Solahart SE3000H User manual

Battery System Quick Start Guide

Battery System: SolarEdge Energy Bank and SolarEdge Energy

Hub Series Inverter

System Overview Diagram

Note:Installation of the PV system is not within the scope of this document.

Warnings

Disclaimer of Liability and Warranty: This pictorial guide does not replace installation manuals supplied

with the components. Solahart assumes no responsibility for loss, damage or expense resulting from

improper installation, handling or misuse of components. Refer to the warranty statement in the Solahart

Owner’s guide for full warranty terms and conditions.

Installer Responsibilities

The installer is solely responsible for:

•Observing and conforming to all relevant Australian Standards, all relevant Clean Energy Council

Accreditation guidelines and all applicable laws, ordinances, regulations, codes of practice and local

or national building codes, including any that may have superseded this guide.

•Ensuring that the installation complies with AS/NZS 3000, AS/NZS 5139, AS/NZS 5033, AS 4777.1,

AS/NZS 1768, and any relevant electrical service and installation rules for the state or territory where

the system is installed.

•Ensuring that the Battery system and associated components are appropriate for the particular

installation and the installation environment.

2

•Ensuring only parts supplied by Solahart Industries and installer supplied parts as specified by

Solahart Industries are utilised (substitution of parts may void the warranty and invalidate certification).

•Ensuring that mounting fasteners have adequate pull-out strength and shear capacities to suit the

installation.

•Ensuring safe installation of all electrical aspects of the Battery system.

•Ensuring that the building and building structures can withstand the additional loads and forces

generated as a result of installing the Battery system.

•Ensuring mounting clearance requirements for all components are maintained.

•Ensuring components are not exposed to direct sunlight, rain fall and snow accumulation.

•Ensuring that the batteries and their components are protected from damage during transportation

and storage.

•Ensuring that the weight of the battery is taken into account when handling and that all WHS policies

are followed.

•Ensuring the Battery is connected to an approved SolarEdge Inverter and the SolarEdge Monitoring

Platform (via an internet connection).

Tools Required

•Drill and drill bits suitable for drilling holes in the desired mounting surface/structure.

•M5 tools.

•Torque wrench.

•Spirit level.

•Adjustable spanner.

•Electricians hand tools (screwdrivers, pliers, side cutters, cable crimps etc.)

•DC cable 600V insulated

•Dolly with lift and ratchet straps

•An Android or IOS smart device.

Note: The SolarEdge Inverters SetApp mobile App must be downloaded before commissioning.

Note: See each component installation guides for additional tools required for installation.

Planning the Installation

Installation environment

•The battery is floor/wall mounted as per the instructions provided in this guide.

•The operating temperature (charge / discharge) for the battery is -10~50℃.

•Avoid exposing the equipment to direct sunlight or rain.

•Install the equipment away from heat/cold source where the temperature can vary significantly.

•Battery may cause interference with radio/TV interference if not installed correctly.

•Keep children / pets away from the equipment.

•Do not install the equipment in places prone to accumulate water.

•Do not put inflammable or explosive matters near the equipment.

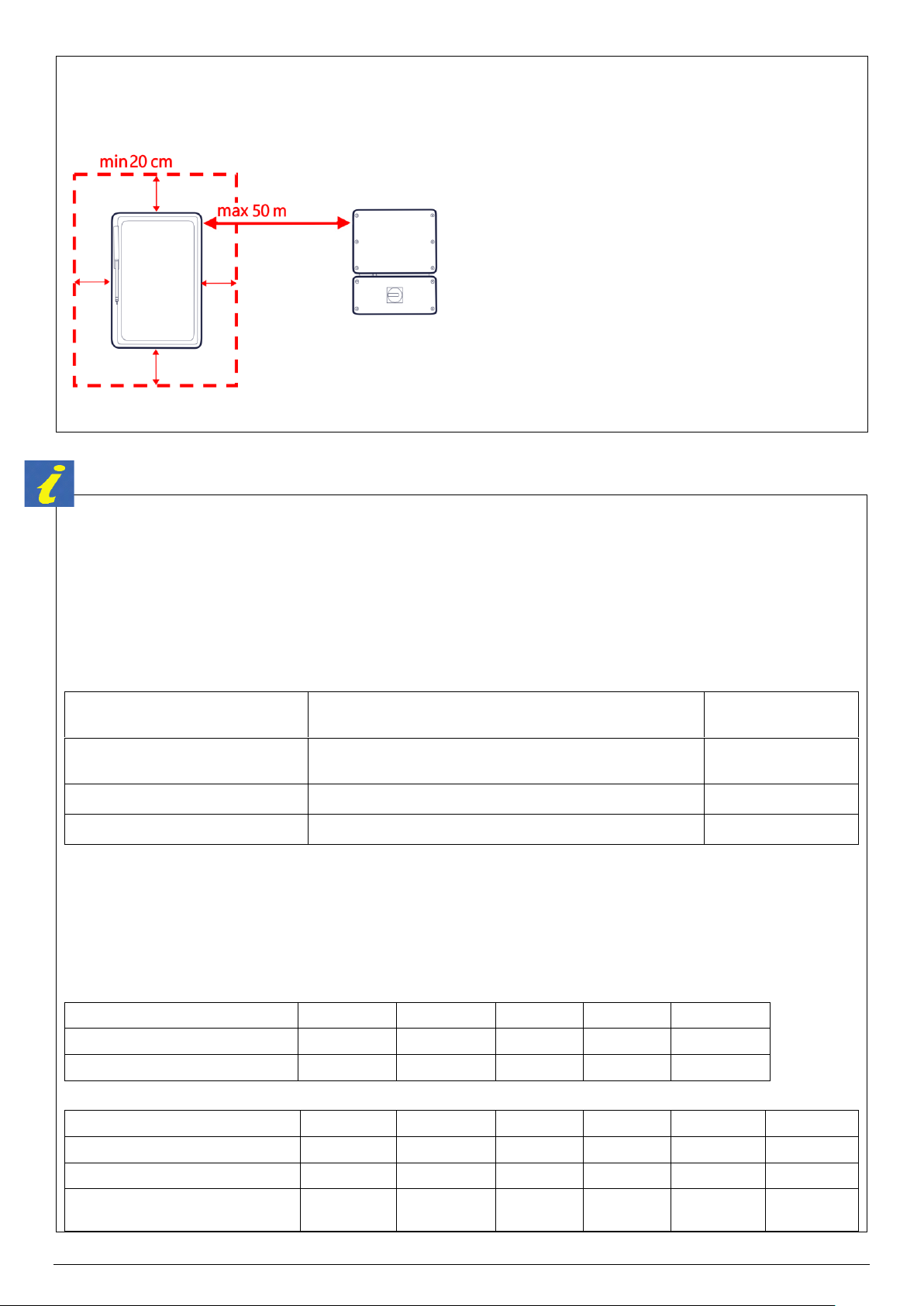

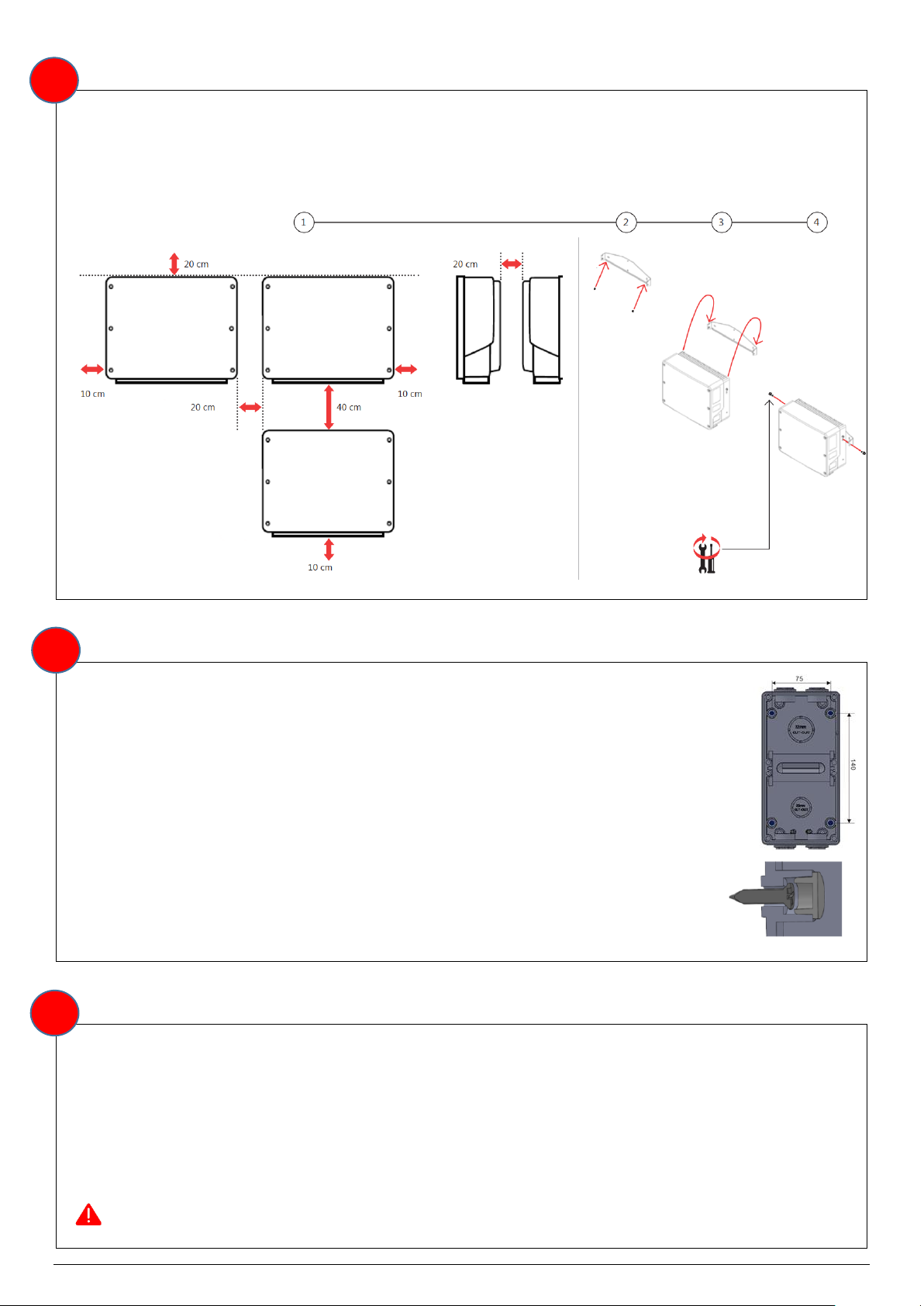

Mounting space requirements

For the SolarEdge Home Battery (High Voltage) for use with SolarEdge inverters

Floor and wall mounting space requirements:

3

20cm spacing around the battery and max 50m away from the inverter.

Note: The Installation location of the Battery must also comply with the requirements of AS/NZS 5139.

Cabling and Conduits

Any earthing cable, AC cable and conduits are not supplied by Solahart and should be selected based on

the following criteria.

Inverter DC/AC cabling must be sized and installed in accordance with AS/NZS 3000, AS/NZS 3008.1.1

and any local applicable codes.

The Battery contains an in-built 25A circuit breaker.

DC CABLE SIZING

Cable description

Cable type

Minimum Conductor

Size

Low Voltage (LV) Battery to Battery

and DC Combiner

Pair, double-insulated DC cables, 90 deg. rated

4 mm2

DC combiner to Inverter

Pair, double-insulated DC cables, 90 deg. rated

4 mm2

Battery earthing (PE)

Earthing cable complying with requirements of AS/NZS 3000

4 mm2

Note: Each 4mm2DC cable must be located in accordance with AS/NZS 3008.1.1 to achieve a current

carrying capacity of >25A (in-built battery circuit breaker).

INVERTER CABLING

Cables from the inverter(s) must be selected so that the current carrying capacity is suitable for the

maximum continuous current as shown below:

Inverter Model - Genesis

SE3000H

SE5000H

SE6000H

SE8250H

SE10000H

Maximum Input Current (Adc)

9 A

13.5 A

16.5 A

20.5 A

25.5 A

Maximum Cont. Output Current

14 A

23 A

27.5 A

37.5 A

45.5 A

Inverter Model –Energy Hub

SE3000H

SE4000H

SE5000H

SE6000H

SE8250H

SE10000H

Maximum Input Current (Adc)

8.5 A

11 A

14 A

16.5 A

22.5 A

25.5 A

Maximum Cont. Output Current

14 A

18.5 A

23 A

27.5 A

37.5 A

45.5 A

Maximum Cont. Output Current

(Back Up Operation)

14 A

18.5 A

23 A

27.5 A

34 A

41.5 A

4

Note: Rated current in backup operation are valid for installations with multiple inverters. For a single

backup inverter operation, rated current in backup is 90% of the stated value

COMMUNICATION CABLING

Cable Description

Cable Type

Cable between Inverter and Meter

CAT6

Cable between Meter and CT

CAT6

Cable between Inverter and

between each connected battery

CAT6

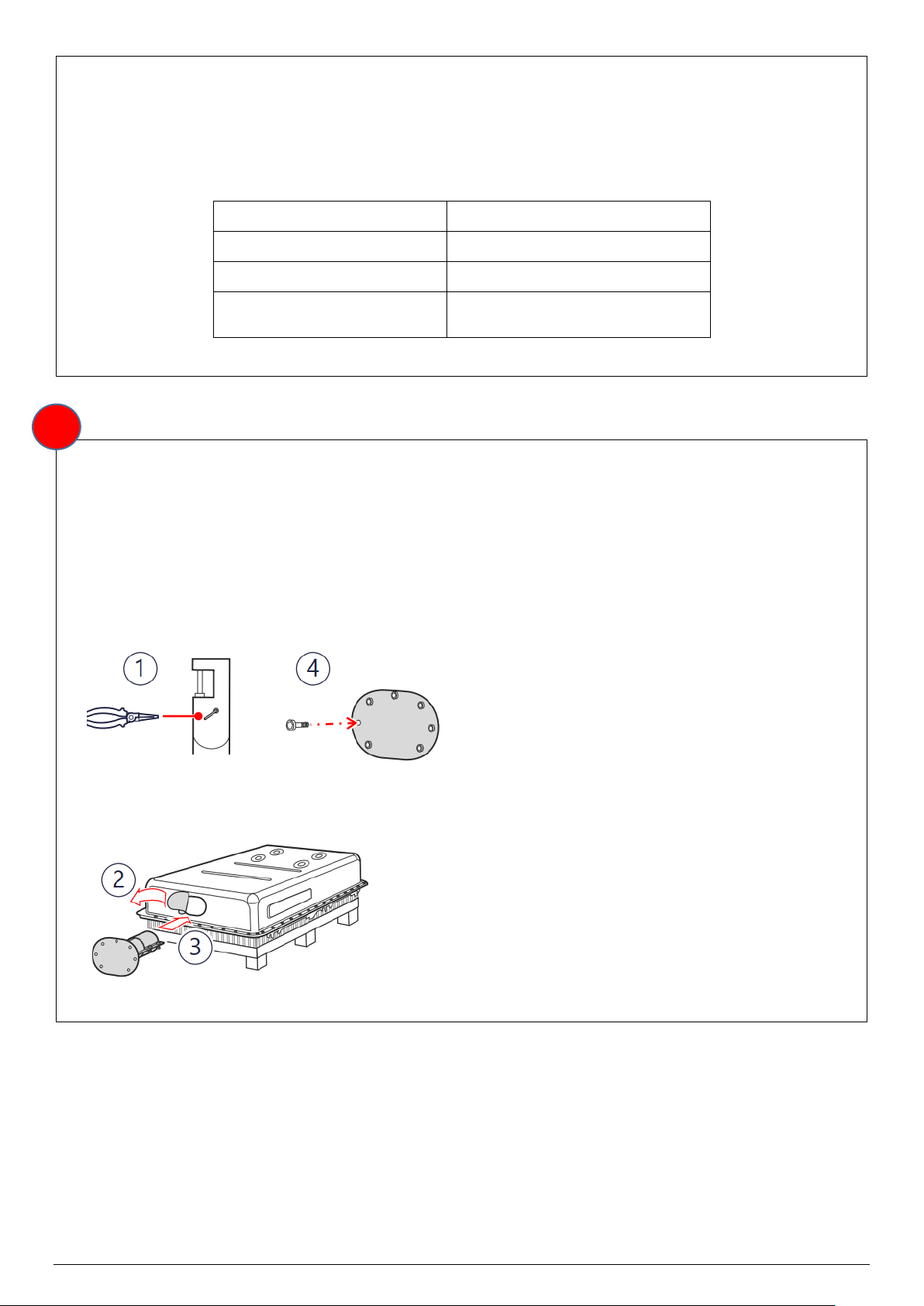

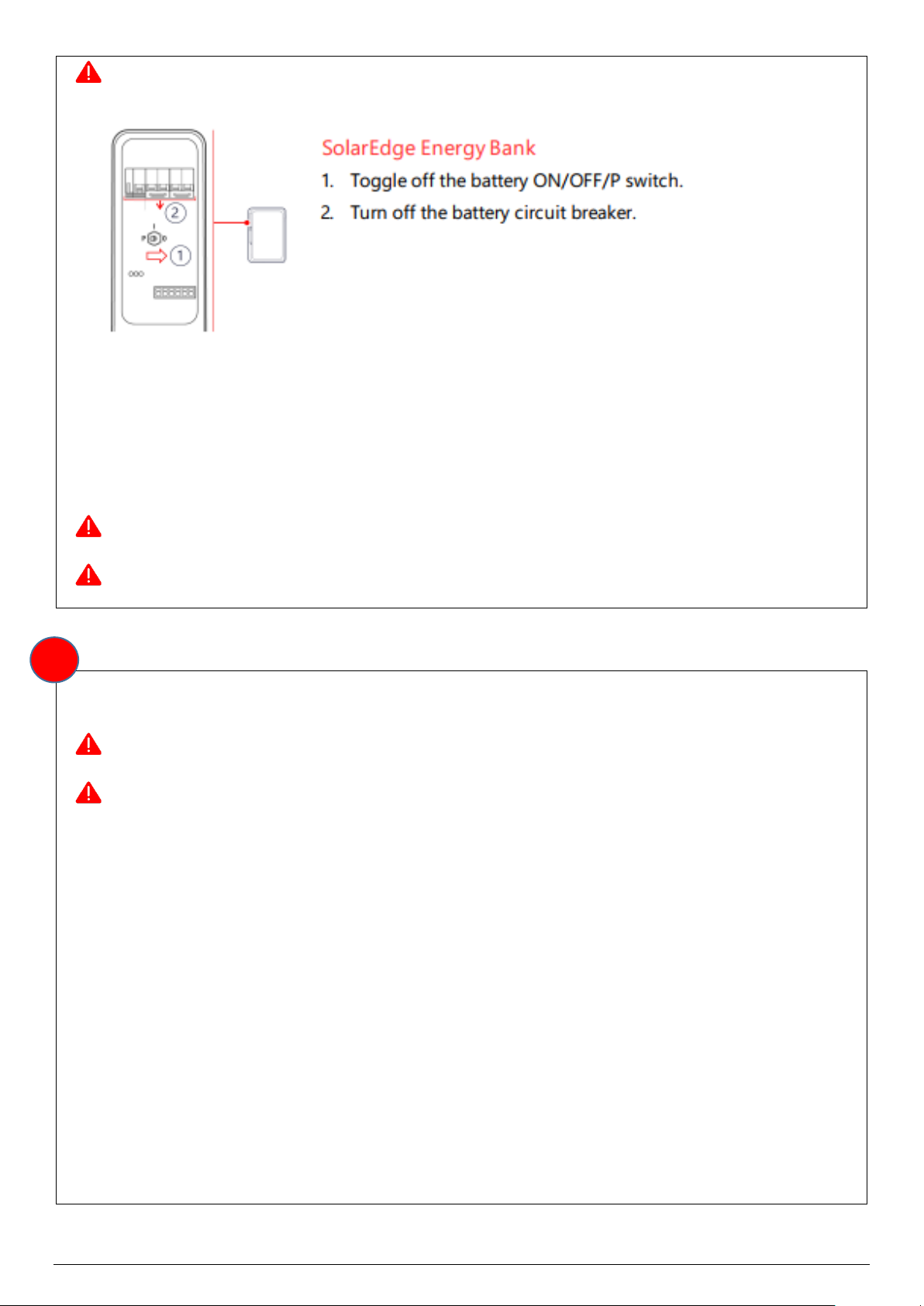

Install the fire extinguisher

Refer to the SolarEdge Home Battery Fire Extinguisher Installation Guide for further information.

1. Use long-nose pliers to straighten and remove the safety pin.

2. Remove the sticker that covers the fire extinguisher’s service hole.

3. Carefully insert the fire extinguisher into the service hole.

4. Secure the fire extinguisher with seven Allen screws (supplied). Apply a torque of 4.5N*m.

1

5

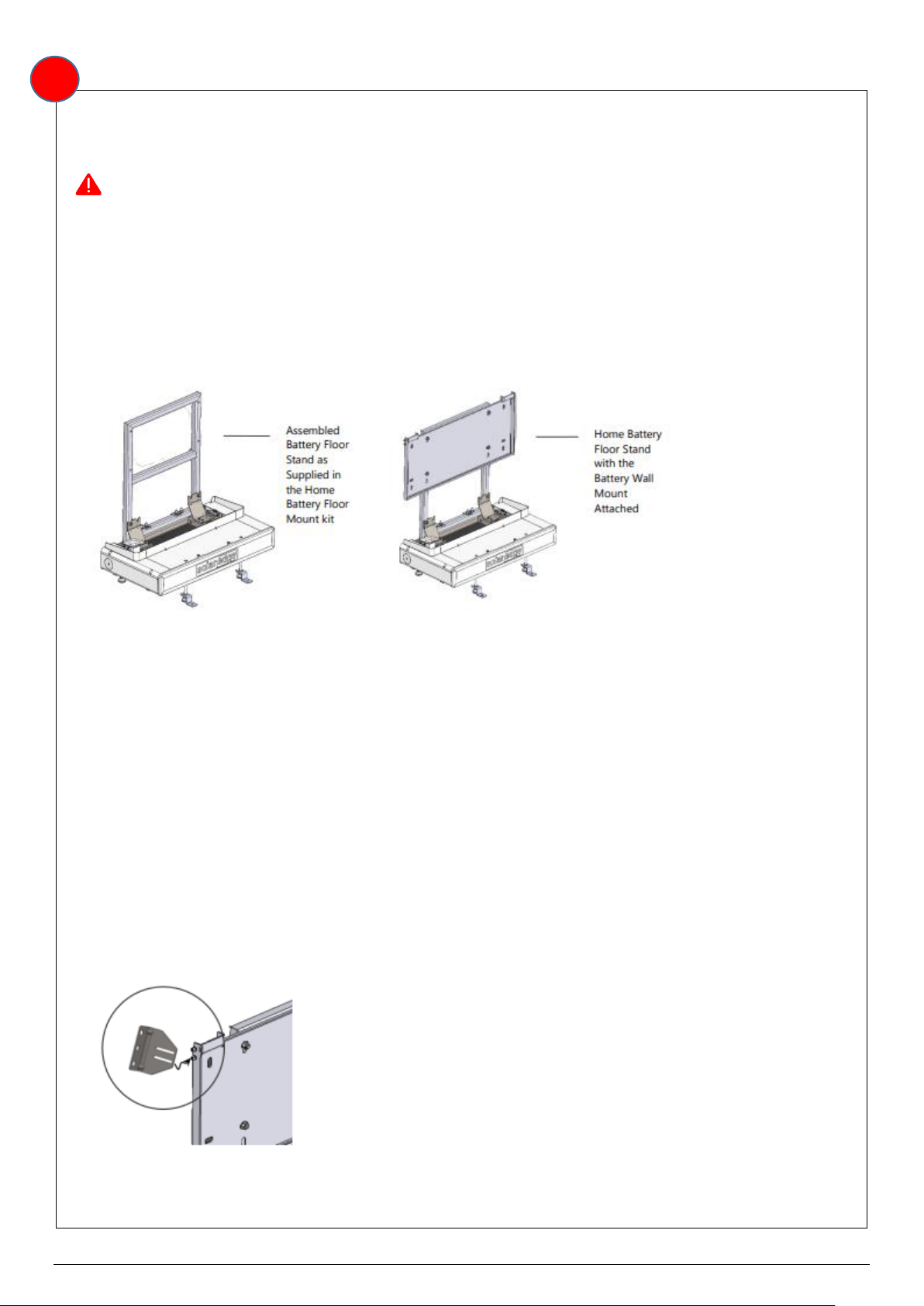

Unpacking and Mounting Battery

Refer to SolarEdge Home Battery User Manual for further mounting instructions.

Unpack contents from the SolarEdge battery packaging as per instruction

Warning: Battery modules are heavy (approximately 121 kg each). It is recommended that the

installation is done by two people.

Floor mounting:

Parts for the Floor Stand Base Mount and Back Holder are supplied as part of the SolarEdge Home

Battery Floor Mount kit

The assembled floor stand includes the base and back holder as illustrated on the left in the Figure

below. The right part of the figure shows the Battery Wall Mount after being attached to the assembled

floor mount stand.

1. Unpackage the SolarEdge Home Battery Floor Mount Stand kit and arrange the parts so you can check

the parts against the parts list.

2. Move and position the floor mount base close to but not against the wall to which it will be secured.

Position the base so that the front of the base is parallel to and facing away from the wall.

3. Level and set the height of the base mount using a 5mm Allen key to turn the leg height adjustment

screws for each of floor mount base legs.

4. Hold the back holder so that the six studs are facing toward you and the connecting strut with four holes

is at the bottom.

5. Lower the back holder over the four connecting studs located at the rear of the base. As you do this,

the two lower studs on the Back Holder must sit in the outer slots of the Back Holder Securing Bracket.

6. Loosely screw the M8 nuts onto each of the back holder and base studs to hold the back holder in

place. Fully tighten at 17Nm to finally secure the back holder.

7. Hold the wall mount, front facing you, and position the mount on the securing studs of the back-holder’s

battery mounting bracket.

8. Loosely screw an M8 nut onto each of the four back holder studs to hold the wall mount in place and

then fully tighten at 17Nm to finally secure the wall mount as shown in Figure 4.

9. Use the M5 short screw to attach the lower slot of the wall bracket to each side of the wall mount and

then position the Floor Mount against the wall

10. Use the holes in the wall bracket to mark the position on the wall for three attachment holes on each

side. Move the Floor Mount aside to allow access to drill. Drill the holes, reposition the Floor Mount and

attach the wall brackets to the wall

2

6

11. (Optional) Insert a floor connector bracket between the bracket securing nut and the foot of each leg.

Position the floor connector bracket and mark a drilling hole. Remove the bracket and drill the floor

attachment holes.

12. Position and hang the battery on the wall mount.

13. Check that the battery is turned off.

14. Open the wiring gutter on the left side of the floor mount base and lay the wires in place. Pass the

cables through the wiring sleeve on the top left side of the floor mount base and connect to the battery.

If installing more than one battery per inverter, use branch connectors.

15. Insert and loosely tighten the long M5 wall bracket securing screw in the upper wall bracket slot on

each side. The long securing screw threads through the battery housing and acts a safety suspension

pin.

16. Recheck that the stand is level and if necessary fine tune the height of the legs until the stand is level.

17. In case the floor stand is being optionally fastened to the floor, replace the floor connector brackets,

and position them over the drilled hole. Secure to the floor at 17Nm and then tighten the M10 bracket

securing nuts on each leg also at 17Nm.

18. Tighten the two Wall Bracket screws M5 on each wall bracket at 17Nm.

19. Assemble the decorative cover

Note: Refer to the manufacturer’s intallation guide for details on mounting multiple batteries.

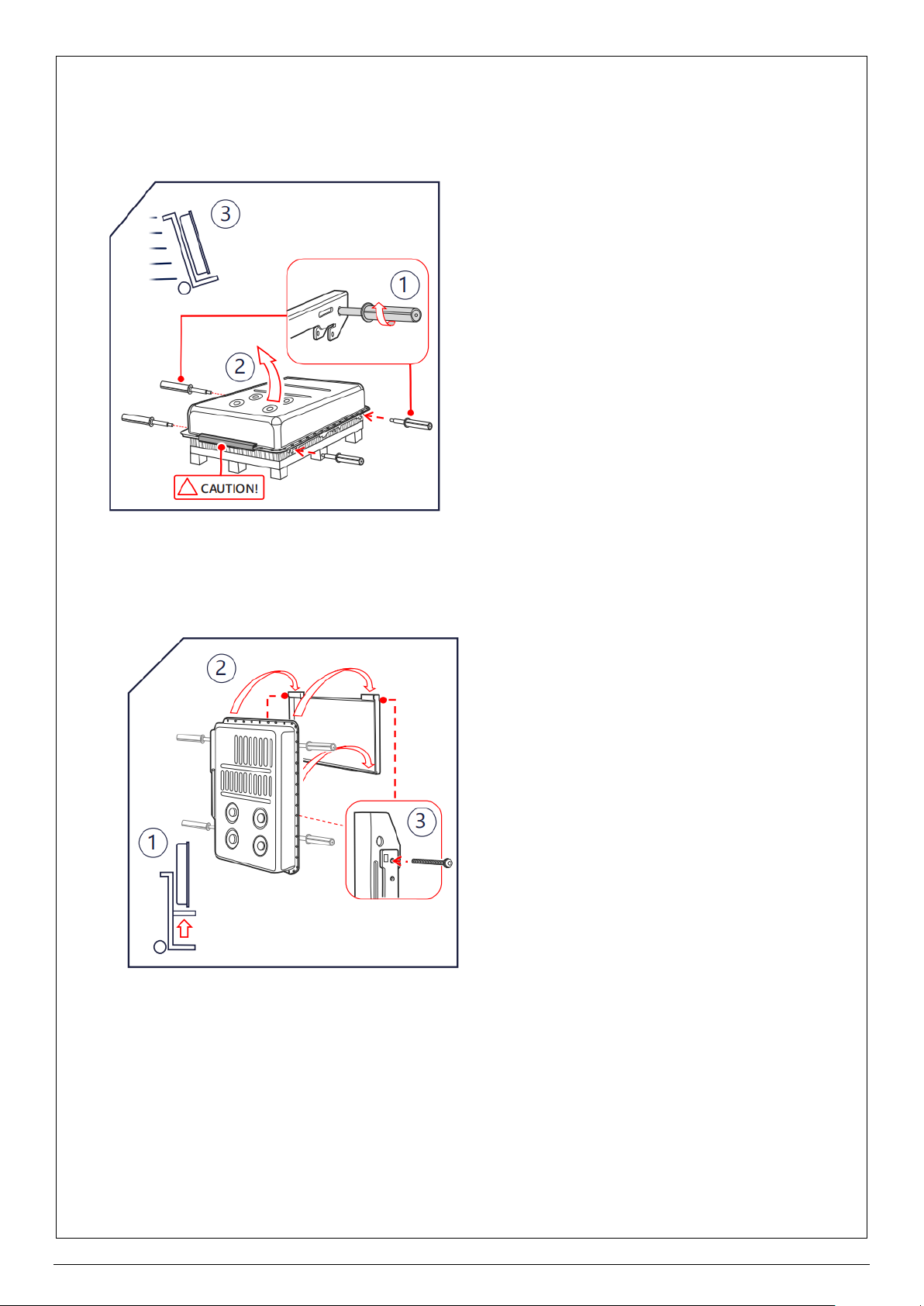

Wall mounting:

Install mounting bracket

When selecting the installation location:

• Maintain a clearance of min 20 cm from other objects.

• Make sure the max distance from the inverter is max 50 m

Warning: Make sure the installation surface sustains the weight of the battery (121kg).

1. Level the bracket.

2. Mark two drilling spots. Use either the inner or outer pair of holes. If necessary, you can use the

additional holes to secure the bracket.

3. Drill holes in the installation surface.

4. Install the mounting bracket and secure with screws.

7

Transport battery

1. Screw in all FOUR handles to the battery frame. Make sure to screw in the handles all the way.

2. Place the battery upright on a dolly and secure it with straps. Stand the battery on the rubber

protector only!

3. Transport the battery to the installation location.

Hang battery on mounting bracket

1. Lift the battery to the height of the mounting bracket.

2. Hang the battery on the mounting bracket, while holding it by the handles.

3. Secure with a mounting bracket screw (supplied) on each side. Apply a torque of 4.7Nm.

Note: The battery shall be installed and mechanically protected according to CEC Battery Installation

Guidelines and AS/NZS 5139. This includes:

•Providing restricted access to the battery system designed to prevent access by unauthorised

persons.

•Where subject to potential physical damage, mechanical protection shall be providedto the battery

system to minimise the risk of such, resulting in electrolyte leakage, including:

oCrushing

oImpact

oPuncturing

•Mechanical protection may be achieved via the use of a suitable battery system enclosure and/ or

bollards.

8

Mounting the Inverter

Follow the relevant User Manual to choose a suitable location and correctly mount the Inverter to the wall

using appropriate fasteners and with regards to clearance requirements. Diagram of the SolarEdge

Genesis inverter mounting below.

Mounting AC Isolator Enclosure(s)

ISOLATOR ENCLOSURES

1. Determine the mounting locations of the enclosures with regard to system clearances,

layout specifications and AS/NZS 3000.

2. Install a minimum of two (2) fasteners diagonally opposite, to fix the enclosure to the

wall.

3. Install the silicone rubber plugs supplied with the enclosure on the internal mounting

points.

Note: Where the Inverter is not adjacent to the switchboard to which it is connected,

an “Inverter AC Isolator” must be installed at the Inverter in accordance with

AS/NZS 3000.

Connecting DC and Communication Cables

For setting up communication between the battery and the inverter, SolarEdge strongly recommends using

SolarEdge Energy Net. If for some reason SolarEdge Energy Net cannot be used, you can set up

communication using an RS485 port

Use the following cable types:

DC - 10 AWG (10-12 AWG), 600V insulated.

Communication - 24 AWG (16-24 AWG), 600V insulated or CAT6

Warning: Carefully read all handling and safety instructions in the installation guides that come

with the battery and the inverter.

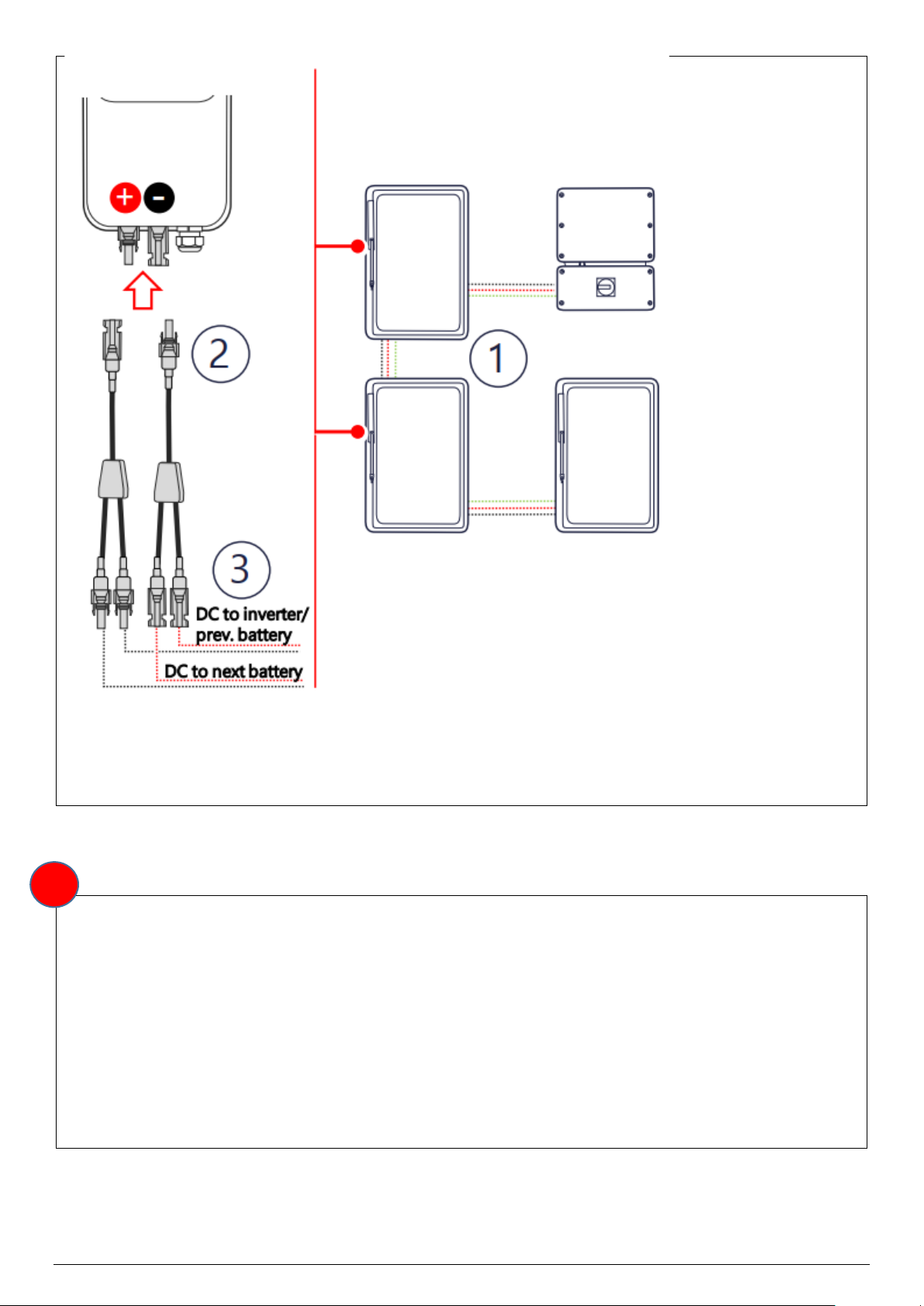

4

3

5

9

Warning: Before connecting the battery to the inverter, power off the battery.

Note: Check the communication cables to ensure the insulation is rated for the highest voltage present

inside the switchboard. Additional insulation may be required.

Note: If extension of communication cable is required, a female RJ45 joiner may be used to avoid crimping

the connector.

Warning: If extension of communication cable is required, ensure cable joints are adequately

protected from moisture.

Warning: Ensure all communication cables are adequately protected against mechanical

damage.

DC and AC Cable Wiring

Warning: Ensure all DC and AC cables are adequately protected against vermin and other

damage.

Warning: Ensure in-built DC isolator is switched OFF prior to wiring.

Note: Ensure the conductors on all cable ends are consolidated (e.g. using bootlace) before termination.

BATTERY

Connect DC cable and earthing wire according to the instructions in Operating Manual.

Ensure each conductor is stripped and exposes appropriate amount of copper. Crimp the cables to the

terminal lugs using mechanical hydraulic press pliers. All crimping shall be performed by an appropriately

qualified technician.

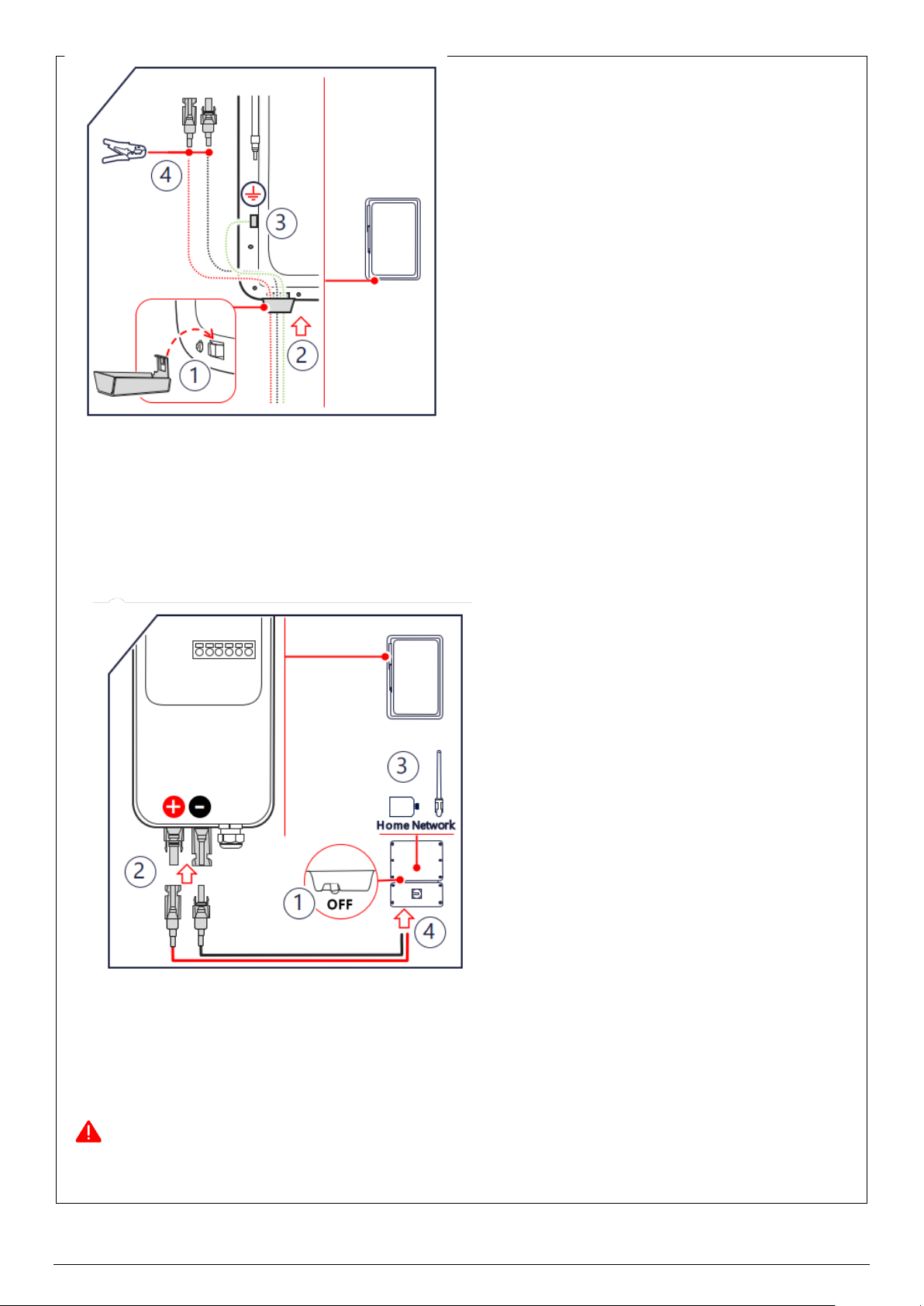

PREPARE CABLES

1. Mount the conduit holder.

2. Pass the DC cables and grounding cable through the conduit holder at the bottom of the battery.

3. Connect the grounding cable to the grounding terminal with a torque of 7.5 Nm.

4. Crimp the DC cables to the MC4 connectors (supplied) and tighten the MC4 connector glands with a

torque of 3.4Nm

6

10

CONNECT TO INVERTER

1. Make sure the inverter is OFF.

2. Connect the DC cables to the DC+ and DC- inputs. Observe correct polarity.

3. Install the SolarEdge Home Network plug-in and antenna in the inverter.

4. Connect cables to the inverter.

POWER ON AND ASSOCIATE

1. To power on and operate the battery, turn on the DC circuit breaker.

2. To associate with the inverter, move the battery’s ON/OFF/P switch to P for 2 seconds and then

release.

Warning: To power off the battery in case of emergency: Turn off the ON/OFF/P switch and DC

circuit breaker.

11

Cover an unused power supply ports with protective covers. Ensure the polarity of the cables is correct to

prevent any fuses from blowing.

NOTE: A DC circuit breaker is ‘in-built’ within the Battery unit. No additional external DC circuit breaker is

required.

Warning: Ensure all cable entries on the Battery are adequately sealed and the Battery IP

rating is maintained.

INVERTER

Follow instructions from SolarEdge User Manual to correctly connect the DC and AC power cables to the

Inverter.

Warning: Ensure Battery DC cable polarity is correct. Reverse polarity may cause damage to

the Battery.

Ensure each DC conductor is stripped and exposes appropriate amount of copper. Prepare DC cables and

accessories and place through battery cover, then crimp to battery terminals. Connect battery terminals to

the inverter

For all AC connections (both On-grid and Back-up), prepare the terminals and AC cables. Place the AC

cable through the terminal cover and screw the three cables tightly on the connectors. Lock the terminal

cover and screw up the terminal cap. Connect the assembled AC terminals onto the inverter.

INVERTER AC ISOLATOR (IF REQUIRED)

Wire the AC power cable from the Inverter to the Inverter AC Isolator in accordance with AS/NZS 3000.

MAIN SWITCH (INVERTER SUPPLY)

Wire the AC power cable from the Inverter AC Isolator (if present) or the Inverter, to the Main Switch

(Inverter Supply) in accordance with AS/NZS 3000 and the manufacturer’s instructions.

12

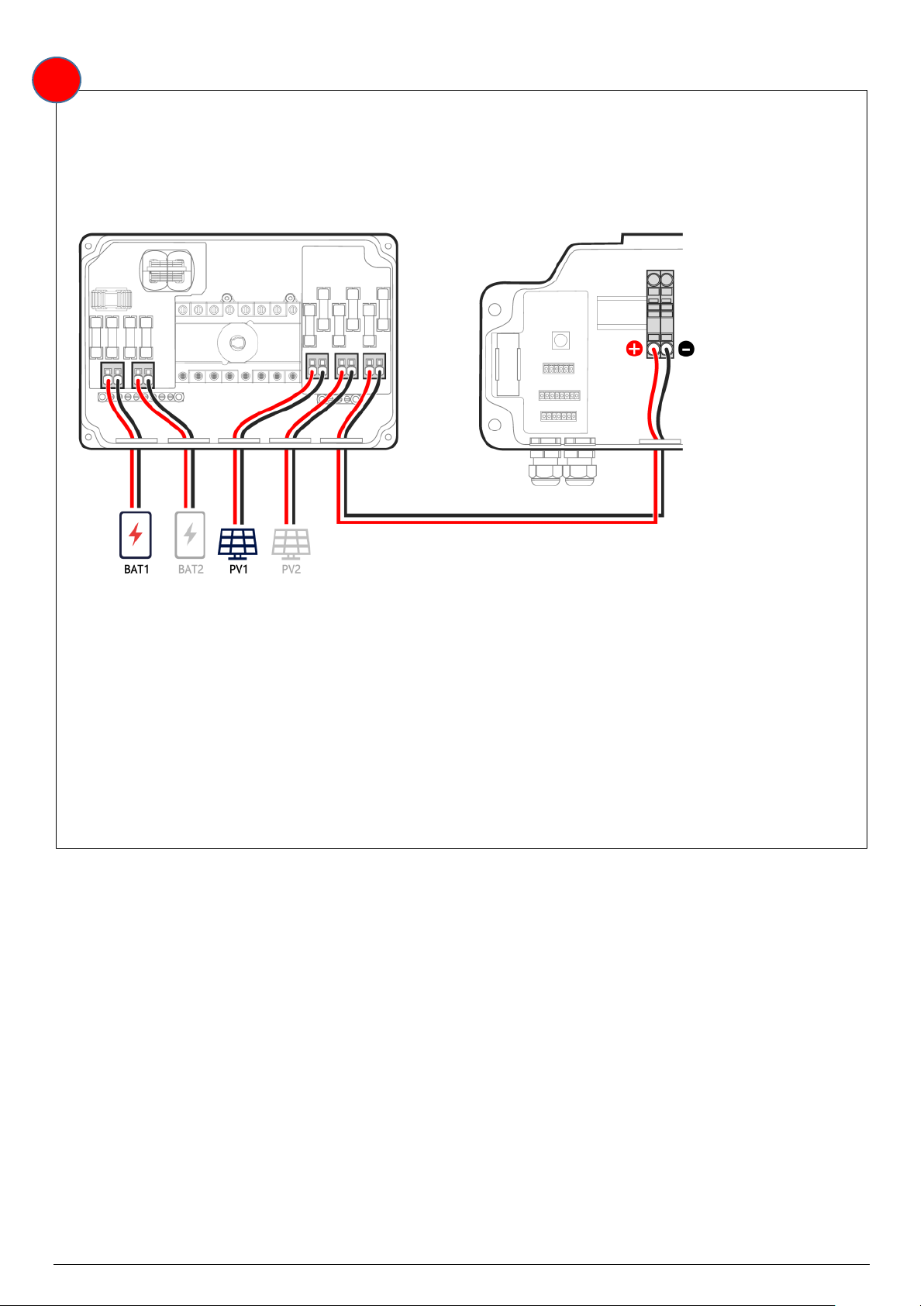

SolarEdge Combiner Box Use Cases (Optional)

With the Combiner Box

If three SolarEdge Home Batteries are to be connected, connect the DC cables from the battery/batteries

and the Power Optimisers to the Combiner Box. Then, connect the cables from the Combiner Box to the

DC terminals inside the inverter's Connection Unit

Without the Combiner Box

When one or two SolarEdge Home Batteries are to be connected, the DC cables from the battery and

Power Optimisers can connect directly to the DC terminals inside the inverter's Connection Unit. In this

case, the DC supplies from the battery/batteries and Power Optimisers must be combined because the

inverter has a single DC input.

Power Optimisers - If there are two or more PV arrays, combine their DC cables into a single home run

cable.

SolarEdge Home Batteries - When installing two SolarEdge Home Batteries, use branch connectors

(available from Solahart).

7

13

As the inverter's Connection Unit has a single DC input, crimp together the DC cable from the Power

Optimisers along with the batteries into one bootlace ferrule, terminating within the DC port of the

inverter.

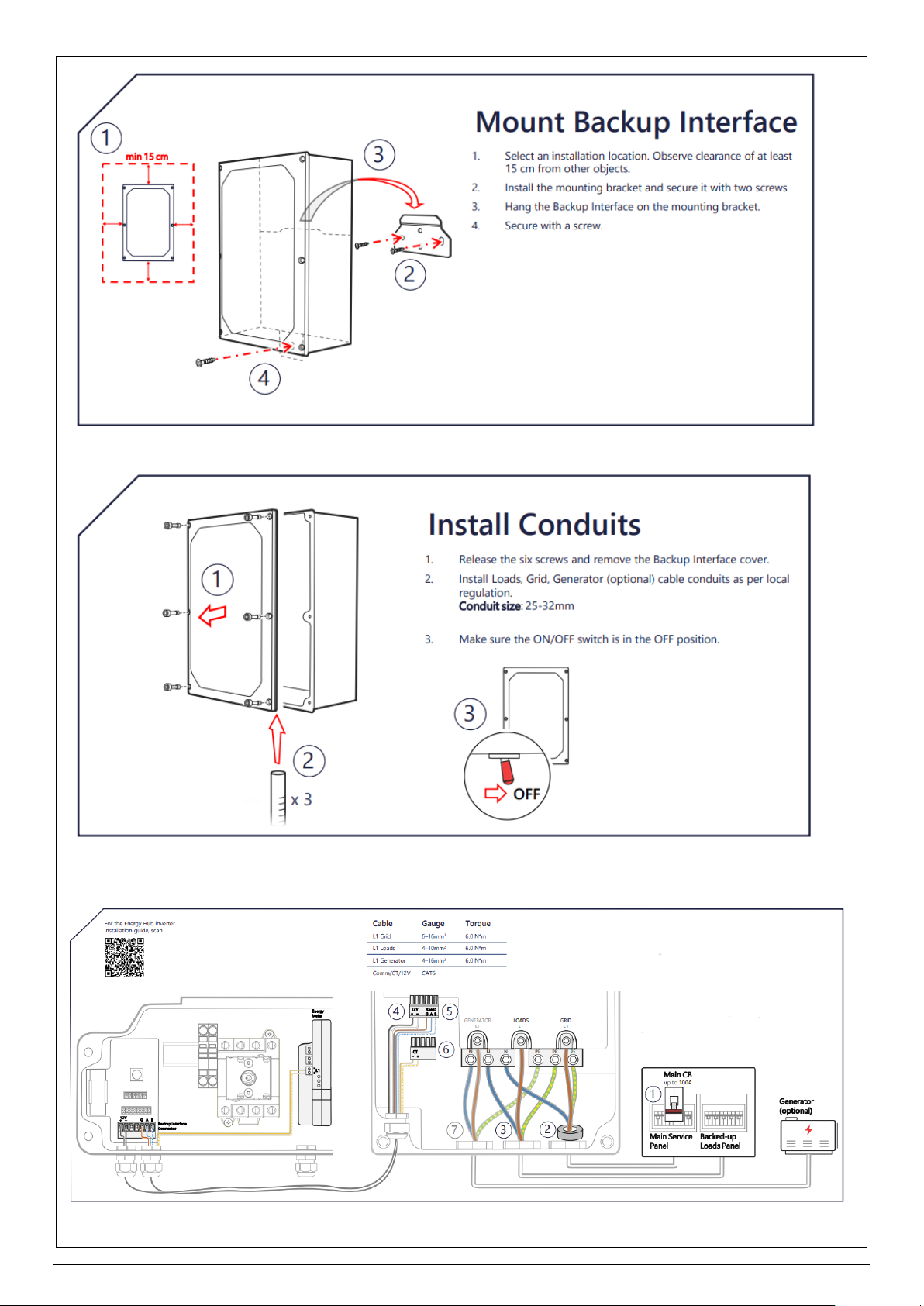

Backup interface (only available for Energy Hub inverters)

Read this before installing or operating the Backup Interface. Failure to do so or to follow any of the

instructions or warnings in this document can result in electrical shock, serious injury, or death, or may

damage the Backup Interface and other property.

Before operating the Backup Interface and inverter, ensure that they are properly grounded. The Backup

Interface and inverter must be connected to a grounded, metal, permanent wiring system, or an

equipment-grounding conductor must be run with the circuit conductors and connected to the equipment

grounding terminal or lead.

Opening the Backup Interface and repairing or testing under power must be performed only by qualified

service personnel familiar with the Backup Interface.

8

14

Connect Backup Interface

15

1. Turn off connection to grid by switching off the main circuit breaker.

2. Thread the L1, Neutral and Ground wires from the Main Service panel through the supplied ferrite

bead. Connect the wires to the L1, Neutral and Ground terminals.

3. Connect wires from the Backed-up Loads panel to the L1, Neutral and Ground terminals.

4. Use a CAT6 cable for the 12V connection between the inverter (Backup Interface connector) and

Backup Interface (6-pin RS485 connector).

5. Use a different CAT6 cable for communication between the inverter (Backup Interface connector)

and Backup Interface (6-pin RS485 connector).

6. Connect the Backup Interface’s CT to the inverter’s Energy Meter (L1 connector) using spare

wires of the communication CAT6 cable.

7. Optional, if a generator is installed: Connect wires from the generator to the L1, Neutral and

Ground terminals.

16

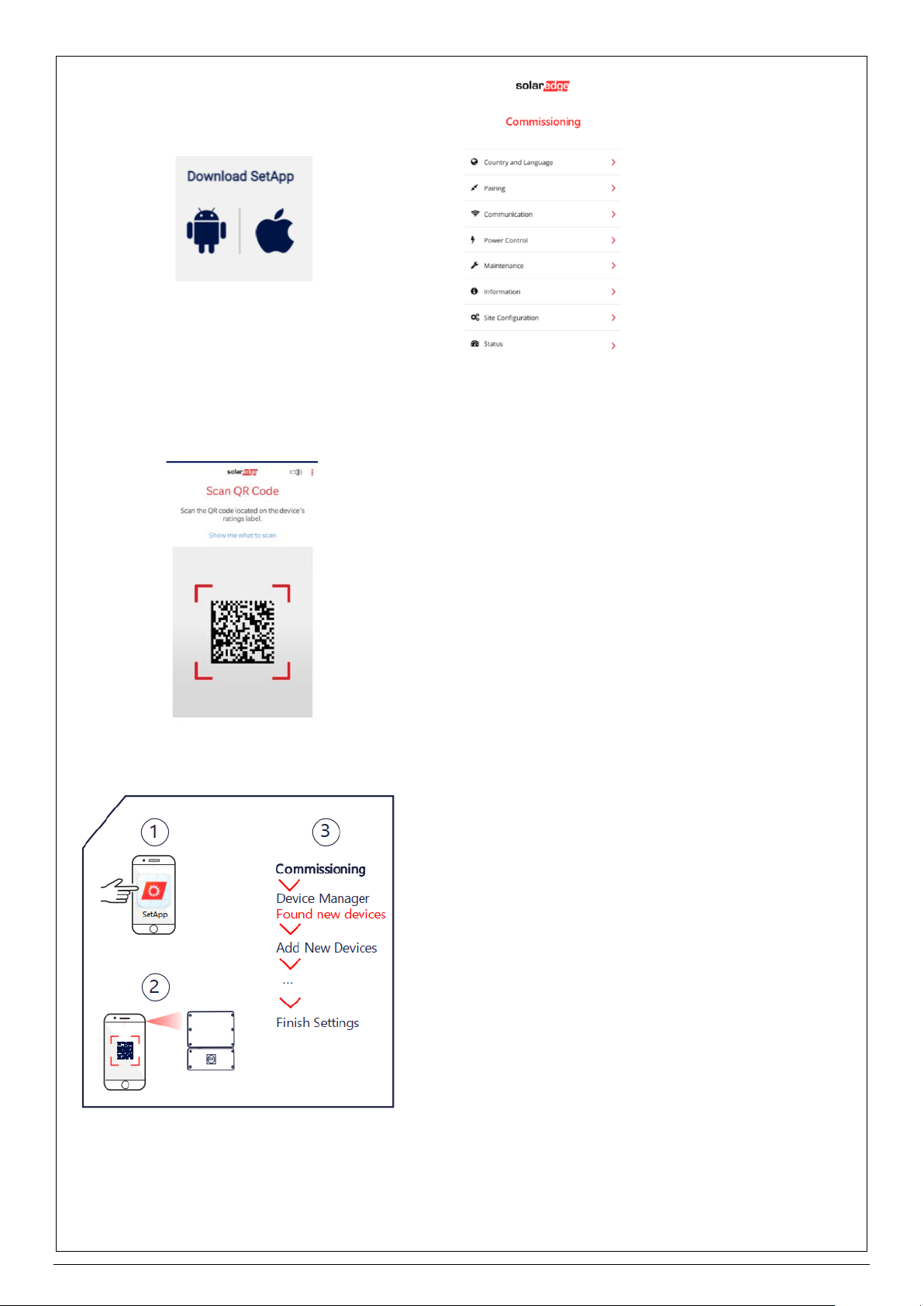

Commissioning

Warning: Before turning on the battery, please ensure that:

1. The equipment is levelled and installed firmly in a place where is convenient for operation

and maintenance. The installation place is clean and well ventilated.

2. The ground cable, power cables, communication cables and terminal resistance are

connected correctly and securely. Ensure that the polarity of all conductors is correct.

3. The CT is installed on and monitoring the appropriate active conductor and is correctly

orientated.

4. The cable ties meet the cabling requirements and are reasonably distributed. No cables

or ties are broken.

5. Unused ports are sealed.

6. The SolarEdge inverter is correctly commissioned following the user manual.

9

17

Configure installation

1. Run SetApp.

2. Scan the QR code on the inverter.

3. Follow the on-screen instructions

For post-installation settings, see Connection and Configuration application note.

The battery operation is managed by the SolarEdge inverter connected to the battery.

Configure installation

The purpose of the battery self-test is to check the battery's charge and discharge functionality.

1. Make sure the battery's circuit breaker switch is ON.

18

2. Switch the inverter ON/OFF/P switch to ON.

3. In SetApp, select Commissioning > Maintenance > Diagnostics > Self-Test > Battery Self-Test

> Run Test.

4. Wait for all tests to complete and check the results in the summary table. If any of the tests have

failed, see the table below for possible solutions:

Warning: If the battery system is not commissioned immediately after installation, turn off the

Battery Internal Circuit Breaker to avoid over-discharge and permanent damage to the Battery

cells. Once battery and inverter systems have been switched on and connected to the grid, both

systems will need to remain on at all times to ensure safe operation.

Note: Ensure firmware is updated as part of commissioning process of the Battery.

Monitoring Platform (Mandatory)

The Solahart warranty is conditional upon the Energy Bank being connected to the SolarEdge Monitoring

Platform (via an internet connection) for the entire duration of the Warranty Period.

The monitoring platform provides enhanced PV performance monitoring and yield assurance through

immediate fault detection and alerts at the module level, string level and system level.

No hardware or wiring is required to transmit data from the power optimizers to the inverter: the monitoring

sensors and transmittersare built into the SolarEdge power optimizer and solar inverter, andmeasurement

data is transmitted over the regular power lines.

Installers should contact their Solahart dealer to create their SolarEdge account.

10

19

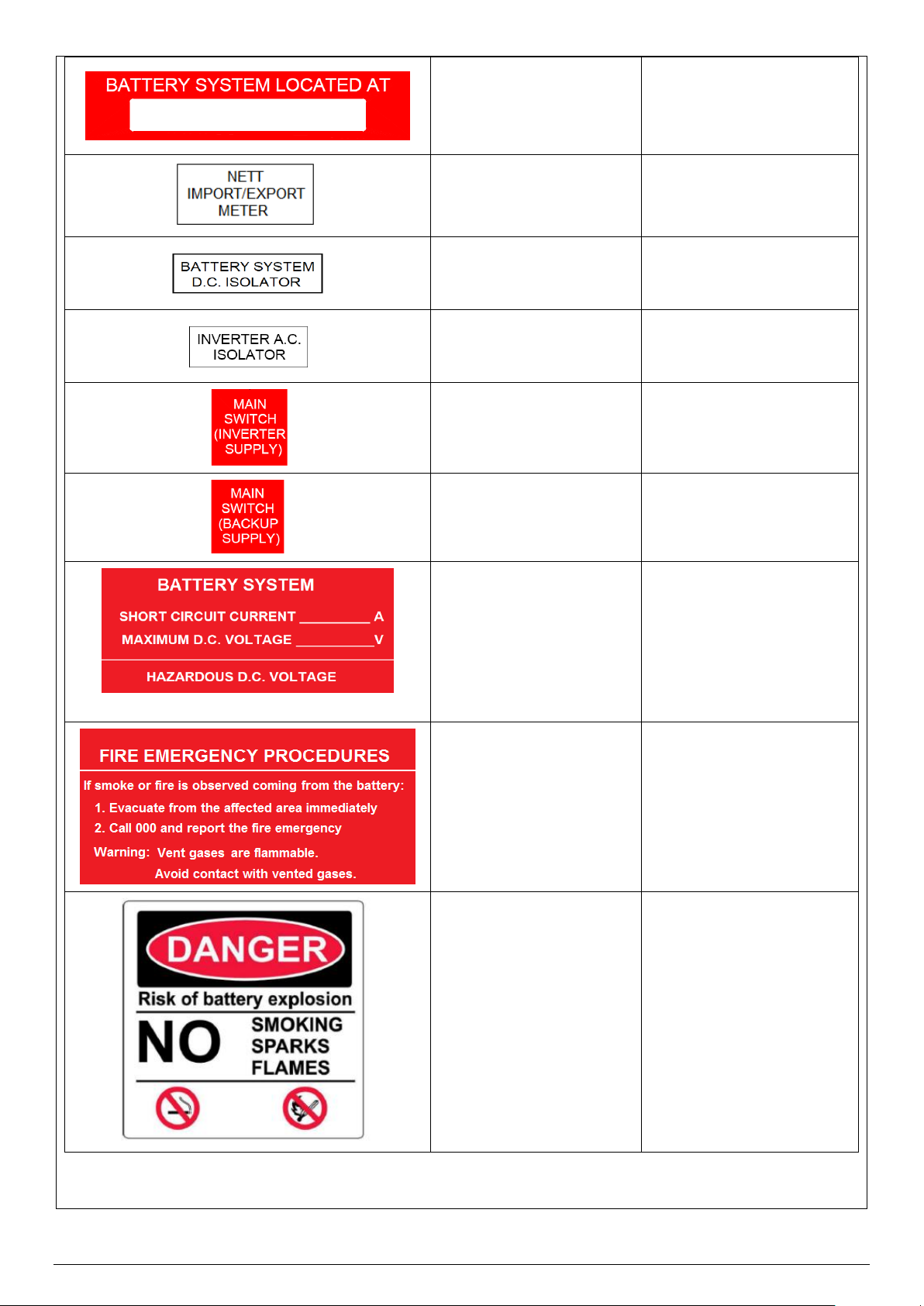

Labelling & Documents

This information is supplied here as a guide only. Additional labels may be required depending upon the

installation and local requirements. Labels must be constructed to AS 1319 and installed according to

AS/NZS 3000, AS/NZS 5139, AS/NZS 4777.1 and any local regulations. Refer to aforementioned

standards for more information.

Battery cables must be labelled according to AS/NZS 5139, section 7.

When segregation of circuits occurs, these circuits must be labelled according to AS/NZS 5139, section

7.

The purpose of labelling is to clearly indicate that the electrical installation has multiple supplies and which

circuits are affected by these supplies. Labelling also identifies the components that isolate the various

supplies. The following table details labels that are supplied for Solahart Battery Systems.

Item

Description

Location

Battery Safety Datasheet (SDS)- provided with the

Battery

Provided with the Battery

Place in document holder

at the main switchboard or

meter box

White text on

green background

On or immediately adjacent

to the meter box and main

switchboard

Black and white

Prominent position

adjacent to the Inverter

Black text on yellow

background

Directly below “Solar PV

and Battery Operating

Procedure” label

White text on

red background

Prominent position on main

switchboard

Note: This label replaces

the DUAL SUPPLY label

for PV systems.

11

20

White text on

red background

Prominent position on main

switchboard adjacent to

Inverter location label

Black text on

white background

Next to meter

Black text on

white background

Battery D.C. Circuit

Breaker

Black text

on

white background

Inverter AC isolator

(If required)

White text

on

red background

Inverter main switch in

switchboard

White text

on

red background

Inverter AC backup load

switch in switchboard

White text on

red background

Prominent position

adjacent to the Battery

White text on

red background

Prominent position

adjacent to the Battery

Black and white text with

symbols on

white background

Prominent position

adjacent to the Battery

This manual suits for next models

5

Table of contents

Other Solahart Solar Panel manuals