Solahart GoodWe Lynx Home F Series User manual

1

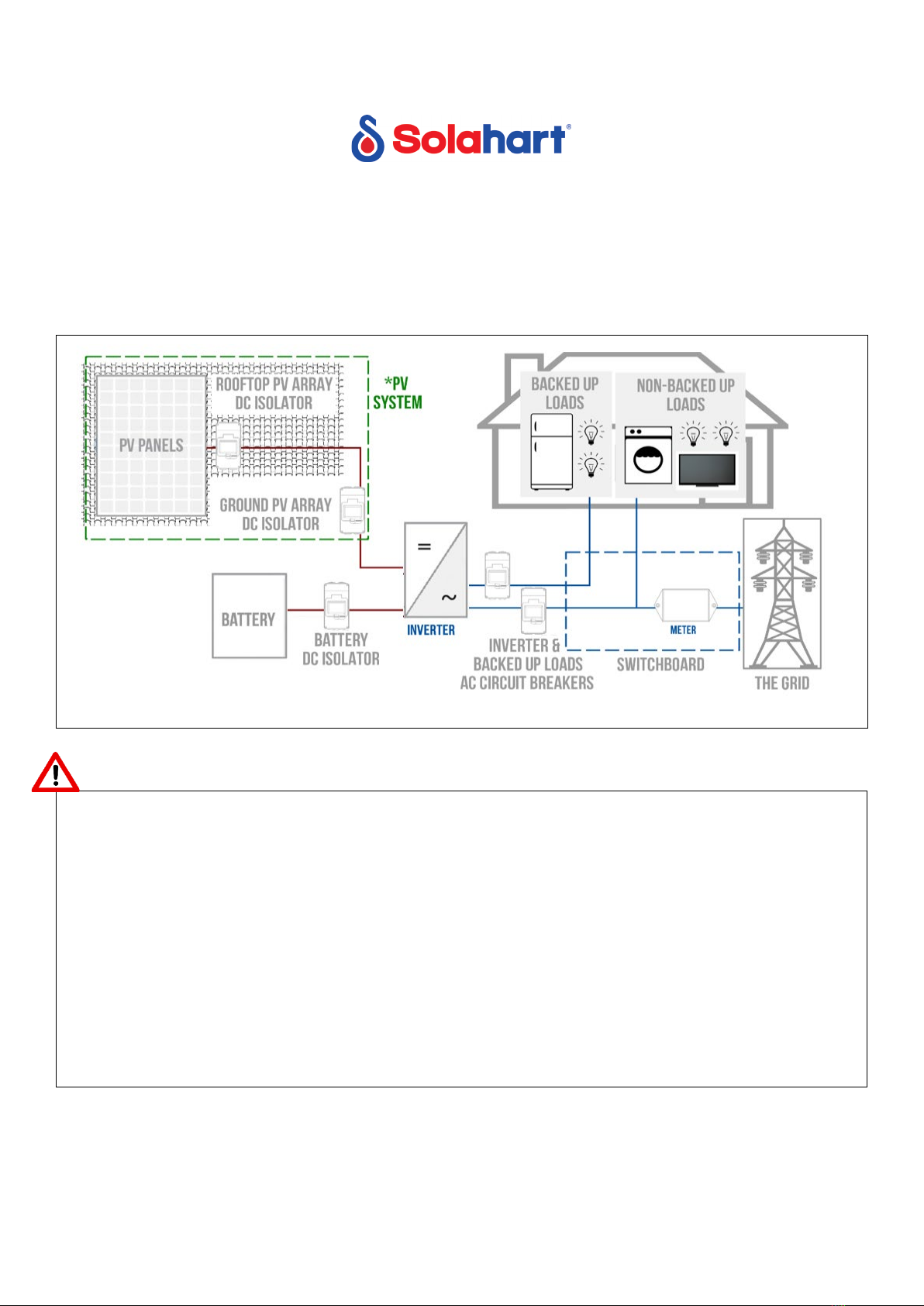

Battery System Quick Start Guide

Battery System: GoodWe Lynx Home F Series Battery and

GoodWe ET* GEH ** EH*** Series Inverter

*GW5kL-ET, GW10KL-ET, GW15K-ET, GW20K-ET, GW25K-ET, GW29.9K-ET ** GEH8.6-1U-10, GEH10-1U-10 *** GW5000-EH

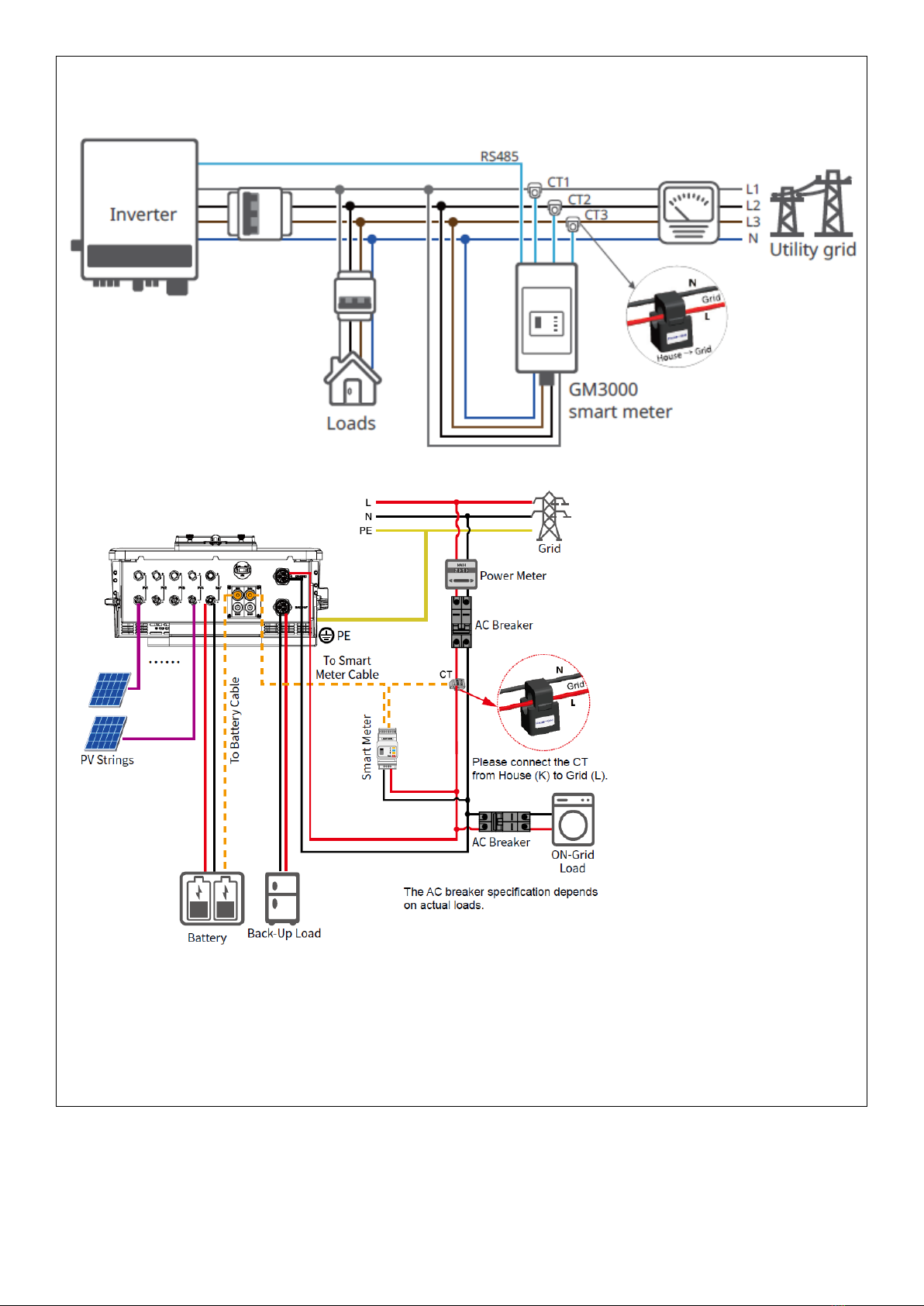

System Overview Diagram

Note:Installation of the PV system is not within the scope of this document.

Warnings

Disclaimer of Liability and Warranty:This pictorial guide does not replace installation manuals supplied

with the components.

Solahart assumes no responsibility for loss, damage or expense resulting from

improper installation, handling, or misuse of components. Refer to the warranty statement in the Solahart

Owner’s guide for full warranty terms and conditions.

The Australian Consumer Law: Our goods come with guarantees that cannot be excluded under the

Australian Consumer Law. You are entitled to a replacement or refund for a major failure and compensation

for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or

replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

Installer Responsibilities

The installer is solely responsible for:

•Observing and conf

orming to all relevant Australian Standards, all relevant Clean Energy Council

Accreditation guidelines and all applicable laws, ordinances, regulations, codes of practice and local

or national building codes, including any that may have superseded this guide.

2

•Ensuring that the installation complies with AS/NZS 3000, AS/NZS 5139, AS/NZS 5033, AS 4777.1,

AS/NZS 1768, AS 3008

and any relevant electrical service and installation rules for the state or

territory where the system is installed.

•Ensuring that the

Battery system and associated components are appropriate for the particular

installation and the installation environment.

•

Ensuring only parts supplied by Solahart Industries and installer supplied parts as specified by

Solahart Industries are utilised (substitution of parts may void the warranty and invalidate certification).

•Ensuring that mounting fasteners have adequate pull-

out strength and shear capacities to suit the

installation.

•Ensuring safe installation of all electrical aspects of the Battery system.

•Ensuring that the building and building structures are capable of withstanding the additional loads and

forces generated as a result of installing the Battery system.

•Ensuring mounting clearance requirements for all components are maintained.

•Ensuring components are not exposed to direct sunlight, rain fall and snow accumulation.

•Ensuring that the batteries and their components are protected from damage during transportation

and storage.

•Ensuring that the weight of the battery is taken into account when handling and that all WHS policies

are followed.

Tools Required

Use insulating tools and wear personal protective equipment (PPE) when operating the equipment to

ensure personal safety. Wear anti-static gloves, cloths, and wrist strips when touching electron devices to

protect the equipment from damage.

•Drill and drill bits suitable for drilling holes in the desired mounting surface/structure.

•M5, M6 & M10 tools.

•Torque wrench.

•Spirit level.

•Adjustable spanner.

•Electricians hand tools (screwdrivers, pliers, side cutters, cable crimps etc.)

•An Android or IOS smart device.

Note: The GoodWe mobile App “PV Master” must be downloaded before commissioning.

Note: See each component installation guides for additional tools required for installation.

3

Planning the Installation

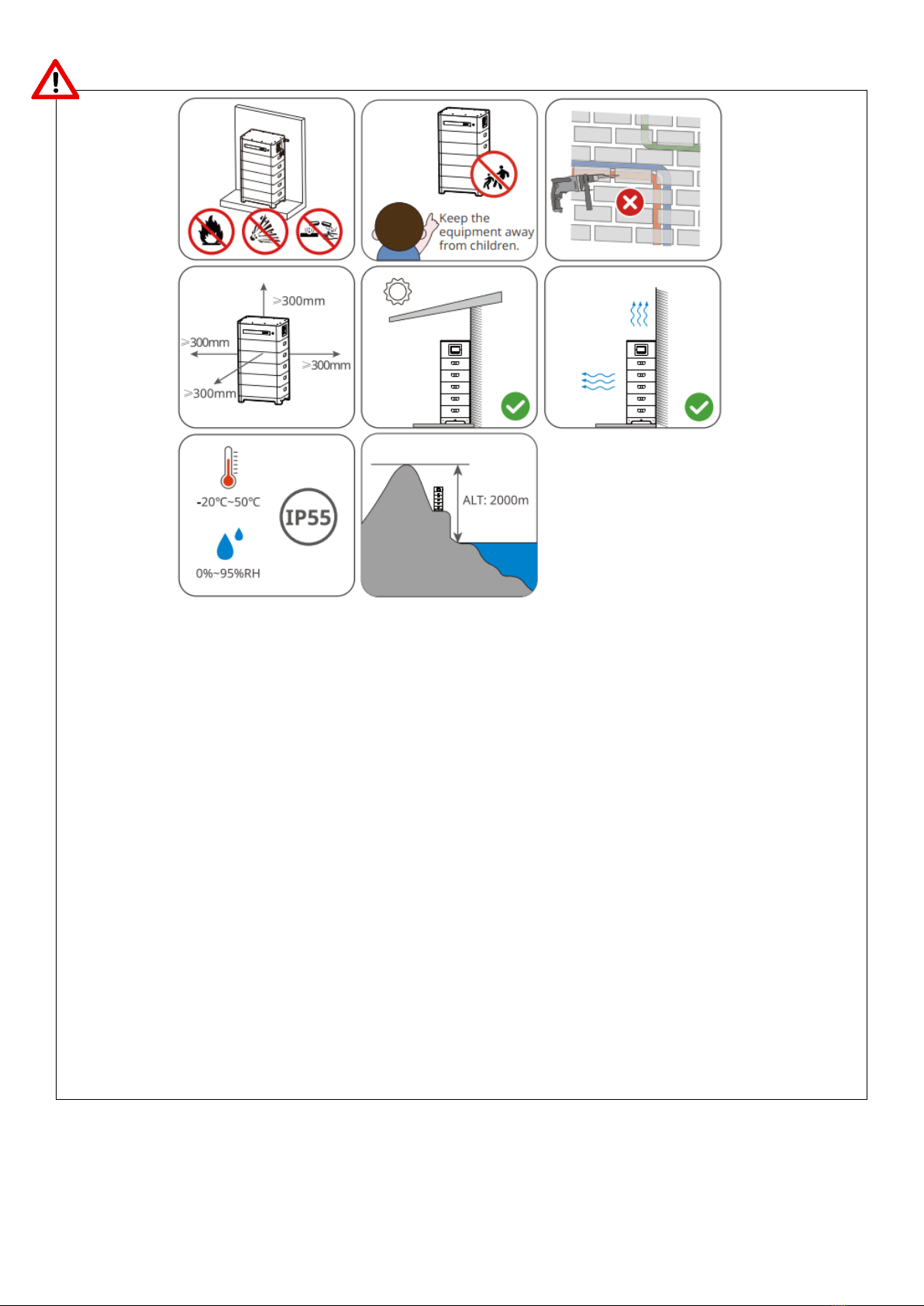

Installation environment

• The battery is floor/wall mounted as per the instructions provided in this guide.

• The operating temperature (charge / discharge) for the battery is -0

℃

~50

℃/

-20

℃

~50

℃.

• Avoid exposing the equipment to direct sunlight or rain.

• Install the equipment away from heat/cold source where the temperature can vary significantly.

• Install the equipment away from strong interference to ensure its reliable operation.

• Keep children / pets away from the equipment.

• Do not install the equipment in places prone to accumulate water.

• Do not put inflammable or explosive materials near the equipment.

4

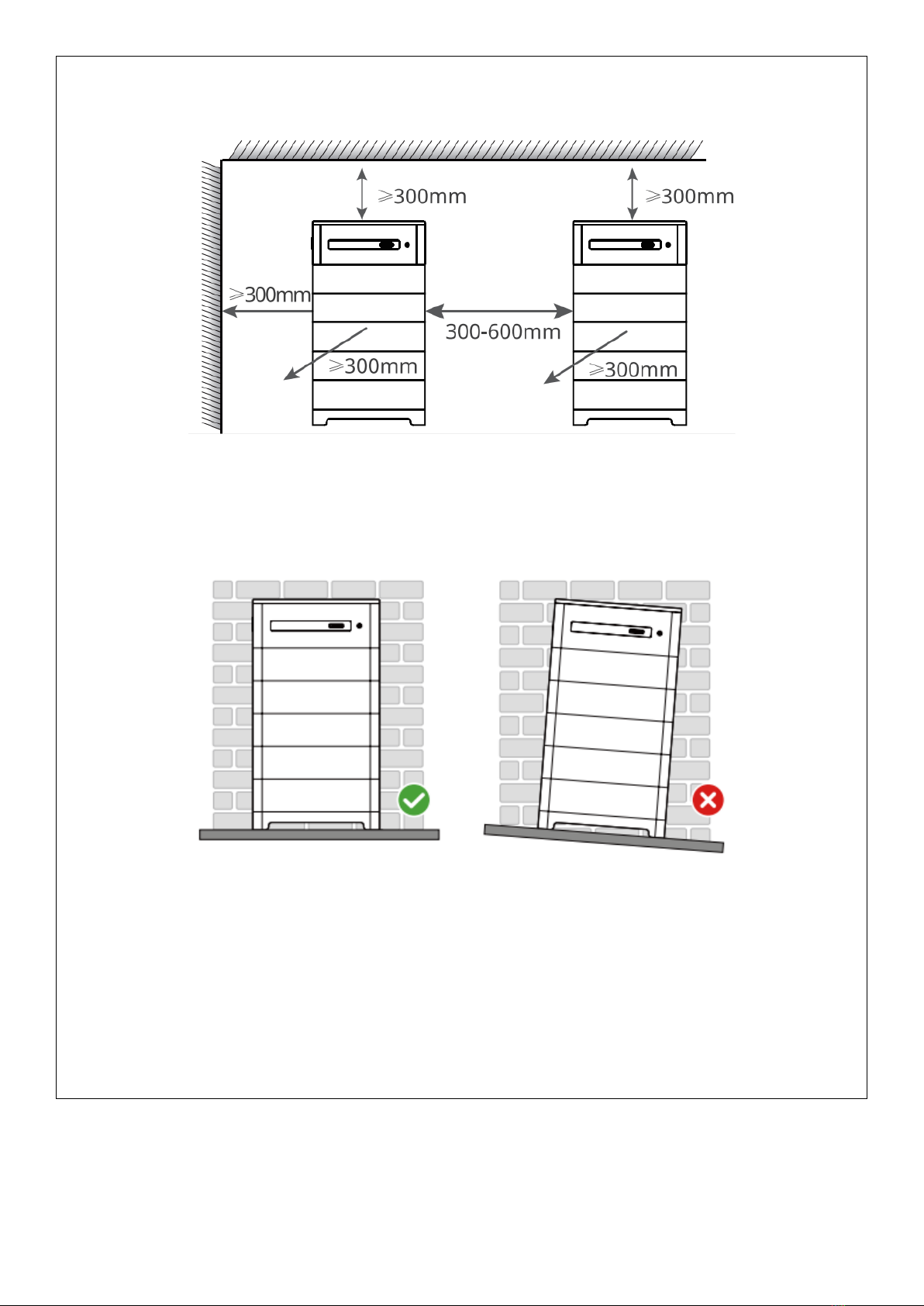

Mounting space requirements for the GoodWe Lynx F Series Battery

Floor mounting space requirements:

Angle requirements:

Note: Battery mounting and installation must comply with Australian standards.

Note: The Installation location of the Battery must also comply with the requirements of AS/NZS 5139.

Note: Refer to the relevant inverter guide for inverter spacing requirements.

5

Cabling and Conduits

Note: Each kit contains connectors/terminal lugs.

Any earthing cable, AC cable and conduits are not supplied by Solahart and should be selected based on

the following criteria.

Inverter DC/AC cabling must be sized and installed in accordance with AS/NZS 3000, AS/NZS 3008.1.1

and any local applicable codes.

DC CABLING

Cable description Cable type Conductor Size

Low Voltage (HV) Battery to Battery

DC Circuit Breaker/Isolator Pair, double insulated single core cables 3-4 mm2

HV Battery DC Circuit

Breaker/Isolator to Inverter Pair, double insulated single core cables

4-6 mm2 (ET Inverter)

12-13 mm2 (GEH Inverter)

6-10 mm2 (EH Inverter)

Battery earthing (PE) Earthing cable complying with requirements of

AS/NZS 3000 10 mm2

Note: Where only one battery tower connected is to the inverter, each DC cable must be installed in

accordance with AS/NZS 3008.1.1 to achieve a current carrying capacity of >25A (in-built rating of

battery circuit breaker). External 32A DC circuit breaker must be installed between the battery

towers and inverter.

Where more than one battery tower is connected, refer to the table below. Some inverters are capable of

max continuous current of 50A. DC cable must achieve a current capacity of >50A for these inverters

(external 63A DC circuit breaker must be installed between the battery towers and inverter).

DC CABLING

Cables must be selected so that the current carrying capacity is suitable for the maximum continuous

current as shown below:

Inverter Model ET Series GEH Series EH

Series

GW5KL-

ET

GW10KL-

ET

GW15KL-

ET

GW20KL-

ET

GW25K

-ET

GW29.9K

-ET

GEH8.6

-1U-10

GEH10

-1U-10

GW500

0-EH

Max.

Continuous

Charging

Current (A)

25 A 25 A 50 A 50 A 50 A x 2

(2

inputs)

50 A x 2

(2 inputs)

50 A 50 A 25 A

Max.

Continuous

Discharging

Current (A)

25 A 25 A 50 A 50 A 50 A x 2

(2

inputs)

50 A x 2

(2 inputs)

50 A 50 A 25 A

6

Refer to the following table for circuit breaker sizing between battery and inverter:

1 Battery Tower 2

Battery

Towers

3

Battery

Towers

4

Battery

Towers

5

Battery

Towers

6

Battery

Towers

7

Battery

Towers

8

Battery

Towers

Number

of

batteries

2 3 4 5 10 15 20 25 30 35 40

3 Phase Hybrid

GW5kL-

ET

32 A 32 A 32 A 32 A 32 A 32 A 32 A 32 A 32 A 32 A 32 A

GW10KL-

ET

32 A 32 A 32 A 32 A 32 A 32 A 32 A 32 A 32 A 32 A 32 A

GW15K-

ET

32 A 32 A 32 A 32 A 63 A 63 A 63 A 63 A 63 A 63 A 63 A

GW20K-

ET

32 A 32 A 32 A 32 A 63 A 63 A 63 A 63 A 63 A 63 A 63 A

GW25K-

ET (per

DC input)

32 A 32 A 32 A 32 A 63 A 63 A 63 A 63 A 63 A 63 A 63 A

GW29.9K

-ET (per

DC input)

32 A 32 A 32 A 32 A 63 A 63 A 63 A 63 A 63 A 63 A 63 A

1 Phase Hybrid

GEH8.6-

1U-10

32 A 32 A 32 A 63 A 63 A 63 A 63 A 63 A 63 A 63 A

GEH10-

1U-10

32 A 32 A 32 A 63 A 63 A 63 A 63 A 63 A 63 A 63 A

GW5000-

EH

32 A 32 A 32 A 32 A 32 A 32 A 32 A 32 A 32 A 32 A 32 A

Note: Maximum batteries per tower for GE inverters is 4. Please note battery tower stacks are in series so

multiple stacks need to be the same size. E.g if one tower stack was 4 , the next tower needs to be 4.

AC CABLING

Cables must be selected so that the current carrying capacity is suitable for the maximum continuous

current as shown below:

ET Series GEH Series EH

Series

Inverter Model GW5KL-

ET

GW10KL-

ET

GW15KL-

ET

GW20KL-

ET

GW25K

-ET

GW29.9K

-ET

GEH8.6

-1U-10

GEH10

-1U-10

GW500

0-EH

Max AC

Current (On

Grid) -

incoming

15.2 A

22.7 A

34.0 A

45.0 A

50.0 A

50.0 A

45.5 A

45.5 A

43.4A

Max AC

Current

(Backup,

continuous)

8.5 A

16.5 A

22.7 A

30.3 A

37.9 A

45.5 A

39 A

43.5 A

21.7A

7

COMMUNICATION CABLING

Communication cables are provided and pre-fitted on GoodWe Inverters. Extension of communication

cable is permitted to the maximum length specified in the table below.

Cable Description Cable Type Provided Cable

Length Maximum Length

Cable between Inverter and

Smart Meter

Data cable with RJ 45 connector pre-

crimped on Meter end 10 m 100 m

Cable between Smart Meter and

CT Data cable with 1 twisted pair 3 m 5 m

Cable between Inverter and

Battery

Data cable with RJ 45 connector pre-

crimped on Battery end 3 m 100 m

Note: Check insulation voltage rating of these communication cables.

NOTE: ADDITIONAL CONDUIT TERMINATORS/GLANDS MAY BE REQUIRED DEPENDING ON THE

INSTALLATION LOCATION.

Note: Refer to AS/NZS 3000 for appropriate conduit sizing.

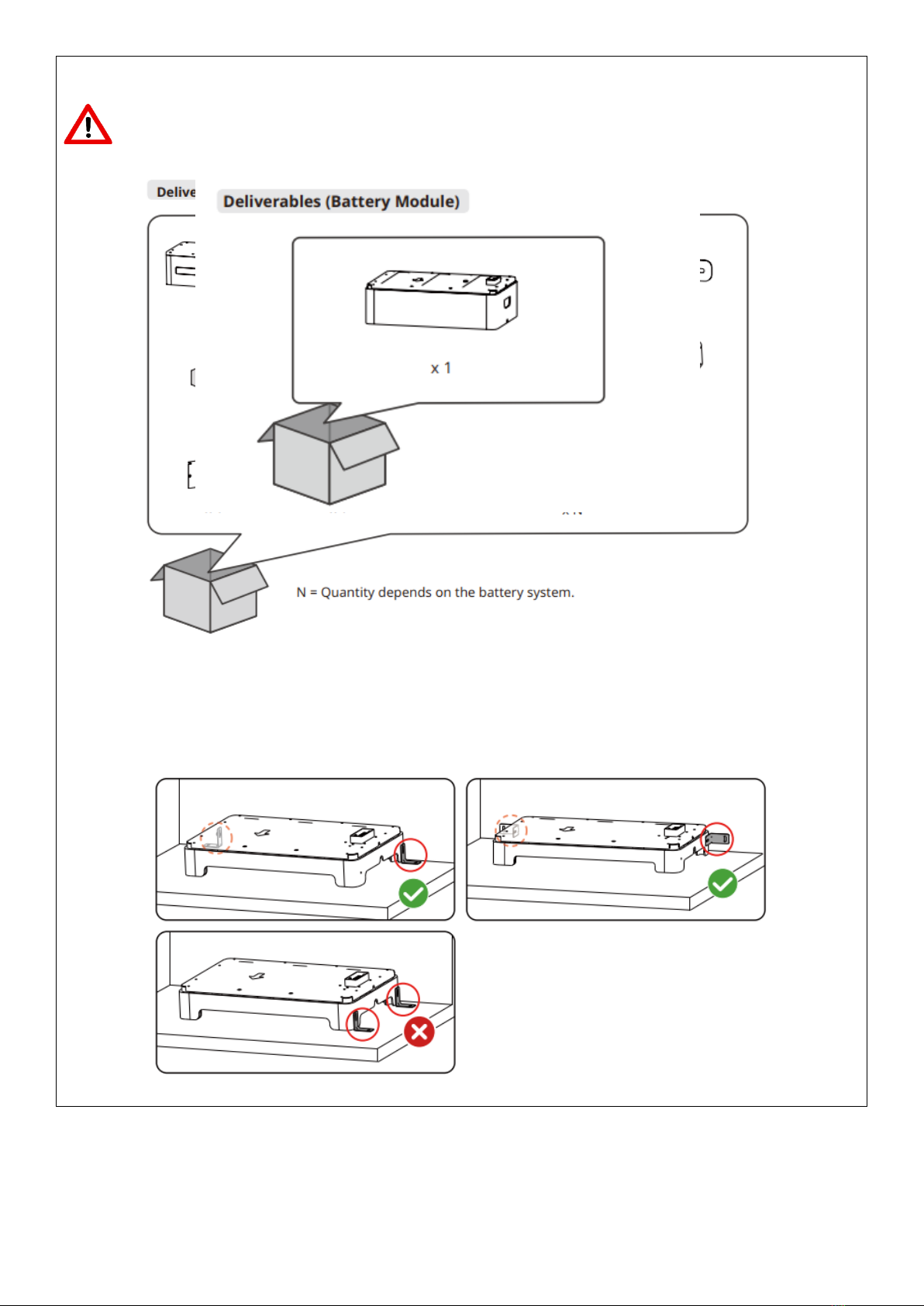

Unpacking and Mounting Battery

Refer to GoodWe Lynx F-Series User Manual for further mounting instructions.

1

8

Unpack contents from the GoodWe battery packaging.

Warning: Battery modules are heavy (approximately 45 kg each). It is recommended that the

installation is done by two people.

Note: If multiple batteries are to be connected, check that the production date is similar and cell grade is

the same.

9

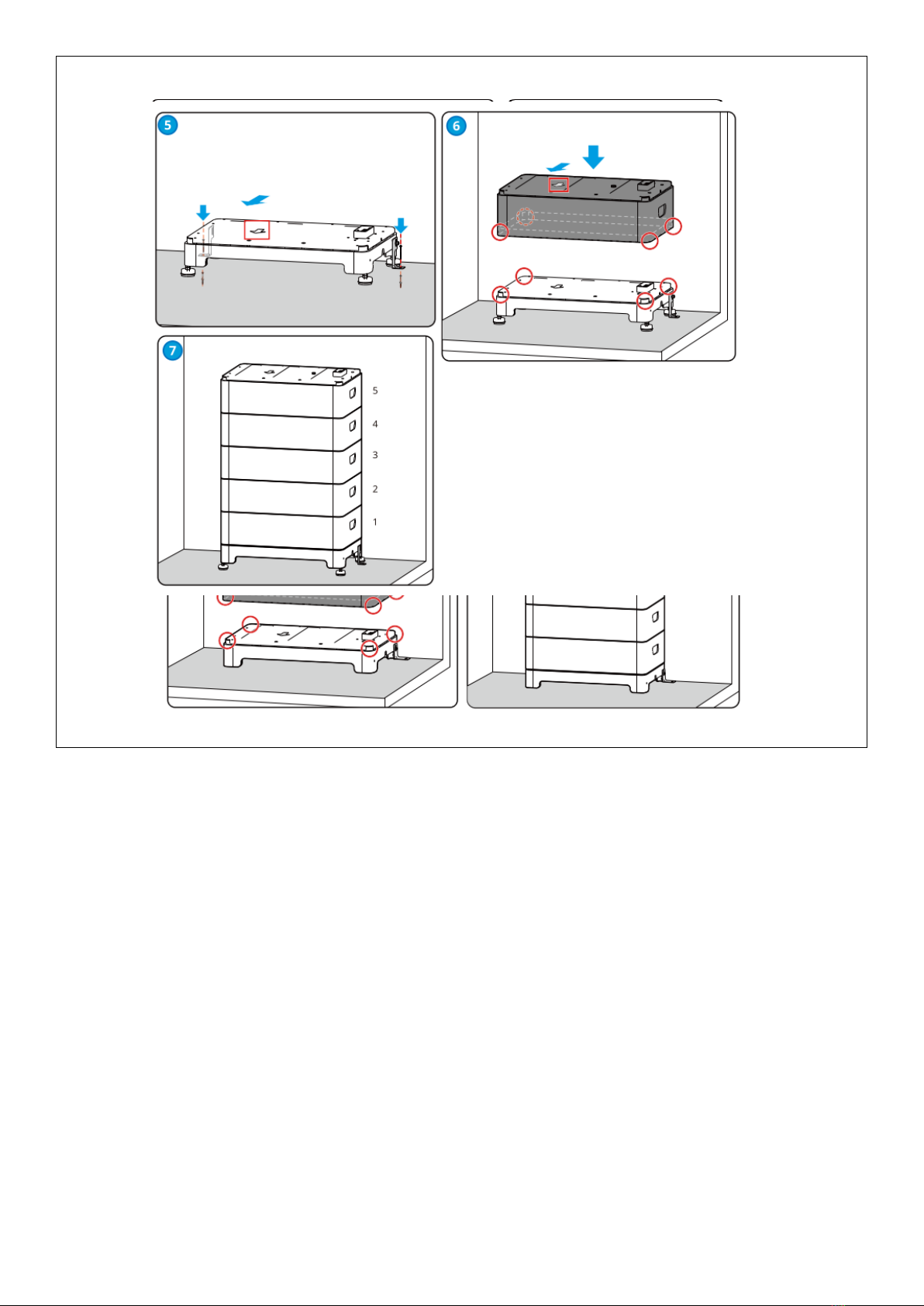

• Ensure that the base stands on the floor vertically.

• Ensure that the base clings to the wall and the arrow points outward.

• Ensure that all batteries cling to the wall and the arrow points outward.

• Align the holes of the upper and the lower battery modules when placing the upper battery module.

• Ensure that the locking bracket clings to the wall.

• Do not install the two locking brackets on one side

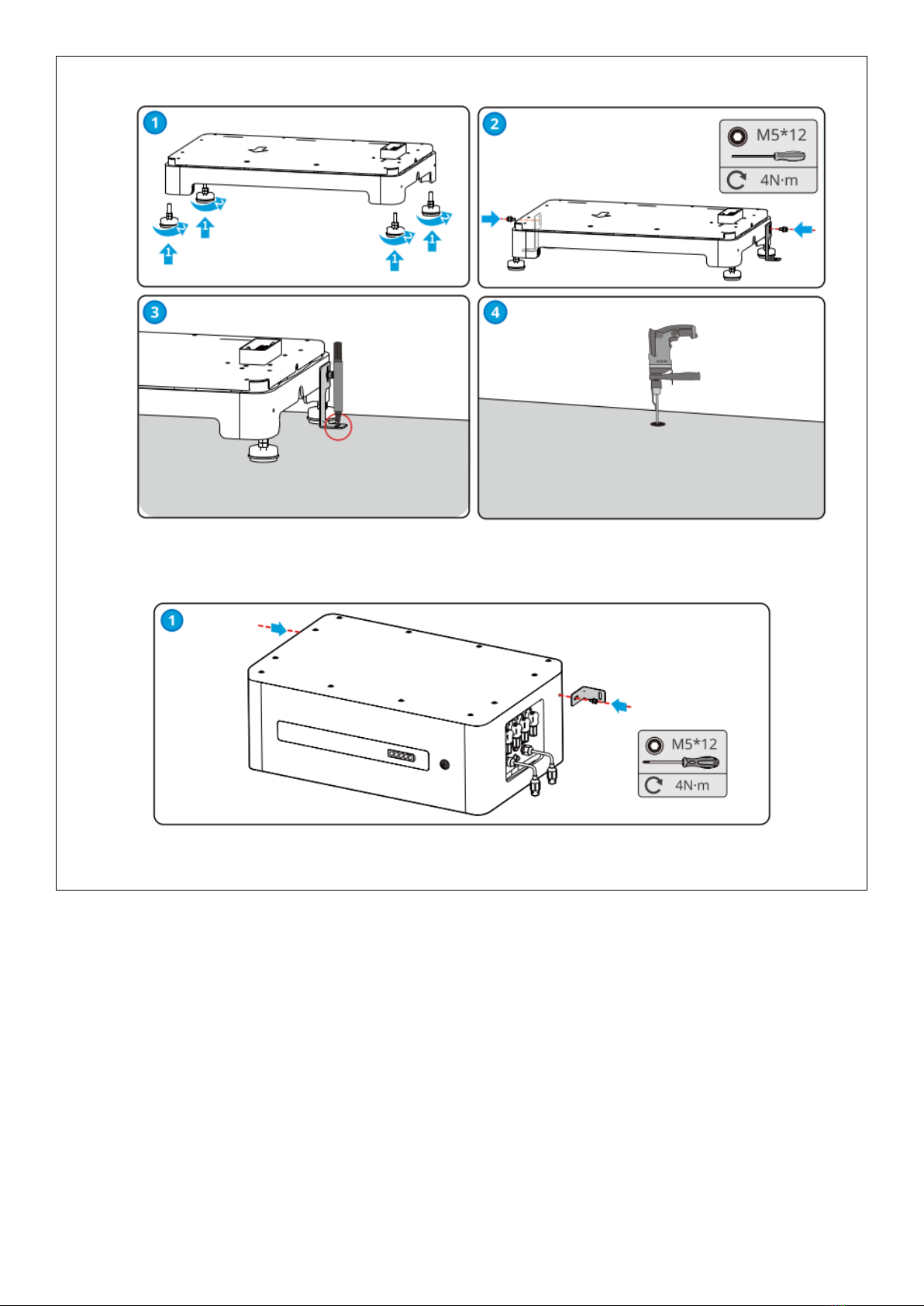

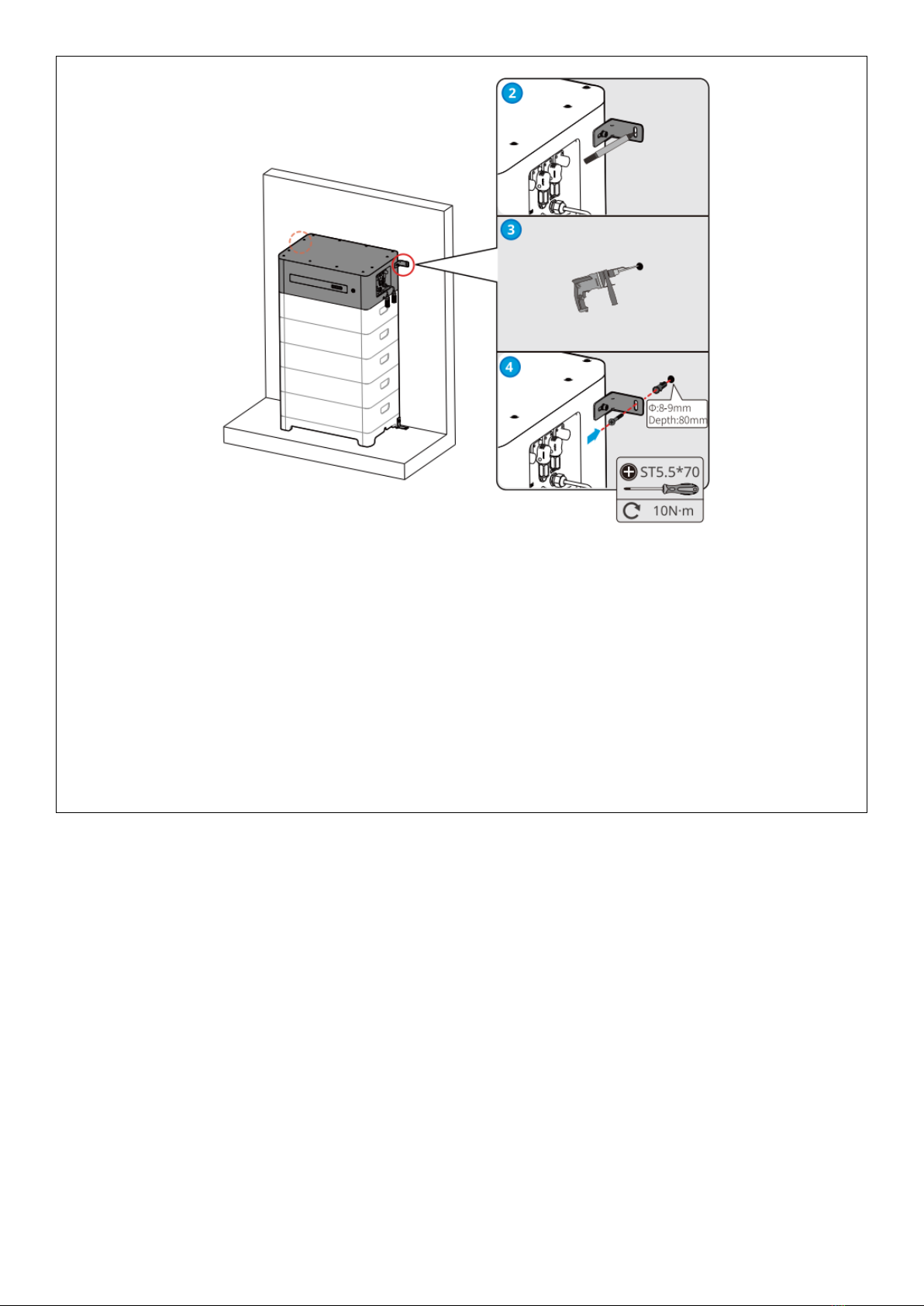

Battery System Installation(Without adjustable leveling feet)

Floor mounting:

1. Make sure that the floor is flat and horizontal. Install the anti-dumping bracket on both sides.

2. Align the battery and the wall, then put the anti-dumping bracket close to the wall. Mark the drilling

position and remove the battery.

3. Drill a hole on the wall using the power drill. The hole diameter shall be 10mm at a depth of 80mm.

10

4. Fix the expansion bolts, tightening torque: 4N·m.

11

Battery System Installation(With adjustable leveling feet)

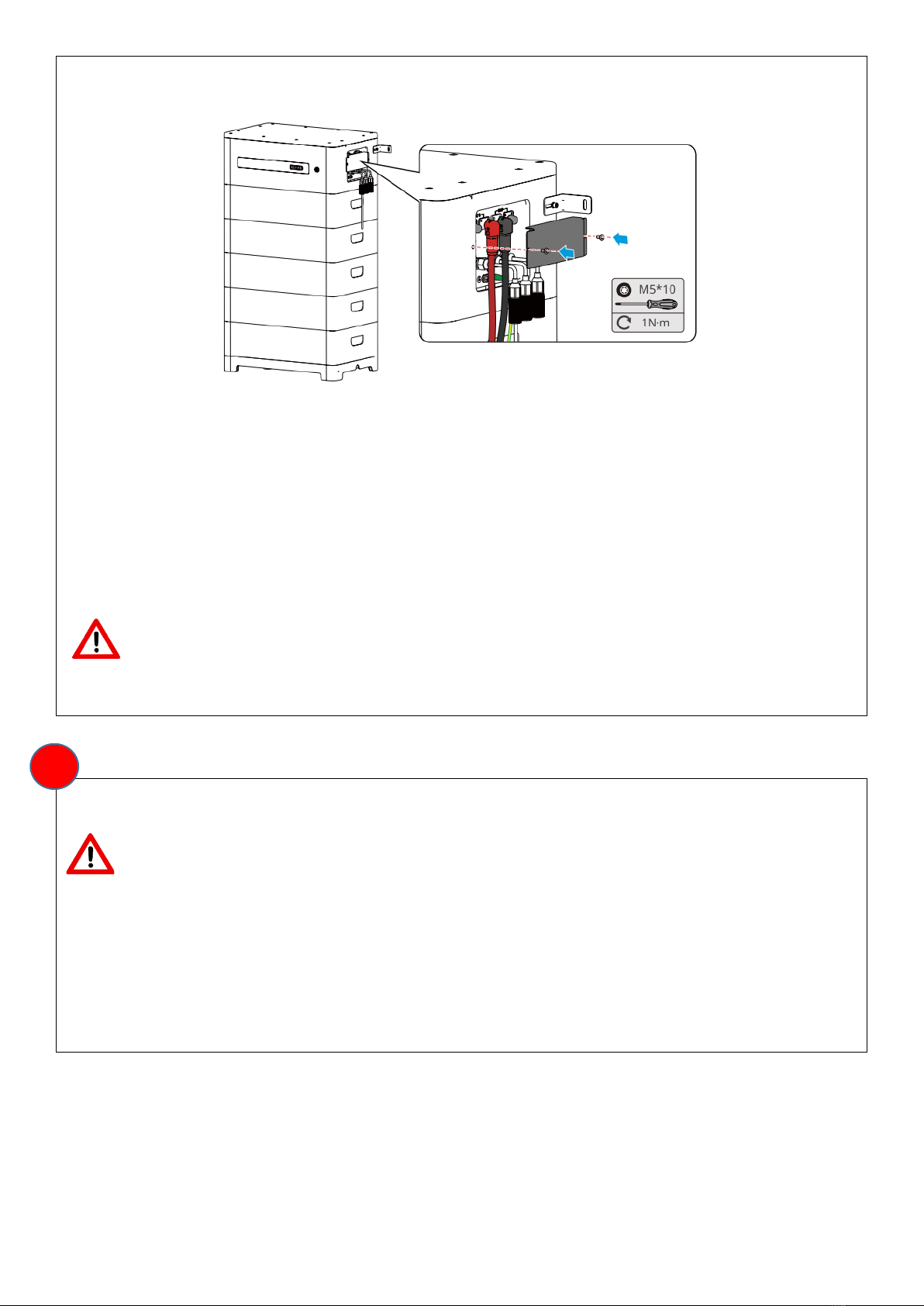

Installation of PCU

12

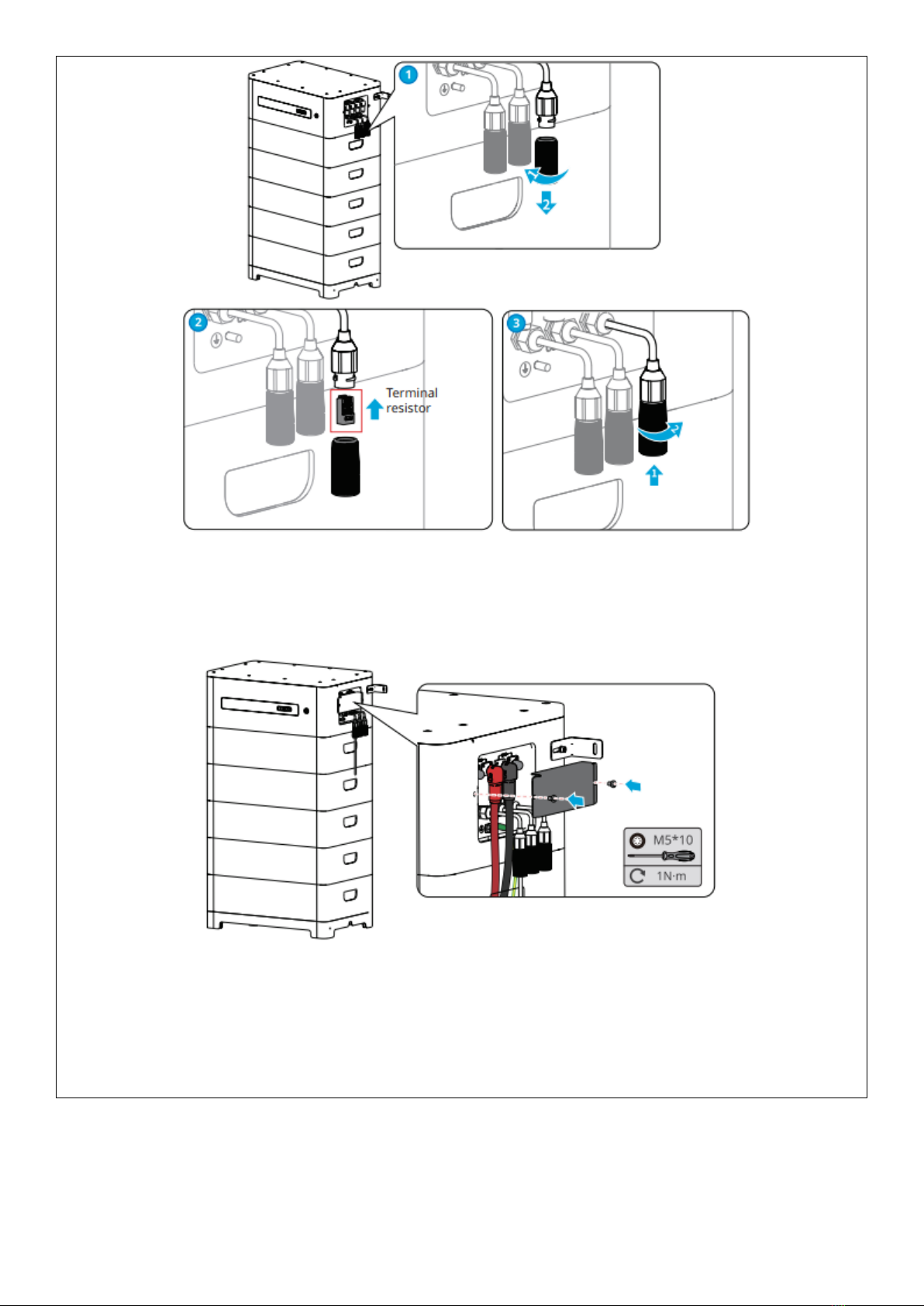

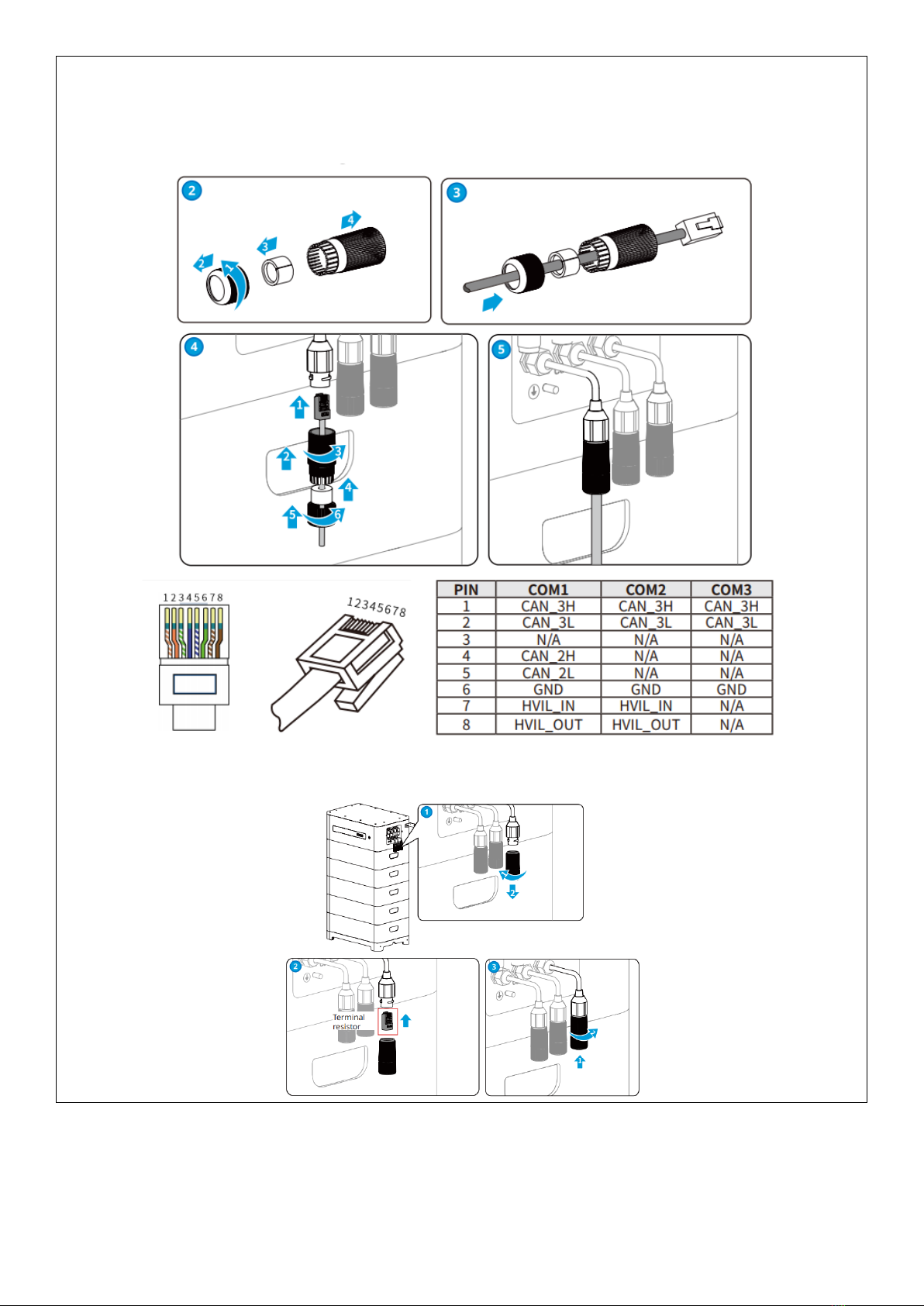

Connecting Terminal resistor

13

Installing the protection cover

Note: The battery shall be installed and mechanically protected according to CEC

Battery Installation

Guidelines and AS/NZS 5139. This includes:

14

•

Providing restricted access to the battery system designed to prevent access by unauthorised

persons.

•Where subject to potential physical damage, mechanical protection shall be provided to the battery

system to minimise the risk of such, resulting in electrolyte leakage, including:

oCrushing

oImpact

oPuncturing

•Mechanical protection may be achieved via the use of a suitable battery system enclosure and/ or

bollards.

Mounting the Inverter

Follow the GoodWe ET, GEH, EH Series User Manuals to choose a suitable location and correctly mount

the Inverter to the wall using appropriate fasteners and with regards to clearance requirements.

A lock can be installed on the inverter for anti-theft purposes.

Mounting AC Isolator Enclosure(s)

ISOLATOR ENCLOSURES

1. Determine the mounting locations of the enclosures with regard to system clearances,

layout specifications and AS/NZS 3000.

2. Install a minimum of two (2) fasteners diagonally opposite, to fix the enclosure to the

wall.

3. Install the silicone rubber plugs supplied with the enclosure on the internal mounting

points.

Note: Where the Inverter is not adjacent to the switchboard to which it is connected,

an “Inverter AC Isolator” must be installed at the Inverter in accordance with

AS/NZS 3000.

3

2

15

Mounting Smart Meter

The Smart Meter can be attached to a DIN rail inside the switchboard via mounting clips supplied with the

Meter.

Note: Check Smart Meter and CT communication cable to ensure insulation is rated for the highest voltage

present inside the switchboard. Additional insulation may be required.

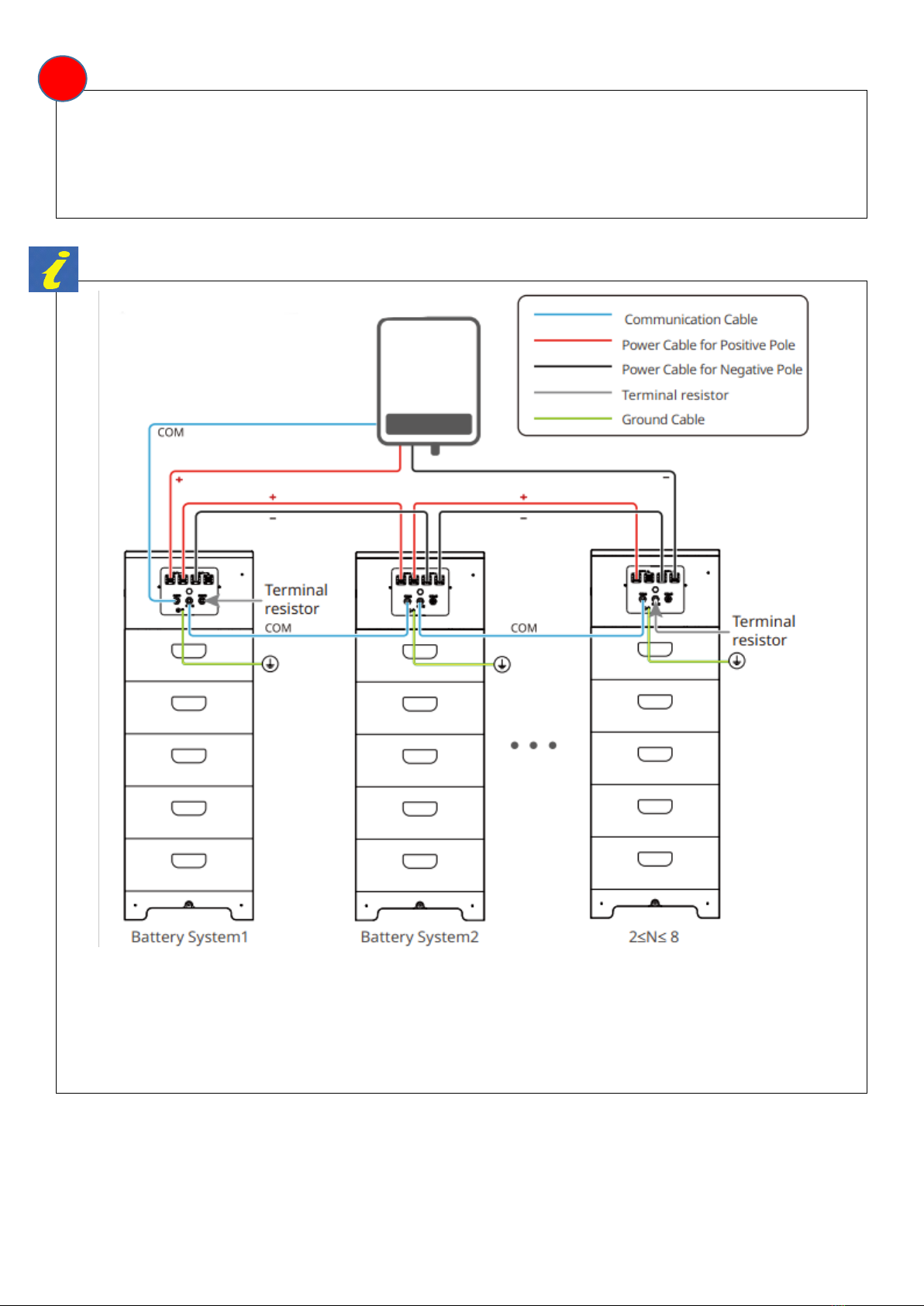

Battery - Inverter Wiring Diagrams

4

16

ET Series Inverters

Refer to the relevant ET Series Inverter manual for further information,

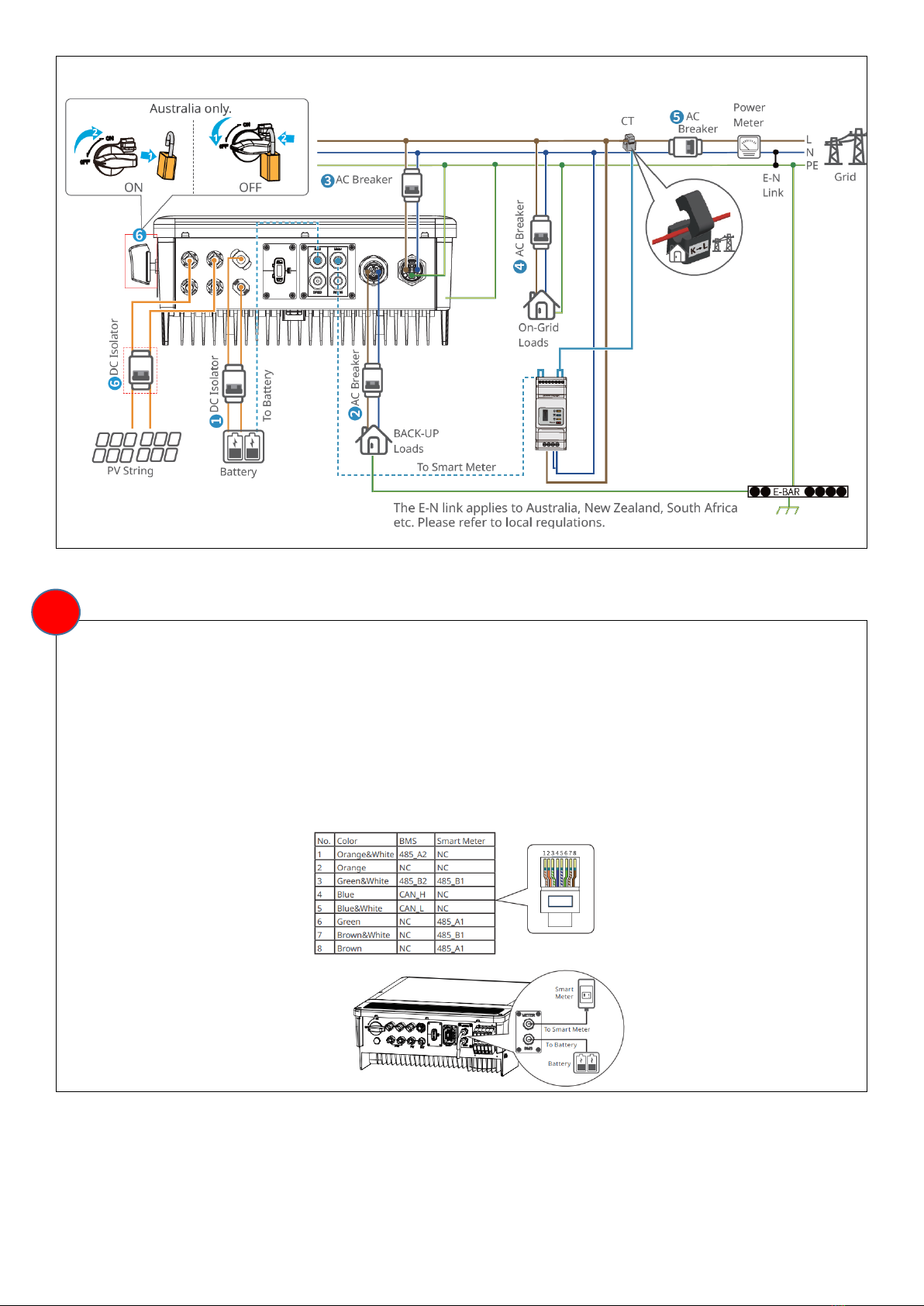

GEH Series Inverters

17

EH Series Inverters

Communication Cable Wiring

INVERTER

Communication cables to the Battery (CAN COM) and the Smart Meter (RS-485) are pre-installed at the

inverter. Check all connections prior to installation.

All communication cabling between inverter, battery and metering shall be mechanically protected to

prevent damage from vermin and tampering from unauthorised users.

ET Series

5

18

GEH and EH Series

BATTERY

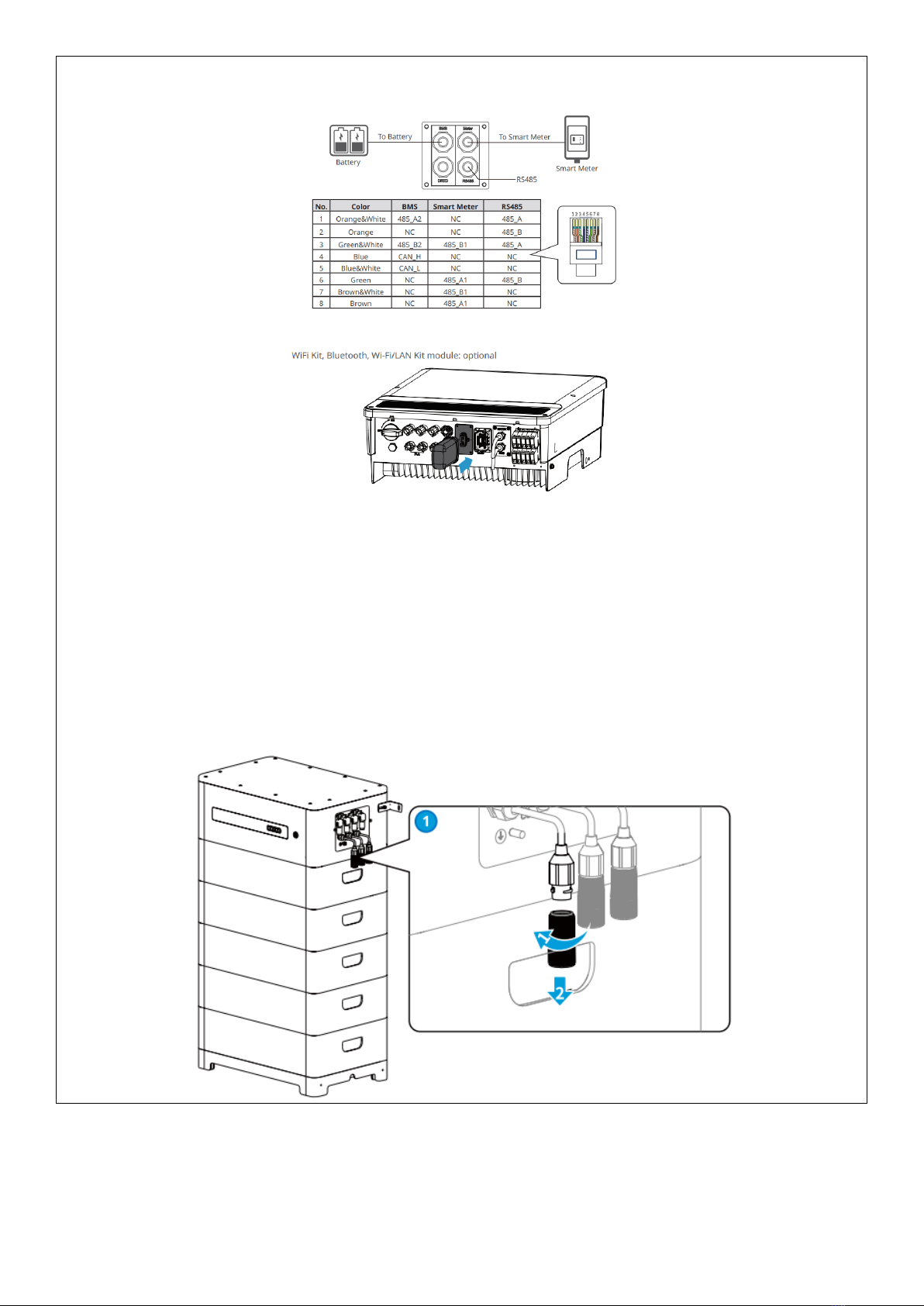

Connecting the Communication Cable

•Do not use RJ45 cable with protective cover.

•When one battery is applied, connect one communication cable to the inverter by RJ45 connector

and connect the other cable to the terminal resistance.

•When multiple batteries are applied, connect the communication ports in series using net cables.

Connect one communication cable of the last battery to the terminal resistance.

1. Remove the waterproof module.

19

2. Route the cable through the waterproof module.

3. Crimp the RJ45 Registered Jack.

4. Secure the back cover.

5. Connect the communication cable and the terminal resistance to the battery.

20

6. Secure the cover.

METER

Follow instructions from GoodWe ET, EH and GEH User Manual to connect the communication cable from

the Inverter.

Note: Check the communication cables to ensure the insulation is rated for the highest voltage present

inside the switchboard. Additional insulation may be required.

Note: If extension of communication cable is required, a female RJ45 joiner may be used to avoid crimping

the connector.

Warning: If extension of communication cable is required, ensure cable joints are adequately

protected from moisture.

Warning: Ensure all communication cables are adequately protected against mechanical

damage.

DC and AC Cable Wiring

Refer to the wiring diagrams on page 12.

Warning: Ensure all DC and AC cables are adequately protected against vermin and other

damage.

Warning: Ensure in-built DC isolator is switched OFF prior to wiring.

Note: Ensure the conductors on all cable ends are consolidated (e.g. using bootlace) before termination.

BATTERY

Connect DC cable and earthing wire according to the instructions in GoodWe Lynx F-Series Operating

Manual.

6

This manual suits for next models

12

Table of contents