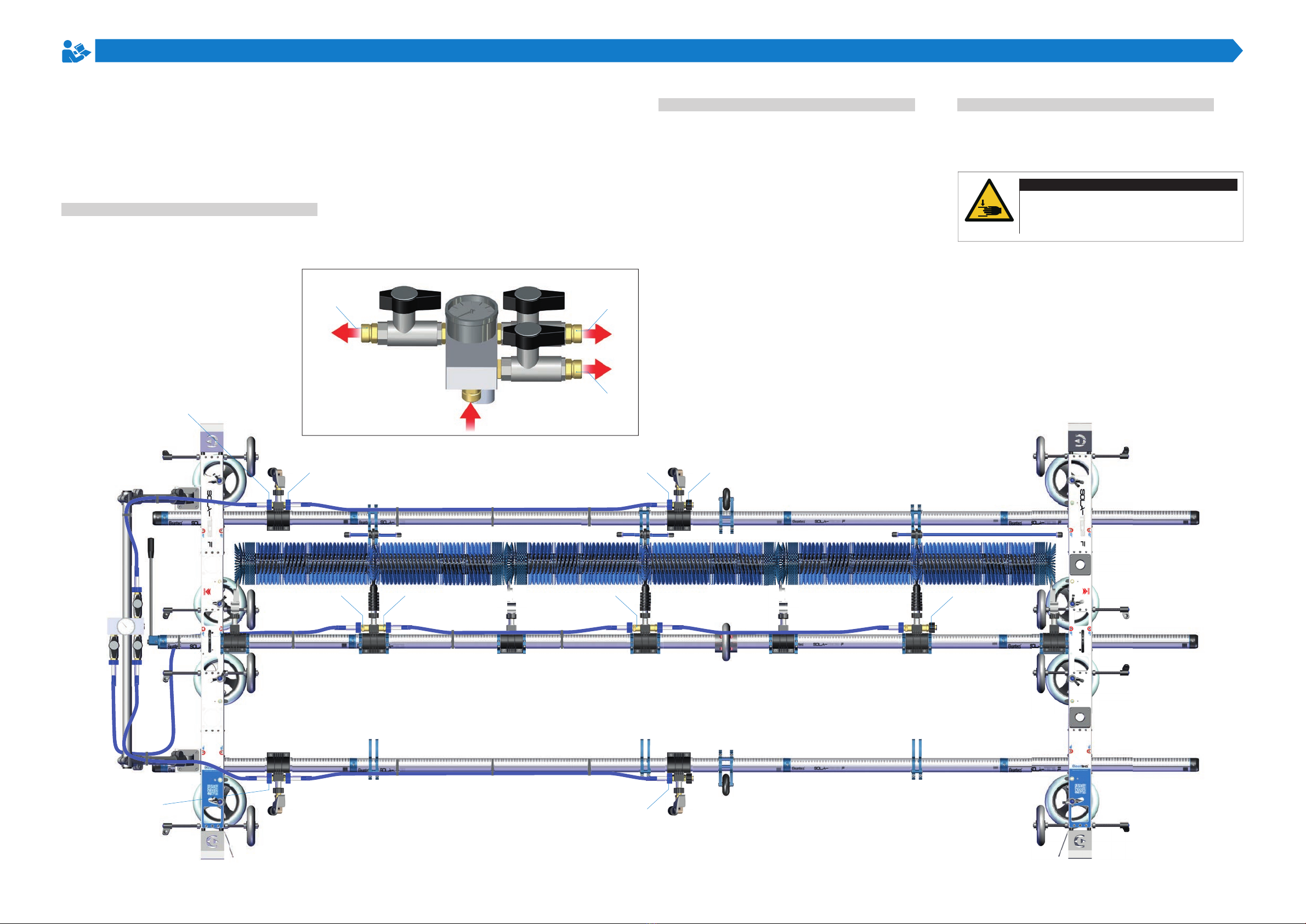

The water distributor is mounted on the lower carrying

handle. The water supply is switched on and off at the

water distributor.

The counter bearing guides the brush roller ends up and

down. It prevents the brush ends from swinging up.

The guide bearing connects the individual drive units to

form one unit and ensures a flexible connection.

The clamping element and its connection fasten the Sola-

Tecs C.

The stop clamp is the position stop for the counter be-

aring, guide bearing and clamping element.

The swivel joint prevents the high pressure hose from

twisting when the middle connecting tube is swiveled.

The plug closes the high-pressure area in the individual

supply lines.

Guide bearings

Stop clamp Clamping element

Water distributor

Counterholder

Swivel joint Plug

Guide bearings

Top carriage

Bottom carriage

6

MA 0302506 R00 2019-07

Introduction

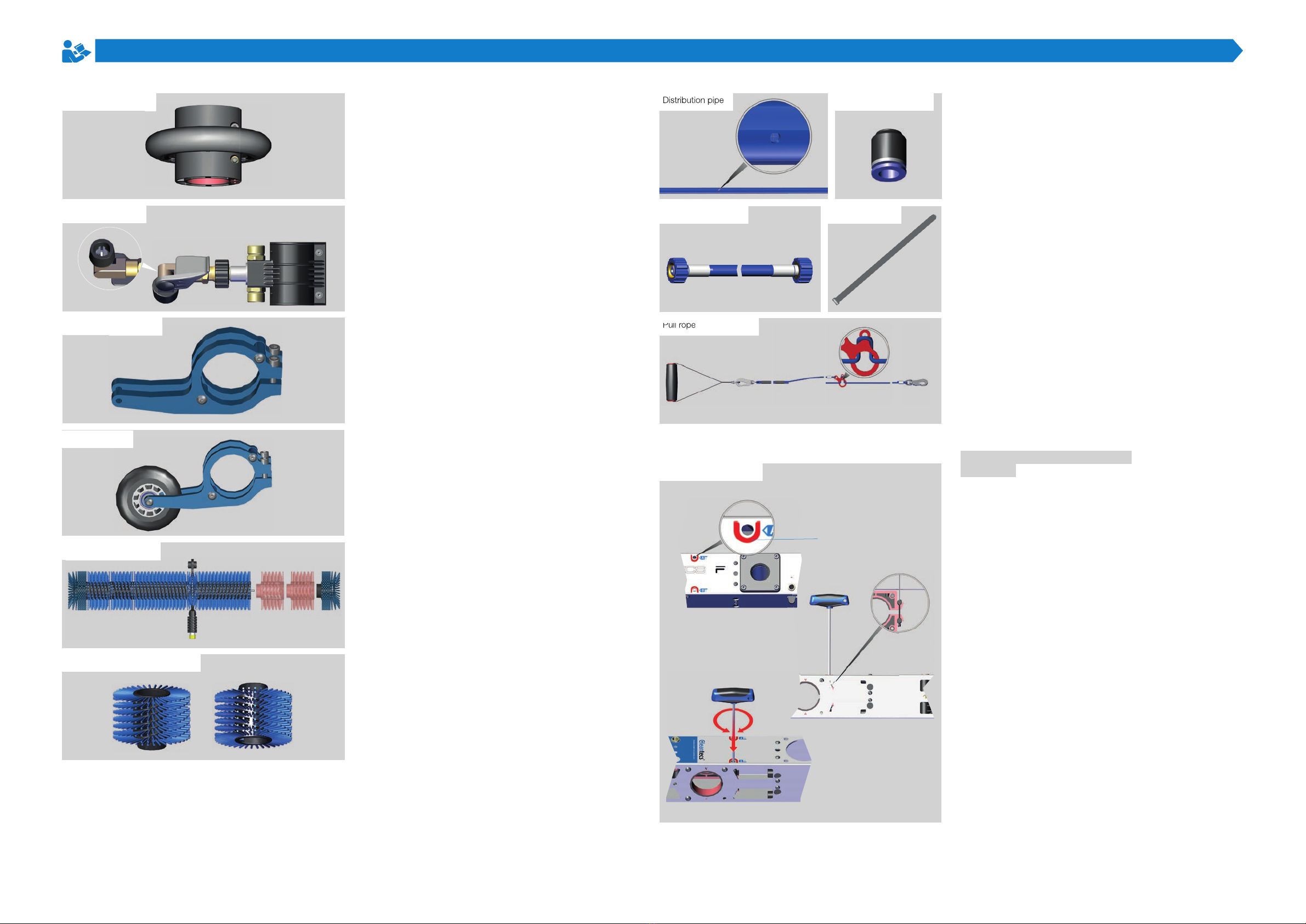

Relief roller

Spray nozzle

Brush stop

From a structure of 3200 mm, the relief roller supports the

middle connecting tube when swiveling.

The spray nozzle cleans the hard-to-reach frame edges of

the photovoltaic panels.

The brush stop prevents the drive unit from sagging when

driving over gaps between the photovoltaic panels.

The roll holder facilitates crossing gaps between photo-

voltaic panels when the drive units rest on the brush stops

when crossing a gap.

Together with the mounted brush rollers, the Sola-Tecs C is

the cleaning/drive unit.

The 100 mm wide brush rollers are screwed to the brush

rollers of the Sola-Tecs C to extend the cleaning width.

Roll holder

Sola-Tecs C

Brush roller 100 mm

Distribution pipe Sealing cap

HD hose Velcro cable ties

Pull rope

The distribution pipe evenly sprays water onto the photo-

voltaic panel.

The sealing cap closes the distributor pipe.

The 2000 mm, 1500 mm and 1000 mm high-pressure ho-

ses supply water to the individual supply lines..

The cable ties fix the high-pressure hoses to the carrier

system.

The pull ropes are for pulling the Sola-Tecs F system over

the photovoltaic panels.

Control elements and their

function

Fixing the connecting tubes: The connecting tubes are

clamped to the carriage at the holes marked with a red [1]

and with a letter [A],[B],[C],[D],[E],[F].

Distribution pipe

Pull rope

Clamping

[1]

7

MA 0302506 R00 2019-07

Introduction

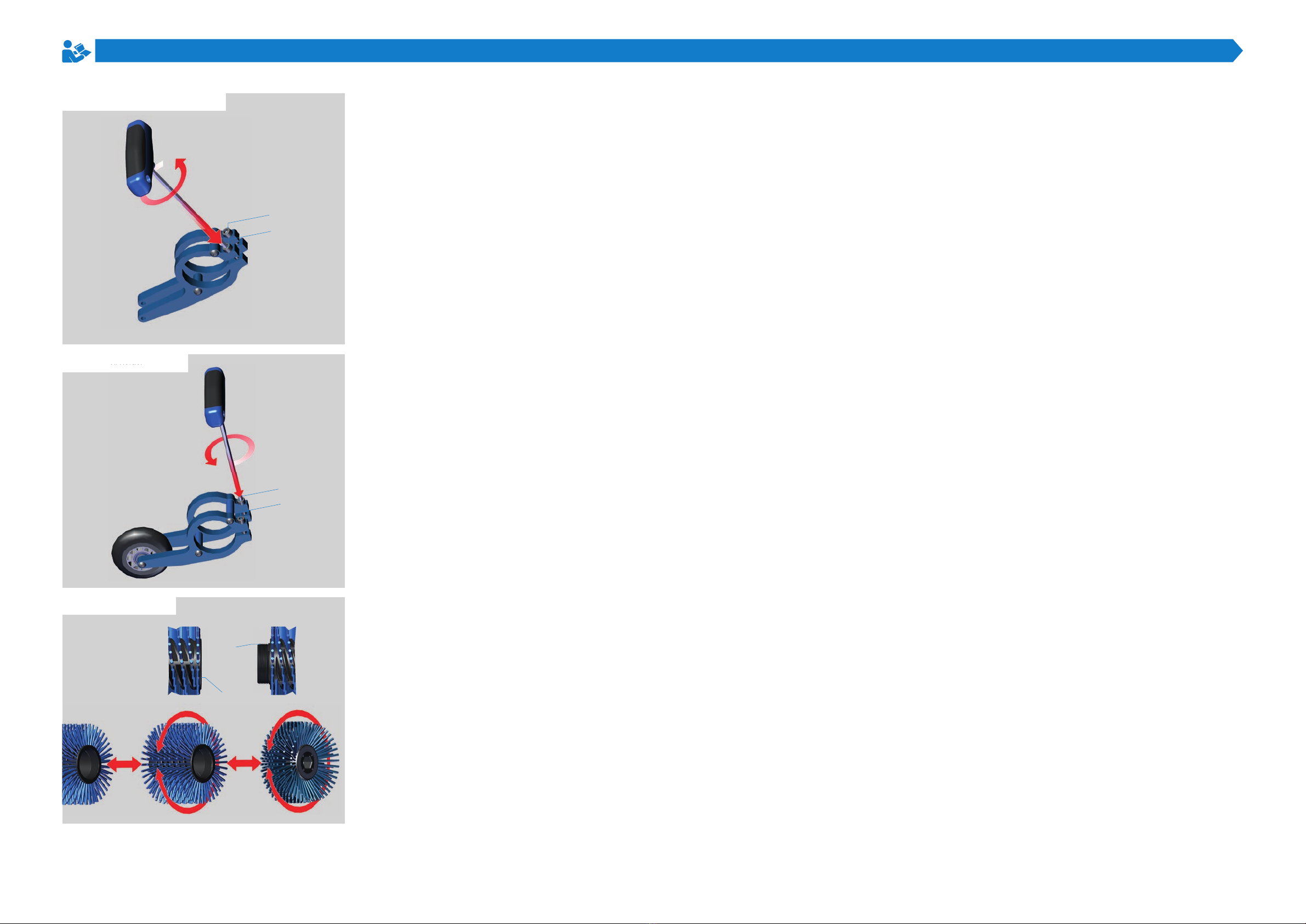

Adjusting the wheels: To adjust the wheels on the frame

of the photovoltaic panel, each wheel can be moved over

the axle.

Compensation for unevenness: The vertical wheels are

spring-mounted to compensate for unevenness. The spring

travel can be mechanically switched off with an adjusting

disc [1].

Wheels

Spring-mounted

Spring-mounted

[1]

Parking

Coupling which

Parking the Sola-Tecs F: When the mounted Sola-Tecs F

is not required, the whole unit can be placed on the sup-

port plates [1].

Connect the connecting tubes:

The connecting tubes are connected via a coupling which

has an active [1] and a passive [2] side. The coupling is lo-

cked via a grub screw [3] on the active coupling side.

Protecting the connecting tubes:

The ends of the connecting tubes are protected with end

caps [4]. There is one version each for the active and

passive coupling.

[1]

[1]

[2]

[4]

[3]

8

MA 0302506 R00 2019-07

Introduction

Adjustment and alignment:

A scale [1] is lasered on the connecting tubes. The scale

always starts on the active coupling side with zero and

is divided into two millimeter steps until the end of the

connecting tube. The scale allows for easier adjustment of

distances. The mark [2] helps to align the connecting tube

horizontally.

Water distribution controls: The distribution of pressuri-

zed water is regulated at the water distributor.

Cleaning brushes controls: The water distributor is sup-

plied with high pressure water at connection [1]. Lever [2]

is used to switch the brush roller on and off.

Scales and markers

Control of water distribution

[1]

[2]

[2]

[1]

Spray nozzle controls: The spray nozzles are controlled

via levers [1] and [2]. The water quantity can be controlled

by gradual opening of the nozzle.

Set the travel limit and clearance of Sola-Tecs C:

The travel limit and clearance are set with the stop clamp.

The stop clamp can be tightened and released with the

screw [1].

Adjust the spray nozzle: By opening the clamping lever

[1], the angle adjustment is released and can be adjusted.

Control of water distribution

Travel limit / clearance of Sola-Tecs C

Adjust the spray nozzle

[2]

[1]

[1]

[1]

[1]

9

MA 0302506 R00 2019-07

Introduction

Adjust brush stop: The brush stop is released and clam-

ped with screws [1] and [2].

Adjust the roll holder: The roll holder is loosened and

clamped with screws [1] and [2].

Adjust the width of the brush roller: The Sola-Tecs C

brush rollers are divided into segments. The individual seg-

ments are connected by a thread [1][2]. The width of the

cleaner can be changed by inserting or removing individual

segments.

Adjust brush stop

Adjust the roll holder

The width of the brush roller

[2]

[2]

[2]

[1]

[1]

[1]

Adjust the roll holder

10

MA 0302506 R00 2019-07

Construction

Assembly of the

connecting tubes

Lay out the connecting tube elements at the level mounting

location as shown. The active couplings must face [down].

The first and last connecting tube element should always

be an L700. The lengths of the connecting tube elements

between the L700 must be determined according to the re-

quired installation size. Make sure that all three connecting

tubes are divided equally. The scale must be continuous

from one connecting tube element to the next. Install the

end caps to protect the connecting tube couplings that are

not required. The end caps are mounted on [VR1] and [VR3]

at the beginning and end and on [VR2] only at the end.

Couple connecting tube elements:

Insert the passive [1] coupling into the active [2] coupling.

Using the hex key 4 [3], tighten the grub screw [4] on the

active coupling to 4NM.

Couple end caps:

The end caps are designed as active [5] and passive [6].

The passive end caps are mounted on the [bottom] and

the active end caps on the [top]. Using the hex key 4 [3],

tighten the grub screw [4] on the active coupling to 4NM.

[VR1]

[VR2]

[VR3]

0200748 0200748

0200748

0200748

0200748

0200747

0200747

0200747

[1]

[2]

[3]

[4]

0200746

0200746

0200746

[6]

[5]

[3]

[4]

AWear gloves during assembly.

This protects your skin from abrasions and

pinching.

WARNING

Risk of injury during assembly

L700 L700L800L1600

11

MA 0302506 R00 2019-07

Construction

Mounting the

connecting tubes on

the lower carriage

The assembled connecting tubes must be mounted on

the lower [1] carriage first. To do this, position the lower

carriage [bottom] in front of the connecting tubes. Hexagon

socket 4 is required to clamp the [VR1] and [VR2] connec-

ting tubes. The hexagon socket 5 is required for the [VR3].

Mount VR1 and VR3:

Insert the hexagon socket 4 into the red mark [2] [A] until

it sits in the screw head. Insert the [VR1] into the pipe

duct up to 230 mm [3]. Align the line of the scale with

the triangle [4] on the carriage. Tighten the screw until

the [VR1] can no longer be turned (by hand). Tighten the

second screw at the mark [B] in the same way. Repeat this

procedure for [VR3] and the [E], [F] marks.

Mount VR2:

Insert the hexagon socket 5 into the red mark until it sits in

the screw head [C]. Insert the [VR2] into the pipe duct up to

230 mm. Align the continuous line of the scale with the [4]

triangle on the carriage. Tighten the screw until the [VR2]

can no longer be turned (hand-tight). Tighten the second

screw at the mark [D] in the same way.

[VR1]

[VR2]

[VR3]

AWear gloves during assembly.

This protects your skin from abrasions and

pinching.

WARNING

Risk of injury during assembly

[2] [3] [4]

[1][3]

12

MA 0302506 R00 2019-07

Construction

Preparing the

attachments

Check attachments for completeness and damage to avoid

problems during mounting. For a better overview: Place the

connecting tube attachments where they are to be moun-

ted. Pay attention to the correct quantity and order.

VR1 and VR3 attachments:

The same attachments are fitted to the connecting tubes

[VR1] and [VR2]. The attachments are each turned by 180°.

1. Brush stop [1] - the brush stop is always mounted oppo-

site the Sola-Tecs C. Its task is to make sure the Sola-Tecs

C follows the direction of the photovoltaic panels

2. Roll holder [2] - the roll holder supports the connecting

tube. It must be mounted from a structural length of 3200

mm.

3. SOLA-TECS F spray nozzle [3] – the spray nozzle cleans

the lower edges of the aluminum frames of photovoltaic

panels. It is mounted on each horizontal frame where a

lower edge is to be cleaned.

VR2 attachments:

The [VR2] connecting tube is used for all attachments

which hold and supply the Sola-Tecs C.

4. Counterholder [4] - the counterholder supports the free

end of the brush roller and reduces oscillation.

5. Clamping element [5] - the connection for the Sola-

Tecs C is located on the clamping element. The cleaner is

connected to the carrier system and supplied with high-

pressure water.

6. Guide bearing [6] - the guide bearing supports the end of

the brush roller and reduces oscillation.

7. Relief roller [7] - the relief roller supports the connecting

tube. It must be mounted from a structural length of 3200

mm.

8. Stop clamp [8] - the stop clamp determines the free

space available to the Sola-Tecs C to react to unevenness.

The stop clamps always come in front of and behind...

... the counterholders.

... the clamping elements.

... the guide bearings.

Installation position of add-on parts

[1]

[2]

[2]

[3]

[3]

[1]

[4]

[6]

[4]

[8]

[8]

[5]

13

MA 0302506 R00 2019-07

Construction

Assembly of the

attachments and the

upper carriage

The prepared attachments are now pushed onto the [VR1],

[VR2] and [VR3] connecting tubes and positioned and fixed

at the intended assembly point up to the required one.

Hexagon sockets 3 and 5 are required.

VR1 and VR3:

Push the spray nozzle [1] with the nozzle head to the [outsi-

de] position. Fix the spray nozzle in the mounting position

with hexagon socket 3 (page 12).

Push the brush stop [2] with the fork to the [inside] po-

sition. Fix the brush stop in the mounting position with

hexagon socket 5 (page 12).

Push the roll holder [3] with the wheel [outside] to the

middle of the structural length. Fix the roll holder in the

mounting position with hexagon socket 5 (page 12).

VR2:

Push the counter bearing [4] to the [outside] with the arm

and slide it into position together with the stop clamps. Fix

the stop clamps in the mounting position with hexagon so-

cket 5 (page 12).

Push the clamping element [5] to the [outside] with the

connection and slide it into the position together with the

stop clamps. Fix the stop clamps in the mounting position

with hexagon socket 5 (page 12).

Push the guide bearing [6] to the [outside] with the arm and

slide it into position together with the stop clamps. Fix the

stop clamps in the mounting position with hexagon socket

5 (page 12).

Place the relief roller [7] in the middle of the structural

length and fix it with hexagon socket 5.

[outside]

[4]

[5]

[5]

[5]

[7]

[2]

[2]

[1]

[1]

[2]

[2]

[1]

[1]

[1]

[1]

[2]

[2]

[3]

[3]

[6]

[6]

[4]

AWear gloves during assembly.

This protects your skin from abrasions and

pinching.

WARNING

Risk of injury during assembly

14

MA 0302506 R00 2019-07

Construction

Mounting the connec-

ting tubes on the top

carriage

After mounting the attachments, the [top] carriage [1] must

be mounted. Hexagon socket 4 is required to clamp the

[VR1] and [VR2] connecting tubes. The hexagon socket 5 is

required for the [VR3].

Mount VR1, VR2 and VR3:

Insert the [VR1], [VR2] and [VR3] into the pipe ducts. Push

the carriage onto the connecting tubes up to the counter

bearing. Insert the hexagon socket 4 into the red mark [A]

[2] until it sits in the screw head. Tighten the screw until

the [VR1] can no longer be turned (by hand). Tighten the

second screw at the mark [B] in the same way. Repeat

this procedure for [VR3] and the [E], [F] marks. Insert the

hexagon socket 5 into the red mark until it sits in the screw

head [C]. Tighten the screw until the [VR2] can no longer be

turned (hand-tight). Tighten the second screw at the mark

[D] in the same way. Check whether the line of the scale is

aligned with the [4] triangle on the carriage.

[VR1]

[VR2]

[VR3]

AWear gloves during assembly.

This protects your skin from abrasions and

pinching.

WARNING

Risk of injury during assembly

[2]

[2]

[4] [1]

15

MA 0302506 R00 2019-07

Construction

Mounting the

Sola-Tecs C

In this step, the Sola-Tecs C cleaning devices are installed.

Hexagon socket 5 is required for this. The construction

procedure is described from bottom to top. Before moun-

ting the cleaning brush, all stop clamps should be loosened

with the hexagon socket 5. For more assembly space, the

[top] carriage should be loosened again at the red mar-

kings.

Installation of the first cleaner:

Push the cleaner [1] onto the clamping element [2]. Tighten

the quick fitting [3] by hand. Thread the cleaner into the

counterholder [6] by moving the clamping element [2] and

the stop clamps [4] with the brush roller [5]. The counter

bearing [6] and the stop clamps [4] must be approx. 5 mm

from the carriage.

Assembly of second cleaner:

Thread the guide bearing [7] and the stop clamps [4] into

the brush roller [5] of the first cleaner [1] by moving it on

the connecting tube [VR2]. Push the second cleaner [1]

onto the clamping element [2]. Tighten the quick fitting [3]

by hand. Thread the cleaner into the guide bearing [7] by

moving the clamping element [2] and the stop clamps [4]

with the brush roller [5]. Thread the guide bearing [7] with

the stop clamps [4] into the brush roller [5] of the second

cleaner [1] by moving it on the connecting tube [VR2].

Installation of third cleaner:

Push the third cleaner [1] onto the clamping element [2].

Tighten the quick fitting [3] by hand. Thread the cleaner

into guide bearing [7] by moving the clamping element [2]

and the stop clamps [4] with the brush roller [5]. Thread the

counter bearing [6] with the stop clamps [4] into the brush

roller of the last cleaner by moving it on the connecting

tube [VR2].

Top carriage:

Clamp the carriage [top] at a distance of 5 mm from the

stop clamp [4] of the counter bearing [6] (page 14).

[6] + [5] [4] on the carriage [1] + [2] [5] + [7]

[1]

[7]

[6]

[2]

[VR2]

[3]

[4]

[5]

AWear gloves during assembly.

This protects your skin from abrasions and

pinching.

WARNING

Risk of injury during assembly

16

MA 0302506 R00 2019-07

Construction

Setting the working

width and assembly

of the lever

During this assembly step, the exact working width is set

and the clearance of the brush roller is fixed. To be able

to set the working width, the setting dimension must be

calculated. Measuring tape is required to do this. The hexa-

gon sockets 4 and 5 are required to fix the settings.

Determine the setting width:

To determine the setting width: Measure the cleaning

object vertically from the upper outer edge to the lower

outer edge to obtain the measurement of the cleaning

width [1]. To take the spring travel of the [bottom] carriage

into account, 2 cm must be subtracted from the measured

cleaning width. This will give you the setting dimension.

Setting the working width:

The horizontal wheels must be positioned in the unsprung

position [2]. Take the tape measure and measure the

distance [1] between the wheels [3] at the highest point

[inside]. Correct the dimension with the [top] carriage only.

When the correct dimension is set, clamp the [top] carriage

over the clamp points [C] and [D] on the [VR1] and [VR3].

Mounting the lever:

The lever [4] for the 180° flipping of the brush roller is

mounted on the [VR2]. The lever is mounted as described

on page 10. The lever position is not yet suitable for

flipping and must be corrected after assembly.

Correct lever position:

Release the [C] and [D] clamps on the [bottom] carriage.

Insert hexagon socket 4+5 into the clamping screw [C] of

the [bottom] and [top] carriages to prevent twisting of the

tube clamping unit. Move the lever 90° until it is parallel [5]

to the carriage. Re-fix the [bottom] and [top] carriages to

the [C] and [D] clamps.

Rough pre-positioning of the cleaners:

The cleaners must be pre-positioned to attach the Sola-

Tecs F to the photovoltaic system. Fix the stop clamps [6]

with the screws on [VR2]. Fix the brush stop [7] with the

screws on the [VR1] so that the head of the Sola-Tecs C

rests in the fork.

[VR2]

[1]

cleaning width

cleaning width mi-

nus 2 cm = Adjust-

ment dimension

[2] Above

[2] Below

[4]

[3]

[3]

[3]

[3]

[5] 90°

AWear gloves during assembly.

This protects your skin from abrasions and

pinching.

WARNING

Risk of injury during assembly

[6] [7]

[VR1]

[VR3]

[Inside]

[Inside]

17

MA 0302506 R00 2019-07

Construction

Mounting the

support frame, water

distributor and

distributor pipe

In this assembly step, the bottom support frame, the dis-

tribution pipes and the water distributor are mounted.

Hexagon socket 6 and the hose cutter are required. The

bottom support frame is delivered in pre-assembled indivi-

dual parts. The set consists of two carrying arms and a

handle tube. The distribution pipe is delivered in a length of

1500 mm and cut to the required length.

Mounting the support frame:

The support arms [1] are pushed onto [VR1] and [VR3].

Then, insert the handle tube [2] horizontally into the

connectors [3] and tighten the screws with the hexagon

socket 6. The clamp [4] must be fixed to the support arms

with hexagon socket 5 to attach it to the carriage. On the

angle connectors [5], the angle of the support arm can be

adjusted to the working height using the hexagon socket 6.

However, the angle should always be set so that the lever

for turning the brush roller can be actuated.

Mounting the water distributor:

The water distributor is mounted on the lower support arm.

To do this, unscrew the connector shells [6] and [7]. Loosen

the screw [10] with hexagon socket 6 and place the water

distributor on the handle tube. Make sure that the pressure

gauge [8] points upwards and the two connections [9] point

to the right. Then reattach the lower connector shell [7] to

the upper one [8]. Use the screws [10] for this purpose.

Tighten the two screws with the hexagon socket 6.

Cutting to size and assembly of distributor pipe:

The distributor tube for the Sola-Tecs C on the top carriage

must reach to the end of the brush roller [11]. The distribu-

tion pipe for the remaining connections should be approx.

150 mm [12] long. The cut distributor pipes are inserted

into the quick coupling [13]. The IQS closing cap [14] is

fitted to close the open side of the distributor pipe.

AWear gloves during assembly.

This protects your skin from abrasions and

pinching.

WARNING

Risk of injury during assembly

[14]

[13]

[5]

[3]

[1]

[4]

[6]

[7]

[10]

[2]

[8]

[9]

≈ 150 mm until the end brush roll

[11]

[12]

18

MA 0302506 R00 2019-07

Aufbau

Mounting the high-

pressure hoses

In this assembly step, the high-pressure hoses are laid and

assembled. Tools are not required for assembly. The Velcro

cable ties are required to secure the high-pressure hoses.

Mounting high-pressure hoses on the VR2:

The high-pressure hoses supply the system with water and

drive energy. The high-pressure hose of 2000 mm is scre-

wed onto the water distributor connection [1]. The high-

pressure hose is then laid under the carriage to connection

[2] of the first clamping element and screwed on. The

high-pressure hose of 1000 mm is laid and screwed from

connection [3] of the second clamping element along the

connecting tube to connection [4] of the following clamping

element. Depending on the structural width, the following

clamping elements are connected directly to high-pres-

sure hoses. The M22x1.5 plug [5] is screwed onto the free

connection of the last clamping element. The high-pressure

hoses are prevented from hanging down with the Velcro

cable ties on the connecting tube.

Mounting high-pressure hoses on the VR1:

The 1000 mm high-pressure hose is screwed to the water

distributor connection [6] and laid and screwed onto the

carriage to connection [7] of the first spray nozzle. Ano-

ther 1000 mm or 1500 mm high-pressure hose is screwed

to the connection [8] of the first spray nozzle. The high-

pressure hose is laid and screwed along the connecting

tube to the connection [9] of the second spray nozzle. The

M22x1.5 plug [5] is screwed onto the free connection of

the last clamping element. The high-pressure hoses are

prevented from hanging down with the Velcro cable ties on

the connecting tube.

Mounting high-pressure hoses on the VR3:

The 1000 mm high-pressure hose is screwed to the water

distributor connection [10] and laid and screwed over the

carriage to the connection [11] of the spray nozzle. The

remaining high-pressure hoses are laid as on [VR1].

AWear gloves during assembly.

This protects your skin from abrasions and

pinching.

WARNING

Risk of injury during assembly

[2]

[7]

[10]

[4]

[9]

[11]

[3]

[8]

[5]

[5]

[1]

[6]

[10]

19

MA 0302506 R00 2019-07

Construction

Mounting the top

support frame

In this assembly step, the partially pre-assembled support

frame for the top carriage will be mounted and attached to

the carriage. Hexagon socket 6 is required for mounting.

Mounting the top support frame:

Place the support tubes [1] and [2] with the cross holes [3]

facing [down] parallel to the mounting surface. Take the

stiffener [4]. Thread the stiffener with the connectors [5],

[6] from [down] onto the support tubes [1] and [2]. Slide

the stiffener 30 cm onto the support tubes. Align the holes

horizontally to the mounting surface. Tighten the screws on

the connectors [5] and [6]. Take the handle tube [7]. Thread

the grip tube [7] onto the carrier tubes with the connectors

[8] and [9]. Push the grip tube [7] onto the carrier tubes [1]

so far that you reach the top position for placing the Sola-

Tecs F upright. Tighten the screws on the connectors [8]

and [9]. Take the spring pins [10] and insert them into the

cross hole [3].

Mounting the top support frame on the carriage:

The carriage [top] is lifted. The support frame is inserted

into the holder [11] and [12] from below. The Sola-Tecs F

can be stored ready for use with a support frame.

AWear gloves during assembly.

This protects your skin from abrasions and

pinching.

WARNING

Risk of injury during assembly

[1]

[2]

[7]

[9]

[8]

[6]

[5]

[4]

[10]

[3]

[11]

[12]

20

MA 0302506 R00 2019-07

Construction

Set Sola-Tecs C on the

photovoltaic panels

In this last assembly step, the Sola-Tecs C is set to the

working height. Hexagon socket 5 is required for this.

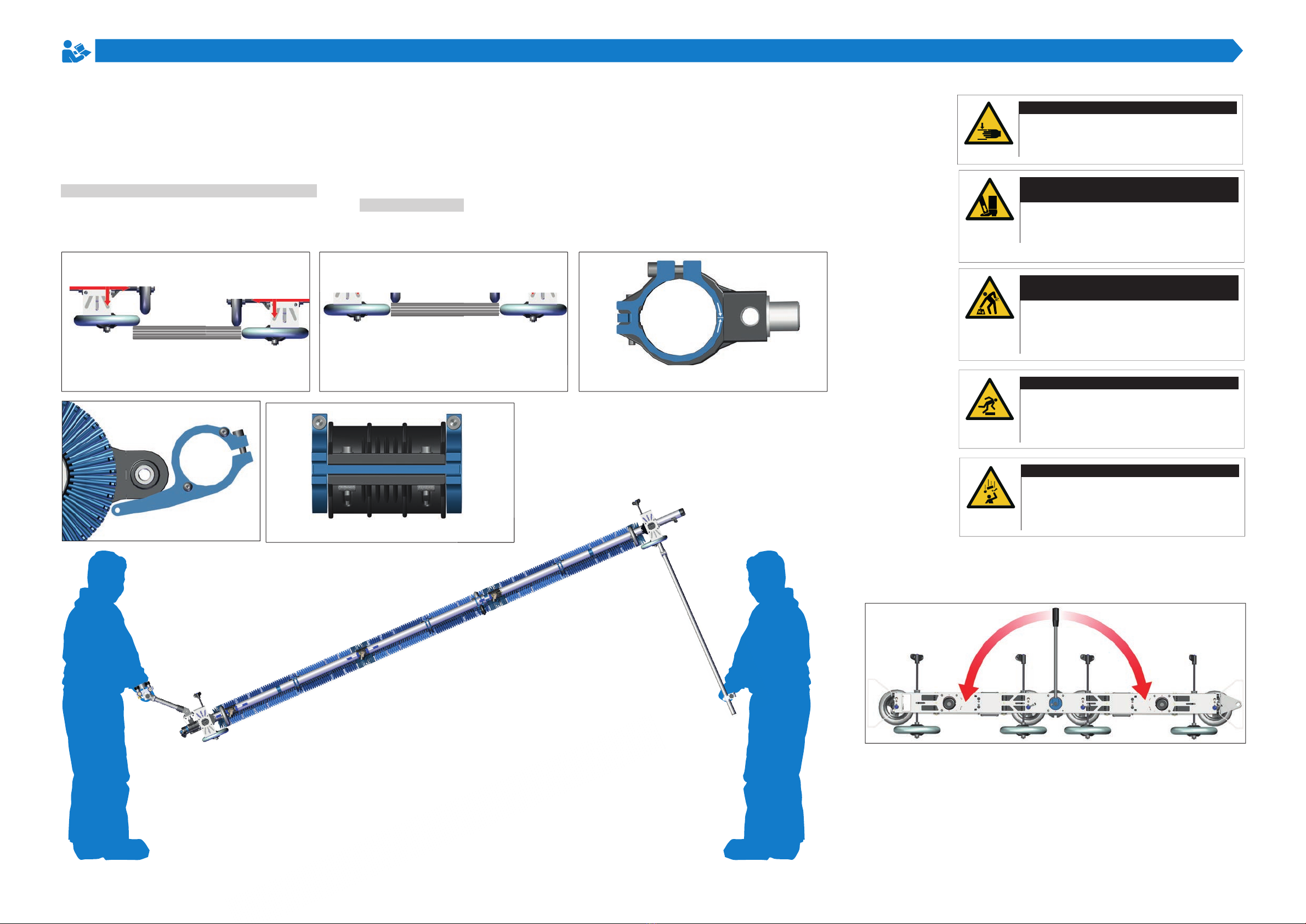

Place Sola-Tecs F on photovoltaic panels:

Twp people are needed to set up the Sola-Tecs F system.

One person carries the system on the lower carrying

handle, one person carries it on the upper carrying hand-

le. Lift the system at the same time. Place the system on

the photovoltaic panels from the front of the system. Make

sure that the wheels of the [upper] carriage are in contact

with the frame first [1]. Let the wheels of the [bottom]

carriage rest on the photovoltaic panels 5. Pull the wheels

of the [bottom] carriage towards the carriage [1] so that the

wheels rest on the outside of the frame. Adjust the top and

bottom wheels vertically so that they are positioned in the

middle [2] of the frame.

Set Sola-Tecs C:

Loosen all the stop clamps on the [VR2] with hexagon

socket 5. Adjust the stop clamps as shown in figures [3]

and [4] and fix them again. Loosen the brush stop on the

[VR1] with the hexagon socket 5. Adjust and fix the brush

stops as shown in figure [5]. Hit the brush roller 180° using

the lever [6]. Loosen the brush stop on the [VR3] with the

hexagon socket 5. Adjust and fix the brush stops as shown

in figures [3] and [4].

AWear gloves during assembly.

This protects your skin from abrasions and

pinching.

WARNING

Risk of injury during assembly

[2]

Laufwagen unten

Laufwagen oben

[3] [4]

[6]

[7]

[1] [1]

AMake sure to lift the machine ergonomically.

This protects you from injuries caused by

straining your back.

WARNING

Risk of injury when lifting heavy parts

ACheck that the machine is positioned

correctly.

This protects you from injuries caused by the

machine falling down.

WARNING

Risk of injury due to falling machine

ACheck your work area for bumps and

obstacles.

This protects you from injuries caused by

falling.

WARNING

Risk of injury due to falling

[5]

ACheck the area to be cleaned for parts that

can fall off.

This protects you from injuries caused by

falling parts.

WARNING

Risk of injury due to falling parts

This manual suits for next models

3

Table of contents

Popular Cleaning Equipment manuals by other brands

Strava

Strava 100.600 user manual

Elma

Elma Elmasonic xtra ST operating instructions

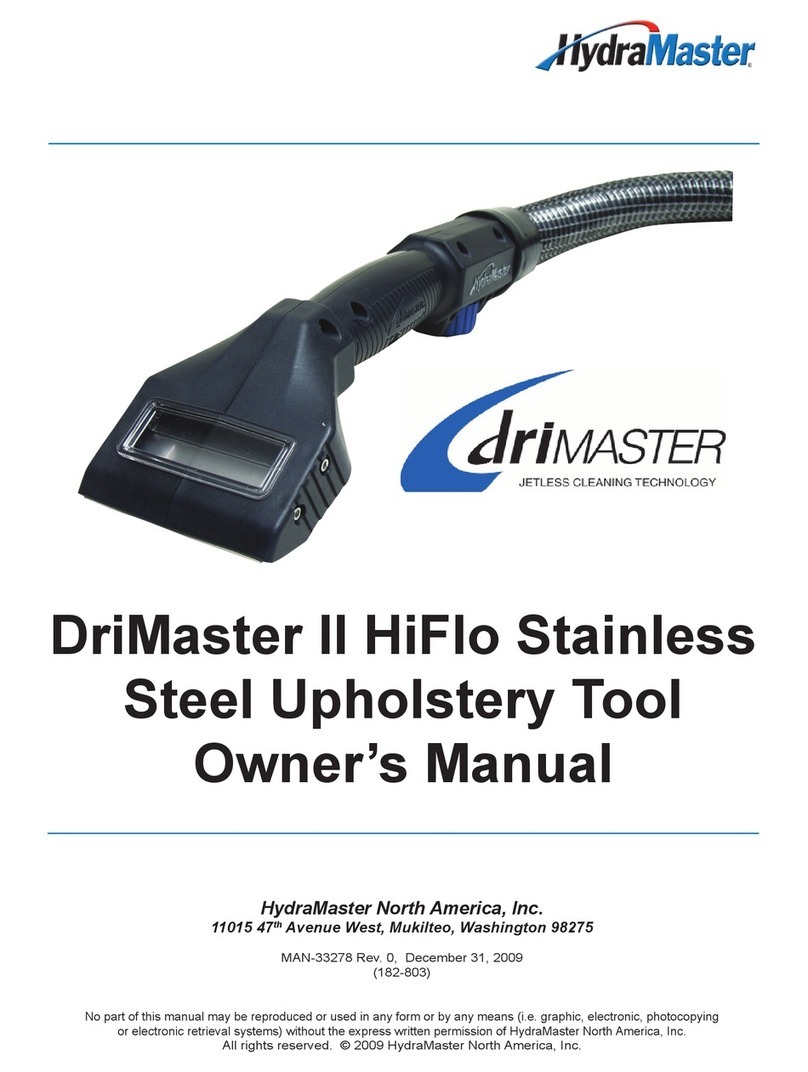

HydraMaster

HydraMaster DriMaster II HiFlo owner's manual

Dane Technologies

Dane Technologies QuicKLEEN Owner's manual & operating instructions

Kärcher

Kärcher Puzzi 8/1 instruction manual

Streamline

Streamline DRAGONFLY4-OV8-25 instruction manual