HERKULES G505 User manual

Part# 1003564-01

3/10/2011

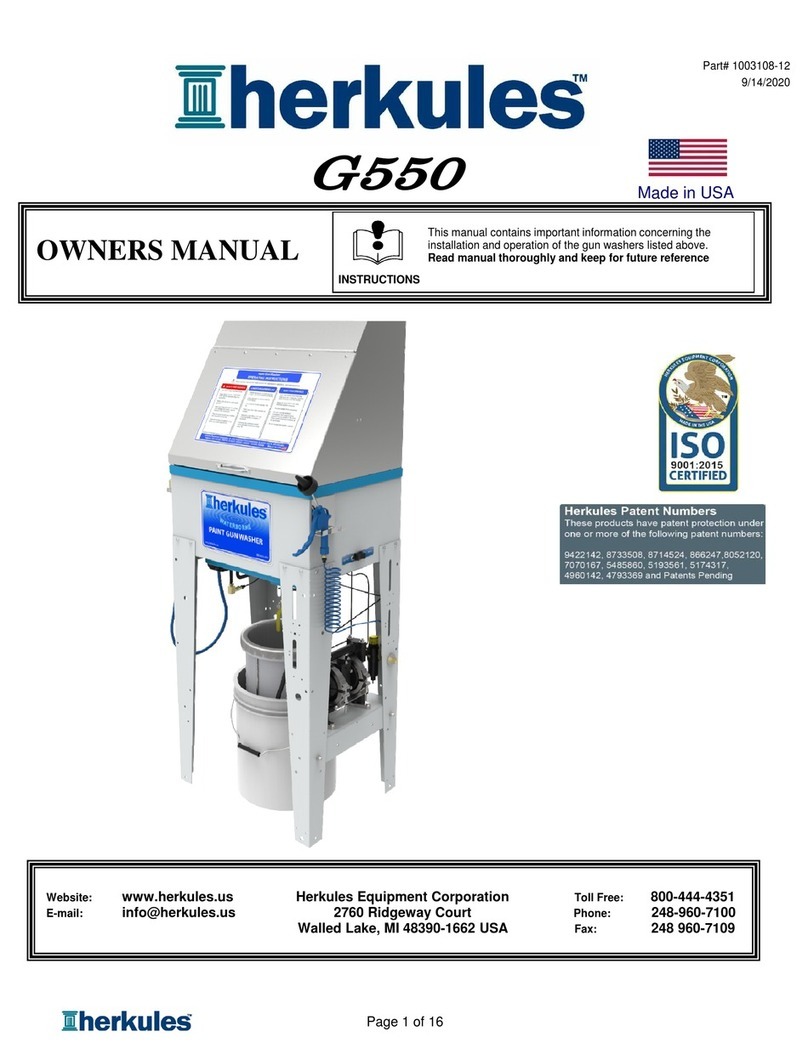

This manual contains important information concerning the

installation and operation of the gun washers listed above.

Read manual thoroughly and keep for future reference

INSTRUCTIONS

This manual contains important information concerning the

installation and operation of the gun washers listed above.

Read manual thoroughly and keep for future reference

INSTRUCTIONS

Herkules Equipment Corporation 2760 Ridgeway Court Walled Lake, MI 48390-1662 USA

248-960-7100 800-444-4351 Fax 248 960-7109

Patents USA 7070167 4793369, 4960142, 5174317, 5193561, 5485860 Canada 1299468 & Patents Pending

website: www.herkules.us Made in the USA e-mail: info@herkules.us

Page 1 of 12

Warnings ……………………………………………………………………………………………………………………… 3-4

Model Information ……………………………………………………………………………………………………………. 5

Installation ………………………………………………………………………………………………………………….. 5

Operation ……………………………………………………………………………………………………………………. 6

Troubleshooting ……………………………………………………………………………………………………………… 7

Drawings with part lists: …………………………………………………………………………………………………… 8-9

Available Options ……………………………………………………………………………………………………………… 10

Table of Contents

Warning Symbol Caution Symbol

Serial Number

Model Number

Purchase Date

Distributor

CAUTION

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions. This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

This product has patent protection under

one or more of the following patent numbers:

7070167, 5485860, 5193561, 5174317

4960142, 4793369, 1299468

and Patents Pending

website: www.herkules.us 1002742

PATENT NUMBERS

Page 2 of 12

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly

and result in serious injury.

•

This equipment is for professional use only.

•

Read all instruction manuals, tags, and labels before operating the equipment.

•

Use the equipment only for its intended use.

•

Do not alter or modify this equipment.

•

Do not exceed the maximum working pressure of the lowest rated system component.

•

Do not operate the gun washer at a pressure above the maximum working pressure rating of the

gun(s) being cleaned.

•

Route the hoses away from traffic areas, sharp edges, moving parts, and hot surfaces.

•

Do not use the hoses to pull the equipment.

•

Do not move pressurized equipment.

•

Comply with all applicable local, state and national fire, electrical and other safety regulation.

PRESSURIZED EQUIPMENT HAZARD

Spray from hose leaks or ruptured components can splash fluid in the eyes or on the skin and cause

serious injury.

WARNING

•

Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

•

Tighten all fluid connections before operating the equipment.

•

Replace worn, damaged, or loose parts immediately.

WARNING

Page 3 of 12

FIRE AND EXPLOSION HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition

and result in fire or explosion and serious injury.

•

Ground the equipment. See Installation for grounding procedure.

•

Provide fresh air ventilation to avoid the build up of fumes.

•

Extinguish all open flames or pilot lights in the gun washer area.

•

Disconnect all electrical equipment in the gun washer area.

•

Keep the gun washer area free of debris, including cleaning solutions, rags, and gasoline.

•

Do not turn on any light switch in the gun washer area while operating or if fumes are present.

•

Do not smoke in the gun washer area.

•

Do not operate a gasoline engine in the gun washer area.

•

If there is any static sparking while using the equipment, stop operation immediately. Identify and

correct the problem.

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can cause serious injury or death if splashed in eyes or on the

s

kin

,

s

w

a

ll

o

w

ed,

o

r inh

a

l

ed

.

WARNING

skin

,

swallowed

,

or

inhaled

.

•

Know the specific hazards of the fluid you are using. Read the fluid manufacturer's warnings.

•

Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local, state

and national guidelines.

•

Wear the appropriate protective clothing, gloves, eyewear and respirator.

•

Pipe and dispose of the exhaust air safely. If diaphragm fails, the fluid may be exhausted along with

the air.

WARNING

Page 4 of 12

Model Information

Dimensions in./(mm)

A

BCD

Manual cleaning waterborne Gun Washer includes 16.40 12.45 14.5 26.25

pressure cleaning nozzle, cleaning brush and air gun. (417) (316) (368) (667)

G505

lbs/(kg)

Description Weight

NOTE: Dimensions listed are overall measurements.

Model

31.0

(14)

BC

D

A

Installing the Gun Washe

r

1) Mount the Gun Washer to a wall (hardware not included)

in a Spray Booth or another convenient location in the shop.

Note: The G505 can also be used as a bench top model or

mounted to an optional stand (13940).

Grounding the Gun Washe

r

1) Using the ground wire supplied with the unit, ground the unit to a

true earth ground.

Connecting the air line

1) Install a 1/4 in. npt male coupler, that is compatible with

the quick disconnect of your air supply line, into the air

supply port on the side on the unit.

2) Connect air line with at least 80 psi to the coupler.

Installation

BC

D

Air supply

port

A

Ground wire

Page 5 of 12

Connecting an external air line to the Gun Washer (Optional)

1) The G505 is equipped with an external air output port on the

left side of the unit. When installing the unit in a paint booth,

an air line can be run directly from this port to the paint gun.

Note: When installing the unit outside the paint booth a small

air line can be attached to the side port to attach to the

paint gun during cleaning.

Adding water to the Gun Washer

1) Fill the supplied container with water and insert the pick up line.

Note: This GunWasher is designed for cleaning waterborne

paint ony. DO NOT fill container with solvents.

2) Place an empty 1-gallon can under the drain spout.

Note: For larger shops a 5-gallon container kit (13939) is

available.

Preparing the equipment to be washed

1) Remove paint cup from the paint gun. Allow the air line to remain

attached to the paint gun or connect the air line added to the side

of the unit.

2)

Drain any unused paint into a separate container.

Operation

Pick up line

Drain spout

External air

output port

2)

Drain

any

unused

paint

into

a

separate

container

.

3) Remove all gauges and regulators from painting equipment.

Cleaning equipment

1) Place the paint channel of the paint gun under the cleaning nozzel.

Squeeze the trigger of the paint gun while pressing the paint gun

up against the nozzel to activate the pump. Allow the pump to run

for 10-15 seconds.

Note: Position the spray gun so that the flow of water

exiting the paint gun is contained within the Gun Washer

cabinet.

2) Clean the air cap of the paint gun by rubbing it on the panel

mounted brush.

3) Dry the paint gun using the air blow gun on the side of the unit.

4) Dispose of all paint waste according to local, state

and national regulations.

Pick up line

Drain spout

Cleaning

Nozzle

Air Blow

Gun

External air

output port

Page 6 of 12

Troubleshooting

Pump turns on but wash water 1Make sure wash bucket is not empty.

does not flow. 2Make sure the pick up tube is completely submerged in water.

3 Check all fluid connections to ensure that there are no leaks.

Pump does not turn on. 1 Make sure intake filter is not clogged (Clean or replace).

2 Make sure the air line is properly connected with at least 75 psi.

Air pressure is regulated at 75 psi.

3 Check all air connections to ensure that there are no leaks.

Possible SolutionProblem

Page 7 of 12

G505 Parts Layout

39

3

29 2

38

18

6

31

21

30

7

5

36

14

32

11

20

37

26

22

19

12

4

39

3

29 2

38

18

6

31

21

30

24

15

7

9

16

27

17

5

36

14

32

10

11

20

37

26

35

34

28

8

23

1

22

19

12

25

33

4

13

Page 8 of 12

Part # Description

114C RIVET 3/16 X 1/2 ALUMINUM 11 EA

267 ADAPTOR 1/4 NPT BRASS 1 EA

3318 PUMP DIAPHRAGM 1/8 PORTS 1 EA

4990 HOSE BARB 1/4 X 1/4 NPT BRASS 1 EA

514187 REG ASSY 3/8 IN X 5/32, 1/8 OUT 1 EA

613903 RED BUSHING 1/8 NPT X 5/16-24 BR 1 EA

71000125 SCREW BHSC 10-32 X 5/8 SS 2 EA

81003670 CAM LATCH - 1/4 TURN 2 EA

91000986 BULKHEAD PTC 5/32 1 EA

10 1001119 BOLT HOOK 1/4-20 1 EA

11 14185 BULKHEAD AIR INLET ASSEMBLY 1 EA

12 1002643 BULKHD 3/4-16UNS X 1/4 NPT W/NUT BR 1 EA

13 1002644 BULKHEAD 1-14UNS X 3/8 NPT W/NUT BR 1 EA

14 14186 BULKHEAD WATER INLET ASSEMBLY 1 EA

15 002-120A-72 GROUNDING WIRE 1 EA

16 13800 GUN AIR FOR WATERBORNE GUN WASHER 1 EA

17 1002968 TUBE COILED 5/32 OD X 6 NYLON 1 EA

18 1003366 NOZZLE W/GUARD PLASTIC 1 EA

19 1003676 CABINET WELDMENT FOR G505 1 EA

20 1003431 TOP COVER PANEL FOR WALL MOUNT GWR 1 EA

21 1003432 PUMP MOUNT PANEL FOR WALL MOUNT GWR 1 EA

22 008-247S SCREW BHSC 8-32 X 1-1/4 SS 2 EA

23 1003435 DOOR PANEL FOR WALL MOUNT GWR 1 EA

24 1003457 SPLASH GUARD FOR WALL MOUNT GWR 1 EA

25 002-150 WASHER FLAT #8 ZINC 2 EA

26 1003502 VALVE PUSH 1/4 NPT X 5/16-24 BRASS 1 EA

27

1003504

CONTAINER SQ 6

-

1/4 X 8

-

1/4 HDPE

1

EA

Quantity

G505 Parts Layout

27

1003504

CONTAINER

SQ

61/4

X

81/4

HDPE

1

EA

28 1003554 GROMMET .688 ID X .07 GROOVE RUBBER 2 EA

29 1003557 NUT NYLOCK 10-32 SS 2 EA

30 1003559 BRUSH PANEL MOUNT NYLON 1 EA

31 002-131 ELBOW STREET 1/4 NPT BRASS EXTRUDED 1 EA

32 002-172S NUT NYLOCK 8-32 SS 2 EA

33 84 NUT HEX 1/4-20 ZINC 2 EA

34 100-079 TUBE FLEX SPIRAL 11.5mm x 10mm GRAY 10 IN

35 39C HINGE BUTT 1 X 2 X .035 SS 2 EA

36 85D WASHER FLAT 1/2 SAE MIN TH .110 Z 2 EA

37 C4B ELBOW 1/4 NPT BRASS 1 EA

38 M26 NIPPLE 1/4 NPT X 2-1/2 BRASS 1 EA

39 1003684 8-32 x 1/4" PHIL PH SELF TAP - SS 1 EA

Page 9 of 12

Part # Description

11002643 BULKHD 3/4-16UNS X 1/4 NPT W/NUT BR 1 EA

2990 HOSE BARB 1/4 X 1/4 NPT BRASS 1 EA

3993 PLUG SOCKET 1/4 NPT 1 EA

14185 Parts Layout

Quantity

14186 Parts Layout

21

3

Part # Description

11002644 BULKHEAD 1-14UNS X 3/8 NPT W/NUT BR 1 EA

21002654 HOSE BARB 3/8 X 3/8 NPT BRASS 1 EA

31002650 HOSE BARB 90 DEG 3/8 X 3/8 NPT BR 1 EA

Quantity

21

3

2

1

3

Page 10 of 12

Part # Description

111238 FILTER/REG ASSY-MTL SET 38 PSI 1 EA

2002-131 ELBOW STREET 1/4 NPT BRASS EXTRUDED 1 EA

3990 HOSE BARB 1/4 X 1/4 NPT BRASS 2 EA

4T12 NIPPLE CLOSE 1/4 NPT BRASS 1 EA

5

1002088

CROSS 1/4 NPT MALEABLE

1

EA

14187 Parts Layout

Quantity

3

5

2

14

6

5

1002088

CROSS

1/4

NPT

MALEABLE

1

EA

6T25 FITTNG PTC 90D SVL 5/32Tx1/4NPT 1 EA

3

5

2

14

6

Page 11 of 12

G505 Available Options

Stand Assembly Kit # 13940

Stand

Assembly

Kit

#

13940

5-Gallon Container Kit # 13939

Includes (1) stand and mounting hardware

Includes (2) 5-Gallon containers, hose & hose fittings

Page 12 of 12

Table of contents

Other HERKULES Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Suevia

Suevia 130.5011 EASYCLEANER Mounting instructions

i-MO

i-MO Öko 2000 user guide

unGer

unGer Hydro Power Ultra UNP01 operating instructions

Black & Decker

Black & Decker BHPC130 Original instructions

Uni-ram

Uni-ram UG5000E operating manual

Axi

Axi MTC HC-300 Installation, operating and maintenance manual