Nic WA-5F User manual

WA-5F Service Manual

Document

Number NIC-704-2015-01 Date of

Issue Apr. 14, 2017

Control

Department Technical Center Page 1/36

1

WA-5F

Service Manual

Nippon Instruments Corporation

Technical Center

Date Prepared

Checked Approved

First Edition

Apr. 14, 2017

Kinoshita

Yamada Kato

WA-5F Service Manual

Document

Number NIC-704-2015-01 Date of

Issue Apr. 14, 2017

Control

Department Technical Center Page 2/36

2

Revision History

Revision No.

Revision Date

Reason for Changes

Prepared

Approved

01 Apr. 14, 2017 First Edition issued Kinoshita Kato

Distribution List

Destination Date Destination

Date Destination

Date

President -

Executive Director -

Application Technology Dept.

-

Sales Dept. -

R&D Dept. -

3

Atmospheric Mercury Analyzer

Mercury/WA-5F Service Manual

Contents

1. Introduction....................................................................................................................5

Overview ................................................................................................................5

Basic configuration of this system ..........................................................................5

Part names and functions of the Mercury Analyzer ................................................6

Front (inside front cover) .................................................................................6

Back................................................................................................................7

Internal components viewed from the right......................................................8

Internal components viewed from the left........................................................9

Intended readers of this Service Manual................................................................9

2. Safety instructions.......................................................................................................10

Meaning of safety alert symbols...........................................................................10

Cautions on installation ........................................................................................10

Cautions on maintenance.....................................................................................10

3. Maintenance................................................................................................................11

Inspection items ...................................................................................................11

Daily inspection.............................................................................................11

Annual inspection..........................................................................................12

Errors and warnings .............................................................................................13

Troubleshooting....................................................................................................16

Decrease in sensitivity...................................................................................16

Abnormal blank value....................................................................................17

Abnormal increase in sensitivity....................................................................17

Maintenance.........................................................................................................18

Leak check....................................................................................................18

Replacing the septum....................................................................................19

Cleaning the gas scrubbing bottle and dehumidifying bottle .........................19

Detaching and attaching the cover................................................................20

Detaching and attaching the collector tube (H2)............................................20

Cleaning the absorption cell..........................................................................21

Cleaning the joints.........................................................................................22

4

How to reduce the blank value of collector tubes..........................................23

4. How to remove and install the components.................................................................24

Collector tube adaptor..........................................................................................24

Heater H1.............................................................................................................24

Heater H2.............................................................................................................26

Gas scrubbing bottle and dehumidifying bottle.....................................................26

Cell.......................................................................................................................26

Adjusting the sensitivity of the optical system.......................................................27

Mercury lamp........................................................................................................29

Photoelectric tube preamplifier.............................................................................31

Second collector tube...........................................................................................31

Solenoid valve and active carbon filter.................................................................32

Flow sensor..........................................................................................................33

Air pump...............................................................................................................33

Control boards......................................................................................................34

Switching power supply........................................................................................35

5

1. Introduction

Ensure to refer to this Service Manual before conducting the inspection, repairs, or

maintenance of the Mercury Analyzer WA-5F.

Overview

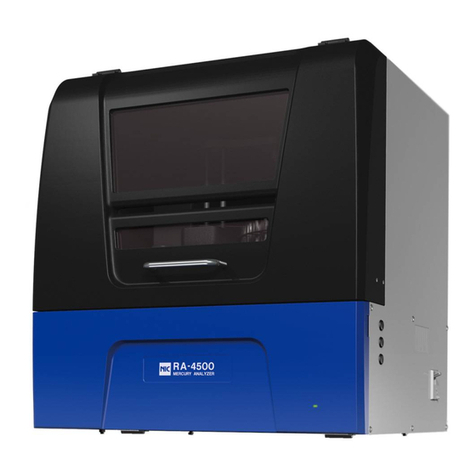

The Mercury/WA-5F is a mercury measuring system which allows the amount of

mercury collected in a dedicated mercury collector tube to be quickly measured with

high sensitivity and in a wide range through simple operations.

The operations are carried out on a PC where the measurement results can be

analyzed through various methods such as statistical calculations.

Basic configuration of this system

This system consists of the following:

(1) Mercury Analyzer: WA-5F

(2) Data analysis / System control software: WA5Win

(3) Standard accessories

(4) Personal computer

6

Part names and functions of the Mercury Analyzer

* This section is identical to the content in the Instruction Manual.

Front (inside front cover)

No.

Item Remarks

Standard gas inlet Comes with a built-in septum.

Heating furnace (H1) for collector tube Comes with a built-in cooling fan.

Mounting port for collector tube Made of fluoride resin.

Electronic cooling unit

Gas scrubbing bottle

Removes any acidic gas.

- For measuring the mercury in the

ambient air:

the standard buffer solution (1+1), pH

6.86

- For measuring the mercury in the

samples of reducing vaporization:

NaOH, 0.1M

Dehumidifying bottle Removes moisture.

Opening for connecting to the detector

Valve for connecting optional units (EV)

Flow control needle valve Adjusted to 0.5 L/min.

1

2

3

4

5

6

7

9

8

7

Back

No.

Item Remarks

OUTLET Connection port for outlet gas tube (O.D.: 6 mm)

Main power switch

Connection port for power cable 100-240 VAC

Fuse 100V 10A or 250V 5A

AC OUT Power outlet for Auto Tube Changer

* Linked with the main switch.

LAN port for PC connection Port for a LAN cable.

Serial port (Not used)

Connection port for dry gas meter

Option (Not used)

Auto Tube Changer (Signal) Port for control signal cable

Auto Tube Changer (Power) Port for power cable

1

2

3

4

5

6

7

8

9

8

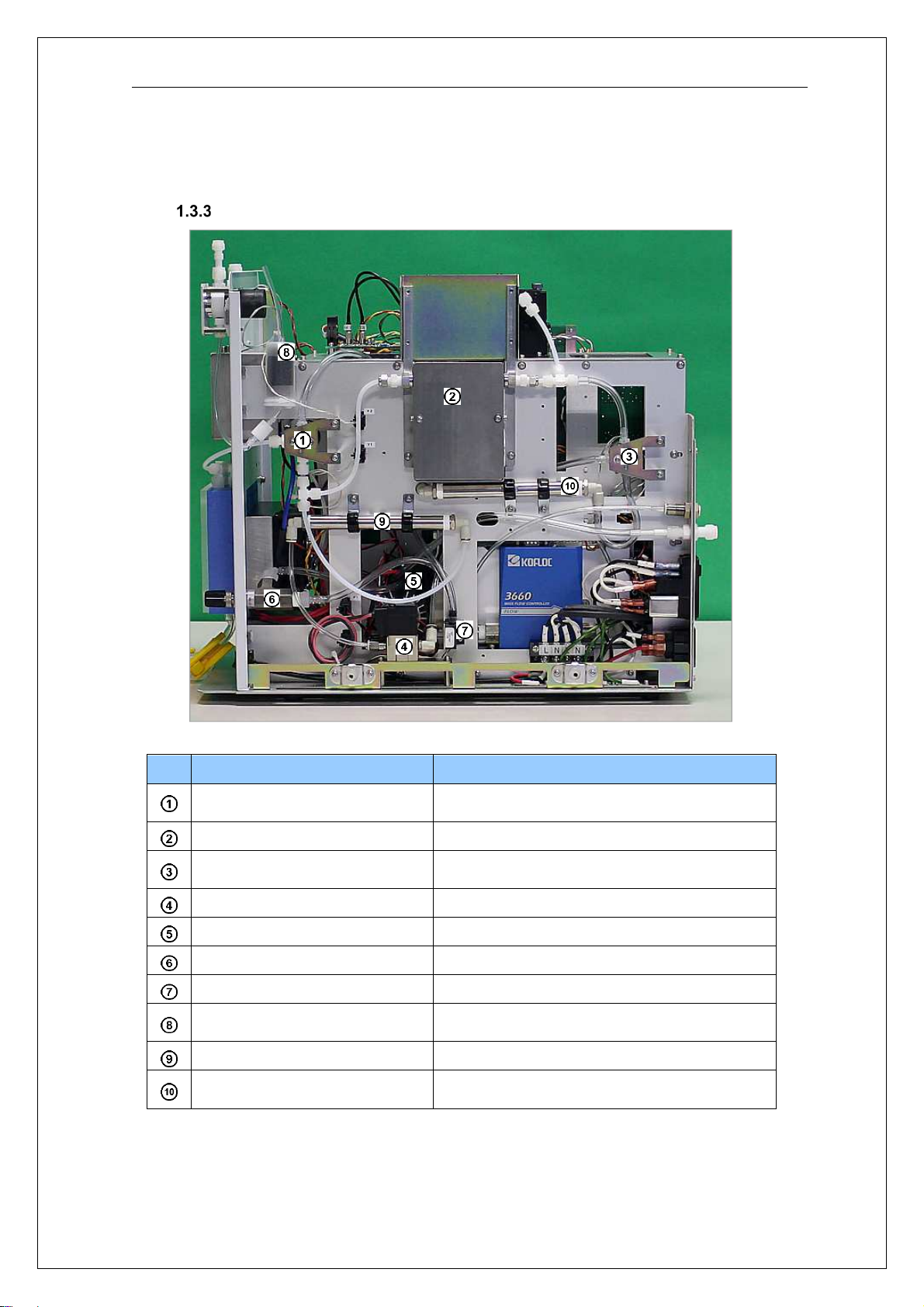

Internal components viewed from the right

No.

Item Remarks

Valve V1 Switches between the sampling/detection

lines.

Re-collecting furnace (H2) Comes with a built-in cooling fan.

Valve V2 Switches between the detection/bypass

lines.

Valve VF Prevents backflow.

Air pump

Flow control needle valve Adjusted to 0.5 L/min.

Flow sensor For measuring the flow rate

Active carbon for carrier gas For purging carrier gas during

transfer/sampling

Active carbon for carrier gas For purging carrier gas during measurement

Active carbon for outlet gas For removing mercury from the outlet gas

after measurement

9

Internal components viewed from the left

No. Item Remarks

Main circuit board

SSR1 For controlling the H1

SSR2 For controlling the H2

Power board for optical system

Power board for electronic cooling

unit

Power board for main circuit board

MFC control board

Intended readers of this Service Manual

The intended readers of this manual are engineers who have received proper training

and will be dispatched to a site or work at a factory to conduct the inspection, repairs,

or maintenance of the system.

6

1

2

3

4

5

7

10

2. Safety instructions

Observe the following instructions to ensure safety.

Meaning of safety alert symbols

Warning

indicates safety instructions required to prevent severe injury

or death.

Caution indicates safety instructions required to prevent moderate or

minor injury or property damage.

Cautions on installation

Warning

• To prevent an electric shock, be sure to connect the grounding wire.

• To prevent an electric shock and fire, be sure to check the power cables

and plugs for any damage.

Cautions on maintenance

Warning

• Shut off the power supply before starting the maintenance work.

Otherwise, you may suffer an electric shock.

Caution

• Conduct the maintenance of the heater section only after the power has

been turned off and the heater has cooled down. Otherwise, you may burn

yourself.

• Be careful when touching any glass parts. Otherwise, you may get injured

if they are broken.

• Be sure to discharge any liquids accumulated in the drain tank once the

work is complete. In addition, before starting the discharge, be sure to turn

off the power.

11

3. Maintenance

* This chapter is identical to the content in the Instruction Manual.

To keep the system in proper condition, observe the instructions related to inspection,

repairs, and maintenance.

Inspection items

Daily inspection

Inspection before starting work

Inspection items Criteria Corrective action

Gas scrubbing bottle Must be clean. Clean.

Status Must be any mode other than

OFF-LINE. Connect the cables.

Check the ports.

System check Must be complete without any

errors. Check the message.

Measurement method

The measurement method is

properly specified in the

system setting.

Change the setting on “Setup”

screen – “System” tab.

Error/Warning At the expiry of the standby

countdown timer, no errors or

warning messages are

displayed on the screen.

Inspection during measurement

Items Criteria Corrective action

Blank value After the purge measurement

has been repeated, the HEIGHT

value on LOW side must be

0.0002 or less.

Repeat the blank

measurement or clean the

line.

Calibration curve The calibration curve created

with the standard solution must

have a correlation coefficient of

0.9990 or higher.

Replace the collector tube

or clean the line.

Sensitivity The slope of the calibration curve

must be within ±30% of the slope

at the time of delivery.

Replace the collector tube

or clean the line.

History The blank value obtained

immediately after measurement

of the standard gas must be up

to 2% of the amount of mercury

detected immediately before the

measurement.

Clean the gas scrubbing

bottle and replace the

mercury collector tube.

Accuracy The standard gas must be

measured within ±5% accuracy

after measurement of actual

samples.

Review the method and the

sample volume.

12

Annual inspection

Annual inspection

Inspection items Criteria Corrective action

Mercury collector tube The quartz tube must be clean.

No discoloration of the quartz

wool.

Replace the mercury

collector tube.

Absorption cell Must be clean. Disassemble and clean the

absorption cell or replace it.

Flow rate No variations exceeding 0.02

L/min. Clean the needle valve or

replace the pump.

Output voltage of

detector (Ref)

Must be 4 ± 0.5V on the

Maintenance screen of

WA5Win.

Wipe any dirt and stains off

the lamp, lens, etc.

Active carbon filter No damage or discoloration. Replace.

Air pump

No abnormal noise.

During the flow rate check of the

system checks, adjust the flow

rate to 0.5 L/min, and the flow

rate must be stable.

Replace.

Electronic cooling unit

The (internal) temperature of the

cooling unit must be at least 8°C

lower than the room

temperature.

Repair.

13

Errors and warnings

Measurement is disabled in the event of an error. You cannot resume measurement until the

cause of the error is removed and either the main unit is powered on again or “Run” – “Reset”

is executed from the menu.

(1) Warning message

Message Description and corrective action

STAND-BY xx:xx Appears for 20 minutes after the power is turned

on.

Because the heater and the optical system are

still unstable during the countdown period, any

measured data in the period is unreliable.

Close the door of the TC-WA.

(appears only when the TC-WA is

connected.)

Appears if the door of the TC-WA is open when it

starts running.

The process resumes when the door is closed.

(2) Error message 1

Error

code

Message Description and corrective action

01 A/D FULL

The voltage of theA/D

converter of the optical system

has reached its upper limit.

Generated if the voltage of SIG1 or REF is 5V or

higher.

If the error occurs on the SIG side, it may be caused

by dirt or stains on the cell. If the error occurs on the

REF side, it may be caused by an increase in the

lamp’s light quantity, an increase in the sensitivity of

the photoelectric tube, or a fault in the circuit.

02 LAMP BROKEN

The light quantity of the lamp

(REF voltage) has dropped

below its lower limit.

Generated if the REF voltage is 0.5V or lower.

It may be caused by the degradation of the lamp, a

fault in the photoelectric tube for light quantity

compensation, or a fault in the circuit.

03 CELL DARK

The absorption cell is not clean.

Generated if the SIG voltage is 0.5V or higher.

Clean the absorption cell.

04 MOTOR ALARM (PUMP)

An alarm is generated from the

motor driver IC for air pump.

Generated if the motor driver IC for air pump has an

error.

Restart the system. If the error still persists, contact

us.

06 COOLING ERROR (H1)

FAN1 may not be running. Generated if the temperature of H1 is not lower than

150°C on completion of the cooling process

. The fan

may not be running or the cooling time may be too

short.

07 COOLING ERROR (H2)

FAN1 may not be running. Generated if the temperature of H2 is not lower than

300°C on completion of the cooling process

. The fan

may not be running or the cooling time may be too

short.

08 COOLING ERROR (H3)

FAN1 may not be running. Generated if the temperature of H3 is not lower than

150°C on completion of the cooling process

. The fan

may not be running or the cooling time may be too

short.

14

09 HEATER BROKEN (H1)

The temperature of H1 does

not rise enough.

Generated if the temperature of H1 is below 400°C

on completion of the transfer.

Turn off the power and then restart the system. If

the error still persists, contact us.

10 HEATER BROKEN (H2)

The temperature of H2 does

not rise enough.

Generated if the temperature of H2 is below 400°C

on completion of the measurement.

Turn off the power and then restart the system. If

the error still persists, contact us.

20

FLOW ERROR

The flow rate is too low. Generated if the flow rate drops below 0.2 L/min

during measurement.

Check that the pump is running properly. Check the

line for any disconnection.

The errors from 01 through 04 are detected while the system status is READY.

When the errors from 06 through 10 and 20 are detected, the system bypasses the

subsequent sequences and proceeds to the cooling process. When H1 and H2 have

cooled down, the system stops.

15

(3) Error message 2

Potential errors when the TC-WA is connected

Error

code

Message Description and corrective action

11

HEATER BROKEN (H3)

The temperature of H3 does not

rise enough.

Check whether the TC-WA is

turned on.

Generated if the temperature of H3 is below 400°C

on completion of the transfer.

Check the power cable and switch of the TC-WA. If

there is no problem with them, contact us.

12

TC-WA TIME OUT

ERROR (TABLE)

The operation of the table motor

cannot be completed.

A failure has occurred while the table is actuated.

Turn off the power, open the front cover, and check

the status.

If the problem cannot be corrected, contact us.

13

TC-WATIME OUT ERROR (LIFT)

The operation of the lift motor

cannot be completed.

A failure has occurred while the lift is actuated.

Turn off the power, open the front cover, and check

the status.

If the problem cannot be corrected, contact us.

14

TC-WA LIFT UP ERROR

The lift does not move up. Generated if the lift does not move up during

loading of the collector tube into the heating

section.

Turn off the power, open the front cover, and check

the status.

If the problem cannot be corrected, contact us.

15

TC-WA NO SAMPLE

The measured collector tube does

not move down.

Generated if the measured collector tube does not

move down.

Turn off the power, open the front cover, and check

the status.

If the problem cannot be corrected, contact us.

16

TC-WA MOTOR ALARM (TABLE)

An alarm is generated from the

motor driver IC for table.

Generated if a failure occurs in the motor driver IC

for table.

Restart the system. If the error still persists, contact

us.

17

TC-WA MOTOR ALARM (LIFT)

An alarm is generated from the

motor driver IC for lift.

Generated if a failure occurs in the motor driver IC

for lift.

Restart the system. If the error still persists, contact

us.

When the error 11 is detected, the system bypasses the subsequent sequences and

proceeds to the cooling process. When H3 has cooled down, the system stops.

When the errors from 12 through 17 are detected, the system immediately cancels the

measurement and stops.

(4) Error message 3

Potential errors when the gas meter is connected

Error

code

Message Description and corrective action

19

GAS METER ERROR Generated if the sampling pulse from the gas

meter cannot be detected during measurement in

the direct sampling mode.

When the error is detected, the system bypasses the subsequent sequences and stops.

16

Troubleshooting

Decrease in sensitivity

A decrease in peak sensitivity is mainly caused by the following three factors:

Problems with the standard gas

Leakage from the syringe, contamination of the syringe, or abnormal temperature

of the Mercury Vapor Calibration Box.

Problems with the system

Malfunction of heaters/valves or leakage

* If the leakage does not stop, disconnect the joint on the outlet side of the

dehumidifying bottle, and plug the inlet of the tube leading into the main unit

with your finger. If the leakage is still observed in this condition, there is a

problem inside the system. Open the cover and retighten the Teflon joint.

Contamination/degradation of the line

Contamination of the collector tube, scrubbing solution, or joints

Contaminated/degraded points can be identified by feeding the standard gas

from intermediate points in the line.

e.g. Disconnect the joint at the outlet of the dehumidifying bottle and connect the

disconnected tube to the standard gas inlet. Carry out measurement at this point.

If the sensitivity recovers, there is a problem with the line upstream of the

dehumidifying bottle. If the sensitivity does not improve, there is a problem with

the line between the dehumidifying bottle and the absorption cell.

* If the tube cannot be directly connected to the inlet, use a short tube or a reducing

Teflon joint.

17

Abnormal blank value

An increase in a blank value is mainly caused by the contamination of the gas line with

mercury. If contaminated components are the cause of the increase, it becomes difficult

to measure low concentrations of mercury. Identify the location where the problem

occurred, and clean or replace the component.

The location of the problem can be identified by installing the mercury removal filter at

an intermediate point in the line and performing a comparative measurement. Using a

Tygon tube or other means, install activated carbon for filter or a mercury collector tube

at an intermediate point in the line, and measure the amount.

* When you take a sample of the standard gas, mercury particles may adhere to the

syringe needle and contaminate the standard gas inlet. Wipe the tip of the needle

with Kimwipes or other material before feeding the gas.

Abnormal increase in sensitivity

An abnormal increase in peak sensitivity may be caused by the following two factors:

Problems with the standard gas

- the syringe is contaminated with mercury,

- the indicated temperature of the Mercury Vapor Calibration Box is low, or

- the septum of the Mercury Vapor Calibration Box is contaminated.

Decreased flow rate between H2 and the absorption cell

- leakage,

- clogging in the collector tube, or

- a failure in the pump

18

Maintenance

Leak check

Check the line for any leakage from a loose joint or other points. Disconnect the

standard gas inlet and plug the top of the collector tube with your finger to stop the

supply of carrier gas. At this point, the flow rate should drop to near zero. If the flow rate

does not drop, there is a leak from the degradation of the septum, a loose joint, etc.

Caution

After the completion of the leak check, slowly slide your finger off the top of

the collector tube. If you burst it open, the collecting agent may be scattered

into the gas line, thus making normal measurement impossible.

If any leakage is detected, check the connections. If retightening does not stop the

leakage, disconnect a joint at an intermediate point in the line and plug the line with your

finger to identify the location of the leak.

19

Replacing the septum

Remove the standard gas inlet.

Remove the box nut on the side where the septum

is placed.

Replace the septum with a new one.

Install the parts in the order shown in the left

figure.

Cleaning the gas scrubbing bottle and dehumidifying bottle

Open the front cover.

Detach the collector tube, and remove the screws

fixing the connecting port of the collector tube.

Remove the transparent plate of the electronic

cooling unit.

Remove the funnel and roller clamp of the gas

scrubbing bottle and dehumidifying bottle.

Pull out the gas scrubbing bottle and the

dehumidifying bottle, and clean them after

detaching the silicone tube.

* Do not clean the silicone tube, but instead replace it

with a new one.

20

Detaching and attaching the cover

How to detach:

Turn off the power and disconnect all cables.

Remove the 2 screws on the back and the 4 screws

on both sides.

Slide the cover towards the back.

How to attach:

Place the cover on the back of the main body.

Close the cover while paying attention to the lugs (4

places) inside the cover.

Install and tighten the screws on the back and on

both sides.

Detaching and attaching the collector tube (H2)

Remove the cover of the system.

Remove the reducing Teflon joints (FLW-30-6RU4-S)

and pull out the collector tube from H2.

* When attaching the joints, first tighten them lightly by

hand and then further tighten them about 1/6 turn with a

wrench. After tightening, check that the tubes do not

come off when pulled.

(The joints will break if tightened too much.)

Check the quartz tube and wool of the collector tube for

any dirt or stains.

If the wool is discolored or if there is a gap in the

wool, change it.

Reverse the procedure to attach the collector tube.

Other manuals for WA-5F

1

Table of contents

Other Nic Measuring Instrument manuals