Solar Stik SOLAR VENTURE 300W PHOTOVOLTAIC ARRAY Installation instructions

October 2020

OPERATOR AND MAINTENANCE MANUAL

FOR THE

SOLAR VENTURE 300W

PHOTOVOLTAIC ARRAY

P/N 19-1000010

DISTRIBUTION STATEMENT A. Approved for public release; distribution is unlimited.

Updated:2020108

Version 1.0

Solar Venture 300W PV Array Operator and Maintenance Manual

October 20202 |

Contents

GENERAL INFORMATION, THEORY OF OPERATION, AND EQUIPMENT DESCRIPTION

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Product Safety Information and Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Information Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Fire Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Recommended Fire Extinguisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electric Shock Hazard Related to PV Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Environmental and Handling Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Wind . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Impact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Dust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Equipment Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Kit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

OPERATOR INSTRUCTIONS

Solar Venture 300W PV Array Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Position and Orient System Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Deploy the PV Array Support Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Install the Large Ground-securing Mesh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Install the Small Ground-securing Mesh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Install the PV Array on the Support Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connect the Solar Cable to the PV Panel Leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connect PV Array(s) to Solar Only Input Port of Power Hub . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Position the PV Arrays for Optimal Power Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Derating, Solar Loading, and Airflow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Secure the Array to the Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Disassembling and Repacking the PV Array . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

MAINTENANCE

Preventive Care and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

PV Array Conditional Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Measuring PV Array Voltages: Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Procedure to Measure PV Array Voc with a Multimeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

SUPPORTING INFORMATION

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

ABOUT SOLAR STIK, INC.

Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

| 3October 2020

Solar Venture 300W PV Array Operator and Maintenance Manual

List of Figures

Figure 1. Solar Venture 300W PV Array with ground securing ......................................................................................... 4

Figure 2. Solar Venture 300 W PV array with a small HPS ............................................................................................... 9

Figure 3. Solar Venture 300W PV Array components in transport case (top) and unpacked (bottom) .......................... 10

Figure 4. Working-space radius for the PV arrays and associated equipment .............................................................. 11

Figure 5. Deploying the PV array support frame ............................................................................................................ 12

Figure 6. Large ground-securing mesh installation ........................................................................................................ 13

Figure 7. Small ground-securing mesh installation ........................................................................................................ 14

Figure 8. Ground-securing mesh conguration for 30º array deployment ..................................................................... 15

Figure 9. Ground-securing mesh conguration for 60º array deployment ..................................................................... 15

Figure 10. Connecting array hooks to support frame..................................................................................................... 16

Figure 11. Locking the array into place on the support frame ....................................................................................... 16

Figure 12. Connecting the PV array to the Solar Cable.................................................................................................. 17

Figure 13. PV arrays connected to Solar Only Input ports of Power Hub ..................................................................... 18

Figure 14. Ground-securing sandbag placement .......................................................................................................... 20

Figure 15. Packing the Solar Venture 300W PV Array.................................................................................................... 21

Figure 16. Measuring PV array open circuit voltage Voc ................................................................................................ 23

Section Page(s) Description Date

Published June 2020

Revision History

Solar Venture 300W PV Array Operator and Maintenance Manual

October 20204 |

Introduction

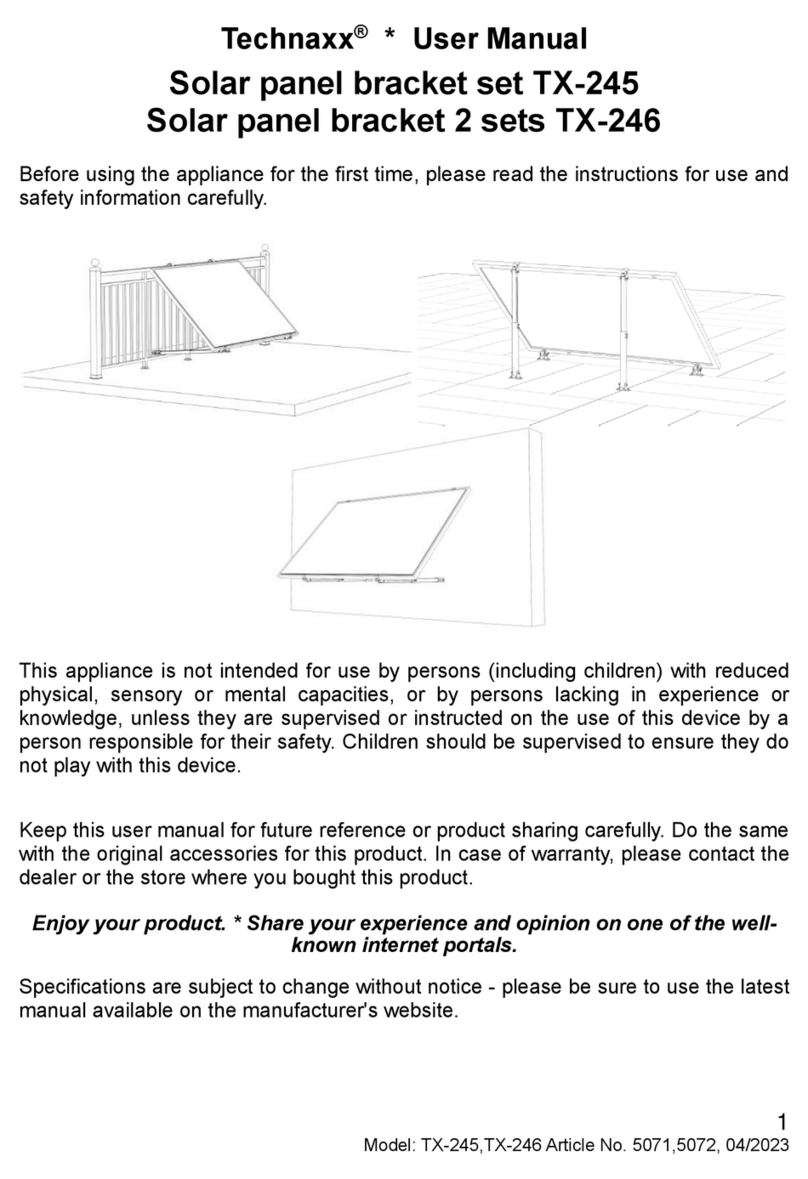

The Solar Venture 300W Photovoltaic (PV) Array is designed to generate renewable power in

expeditionary applications where weight, rugged design, and extreme portability are factors.

The Venture design can be deployed on any terrain, and the PV array can generate up to 300 Watts

of power for applications where independence from traditional power sources is required:

• PV power generation for remote locations where fuel-driven generators are not an option

• Decreased fuel consumption in a Hybrid Power System (HPS)

• Peak-shaving to decrease reliance on power from utility or grid

The Solar Venture 300W PV Array is modular and scalable, allowing users to tailor power generation

capability to load requirements.

Setup requires no tools and the 300 W Array is “Plug & Play” compatible with Hybrid Power

Systems.

The mono-crystalline cells in the high efciency Venture-Series panels are laminated onto a carbon-

ber structure, which combines extremely high PV performance with incredibly light material for

an extraordinary watt-to-weight ratio. The Venture offers a superior integration of technologies to

provide the operator with highest power in the smallest renewable generator footprint.

Figure 1. Solar Venture 300W PV Array with ground securing

GENERAL INFORMATION, THEORY OF OPERATION, AND

EQUIPMENT DESCRIPTION

| 5October 2020

Solar Venture 300W PV Array Operator and Maintenance Manual

Your safety and the safety of others is very important. This manual provides guidance on safe

operating practices and how to achieve maximum performance from the Solar Venture 300W PV

Array. Always observe and follow all safety protocols outlined below:

This is the safety alert symbol. This symbol alerts you to potential hazards that can kill you or

hurt you and others. All safety messages will follow the safety alert symbol and the word

“DANGER”, “WARNING”, or “CAUTION”. These words are dened as:

DANGER Indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

All safety messages will identify what the potential hazard is, how to reduce the chance of injury, and

what can happen if the instructions are not followed.

Product Safety Information and Instructions

This manual contains important safety instructions that must be followed during the installation and

operation of the PV array. Read all instructions and safety information contained in this manual.

Exercise caution when handling or operating equipment. Live power may be present.

Safety Information Labels

Solar Venture 300W PV Array Operator and Maintenance Manual

October 20206 |

Fire Hazard

Fire Types

Class A fire - Fires in ordinary combustibles such as wood, paper, cloth, trash, and plastics.

Class B fire - Fires in ammable liquids such as gasoline, petroleum, oil, and paint.

Class C fire - Fires involving energized electrical equipment such as motors, transformers, and

appliances. Remove the power source and the class C re becomes a class A or B re.

Recommended Fire Extinguisher

NSN 4210-00-288-7219 Fire Extinguisher, Carbon Dioxide, 10 lb

Carbon dioxide is a liqueed gas, which is highly effective ghting class B and C res. These

extinguishers are ideal for areas where contamination and/or cleanup are a concern, such as data

processing centers, labs, and telecommunication rooms.

Use Sweeping Motion

WARNING

Only CO2(carbon dioxide) re extinguishers should

be used with this equipment.

Using the Fire Extinguisher

When using the extinguisher on a re, remember PASS:

Pull the pin.

Aim the nozzle or hose at the base of the re from a safe distance.

Squeeze the operating lever to discharge the re extinguishing agent.

Sweep the nozzle or hose from side to side until the re is out. Move forward or around the re as

the re diminishes.

Watch the area for reignition until the cause has been xed.

| 7October 2020

Solar Venture 300W PV Array Operator and Maintenance Manual

Electric Shock Hazard Related to PV Panels

WARNING

Standing water around the electrical equipment and/or intrusion of water into the System

components can increase the risk of electrical shock.

DON’T LET THIS BE YOU!

HIGH VOLTAGE: PV arrays and generators produce potentially lethal line voltages. When servicing

equipment, extreme care should be taken to protect against electrocution. Always work with another

person in case an emergency occurs. Disconnect power before checking controllers or performing

maintenance. Be sure the generator is properly grounded. Wear safety glasses whenever working on

any part of the System that requires exposure to mechanical or direct electrical contacts.

• PV panels produce electricity when exposed to sunlight.

• Live power may be present at multiple terminals.

• Never route the cables through standing water.

• All cables and connections should remain dry and should be inspected regularly to ensure safe

operating conditions.

Solar Venture 300W PV Array Operator and Maintenance Manual

October 20208 |

Environmental and Handling Precautions

This equipment is ruggedized, yet there are a few things the operator can do to prevent failures and

prolong the operational life of the product.

Water

• Do not operate equipment in or around standing water.

• Do not place cables that conduct electricity in or near

standing water.

Impact

The PV panels should be protected from being struck by

hard objects.

Dust

• This equipment is designed for operation in climates

where high levels of dust or other particulates may

exist.

• Clean the surface of the PV panels regularly to maintain

maximum output. Dirty panels produce less power.

Heat

• Heat and solar loading reduce efciency and life

expectancy. Shade products (except PV panels) to

prevent the negative effects of heat.

• PV panels should be placed so that they are exposed

to adequate airow.

Wind

It is imperative to properly secure the PV panels to

the ground using sandbags so they do not become

dangerous projectiles in high winds.

| 9October 2020

Solar Venture 300W PV Array Operator and Maintenance Manual

PV cells convert sunlight into electrical power. All PV cells are made of materials called

semiconductors that absorb photons when sunlight strikes the PV cell. The absorbed photons

then knock electrons loose within the PV cells, allowing them to ow, which produces an electrical

current. PV cells contain one or more electric elds that force the direction of electron ow. Placing

metal contacts on the top and bottom of a PV cell harnesses this current so it can power external

appliances, much like a traditional power generator.

On their own, PV cells produce a limited amount of power, but when arranged and electrically

connected in a PV panel, the power generated is directly related to how much cumulative current and

voltage the PV cell arrangement is congured for. The panel’s total output voltage and current will

determine its “watt” rating.

The cell conguration of the Venture 300 Array generates up to 300 W of DC power for an application.

Figure 2. Solar Venture 300 W PV array with a small HPS

Theory of Operation

Solar Venture 300W PV Array Operator and Maintenance Manual

October 202010 |

Kit Components

Solar Venture 300W PV Array

1Hard transport case

2 4-section foldable PV array

3 Ground-securing mesh (large and small)

4 Support frame

5 Sandbags (12 ea)

6Solar Cable (sold separately)

Figure 3. Solar Venture 300W PV Array components in transport case (top) and unpacked (bottom)

6

3

5

4

2

1

Equipment Description

| 11October 2020

Solar Venture 300W PV Array Operator and Maintenance Manual

Position and Orient System Components

Identify the best location for each component of the System, keeping in mind the length of all cables

that will be used to connect all of the components. The typical Solar Cable provided is 30’ long

(other lengths are available).

Figure 4. Working-space radius for the PV arrays and associated equipment

Solar Venture 300W PV Array Setup

30’

PV arrays

Power

Management/

Energy Storage

components

The PV array can be deployed within a 30’ radius (the length of the Solar Cable) of the component

to which it will be connected. If the PV array must be deployed more than 30’ from the Power Pak or

Power Hub, etc., extensions are available.

OPERATOR INSTRUCTIONS

Solar Venture 300W PV Array Operator and Maintenance Manual

October 202012 |

Deploy the PV Array Support Frame

Locking pins in

storage position

Transport strap

A B

C

D

E

Loosen the transport strap securing the foldable array support frame (Figure 5A). Remove the

two locking pins (Figure 5B) to allow the frame to expand. Expand the support frame (Figure 5C)

and install the locking pins in the “deployed” position (Figure 5D) after the support frame is fully

extended (Figure 5E).

Tensioning clamps

Locking pins in

deployed position

Figure 5. Deploying the PV array support frame

| 13October 2020

Solar Venture 300W PV Array Operator and Maintenance Manual

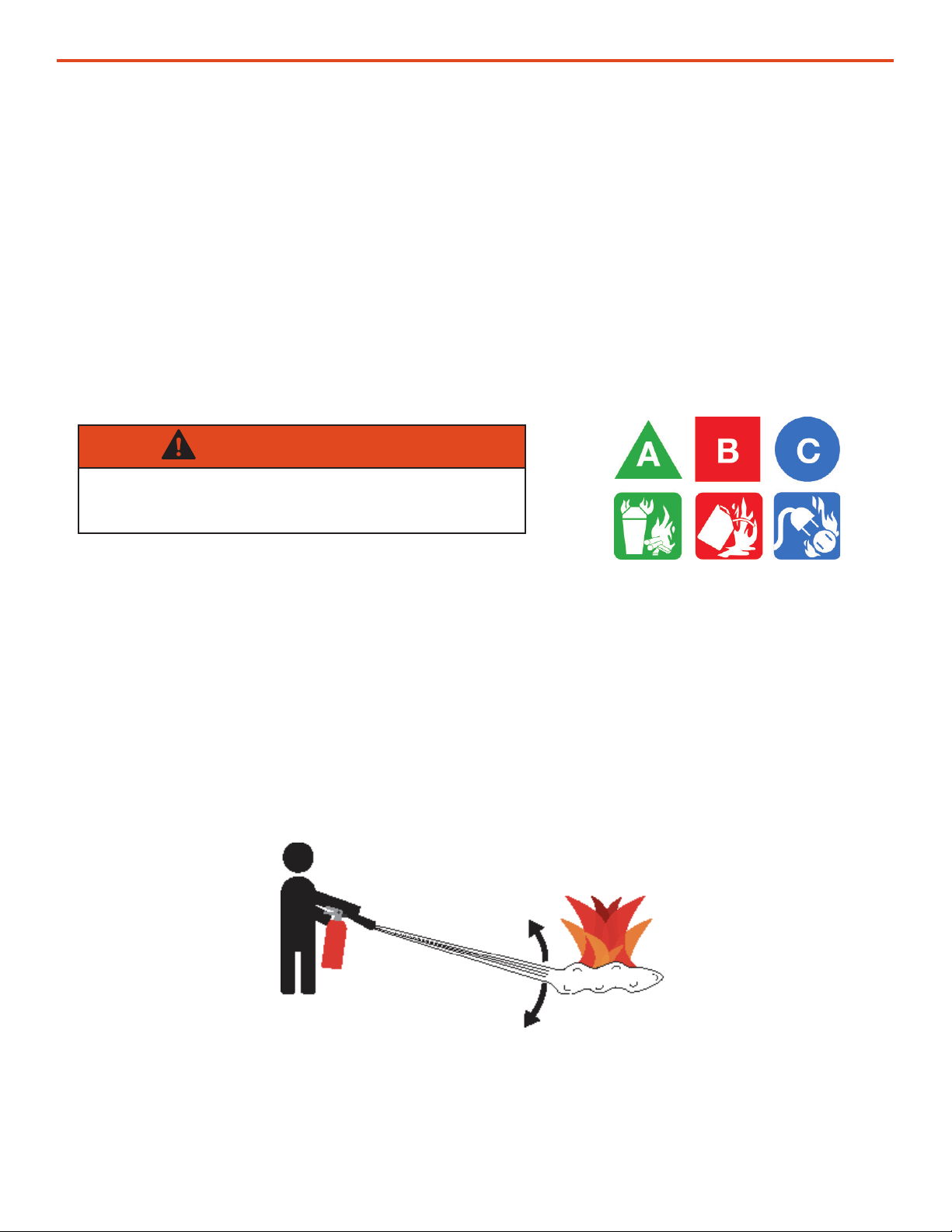

Install the Large Ground-securing Mesh

The large ground-securing mesh has three (3) clips on the short side and four (4) on the long side

(Figure 6A). The clips on the short side connect to the rings on the three (3) cleats (Figure 6B) of the

support frame. Connect the four (4) clips on the long side of the ground-securing mesh to the wire

loops (Figure 6C) at the low end of the support frame bar (Figure 6D). The mesh will be stretched

tight when all of the connections are made.

A

BC

D

Cleat rings Wire loop

Figure 6. Large ground-securing mesh installation

Solar Venture 300W PV Array Operator and Maintenance Manual

October 202014 |

Install the Small Ground-securing Mesh

The small ground-securing mesh has three (3) clips on the short side and four (4) on the long side

(Figure 7A). The clips on the short side connect to the rings (Figure 7B) on the three (3) cleats of the

support frame (Figure 7C).

Figure 7. Small ground-securing mesh installation

A

B

C

Cleat rings

| 15October 2020

Solar Venture 300W PV Array Operator and Maintenance Manual

Figure 8. Ground-securing mesh conguration for 30º array deployment

Ground-securing Mesh Configuration for Low- and Steep-angle Deployments

Figure 9. Ground-securing mesh conguration for 60º array deployment

Connect the large and small ground-securing meshes as shown in Figure 8 to deploy the PV array

at 30º and as shown in Figure 9 to deploy the PV array at 60º.

Solar Venture 300W PV Array Operator and Maintenance Manual

October 202016 |

A

A B C

Install the PV Array on the Support Frame

The PV array has eight (8) grommet-reinforced holes, four (4) on the top and four (4) on the bottom

(Figure 10A, orange circles). The support frame has eight (8) complementary panel mounting hooks

(Figure 10B, orange circles). Connect the bottom of the PV array to the lower row of mounting hooks

rst and the top row of hooks second (Figure 10B).

B

Connect array to

lower hooks rst

Connect array

to upper hooks

second

The hooks on the upper row are part of a sliding tensioning clamp. Unlock and lift the clamp lever

to allow the hook to slide down (Figure 11A). Place the hook into the hole, then tighten (Figure

11B) and lock the clamp (Figure 11C). Repeat for each of the four mounting holes until the array is

secured to the support frame (Figure 11D).

Array backside

Power output

leads

D

Figure 10. Connecting array hooks to support frame

Figure 11. Locking the array into place on the support frame

| 17October 2020

Solar Venture 300W PV Array Operator and Maintenance Manual

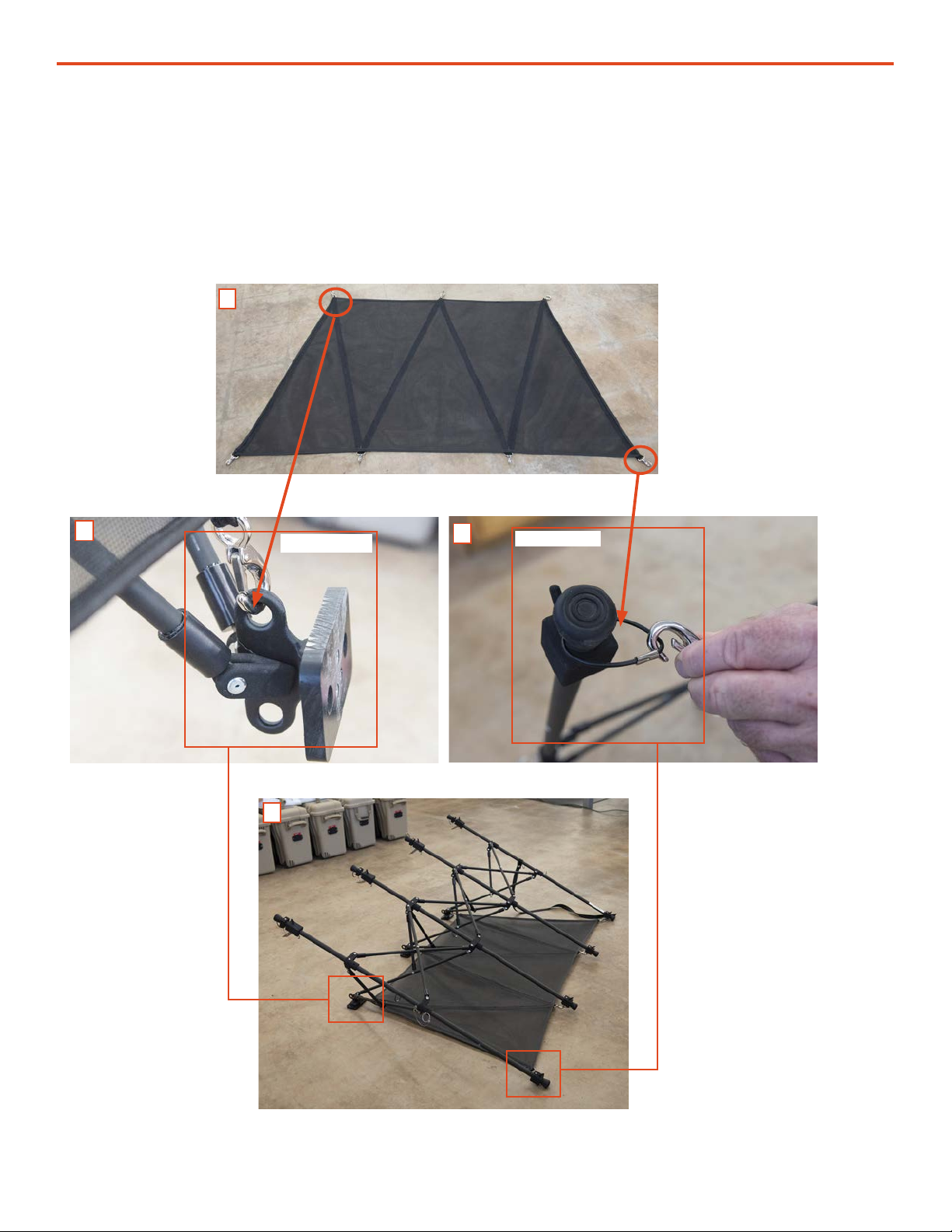

Connect the Solar Cable to the PV Panel Leads

Connectors

AB

C D

Connect the leads on the PV array (Figure 12A) to the Solar Cable (Figure 12B). The locking

connectors are polarized (Figure 12C–D).

Figure 12. Connecting the PV array to the Solar Cable.

Connectors

Solar Venture 300W PV Array Operator and Maintenance Manual

October 202018 |

Figure 13. PV arrays connected to Solar Only Input ports of Power Hub

Connect PV Array(s) to Solar Only Input Port of Power Hub

NOTICE

Do not secure the PV array to the ground until adequate cable length to the Power Hub has been

veried and the arrays have been oriented optimally toward the sun.

Connect the Solar Cable(s) to the Solar Only Input ports on the side of the Power Hub. A maximum

of six (6) PV arrays can be connected to the Power Hub.

PV arrays

Power Hub

Note: This example describes connection to a Power Hub however, other Solar Stik components

such as the PRO-Verter S, Power Paks and BOS have PV-input capabilities. Consult the Manuals for

these components for details.

| 19October 2020

Solar Venture 300W PV Array Operator and Maintenance Manual

PV Array Orientation for Optimum PV Power Generation

PV generation requires direct sunlight for maximum performance. Optimal PV power generation is

achieved by orienting all PV arrays in the same direction and at the same angle.

Note: Harvesting PV energy will not improve by orienting subsets of PV arrays to capture

morning, midday, and evening sun. In the Northern Hemisphere, the PV arrays should be

positioned so that they face the noon sun, which is usually true South, true North if in the

Southern Hemisphere. The PV arrays may be deployed at, aimed straight up if at or near the

equator.

Seasonal Adjustment of the PV Array Tilt to Improve Output

The PV array performance may be improved by adjusting the tilt and orientation of the panels

seasonally. The angle of the array, relative to the sun, can be adjusted to 30° or 60° prior to securing

to the ground. The sun is higher overhead during the summer and lower on the horizon during the

winter.

Power output of the PV arrays can be monitored in real time on the Power Hub User Interface. (See

the Power Hub Operator Manual for instructions.) Monitoring the power output while orienting and

choosing the best tilt angle for the panels will assist in nding and maintaining optimum power

output throughout the year.

Position the PV Arrays for Optimal Power Generation

NOTICE

The setup location should have good exposure to sunlight and be away from other structures or

potential hazards such as moving-vehicle thoroughfares.

Shading

The PV arrays must be positioned so they are not shaded. During periods of inclement weather or if

the array is not positioned optimally, daily power generation levels may be reduced.

Derating, Solar Loading, and Airflow

Derating occurs when the power output of the PV arrays is diminished below their rated values. PV

arrays may accumulate excessive amounts of heat due to solar loading and lack of airow, resulting

in derating.

Locate PV arrays where airow is unobstructed to reduce the impact of solar loading–induced

derating.

Solar Venture 300W PV Array Operator and Maintenance Manual

October 202020 |

The PV array must be secured with three (3) to six (6) sandbags (Figure 14) to reduce the potential

for damage in high winds.

Sandbags should weigh a minimum of 50 pounds (23 kg) each. Place sandbags on the large ground-

securing mesh under the PV panel and on the small ground-securing mesh behind the panel as

shown below (Figure 14).

Secure the Array to the Ground

WARNING

Failure to properly secure the PV array(s) to the surface with sandbags could result in PV

array damage, injury, or death in high winds. Wind damage can render arrays nonfunctional or

signicantly reduce their functional life expectancy. PV arrays must be properly secured to the

ground even in low-wind environments.

Note: Before the arrays are secured to the ground, be observant and take care to ensure

the support frame is not twisted. If the support frame is twisted, the array will be exposed to

torsional strain, which can cause damage to the cells of the array panel(s).

CAUTION

DO NOT DAMAGE THE ARRAY SUPPORT FRAME.

DO NOT DROP SANDBAGS ONTO THE PV ARRAY SUPPORT FRAME.

Figure 14. Ground-securing sandbag placement

Do not secure the arrays to the ground before establishing proper location and orientation.

This manual suits for next models

1

Table of contents

Other Solar Stik Solar Panel manuals