4

9.- CALIBRATION TEST ....................................................................................................................................

10.- BOUNDARY AND SIDE SPREADING

10.1 Boundary spreading by reducing the fertiliser’s flow

in model D-903 ..........................................................................................................................

10.2 Hidraulic connections of the boundary spreading limiter

in fertiliser spreaders D-903 & D-903 plus .................................................

11.- MANTENANCE

11.1 Lubrication ......................................................................................................................................

11.2 Screws ...................................................................................................................................................

12.- DOSAGE TABLES

12.1 Symbols used in the tables for D-903 ..............................................................

12.2 Symbols used in the tables for D-903 PLUS ..............................................

12.3 Tables .....................................................................................................................................................

13.- ASSEMBLING THE CONVERSION KIT FROM 24M TO 30-36 M

IN MODEL D-903 .......................................................................................................................................

14.- ASSEMBLING THE CONVERSION KIT FROM 30-36 M TO 24 M

IN MODEL D-903 PLUS ......................................................................................................................

15.- SPARE PARTS .......................................................................................................................

.................

.........

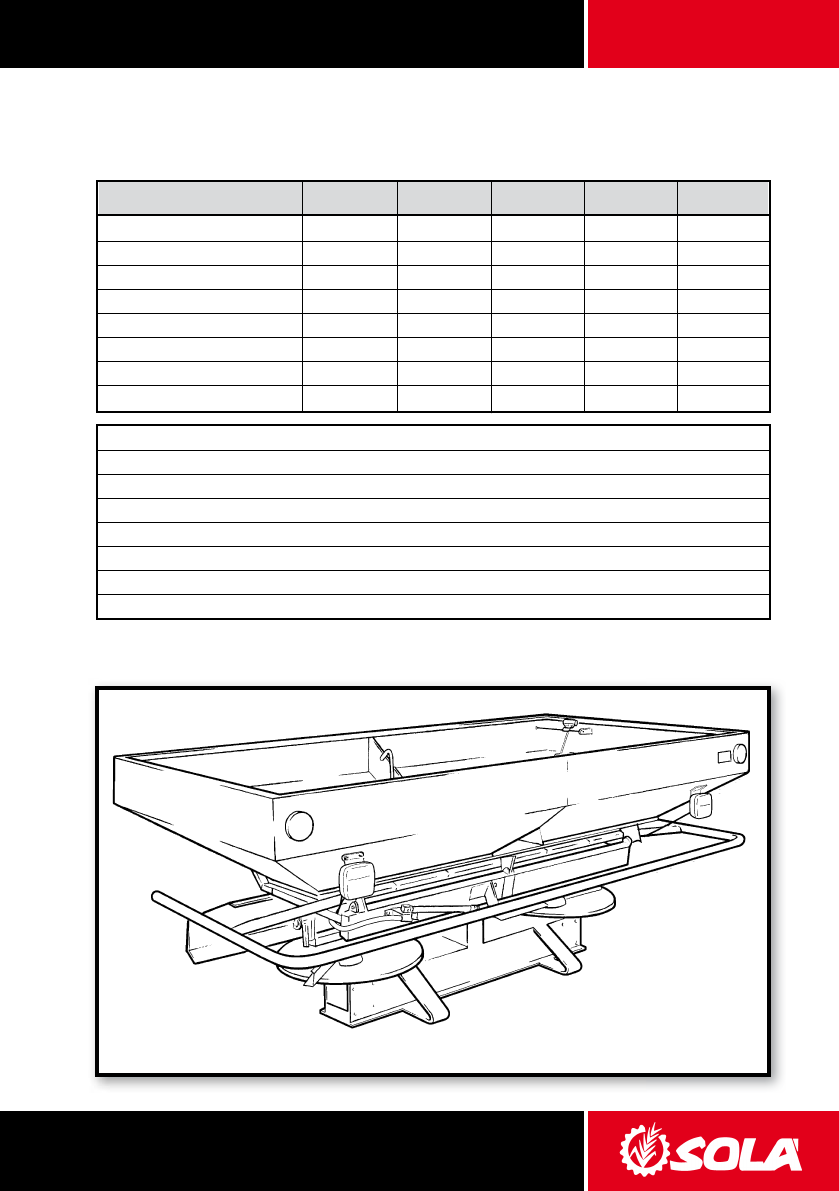

15.1 Chasis D-903 y D-903 PLUS .........................................................................................

15.2 Carro D-903/3000 : D-903 PLUS/3000 ................................................................

15.3 Complementos carro D-903/3000 : D-903 PLUS/3000 .................

15.4 Guardabarros abonadora D-903/3000 .............................................................

15.5 Tolva abonadora D-903 y D-903 PLUS ..............................................................

15.6 Regulación, ditribución y transmisión D-903 PLUS ..........................

15.7 Regulación, ditribución y trans. D-903 y D-903/3000 ..........................

15.8 Kit para conversión de 36 a 24 mts. D-903 PLUS ..................................

15.9 Kit para converion de 24 a 36 mts. D-903 PLUS ..................................

15.10 Mando hidráulico abonadora D-903 y D-903 PLUS ......................

15.11 Lim. orillas mecánico/hidráulico D-903 y D-903 PLUS ..............

15.12 Limitadora orillas D-903/3000; D-903 PLUS/3000 ..........................

15.13 Grupo transmisión ...............................................................................................................

15.14 Abonadora D-900/3000 ................................................................................................

INDEX

37

41

42

45

45

47

48

49

57

61

65

66

68

70

74

76

78

84

90

92

94

96

98

100

102