Solahart HSL60P6-PB-1-250 Technical Document

Solahart PV Systems must be installed and serviced by a suitably qualified person.

Please leave this guide with the PV system owner.

Owner’s Guide

and

Installation Instructions

Single-Phase PV Systems

PATENTS

This PV System may be protected by one or more patents or registered designs in the name of

Solahart Industries Pty Ltd.

TRADE MARKS

® Registered trademark of Solahart Industries Pty Ltd.

™ Trademark of Solahart Industries Pty Ltd.

Note: E ery care has been taken to ensure accuracy in preparation of this publication.

No liability can be accepted for any consequences, which may arise as a result of its application.

Warning: For continued safety of this PV System, it must be installed, operated and maintained in

accordance with these instructions and the installation guide supplied with the PV inverter.

Caution: Only qualified and accredited personnel should perform work on PV systems, such as design,

installation, commissioning, maintenance and repairs. e sure to follow the safety instructions for all system

components. It is also important to observe relevant local codes and regulations for health and safety and

accident prevention.

Only Solahart parts and Solahart approved parts may be used. No substitute parts may be used

without prior approval from Solahart Industries Pty Ltd. Only parts supplied by Solahart Industries

Pty Ltd are overed by the Solahart warranty.

The warranty an be ome void if safety devi es are tampered with or if the installation is not in

a ordan e with these instru tions.

ABOUT YOUR PV SYSTEM

3

CONTENTS

PV SYSTEM OWNER – We recommend you read pages 4 to 7.

The other pages are intended for the installer but may be of interest.

Contents .......................................................................................................................................

About Your PV System ............................................................................................................... 4

Operating Procedures ................................................................................................................. 5

Electrical Safety ........................................................................................................................... 5

Periodic Maintenance ................................................................................................................. 6

Wiring Diagrams .......................................................................................................................... 8

Installation Overview ................................................................................................................ 19

Installation Procedure ............................................................................................................... 21

Installation - Planning ............................................................................................................... 22

Installation - Racking ................................................................................................................ 27

Installation - Wiring ................................................................................................................... 4

Installation - Rooftop Isolator .................................................................................................. 6

Installation - PV Modules .......................................................................................................... 7

Installation - Inverter ................................................................................................................. 42

Installation - Labelling .............................................................................................................. 46

Installation - Commissioning ................................................................................................... 48

Engineering Certification .......................................................................................................... 5

Solahart PV System Warranty - Australia Only ...................................................................... 55

4

ABOUT YOUR PV SYSTEM

MODEL TYPE

Your Solahart PV System is designed for the polycrystalline photovoltaic modules to be roof and/or stand

mounted with the inverter installed in a serviceable position and connected to the electrical distribution grid

(often referred to as ‘the grid’) as per AS 4777.1. These instructions together with the installation instructions

supplied with the inverter give limitations on positioning of the inverter.

This Owner’s Guide and Installation Instructions applies to the following PV modules:

HSL60P6-P -1-250 (250 W module) REC255PE (255 W module)

Note: Unless approved otherwise by Solahart, only modules of the same make and model may be used in

Solahart PV systems.

SYSTEM OPERATION

The Solahart PV System is comprised of two main components; a string or array of photovoltaic modules

and an inverter.

The photovoltaic (PV) modules transform solar radiation into electrical energy in the form of direct current

(DC). In order to utilise this energy and feed it back into the grid, the direct current is transformed into

alternating current (AC) by the inverter. This conversion is also known as DC to AC inversion.

The alternating current generated by the inverter is fed into the main switchboard, which in turn is connected

to the grid.

Note: For safety reasons, the inverter will only operate when the mains electrical supply is available from the

grid. Your Solahart PV System cannot provide a backup electricity supply to your home appliances if the

mains supply is interrupted.

If the energy generated by the PV System is not sufficient to meet domestic demands, the energy necessary

to ensure the standard operation of the connected devices is drawn from the grid.

If the energy generated exceeds that required by property demands, your electrical network operator may

allow the difference to be directly injected into the grid and become available to other users. Energy injected

into the grid can be measured by electricity network operators as either gross (everything generated) or net

(excess generated). Injected energy may or may not be purchased by the local electrical network operator

according to national and local standards, and regulations.

SYSTEM OVERVIEW

• A photovoltaic module is composed of many photovoltaic cells assembled on the same frame.

• A string is composed of a certain number of modules electrically connected in series.

• An array is composed of one or more strings connected in parallel.

• The inverter converts direct current produced by the array into alternating current.

• The PV Array DC Isolators provide a means for isolating the array.

• The Inverter AC Isolator provides overcurrent protection of the inverter and a method of isolating the PV

System from the electrical distribution grid.

Warning: For the inverter to be effectively electrically isolated, both the PV Array DC Isolator(s) and the

Inverter AC Isolator(s) must be in the OFF position.

5

OPERATING PROCEDURES

TO TURN PV SYSTEM ON

1. Turn on the PV Array DC Isolator(s) at the inverter.

2. Then turn on the Inverter AC Isolator at the inverter (if installed) and the Solar Supply Main Switch at the

AC switchboard.

TO TURN PV SYSTEM OFF

1. Turn off the Solar Supply Main Switch at the AC switchboard and the Inverter AC Isolator at the inverter

(if installed).

2. Then turn off the PV Array DC Isolator(s) at the inverter.

Warning: Depending upon the system there may be more than one PV Array DC Isolator.

Warning: To effectively isolate the wiring between the AC isolator and switchboard, the Solar Supply

Main Switch located in the switchboard must also be in the off position.

Warning: PV array DC isolators do not de-energise the PV array and array cabling.

ACTIONS TO UNDERTAKE IN THE EVENT OF AN EARTH FAULT ALARM

1. Limit access to all parts of the PV system

2. Contact Solahart Service on 1800 638 011 or your nearest Solahart dealer.

ELECTRICAL SAFETY

SAFETY REQUIREMENTS

The voltages and currents produced by a single module or modules connected in series (voltages are added

together) or in parallel (currents are added together) can be dangerous.

Note: Only qualified personnel should perform work on photovoltaic systems.

UNIQUE HAZARDS OF DC ELECTRICITY

PV modules generate DC electricity as soon as they are exposed to sunlight. Once the current is flowing,

breaking or opening a connection (e.g. disconnecting a DC cable from the inverter) can cause a DC

electrical arc. Unlike arcs occurring in conventional low voltage AC wiring, DC arcs are not self-extinguishing.

They are a potentially lethal burn and fire hazard, capable of creating high temperatures that can destroy

contacts and connectors.

EARTH FAULTS

An earth fault is a system fault where a short circuit is formed between the DC circuitry of the PV system and

earth. As the PV system owner, please be aware of the current method of communication of earth faults on

your system. Refer to Earth Fault Alarms on page 44 for details.

6

PERIODIC MAINTENANCE

GENERAL

Due to the safety concerns involved with working at heights and working with electricity, we recommend the

householder follow the maintenance schedule provided below. Other maintenance should be performed by a

suitably qualified person, such as a CEC accredited installer. ustralian Standard S/NZS 5033 provides a

recommended maintenance schedule for PV systems.

Modules supplied by Solahart have been designed for easy maintenance. Normal rainfall should naturally

clean the modules. The need for cleaning will vary with the location of the installation, amount of rainfall,

pollution and inclination of the modules.

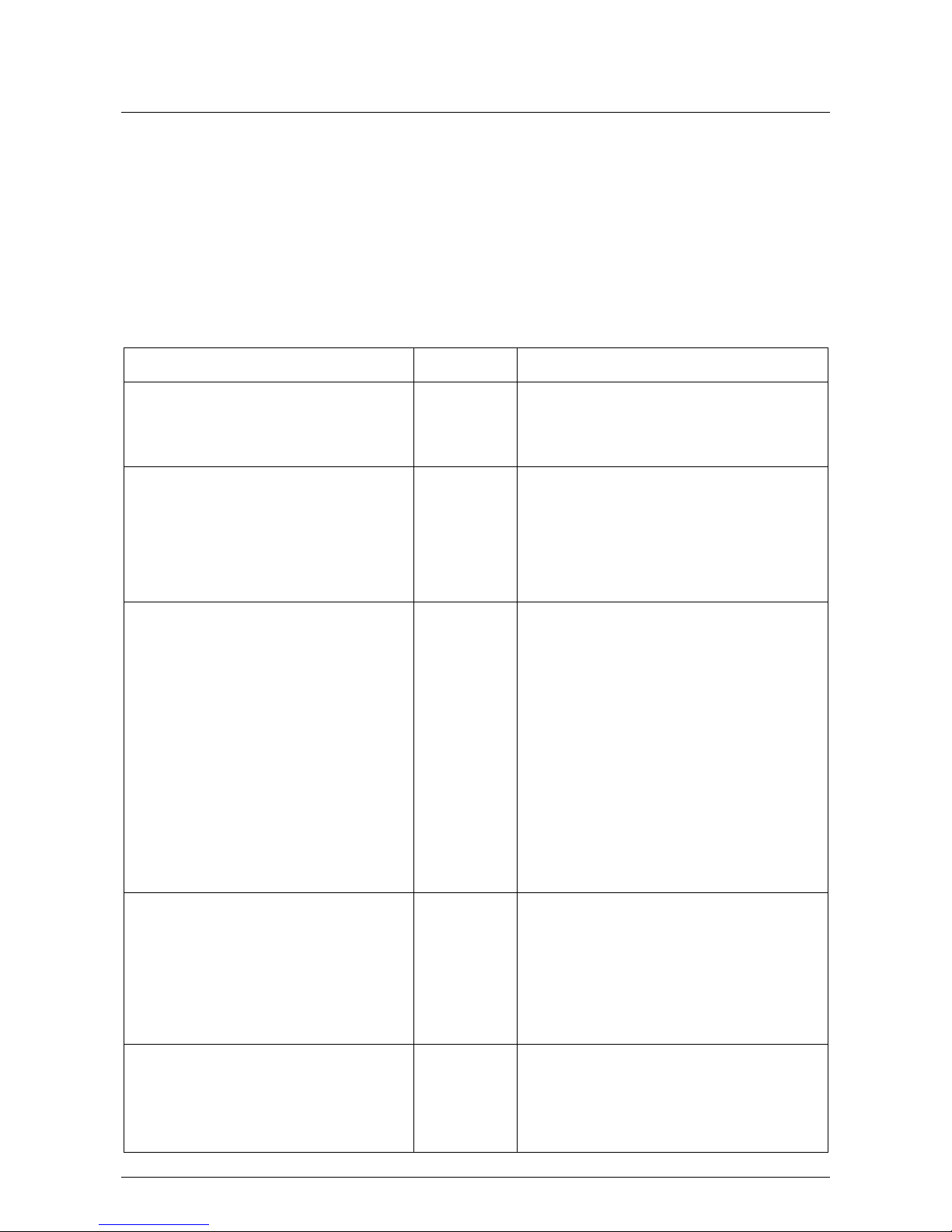

RECOMMENDED MAINTENANCE SCHEDULE

Maintenance Action Frequency Remarks

Under daylight conditions check that your

inverter is operating correctly (refer to the

Inverter Manufacturer’s manual for

details).

Weekly If not operating correctly, contact your

Solahart dealer.

If you have a communications device

installed, such as the SM Webconnect or

BB Wi-Fi logger card, log in to your

inverter manufacturer’s web portal and

check that your system is operating, data

has been logged and communication has

been maintained.

Monthly If you are unable to log in or your system is

not operating correctly, contact your Solahart

dealer.

Visual inspection of PV system

components from ground level, to check

for:

Quarterly

• ccumulation of debris around

components.

Gently remove debris from components that

are safely accessible from ground level.

• Shading of the array. Trim trees, if required.

• Visible damage to any components. Contact your Solahart dealer.

• Cleanliness of PV modules. To optimize electrical output, it is

recommended that the modules are cleaned

when dirt can be seen on the glass surface.

Please contact your Solahart dealer to

arrange module cleaning.

If you have a communications device

installed, such as the SM Webconnect or

BB Wi-Fi logger card, log in to your

inverter manufacturer’s web portal and

ensure that the contact details of the PV

system owner or responsible officer are up

to date to ensure that inverter fault

notifications are delivered.

Quarterly If you are unable to log in, contact your

Solahart dealer.

Contact a suitably qualified person, such

as a CEC accredited installer, to inspect

the system.

Yearly This inspection can be arranged through your

Solahart dealer, and should ensure that:

• Inverter’s ventilation filters and fans are

cleaned.

• ll fastenings are tight, secure and free

PERIODIC MAINTENANCE

7

of corrosion.

• ll cable connections are tight, secure

and free of corrosion.

• Cables are not damaged in any way.

• Earthing of the modules and module rails

is satisfactory.

• Electrical characteristics are within

specification.

• The C and DC isolator/circuit breakers

function correctly.

8

WIRING DIAGRAMS

SB 1.5-1 VL-40 INVERTER SYSTEMS

Number

of

Modules

Number

of

Strings

Modules

per

String

HSL60P6-PB-1-250 Modules REC255PE Modules

System Power

Rating (W) * Isc ( )*

Voc (V)*

System Power

Rating (W) * Isc ( )* Voc (V)*

4 1 4 1000 8.79 150.8 1020 8.95 150.4

5 1 5 1250 8.79 188.5 1275 8.95 188.0

6 1 6 1500 8.79 226.2 1530 8.95 225.6

7 1 7 1750 8.79 263.9 1785 8.95 263.2

* Values measured at standard test conditions (STC) defined as: irradiance of 1000 W/m2, Spectrum M 1.5

and cell temperature 25ºC. Variations from STC values will affect actual Isc and Voc and should be allowed

for.

For earthing arrangement and wiring diagram refer to “Earthing rrangements – ll Systems” on page 18.

WIRING DIAGRAMS

9

SB1600TL-10 INVERTER SYSTEMS

Number

of

Modules

Number

of

Strings

Modules

per

String

HSL60P6-P -1-250 Modules REC255PE Modules

System Power

Rating (W) * Isc (A)*

Voc (V)*

System Power

Rating (W) * Isc (A)* Voc (V)*

6 1 6 1500 8.79 226.2 1530 8.95 225.6

7 1 7 1750 8.79 263.9 1785 8.95 263.2

* Values measured at standard test conditions (STC) defined as: irradiance of 1000 W/m2, Spectrum AM 1.5

and cell temperature 25ºC. Variations from STC values will affect actual Isc and Voc and should be allowed

for.

For earthing arrangement and wiring diagram refer to “Earthing Arrangements – All Systems” on page 18

WIRING DIAGRAMS

10

UNO-2.0-I-OUTD

Number

of

Modules

Number

of

Strings

Modules

per

String

HSL60P6-P -1-250 Modules REC255PE Modules

System Power

Rating (W) * Isc (A)*

Voc (V)*

System Power

Rating (W) * Isc (A)* Voc (V)*

6 1 6 1500 8.79 226.2 1530 8.95 225.6

7 1 7 1750 8.79 263.9 1785 8.95 263.2

8 1 8 2000 8.79 301.6 2040 8.95 300.8

9 1 9 2250 8.79 339.3 2295 8.95 338.4

10 1 10 2500 8.79 377.0 2550 8.95 376.0

* Values measured at standard test conditions (STC) defined as: irradiance of 1000 W/m2, Spectrum AM 1.5

and cell temperature 25ºC. Variations from STC values will affect actual Isc and Voc and should be allowed

for.

For earthing arrangement and wiring diagram refer to “Earthing Arrangements – All Systems” on page 18.

WIRING DIAGRAMS

11

SB 2.5-1 VL-40 INVERTER SYSTEMS

Number

of

Modules

Number

of

Strings

Modules

per

String

HSL60P6-PB-1-250 Modules REC255PE Modules

System Power

Rating (W) * Isc ( )*

Voc (V)*

System Power

Rating (W) * Isc ( )* Voc (V)*

7 1 7 1750 8.79 263.9 1785 8.95 263.2

8 1 8 2000 8.79 301.6 2040 8.95 300.8

9 1 9 2250 8.79 339.3 2295 8.95 338.4

10 1 10 2500 8.79 377.0 2550 8.95 376.0

11 1 11 2750 8.79 414.7 2805 8.95 413.6

12 1 12 3000 8.79 452.4 3060 8.95 451.2

13 1 13 3250 8.79 490.1 3315 8.95 488.8

* Values measured at standard test conditions (STC) defined as: irradiance of 1000 W/m2, Spectrum M 1.5

and cell temperature 25ºC. Variations from STC values will affect actual Isc and Voc and should be allowed

for.

For earthing arrangement and wiring diagram refer to “Earthing rrangements – ll Systems” on page 18.

WIRING DIAGRAMS

12

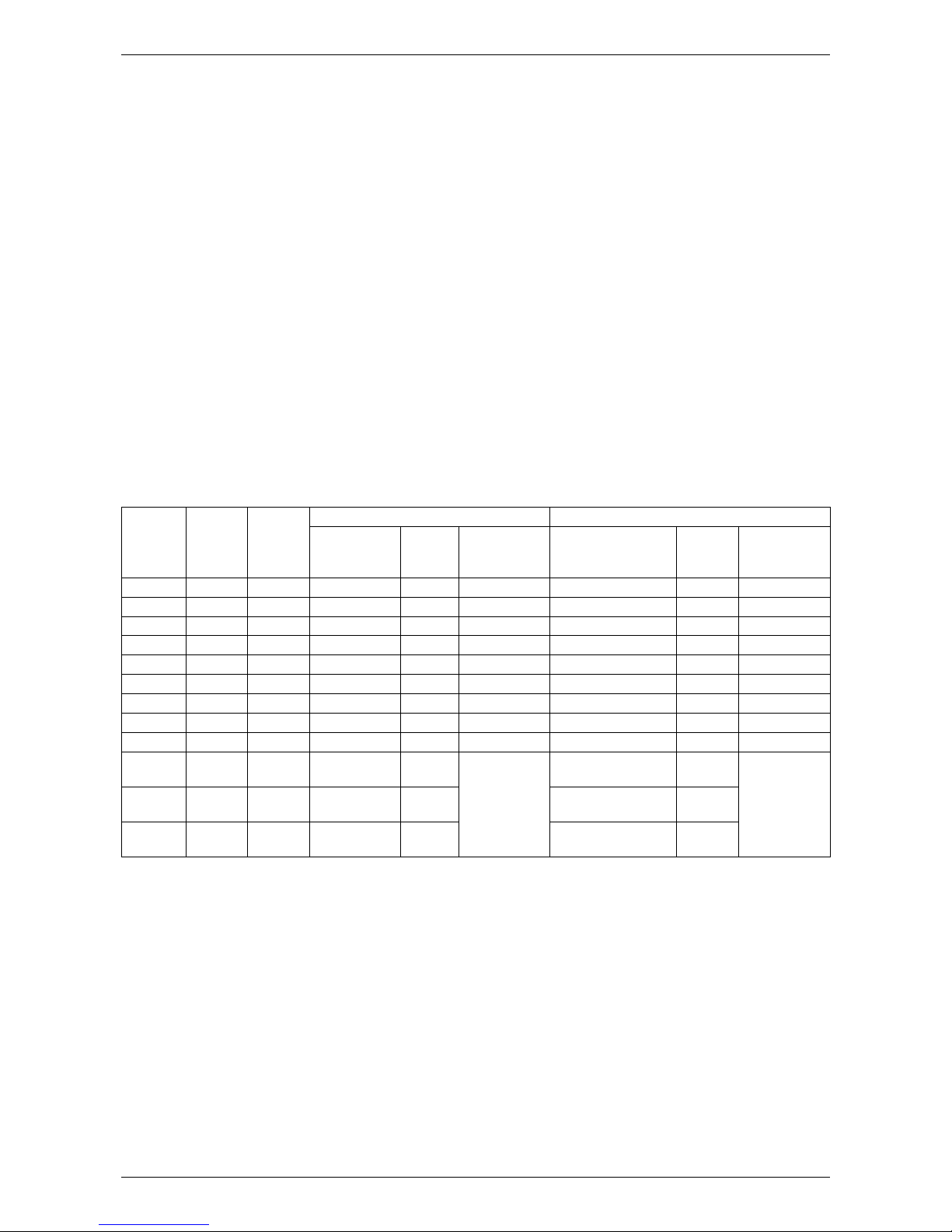

PVI-3.0-TL-OUTD INVERTER SYSTEMS

Number

of

Modules

Number

of

Strings

Modules

per

String

HSL60P6-P -1-250 Modules REC255PE Modules

System Power

Rating (W) * Isc (A)* Voc (V)* System Power

Rating (W) * Isc (A)* Voc (V)*

5 1 5 1250 8.79 188.5 1275 8.95 188.0

6 1 6 1500 8.79 226.2 1530 8.95 225.6

7 1 7 1750 8.79 263.9 1785 8.95 263.2

8 1 8 2000 8.79 301.6 2040 8.95 300.8

9 1 9 2250 8.79 339.3 2295 8.95 338.4

10 1 10 2500 8.79 377.0 2550 8.95 376.0

11 1 11 2750 8.79 414.7 2805 8.95 413.6

12 1 12 3000 8.79 452.4 3060 8.95 451.2

13 1 13 3250 8.79 490.1 3315 8.95 488.8

14 1 14 3500 8.79 527.8 3570 8.95 526.4

10 2 5 + 5 2500 8.79

Refer to string voltages

listed above

2550 8.95

Refer to string voltages

listed above

11 2 5 + 6 2750 8.79 2805 8.95

12 2 5 + 7

6 + 6 3000 8.79 3060 8.95

13 2 5 + 8

6 + 7 3250 8.79 3315 8.95

14 2

5 + 9

6 + 8

7 + 7

3500 8.79 3570 8.95

* Values measured at standard test conditions (STC) defined as: irradiance of 1000 W/m2, Spectrum AM 1.5

and cell temperature 25ºC. Variations from STC values will affect actual Isc and Voc and should be allowed

for.

For earthing arrangement and wiring diagram refer to “Earthing Arrangements – All Systems” on page 18.

WIRING DIAGRAMS

13

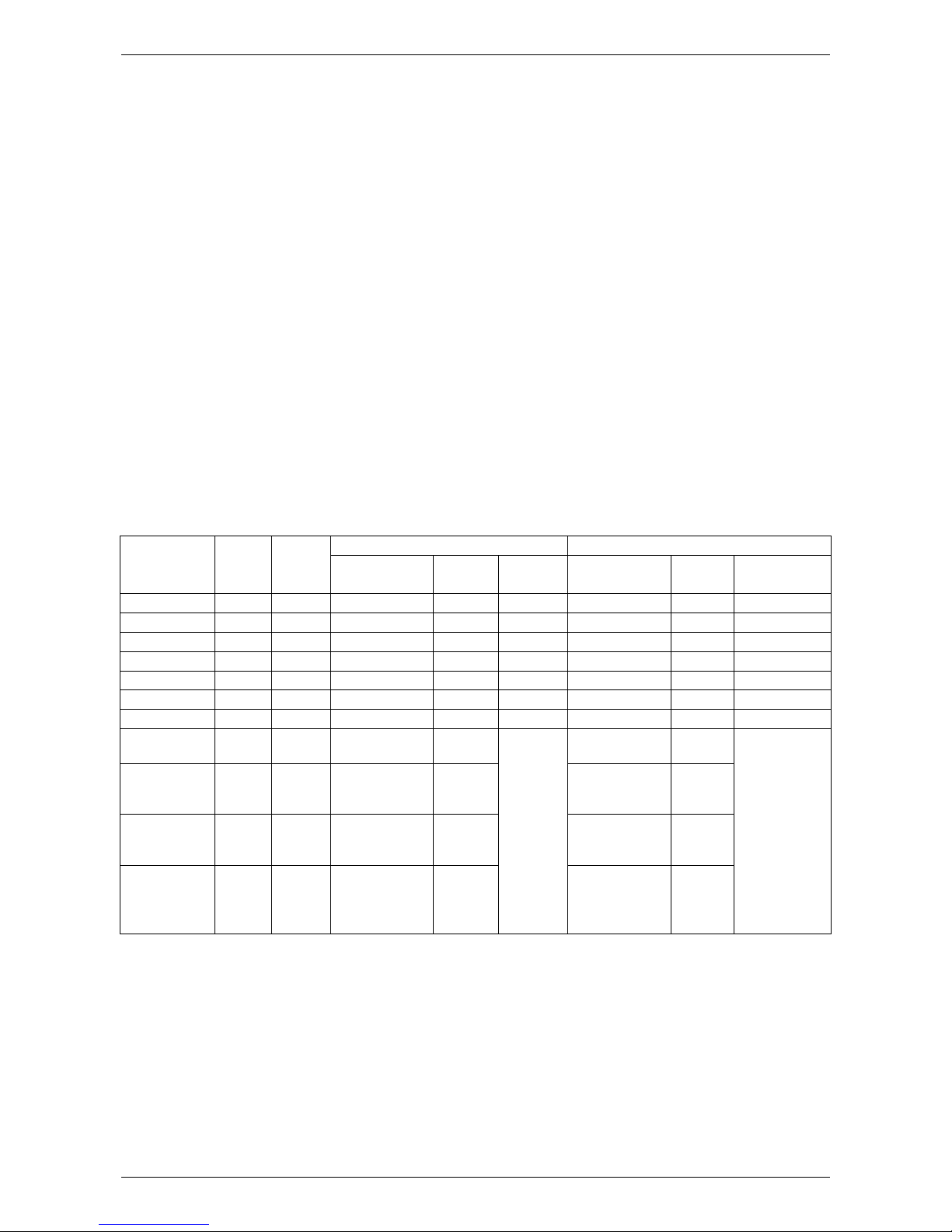

SB3000TL-21 INVERTER SYSTEMS

Number

of

Modules

Number

of

Strings

Modules

per

String

HSL60P6-P -1-250 Modules REC255PE Modules

System

Power

Rating (W) *

Isc (A)* Voc (V)* System Power

Rating (W) * Isc (A)* Voc (V)*

6 1 6 1500 8.79 226.2 1530 8.95 225.6

7 1 7 1750 8.79 263.9 1785 8.95 263.2

8 1 8 2000 8.79 301.6 2040 8.95 300.8

9 1 9 2250 8.79 339.3 2295 8.95 338.4

10 1 10 2500 8.79 377.0 2550 8.95 376.0

11 1 11 2750 8.79 414.7 2805 8.95 413.6

12 1 12 3000 8.79 452.4 3060 8.95 451.2

13 1 13 3250 8.79 490.1 3315 8.95 488.8

14 1 14 3500 8.79 527.8 3570 8.95 526.4

12 2 6 + 6 3000 8.79

Refer to

string

voltages

listed above

3060 8.95

Refer to

string

voltages

listed above

13 2 6 + 7 3250 8.79 3315 8.95

14 2 6 + 8

7 + 7 3500 8.79 3570 8.95

* Values measured at standard test conditions (STC) defined as: irradiance of 1000 W/m2, Spectrum AM 1.5

and cell temperature 25ºC. Variations from STC values will affect actual Isc and Voc and should be allowed

for.

For earthing arrangement and wiring diagram refer to “Earthing Arrangements – All Systems” on page 18.

WIRING DIAGRAMS

14

SB 000TL-21 INVERTER SYSTEMS

Number of

Modules

Number

of

Strings

Module

s

per

String

HSL60P6-P -1-250 Modules REC255PE Modules

System Power

Rating (W) * Isc (A)* Voc (V)* System Power

Rating (W) * Isc (A)* Voc (V)*

6 1 6 1500 8.79 226.2 1530 8.95 225.6

7 1 7 1750 8.79 263.9 1785 8.95 263.2

8 1 8 2000 8.79 301.6 2040 8.95 300.8

9 1 9 2250 8.79 339.3 2295 8.95 338.4

10 1 10 2500 8.79 377.0 2550 8.95 376.0

11 1 11 2750 8.79 414.7 2805 8.95 413.6

12 1 12 3000 8.79 452.4 3060 8.95 451.2

15 2 6 + 9

7 + 8 3750 8.79

Refer to string voltages

listed above

3825 8.95

Refer to string voltages

listed above

16 2

6 + 10

7 + 9

8 + 8

4000 8.79 4080 8.95

17 2

6 + 11

7 + 10

8 + 9

4250 8.79 4335 8.95

18 2

6 + 12

7 + 11

8 + 10

9 + 9

4500 8.79 4590 8.95

* Values measured at standard test conditions (STC) defined as: irradiance of 1000 W/m2, Spectrum AM 1.5

and cell temperature 25ºC. Variations from STC values will affect actual Isc and Voc and should be allowed

for.

For earthing arrangement and wiring diagram refer to “Earthing Arrangements – All Systems” on page 18.

WIRING DIAGRAMS

15

PVI- .2-TL-OUTD INVERTER SYSTEMS

Number of

Modules

Number

of

Strings

Modules

per

String

HSL60P6-P -1-250 Modules REC255PE Modules

System Power

Rating (W) * Isc (A)* Voc (V)* System Power

Rating (W) * Isc (A)* Voc (V)*

5 1 5 1250 8.79 188.5 1275 8.95 188.0

6 1 6 1500 8.79 226.2 1530 8.95 225.6

7 1 7 1750 8.79 263.9 1785 8.95 263.2

8 1 8 2000 8.79 301.6 2040 8.95 300.8

9 1 9 2250 8.79 339.3 2295 8.95 338.4

10 1 10 2500 8.79 377.0 2550 8.95 376.0

11 1 11 2750 8.79 414.7 2805 8.95 413.6

12 1 12 3000 8.79 452.4 3060 8.95 451.2

13 1 13 3250 8.79 490.1 3315 8.95 488.8

15 2

5 + 10

6 + 9

7 + 8

3750 8.79

Refer to string voltages

listed above

3825 8.95

Refer to string voltages

listed above

16 2

5 + 11

6 + 10

7 + 9

8 + 8

4000 8.79 4080 8.95

17 2

5 + 12

6 + 11

7 + 10

8 + 9

4250 8.79 4335 8.95

18 2

5 + 13

6 + 12

7 + 11

8 + 10

9 + 9

4500 8.79 4590 8.95

* Values measured at standard test conditions (STC) defined as: irradiance of 1000 W/m2, Spectrum AM 1.5

and cell temperature 25ºC. Variations from STC values will affect actual Isc and Voc and should be allowed

for.

For earthing arrangement and wiring diagram refer to “Earthing Arrangements – All Systems” on page 18.

WIRING DIAGRAMS

16

PVI-5000-TL-OUTD INVERTER SYSTEMS

Number

of

Modules

Number

of

Strings

Modules

per

String

HSL60P6-P -1-250 Modules REC255PE Modules

System Power

Rating (W) * Isc (A)* Voc (V)* System Power

Rating (W) * Isc (A)* Voc (V)*

5 1 5 1250 8.79 188.5 1275 8.95 188.0

6 1 6 1500 8.79 226.2 1530 8.95 225.6

7 1 7 1750 8.79 263.9 1785 8.95 263.2

8 1 8 2000 8.79 301.6 2040 8.95 300.8

9 1 9 2250 8.79 339.3 2295 8.95 338.4

10 1 10 2500 8.79 377.0 2550 8.95 376.0

11 1 11 2750 8.79 414.7 2805 8.95 413.6

12 1 12 3000 8.79 452.4 3060 8.95 451.2

13 1 13 3250 8.79 490.1 3315 8.95 488.8

14 1 14 3500 8.79 527.8 3570 8.95 526.4

18 2

5 + 13

6 + 12

7 + 11

8 + 10

9 + 9

4500 8.79

Refer to string voltages

listed above

4590 8.95

Refer to string voltages

listed above

19 2

5 + 14

6 + 13

7 + 12

8 + 11

9 + 10

4750 8.79 4845 8.95

20 2

6 + 14

7 + 13

8 + 12

9 + 11

10 + 10

5000 8.79 5100 8.95

21 2

7 + 14

8 + 13

9 + 12

10 + 11

5250 8.79 5355 8.95

22 2

8 + 14

9 + 13

10 + 12

11 + 11

5500 8.79 5610 8.95

* Values measured at standard test conditions (STC) defined as: irradiance of 1000 W/m2, Spectrum AM 1.5

and cell temperature 25ºC. Variations from STC values will affect actual Isc and Voc and should be allowed

for.

For earthing arrangement and wiring diagram refer to “Earthing Arrangements – All Systems” on page 18.

WIRING DIAGRAMS

17

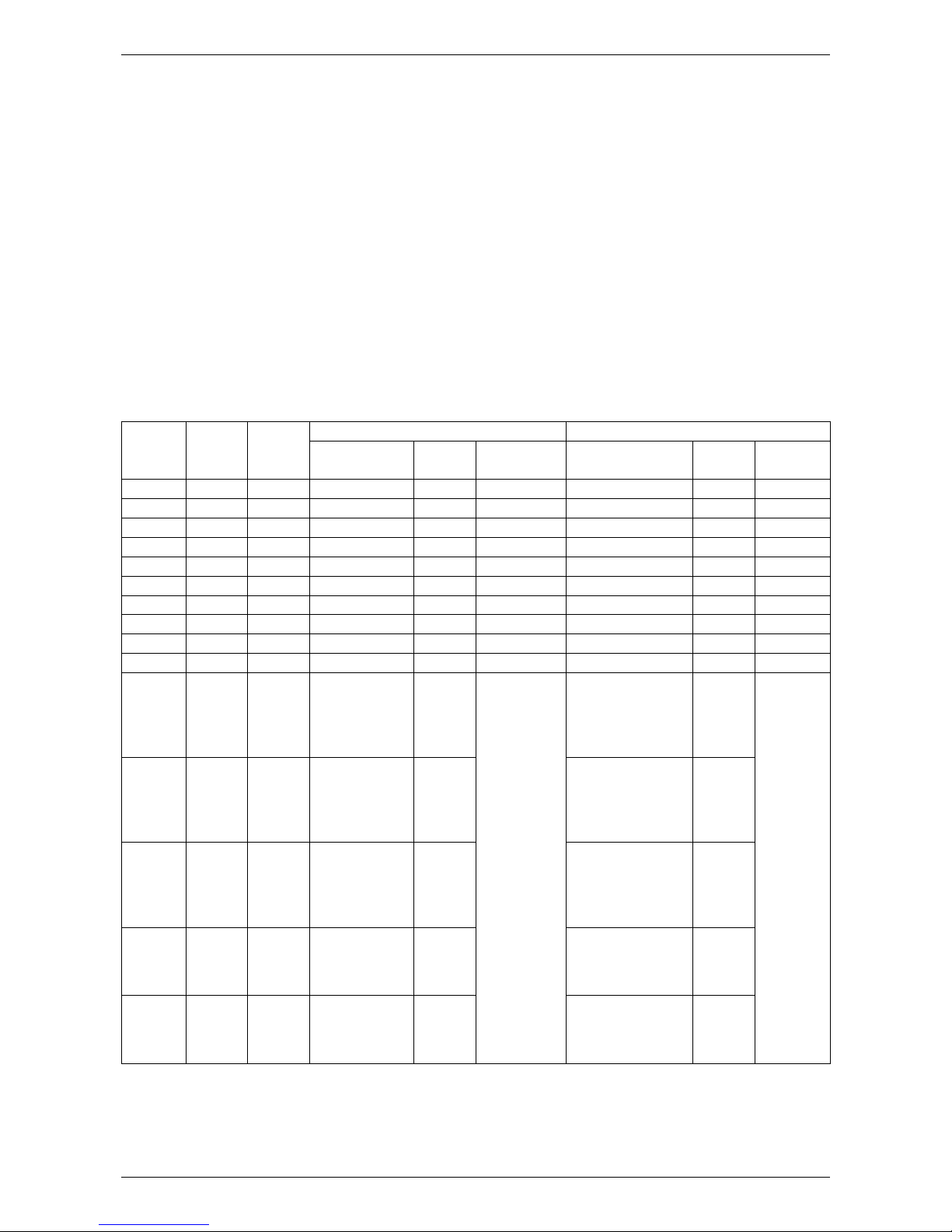

SB5000TL-21 INVERTER SYSTEMS

Number

of

Modules

Number

of

Strings

Modules

per

String

HSL60P6-P -1-250 Modules REC255PE Modules

System Power

Rating (W) * Isc (A)* Voc (V)* System Power

Rating (W) * Isc (A)* Voc (V)*

6 1 6 1500 8.79 226.2 1530 8.95 225.6

7 1 7 1750 8.79 263.9 1785 8.95 263.2

8 1 8 2000 8.79 301.6 2040 8.95 300.8

9 1 9 2250 8.79 339.3 2295 8.95 338.4

10 1 10 2500 8.79 377.0 2550 8.95 376.0

11 1 11 2750 8.79 414.7 2805 8.95 413.6

12 1 12 3000 8.79 452.4 3060 8.95 451.2

13 1 13 3250 8.79 490.1 3315 8.95 488.8

14 1 14 3500 8.79 527.8 3570 8.95 526.4

18 2

6 + 12

7 + 11

8 + 10

9 + 9

4500 8.79

Refer to string voltages

listed above

4590 8.95

Refer to string voltages

listed above

19 2

6 + 13

7 + 12

8 + 11

9 + 10

4750 8.79 4845 8.95

20 2

6 + 14

7 + 13

8 + 12

9 + 11

10 + 10

5000 8.79 5100 8.95

21 2

7 + 14

8 + 13

9 + 12

10 + 11

5250 8.79 5355 8.95

22 2

8 + 14

9 + 13

10 + 12

11 + 11

5500 8.79 5610 8.95

* Values measured at standard test conditions (STC) defined as: irradiance of 1000 W/m2, Spectrum AM 1.5

and cell temperature 25ºC. Variations from STC values will affect actual Isc and Voc and should be allowed

for.

For earthing arrangement and wiring diagram refer to “Earthing Arrangements – All Systems” on page 18.

WIRING DIAGRAMS

18

EARTHING ARRANGEMENTS – ALL SYSTEMS

Earthing connections must be made so the removal of one component (e.g. a module) does not interrupt the

earthing to other parts of a system (e.g. other modules). Daisy chaining is not permitted. The PV system

earth connection must be directly connected to the switchboard earth link, not via the inverter earth

connection. If the earth cable could be exposed to direct sunlight, it must have a physical barrier to protect

the earth cable from this exposure.

Earth wires must be sized in accordance with requirements set out in Earthing and bonding arrangements of

AS/NZS 5033.

Solahart approved earthing plates may be used to earth modules via the racking, instead of wiring directly to

the module frames. Refer to “Earthing” on page 38 for more information.

Warning: Do not drill holes in the modules as this will void product warranty.

The racking may be earthed by means of a rooftop isolator bracket. Refer to “Installation - Rooftop Isolator”

on page 36 for details.

Where it is necessary to make an earthing connection to a rail that does not have a rooftop isolator bracket

fitted, a rail splice piece will provide a suitable surface for connection. In this case, the splice should be

attached to the end of the rail using both fixing bolts, and then the earth lug connected to the splice as shown

in the figures below:

1. Slide rail splice onto end of rail, ensuring an overhang of approximately 50 mm.

2. Secure rail splice by tightening both Allen head bolts to 15 Nm.

3. Drill a hole in the centre of the rail splice, attach the earth cable using the earthing set supplied, and

tighten to 5 Nm.

Rail splice attached to rail with

both Allen head bolts

Earth cable connected to splice

19

INSTALLATION OVERVIEW

The following installation instructions detail installation procedures for photovoltaic modules, inverter, module

racking systems and balance of system (BOS) components.

Prior to the installation of any grid connected PV system, a Site Visit shall be performed in accordance with

the Clean Energy Council’s “Grid-Connected Solar PV Systems - Design Guidelines for ccredited

Installers”.

SAFETY REQUIREMENTS

The voltages and currents produced by a single module or modules connected in series (voltages added

together) or in parallel (currents added together) can be dangerous.

lthough module DC plug connectors are insulated to provide touch safe protection, the following points

must be observed when handling modules in order to avoid the risk of sparking, fire hazard, burn risk, and

lethal electric shocks:

• Exercise extreme caution when wiring modules and look out for damaged or split cable ends.

• Do not perform wiring work in rainy or damp conditions.

• Never insert metallic or otherwise conductive objects into plugs or sockets.

• Ensure that all electrical connections are completely dry and free from contaminants before they are

assembled.

• Ensure that connections are tight and correctly made.

• Keep all materials, tools and work areas clean and dry.

• lways use appropriate safety equipment such as insulated tools and wear personal protective

equipment such as insulated gloves.

• Solar modules produce current when exposed to sunlight. It is recommended that the system is shielded

with an opaque cover during installation, maintenance or repair work.

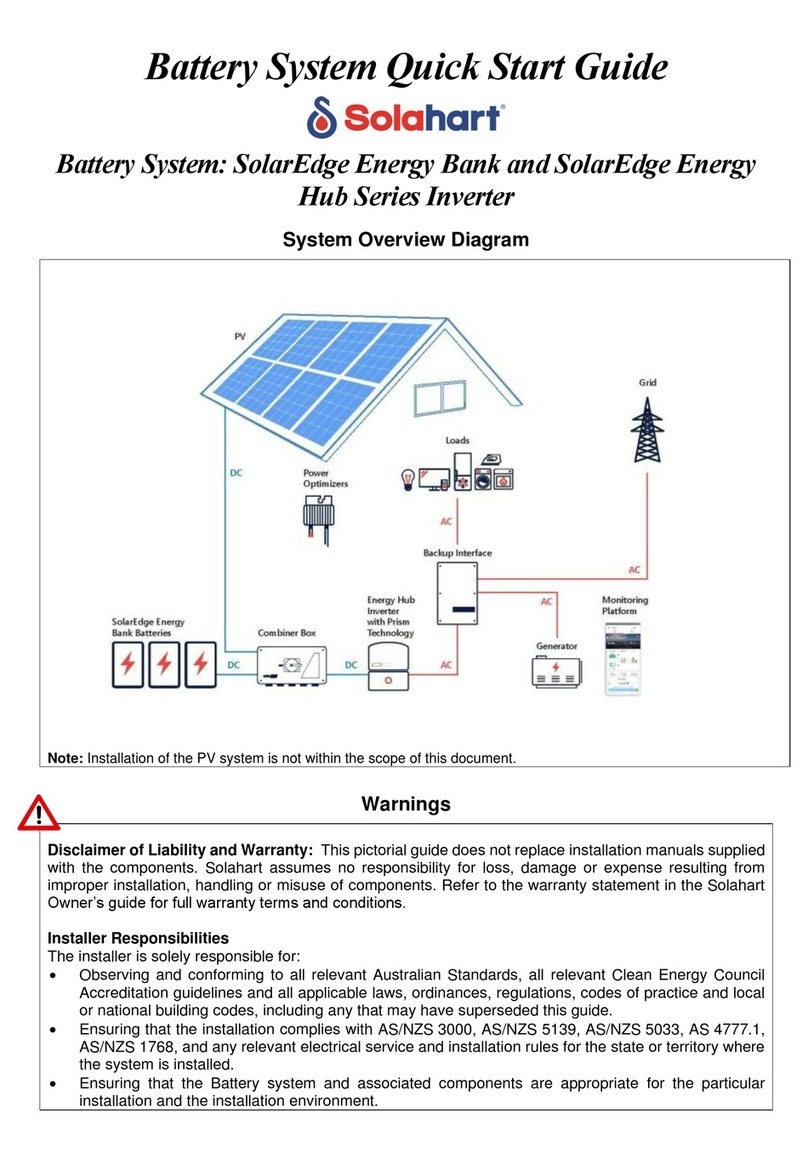

INSTALLER RESPONSIBILITIES

The installer is solely responsible for:

• Observing and conforming to all relevant ustralian Standards, all relevant Clean Energy Council

ccreditation guidelines and all applicable laws, ordinances, regulations, codes of practice and local or

national building codes, including any that may have superseded this Owner’s Guide & Installation

Instructions.

• Ensuring that the installation complies with S/NZS 3000, S/NZS 5033, S/NZS 1170.2, S/NZS

1562.1, S 4777.1, S/NZS 1768, S/NZS 3008, S 2050 and any relevant electrical service and

installation rules for the state or territory where the system is installed.

• Ensuring that the PV System and associated components are appropriate for the particular installation

and the installation environment.

• Ensuring that the roof, roof rafters, battens, purlins, connections, and other structural support members

can support the total assembly under building live load conditions. The roof on which the PV system is to

be installed must have the capacity to resist the combined Design Dead Load and Live Load at each

mounting point.

• Ensuring only parts supplied by Solahart Industries and installer supplied parts as specified by Solahart

Industries are utilised (substitution of parts may void the warranty and invalidate certification).

• Ensuring that lag screws have adequate pull-out strength and shear capacities to suit the installation.

• Maintaining the waterproof integrity of the roof, including selection of appropriate flashing.

• Ensuring safe installation of all electrical aspects of the PV system.

INSTALLATION OVERVIEW

20

DISCLAIMER OF LIABILITY AND WARRANTY

Solahart assumes no responsibility for loss, damage or expense resulting from improper installation,

handling or misuse of PV modules. Refer to “Solahart PV System Warranty - Australia Only” on page 55 for

full warranty terms and conditions.

IEC 61730 INFORMATION

Modules supplied by Solahart are designed to fulfil the criteria of application Class A requirements according

to IEC 61730. Modules are qualified for application Class A: Hazardous voltage (Higher than 50 V DC) and

hazardous power (higher than 240 W) applications where general contact access is anticipated. For the

purposes of AS/NZS 3000, modules are classified as Class I equipment.

FIRE GUIDELINES

Utilise the following fire safety guidelines when installing modules supplied by Solahart:

• Modules supplied by Solahart have a Class C Fire Rating.

• Check with local authorities for guidelines and requirements concerning fire safety for any building or

structure on to which the modules will be installed.

• The system design should ensure that fire fighting personnel can access the system in the event of a

building fire. Check with local authorities for any applicable regulations concerning setbacks or other

placement restrictions that may apply for roof-mounted PV arrays.

• Any electrical equipment can pose a fire risk. Modules must therefore be mounted over a fire retardant

roof covering rated for the application.

ENVIRONMENTAL FACTORS

Solahart’s limited warranty is based upon modules being installed in accordance with the following

conditions:

• Modules are not suitable for installation in potentially hazardous locations.

• Modules should not be installed in locations:

close to fire or combustible materials.

where there is potential for extreme sand and dust damage.

in direct contact with salt water/spray. Avoid installing in areas subject to high salt mist content e.g.

coastal areas.

exposed to extreme air pollution, chemical vapours, acid rain and/or soot, etc.

which experience extreme hail and/or snow.

where they may be exposed to sulphur e.g. near sulphur springs or volcanoes where they may be

exposed to harmful chemicals.

WARNINGS

Warning: This document provides sufficient information for system installation heights up to 10 m. If the

installation site is more than 10 m in height contact Solahart Industries for further advice.

Warning: This system has not been certified for, and should not be installed in, wind region D.

Warning: During installation and when working on the roof, be sure to observe the appropriate OH&S

safety regulations and relevant regulations of your local region.

Warning: Ensure electrical connection/ disconnection is performed only when the relevant circuit is

isolated. Do not connect / disconnect wiring under load conditions.

Warning: Do not expose the PV modules to artificially concentrated light.

Warning: Do not drill holes in the modules as this will void product warranty.

This manual suits for next models

1

Table of contents

Other Solahart Solar Panel manuals