Solar Data Systems Solar-Log 10 User manual

Installation Manual

Solar-Log 10 (Bi-Directional Meter)

2

Dear Valued Customer,

Thank you for choosing Solar-Log®to monitor your PV plant.

Please read this installation manual carefully before installing the

Solar-Log®device. The Solar-Log 10 Meter is easy to install and

effective at monitoring the power consumption.

Technical support is available at (203) 702-7189 Monday through

Friday, 8:00 am to 5:00 pm, EST. Please prepare all relevant

information (Solar-Log®model, part number, problem description,

...) prior to calling, enabling technical support to help you finalize

the installation quickly.

Technical support can also be reached via e-mail at

Please leave this installation manual with the plant owner as a

reference guide.

Thank you.

Solar Data Systems, Inc.

23 Francis J. Clarke Circle

Suite 4A

Bethel, CT 06801

Phone: (203) 702-7189

www.solar-log.net

3

Table of Content

1 Introduction................................................................................ 4

2 Assembly ......................................................................................7

2.1 Meter Printed Circuit Board (PCB) ...................................................8

2.2 Meter Printed Circuit Board (PCB) Terminal Blocks ................10

3 Meter Technical Specifications............................................ 11

4 Safety Label Definitions & Information........................... 12

5 Precautionary and safety Information............................. 13

6 Meter Installation.....................................................................14

6.1 Mounting the Solar-Log 10 Meter.................................................... 15

6.2 Current Transformer Installation & Wiring....................................17

6.3 Current Transformer Installation...................................................... 19

6.4 Current Transformer Warning.......................................................... 20

6.5 AC Power & Current Transformer Wiring Diagram................... 21

6.6 Wiring the Printed Circuit Board (PCB)........................................22

6.7 Current Transformer Diagnostics ................................................... 24

6.8 Modbus RTU RS485 Wiring...............................................................27

7 Preventative / Scheduled Maintenance .........................29

8 Frequently Asked Questions..............................................30

9 Meter Limited Warranty....................................................... 32

4

1 Introduction

The Solar-Log 10 Meter measures electrical power for single (split)

phase and three phase power systems.

All relevant power components, such as currents, voltages, real

power, reactive power, and apparent power are measured.

The Solar-Log 10 Meter stores the measured values internally in the

device as well as on an external website. The Solar-Log 10 Meter

communicates with the Solar-Log®via Modbus-RTU RS485.

Installation must only be performed by qualified personnel following

this installation manual and all applicable local and national electri-

cal codes.

Solar Data Systems, Inc. and its representatives assume no respon-

sibility for damages or injury resulting from the improper installation

of the Solar-Log 10 Meter.

Check the voltage rating and configuration description on the de-

vice labels to ensure that it matches the intended electrical service

to be measured.

The Solar-Log 10 Meter, labelled for 120/208V service MUST NOT be

installed on a 277/480 volt or 347/600 volt service and vice versa.

5

Verify that the Solar-Log 10 Meter’s current transformer are sized

suitably for the current to be monitored.

CAUTION

Internal circuit card components are extremely sensitive to

electrostatic discharge. Prior to handling or touching internal

circuitry, be sure you are safely grounded by touching a

grounded metal object such as a conduit or an earth groun-

ded metal enclosure.

CAUTION

Follow all instructions and safety precautions in this guide.

Prior to performing any work turn off all power supplying the

equipment in which the meter is to be installed.

Only qualified personnel should work on the meter and

should be familiar with the technology and the hazards asso-

ciated with electrical equipment.

Beware of potential hazards and wear personal protective

equipment.

Only connect the meter as described in this manual.

Hazardous voltages can cause shock, burns or death. To

prevent exposure to hazardous voltages, disconnect and

lock out all power sources before servicing and removing

components.

Modifications made to the product may void the warranty.

Never work alone and before performing any tests, installa-

tion or maintenance on this equipment, isolate or disconnect

all hazardous live circuits and sources of electric power.

6

NOTE:

Please call the technical support team with any questions or for

installation assistance, (203) 702-7189.

Assume that all circuits are live until they have been com-

pletely de-energized, tested, and tagged. Pay particular

attention to the design of the power system. Consider all

sources of power, including the possibility of back feed.

7

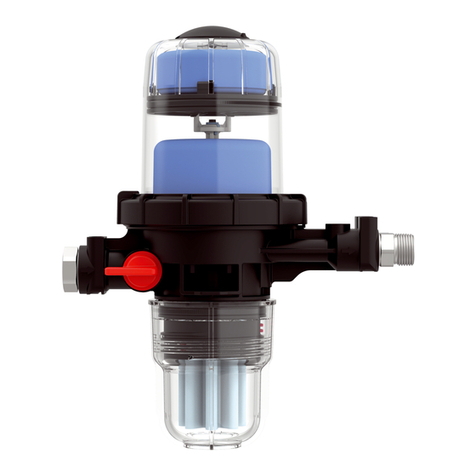

2 Assembly

The single circuit board is mounted inside a NEMA 4x and NEMA 6

enclosure. (IP 66 and IP 67)

Fig. 1. Assembly

8

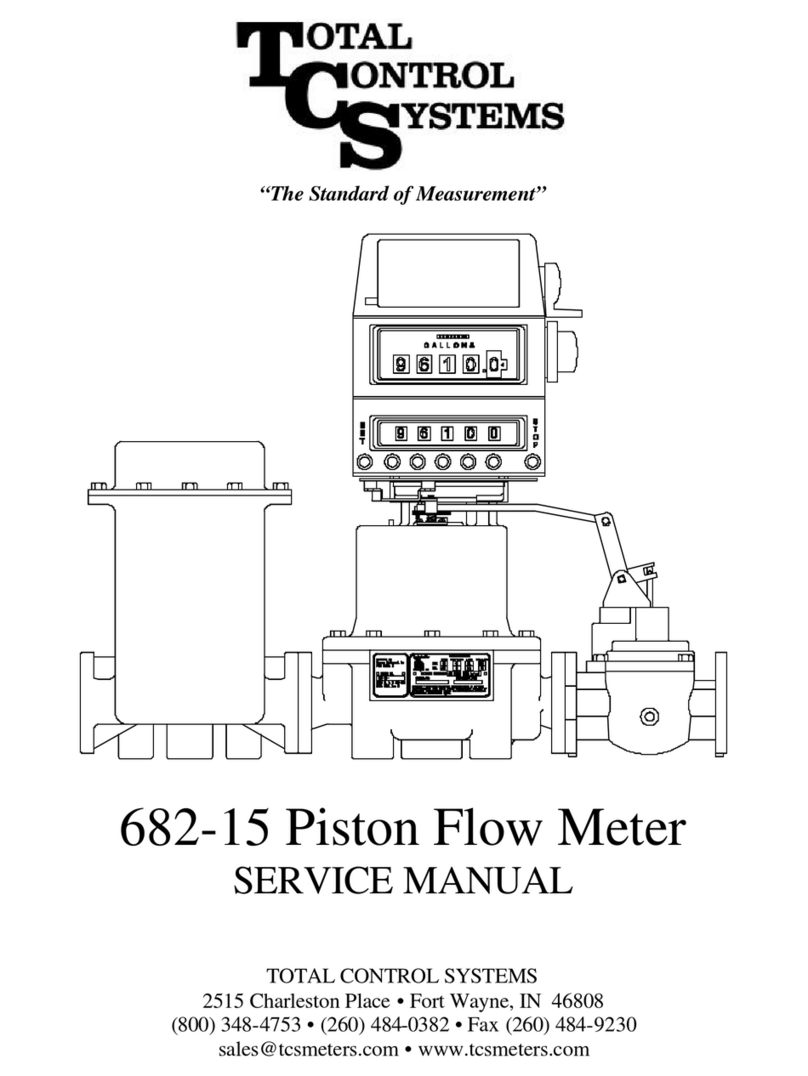

2.1 Meter Printed Circuit Board (PCB)

AC power, current transformers (CTs), and RS485 are connected to

the Meter PCB.

The AC power connections are labeled from 1 to 5 on the lower left

PCB corner, above the label “MAIN POWER INPUTS”.

The current transformers (CTs) connections are labeled 6 to 8 in

the lower middle of the PCB, above the label “CURRRENT SENSOR

INPUTS”. Connected CTs must match the related AC power voltage

input.

• CT A (CURRENT SENSOR INPUTS) must measure the current of

phase A (MAIN POWER INPUTS)

• CT B (CURRENT SENSOR INPUTS) must measure the current of

phase B (MAIN POWER INPUTS)

• CT C (CURRENT SENSOR INPUTS) must measure the current of

phase C (MAIN POWER INPUTS)

RS485 connections are labeled 9 to 10 in lower right hand of the

PCB above the label RS485.

9

1 2 3 4 5

6 7 8

9 10 11

Fig. 2 Meter Printed Circuit Board (PCB)

Power LED

State LED

RS485 Communication LED

RS485 Terminal

Current Transformer Terminal

AC Power Terminal

10

2.2 Meter Printed Circuit Board (PCB) Terminal Blocks

Number

in Fig. 2

Title Port

1 MAIN POWER INPUTS A / L1 Phase A

2 MAIN POWER INPUTS N Neutral

3 MAIN POWER INPUTS B / L2 Phase B

4 MAIN POWER INPUTS N Neutral

5 MAIN POWER INPUTS C / L3 Phase C

6 CURRENT SENSOR INPUTS A Black/White CT Phase A

7 CURRENT SENSOR INPUTS B Black/White CT Phase B

8 CURRENT SENSOR INPUTS C Black/White CT Phase C

9 RS485 + Plus

10 RS485 - Minus

11 RS485 GND

11

3 Meter Technical Specifications

Input Voltage Conguration Single (split) Phase or 3 Phase

Main Voltage Input 100-240VAC~, -15% / +10%

Input Power < 1.2 Watt

Current Transformer Primary* up to 200 A

Current Transformer Secondary 0 to 200 mA

Power Factor 0.0 - 1.0 CosPhi

Accuracy < 1 % with calibrated CTs

Line Frequency 50/60 Hz

Voltage Operating Rate +/- 10 % Of Rated Load

Temperature Range - 40F to 140F

Altitude 2000 Meters Maximum

Voltage Overload 10 %

Current Sensor Overload 10%, 100% for 1 minute

Pollution Degree Degree 4

Installation (Overvoltage

Category)

CAT III

Measurment Category CAT III

Enclosure Material NEMA 4X/6 // IP 66/67 :

Standards EN 62208, GOST

Standard Ranges* 1 Phase, 120/240 VAC: up to 200A

1 Phase (Split Phase), 120/240 VAC up to 200A

3 Phase, 120/208 VAC:up to 200A

*The maximum measurement (primary) current depends on the type of current

transformers (CTs). The available Solar-Log CTs are up to 200A.

12

4 Safety Label Definitions & Information

The Solar-Log 10 Meter may contain one or more of the following

labels.

Operator(s) should familiarize themselves with the meaning of each

label to minimize risk.

The presence of this label is a cautionary indicator identify-

ing a danger risk. The manual should be consulted prior to

proceeding.

The presence of this label indicates an electrical shock haz-

ard exists in the location or area where the label is placed.

Prior to proceeding, the AC power must be disconnected

and the manual consulted for safety information.

13

5 Precautionary and safety Information

CAUTION

Internal circuit card components are extremely sensitive

to electrostatic discharge. Prior to touching any internal

circuitry, be sure to discharge any static on your person by

touching a grounded metal object such as a conduit or an

earth grounded metal enclosure.

WARNING

The AC power connection labeled “MAIN POWER INPUTS”

screw down terminal on the meter printed circuit board

(PCB) exposes high voltage. This poses a risk of serious

injury and/or electric shock. Prior to performing any wiring

or other operations, switch off the AC power and read this

installation manual carefully. Only qualified personnel may

perform installation wiring. Installation and wiring must com-

ply with all local and national electric codes and regulations.

WARNING

NEVER open the Solar-Log 10 Meter cover without first

disconnecting the AC power. Failure to comply increases the

risk of serious injury and/or electric shock.

CAUTION

Always make sure that the enclosure is tightly closed and all at-

tached conduits are sealed. It is recommended to use additional

protection against environmental conditions like rain or dust.

14

6 Meter Installation

Appropriate installation steps

1. Install the Solar-Log 10 meter enclosure. Please carefully review

the mounting instructions in the next chapter of this installation

manual.

2. Install the current transformers (CTs) around the relevant wires

to be measured.

3. Connect the CTs to the relevant Solar-Log 10 Meter terminals.

4. Connect the AC power to relevant Solar-Log 10 Meter terminals.

5. Switch on the AC power.

6. Observe the Solar-Log 10 Meter diagnostics LEDs and make sure

they indicate the correct operation status.

7. Close the enclosure.

WARNING

Disconnect any relevant AC power and take out any relevant

fuses before proceeding with the installation. Only qualified

and trained personnel may perform work on electric power

lines in buildings.

15

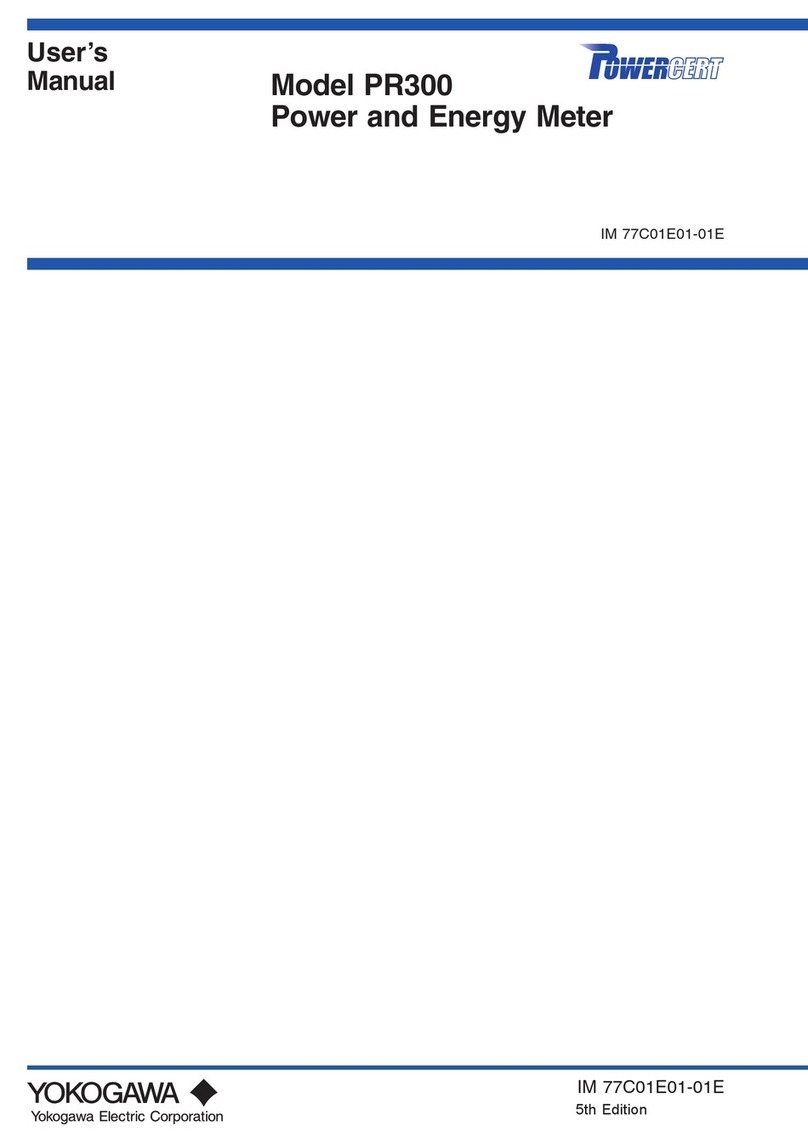

6.1 Mounting the Solar-Log 10 Meter

Use appropriately sized mounting hardware to fasten the meter en-

closure to the selected mounting surface. The distance between the

4 mounting screws is 6.3” W x 4.33” H, as show in Fig. 3 Enclosure

Dimensions (above).

All necessary cable and wire holes, and connected conduits need to

Fig. 3 Enclosure Dimensions.

16

be sealed to maintain the necessary protection class of the NEMA

4x enclosure.

Drill holes according to necessary conduits

WARNING

Do not drill into the Solar-Log®Meter printed circuit board

(PCB) - it will damage it and it will not work anymore!

17

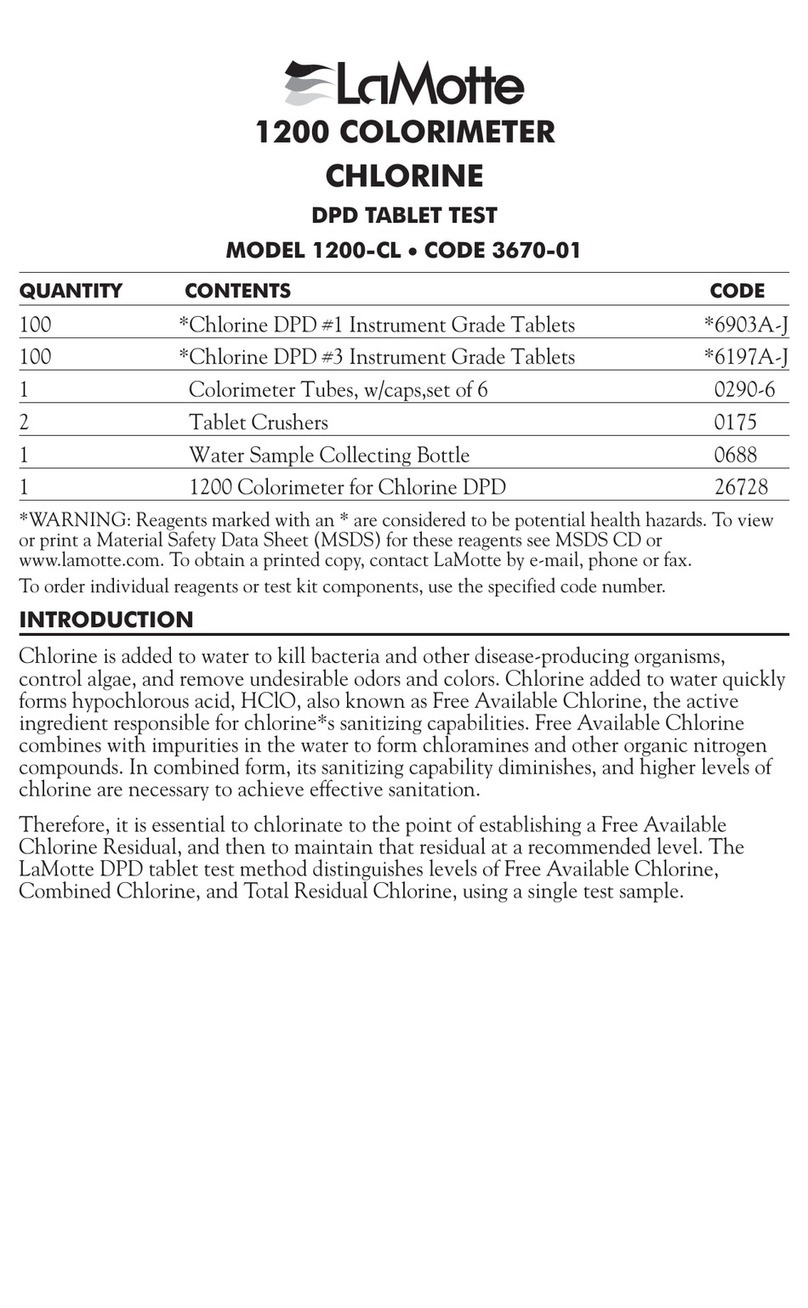

6.2 Current Transformer Installation & Wiring

The Current Transformers (CTs) are connected via the “CURRENT

SENSOR INPUTS” terminal block.

“CURRENT SENSOR INPUTS” A is the input for Phase A

“CURRENT SENSOR INPUTS” B is the input for Phase B

“CURRENT SENSOR INPUTS” C is the input for Phase C

The necessary Solar-Log®CTs are included with every Solar-Log 10

Meter. Each Solar-Log®CT is calibrated (and marked either A, B, or

C) and MUST connect to the relevant CT input port (CURRENT SEN-

SOR INPUTS A, B, or C). The above process leads to the advertised

meter accuracy. Not following these instructions can result in less

accurate power measurements.

Split core CTs are easily installed by wrapping them around already

installed power wires.

Fig. 4 Split Core Current Sensor.

18

Technical Current

Transformer Data

Solar-Log®CT200 A–o

Open transformer (folding mechanism) 1000:1

Primary measurement 200 A

Secondary output 200 mA / max. 6.7 V

Accuracy < 1 % between 1A - 200A (*)

Outer Dimensions 2 inch x 2 inch x 0.5 inch

Opening 0.75 inch

Cable length 10 feet (it can be extended up to 30

feet with 0.75 inch2cable)

(*) for Solar-Log 10 Meter calibrated CTs only

19

6.3 Current Transformer Installation

One Current Transformer (CT) is used per phase. The split core CT

opens by pulling the top part off the assembly. No tool is required.

Installing the CTs in the correct orientation is essential because it

determines the direction of the AC power flow.

The arrows on the Solar-Log®CT stickers show the direction of the

building load power(consumption).

For example, if the Solar-Log 10 Meter is used for metering the

power at the main utility connection of a home, the arrows on the

Solar-Log®CTs will have to point from the utility (outside) into the

house (inside).

Fig. 5 Solar-Log®CT 200A-o

20

6.4 Current Transformer Warning

WARNING

Connecting the current transformers (CTs) in the open

Solar-Log 10 enclosure must be done with extreme caution,

because of the high voltage electricity connected to the

printed circuit board (PCB). Coming into contact with the

high voltage carrying component is dangerous to life and

limb. Only trained, qualified personnel may perform the CT

installation.

The CTs are wrapped around the relevant phase wire first

and then connected to the matching phase on the current

sensor terminal on the Solar-Log 10 PCB.

The current transformers (CTs) connections are labeled 6

to 8 (Fig. 2 Meter Printed Circuit Board (PCB)) in the lower

middle of the PCB, above the label “CURRRENT SENSOR

INPUTS”. Connected CTs must match the related AC power

voltage input.

Each CT connects to two terminals, one labeled “BLK” for

black and the other “WHT” for white.

The CT labeled phase A connects to the “CURRENT SENSOR

INPUTS” terminal A.

The black wire connects to the “BLK” terminal (upper row)

and white wire to the “WHT” terminal (lower row).

Repeat the above for the remaining phases B and C.

Table of contents