Solfex SOLAR CANOPY User manual

INSTALLATION MANUAL

SOLAR CANOPY PV MOUNTING SYSTEM

2 |

Contents

1 Introduction 3

1.1 Short description 3

1.2 Intended use 3

1.3 Standards and technical directives 3

1.4 About this manual 3

2 Safety 4

2.1 Basic safety instructions 4

2.2 Working on roofs 4

2.3 Warnings 4

2.4 Operator‘s responsibilities 5

3 Technical description 6

3.1 System overview 6

3.2 Scope of delivery 7

3.3 Technical specications 8

3.4 Operating conditions 8

4 Planning of the module eld 8

4.1 Dimensions 8

5 Important mounting information 10

5.1 Mounting aids and required tools 10

5.2 Additionally required materials 10

6 Installation 10

6.1 Preparation work 10

6.2 Installing the system 11

6.3 Installing the modules 14

6.3.1 Portrait installation 14

6.3.2 Landscape installation 15

Solar canopy — for universal use on flat roofs

| 3

Introduction

1.1 Short description

The SolarFrame at roof system is a robust mounting

system for PV modules on at roofs. It consists of alumin-

ium triangles, aluminium support rails and all necessary

accessories for attaching the modules to the rails and

connecting the components to one another. Further com-

ponents such as roof xation kits or back plates are also

available. With SolarFrame, both portrait and landscape

module mounting are possible.

1.2 Intended use

The SolarFrame at roof system is to be used for the roof

installation of PV modules only. Any other use is consid-

ered improper.

The observance of the information in these assembly

instructions is a part of proper use. Mounting Systems

GmbH is not liable for damage that results from the

non-observance of assembly instructions, in particular

the safety information, or from the improper use of the

product.

1.3 Standards and technical directives

When planned correctly, SolarFrame fullls the following

standards and technical directives:

Eurocode 9 — DIN V ENV 1999-1-1: Design of aluminium

structures

DIN 1055 — Actions on structures: Basis of design,

safety concept and design rules

1.4 About this manual

Subject

This manual details the installation and assembly of

the SolarFrame at roof system. The illustrations in the

manual show the portrait mounting procedure for framed

modules. Should landscape mounting differ from portrait

mounting, this will be clearly emphasised. Some ad-

ditional components that are repeatedly used are also

indicated. No description is included for materials for spe-

cial substructures that may be required to accommodate

the constructional conditions of the building in addition to

standard materials. These are always specially manufac-

tured and documented separately.

User group

This manual is intended for qualied personnel with a

basic knowledge of mechanics, hand tools and mechani-

cal skills.

4 |

Safety

2.1 Basic safety instructions

The following basic safety instructions and the warning

notes are an essential part of this manual and are of

fundamental importance for handling the product.

• Ensure that the product corresponds to the static

requirements on-site prior to every assembly and

installation.

• Ensure that the building corresponds to the increased

static requirements due to the PV unit, prior to every

mounting and installation.

• Observe occupational health and safety regulations

of the employer‘s liability insurance association.

• Wear a hard hat, protective gloves and safety shoes.

• A second person must be present during the entire

installation process, to give assistance in the event

of an accident.

• A copy of this installation manual must be kept in

the direct vicinity of the unit.

2.2 Working on roofs

When working on roofs, note the following instructions:

• Pay attention to accident prevention regulations for

working on roofs. If appropriate, use a barrier to protect

against falling parts.

• In line with accident prevention regulations, work on

roofs should be carried out using safety harnesses

for individuals or safety scaffolding.

• Observe the relevant local safety regulations.

• Before stepping on to the roof, check the load-bearing

capability of all parts which are under stress.

• Use fall protection.

• Use protective equipment to guard against falling

even when carrying out short jobs.

• Do not carry materials on to the roof via ladders,

but rather use suitable lifting gear.

2.3 Warnings

The warning notes used in this manual identify safety

related information. They consist of:

• Warning symbol (pictograph)

• Indicator word to denote the danger level

• Information about type and source of the danger

• Information about possible consequences if the

danger is not observed

• Measures for avoiding the danger and for preventing

injuries or property damages

The heading of the warning notes identies one of the

following danger levels:

Denotes a potential risk which may

lead to physical injury and property

damage.

CAUTION

Denotes a potentially dangerous

situation which may lead to moder-

ate to serious physical injury and

property damage.

WARNING

Denotes a major risk, failure to

observe which could lead to serious

injury or death.

DANGER

| 5

2.4 Operator‘s responsibilities

The system operator has the following safety-relevant

responsibilities:

• Ensure that the installation of the system is only

performed by persons with manual skills and basic

knowledge of mechanics.

• Ensure that the assigned installation personnel can

evaluate the work assigned to them and can recognize

possible dangers.

• Ensure that the persons commissioned are familiar

with the system components.

• Ensure that the installation manual is accessible

during the assembly. The mounting instructions are

an integral part of this product.

• Ensure that the mounting instructions and in

particular the warnings have been read and understood

by the authorized installation personnel prior to

assembly.

• Ensure that the permissible conditions of use

(see chapter 3.4, page 8) have been upheld.

for damage which results from a violation of these

conditions.

• Ensure that the roof construction has the required

load-bearing capacity, in particular in the vicinity of

the force transmission points.

• Ensure that the durability of the mounted connections

and the root atachments are guaranteed.

• Ensure that any necessary roof penetrations are

professionally sealed.

• Ensure that the appropriate lifting equipment is used

for the mounting process.

used, also in case of replacement.

Otherwise the warranty claim is void.

Solfex Ltd will not be held liable

• Ensure that only Solfex Ltd components are

6 |

Technical description

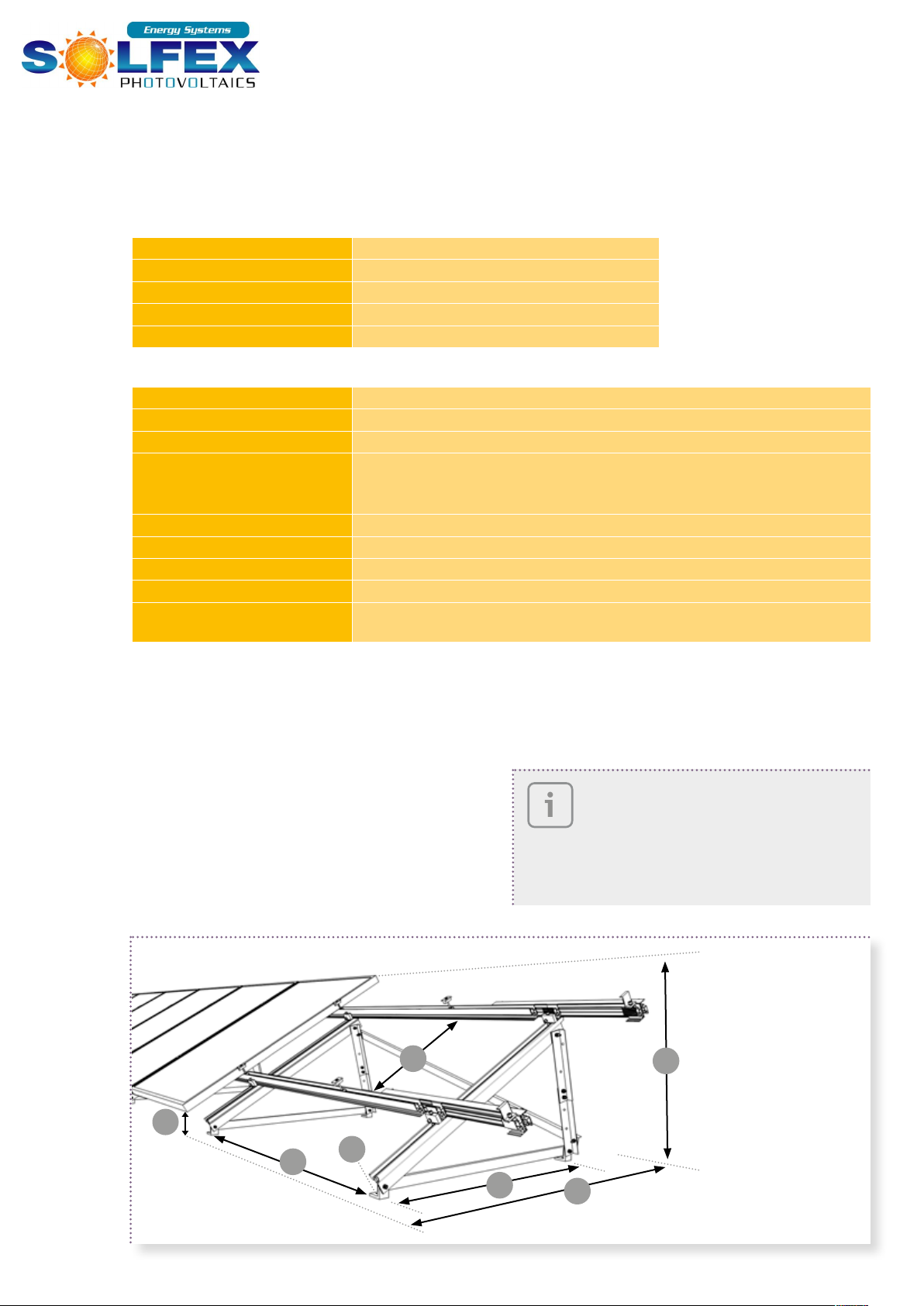

3.1 System overview

All system components are described below. The design

of the individual system components may vary.

They are dependent on:

• Type of roof,

• Type of module,

• Number of modules and

• The conditions on site.

Components:

a Triangle (shown here with foot brackets)

b Triangle (shown here with ground rail)

c X-Stone

d Base rail 13/58

e Splice 13/58 (not visible)

f Telescoping end piece 13/58

g Diagonal strut

h SolRec base plate (optional accessory)

i Module end clamp for landscape installation

j Module clamp

k Module end clamp for portrait installation

a

c

d

g

j

f

k

e

Portrait installation

b

i

h

Landscape installation

| 7

3.2 Scope of delivery

All system parts and requisite small parts

which are required for installation are

included in the delivery. The precise scope

of supply will depend on the size and

number of PV modules which you specify

when ordering. No description is included

for materials for special substructures that

may be required in addition to standard

materials to accommodate the construc-

tional conditions of the building.

a Triangle (shown here with foot brackets)

b Triangle (shown here with ground rail)

c X-Stone*

d Base rail 13/58

e Splice 13/58

f Telescoping end piece 13/58

g Diagonal strut

h SolRec base plate (optional accessory)

i Module end clamp* for landscape

installation, module frames between

32 and 56 mm

j Module clamp*

k Module end clamp* for portrait

installation for frame heights of

35, 43, 46 and 50 mm

l Module end clamp* for portrait

installations for frame heights of

24.5 - 51mm

m Laminate clamp*

n Laminate end clamp*

o Back plate (optional accessory)

p Concrete anchor (optional xation

material)

q Hanger bolt (optional xation material)

r Bolt connection, consisting of Allen

bolt M8 x 20, self-locking nut M8 and

2 washers

s Anti-slip device for modules, consisting

of nut M6 and Allen bolt M6 x 20

t Quickstone prole nut (not an individual

component, but pre-assembled on the

components marked*)

* with Quickstone

b

c

d

a

e f

g h

i j k

m n

o

l

p q

rst

8 |

b

g

h

a

j

f

e

Planning of the module field

3.3 Technical specifications Depth of the frame unit: see table A below

3.4 Operating conditions

Portrait installation

i

4.1 Dimensions

In the following, the dimensions of the mounting system

will be given. The exact spacing between the triangles is

project-specic and must be individually dened in the

planning phase. Width of the unit: Number of horizontal

modules x (module width + 19) + 31mm; maximum 12 m

Notice: The material expansion of a 12 m-row

can be approx. 2 cm. Therefore, a minimum

distance of 10 cm between the rows is recom-

mended. Furthermore, for large systems, it is

wise to leave more space at regular intervals

as maintenance paths.

Application range Flat roof

Roof pitch 0 — 5°, greater pitch subject to prior verification

PV module Framed, unframed

Roof construction The suitability of the entire roof construction, in particular at the load transfer points of

the mounting system, must be examined for static, insulation, leak tightness, and fire

protection requirements prior to installation of the PV system.

Permissible roof load Must be specifically checked for each project.

Attachment method Must be specifically checked for each project.

Triangle and support rails Up to 1,900 PA for a 2.5 m2 surface per triangle and a roof pitch up to 5°

Max. row length 12 m

Distance between the triangles Depending on project planning, portrait installation up to approx. 1.5 m,

landscape installation up to approx. 1.8 m

Support profile, base rails Extruded aluminium (EN AW 6063 T66)

All other profiles Aluminium (EN AW 6060 T6)

Accessories Stainless steel (V2A)

Back plate Aluminium (EN AW 5005)

SolRec base plate PE

| 9

a Height of the frame unit: see table B below

b Pitch: 20°, 25°, 30°

c Distance between the rows: according to project plan

d Distance to ground: at least 8 cm, depending on

module positioning

e Distance between the triangles: according to plan,

portrait mounting up to approx. 1.5 m,

landscape mounting up to approx. 1.8m

f Distance between the foot brackets of the triangle:

955 mm / 1260 mm, depending on selected triangle

type (model A/B)

g Drill hole size in the foot brackets: 11 mm or 13 mm,

depending on selection

h Ground rail, hole pattern for triangle models A and B:

see illustration I below

i Distance between the base rails for portrait installation:

Distance of the clamp points as recommended by the

module manufacturer (usually marked by the drill holes

in the module frame, approx. ½ the module length).

j Distance between the base rails for landscape

installation: Distance of the outer edges of the rails =

module width

a

c

k

I

B

A

20 20

2021820 545

1.110 1.457

327

327 436 327 20 20327 545 545

ø 6,1 mm ø 6,1 mm

b

i

d

Landscape installation

Pitch Landscape installation Portrait installation

20°

995 mm

module length x 0.94; at least 995 mm

25° module length x 0.91; at least 995 mm

30° module length x 0.87; at least 995 mm

Pitch Landscape installation Portrait installation

20° 534 mm (module length x 0.34) + 80 mm; at least 534 mm

25° 615 mm (module length x 0.42) + 80 mm; at least 615 mm

30° 692 mm (module length x 0.50) + 80 mm; at least 692 mm

All dimensions in mm

Hole pattern: Ground rail A Hole pattern: Ground rail B

Depth of the unit, including module

Height of the frame unit, including module

2032720 545 545

10 |

Important mounting information

5.1 Mounting aids and required tools

You will need the following tools to install the system:

• 6 mm Allen key

• Combination wrenches 13

• Folding rule / tape measure

• 9 mm metal drill bit

Appropriate tools for the respective roof mounting

variations, e.g.:

• For riveting onto SolRec oor plates:

6.1 mm drill bit, rivet gun

• For attachment with x anchors into concrete:

12.5 mm concrete drill bit, hammer

5.2 Additionally required materials

Depending on the system plan, the following additional

materials may be necessary:

• Suitable xation material for roof

Material for weighting as ballast, for example gravel,

concrete slabs or other

• Suitable protective mats to protect the roof surface.

Installation

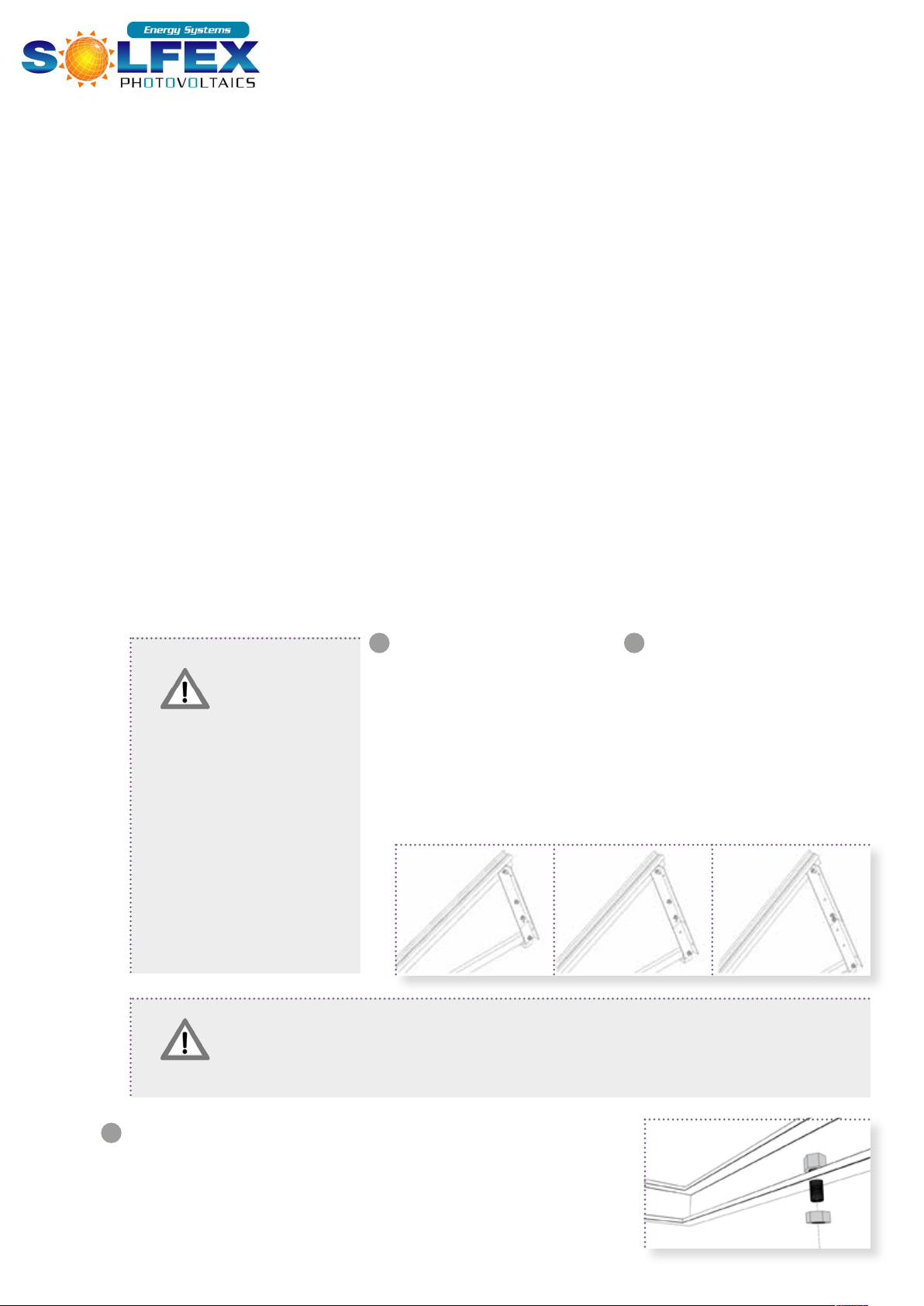

6.1 Preparation work

20˚ 25˚ 30˚

1 2

Preparing the fixation points

• Dene and mark the xation

points, and/or the planned

substructure according to plans,

and prepare for installing the

triangles.

Mounting the anti-slip protection (only for portrait installation)

• Attach one bolt with M6 nut in each of the lower drill holes of the module

frame as an anti-slip protection, and tighten them by hand.

Preparing the triangles

• Unfold the triangles and

pre-mount both of the support

elements with 2 bolts each (self-

locking nut M8, 2 washers and

M8 x 20 Allen bolt) at the desired

angle (tightening torque 8 Nm).

• Tighten all of the screw

connections on the triangle

(tightening torque 8 Nm).

Potentially mortal danger from

falls and falling objects

• Protect yourself against falling.

• Do not remain in the danger

zone.

• Wear a hard hat.

• After the assembly is

complete, ensure secure

positioning of the mounting

system and the modules.

Material damage from improper mounting. Improperly fastened triangles can bend or collapse.

• Carry out all new bolted connections using the abovementioned materials (bolts, washers and nuts).

• After installation, ensure that all bolted connections are tight.

DANGER

CAUTION

3

| 11

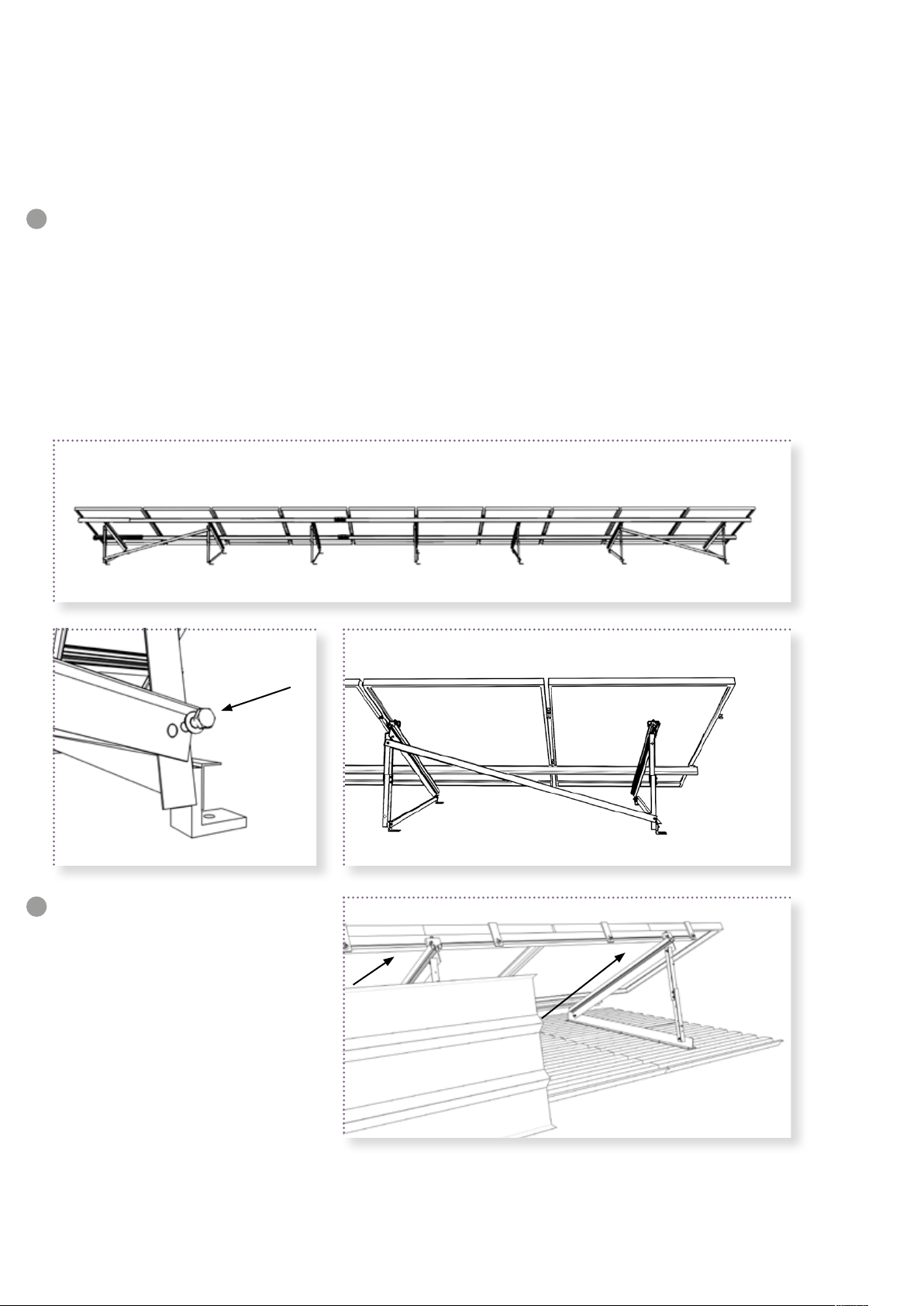

6.2 Installing the system

Mounting the triangles

• While maintaining the planned

spacing, arrange the triangles so

they are parallel, and x them

with the designated connecting

materials.

Fixing the X-stones

• Fix two X-stones per triangle

(see point 4.1 Dimensions) to the

support rail of the triangle at the

specied points. Take care to

observe the differing alignment of

the X-stones for portrait or

landscape installation (see

illustration on the right).

• Insert the Quickstone into the

prole channel so that the form

of the Quickstone ts perfectly

into the prole. The bolt may not

protrude beyond the lower edge

of the Quickstone.

• Fasten the Quickstone loosely

with 2 bolt turns.

• Put the X-stone in the desired

position and line it up

transversely to the support rail.

• Tighten the bolt just enough

so that the X-stone does not slide

down. Do not tighten completely.

Material damage due to improper mounting

Improperly fastened X-stones may slip or rip out.

• All Quickstone connections must be mounted according

to instructions.

• After mounting, check that the bolted connections are tight.

CAUTION

Portrait installation Landscape installation

Material damage due to inappropriate material selection

Inappropriate xation material can cause the triangles to rip out, roof damage and leakage.

• Select appropriate xation material according to the location, roof state, and system design.

Material damage from improper mounting

Improperly xed triangles can rip out and result in leaks.

• All attachments should be of professional quality.

• After mounting, ensure that the xation is correct.

WARNING

WARNING

1

2

12 |

Install base rail

• Mount 2 horizontal base rail sections per row of triangles.

• Align and position the rails according to the selected

module dimensions (distance between the rails,

see page 9 point j and k).

• Lay the rails with the smooth side down on the triangles

and fasten them loosely to the vertically-mounted

x-stones on the side.

• Take care to observe the differing alignment of the rails

for portrait or landscape installation (see illustration on

the right).

• Align the rails and subsequently tighten the vertical and

horizontal X-stone bolts nally (tightening torque 8 Nm).

Connecting the individual rails

• The splice should be slid in half-way from the side,

on the back side of the prole rail.

• Slide the next prole rail into the splice.

• Tighten both bolts of the splice (tightening torque 8 Nm).

Mounting the telescoping end piece

(inclusion is dependent on design)

• If intended, slide a telescoping end piece into the base

rail at the end of each rail section, but wait to tighten.

• If applicable, mount the exible element of the

telescoping end piece onto the X-stone of the last triangle.

• After the precise adjustment to the length of the

module surface area, x the telescoping end piece.

This is done by, tightening the bolt on the end of the

telescoping end piece facing the module surface area

(tightening torque 8 Nm).

3

4

5

TIP: It is best not to pre-calculate

and adjust the exact position of the

telescoping end piece, but instead to

do the exact positioning and nal

mounting while xing the last module.

Portrait

installation

Landscape

installation

| 13

Attaching the diagonal struts

• Mount 2 diagonal struts per unit on the left and

right ends of the row.

• Loosely mount one end of the diagonal in the lowest

pre-drilled bore hole of the strut to the outside triangle

with a self-locking nut M8, 2 washers and an allen bolt.

• Point the strut diagonally to the next triangle in the

row and mark the exact position of that triangle’s

upper-most bore hole on the diagonal.

• Drill a hole with diameter of 9 mm at the marked

location.

• Fix the second end of the diagonal.

• Tighten both diagonal connections nally (tightening

torque 8 Nm).

• If necessary, shorten any protruding ends of the

diagonals (purely for appearance purposes).

Attaching the back plate (alternative

to the diagonal struts)

• Hold the back plates against the

triangles from behind, and x them to

the triangle supports with two drill

screws per triangle.

• Allow the back plates to overlap by

5 cm.

6

7

14 |

Material damage due to

improper mounting

• Improperly fastened module

(end) clamps may rip out.

• All Quickstone connections

must be mounted according

to instructions.

• After installation, ensure that

the bolted connections are tight.

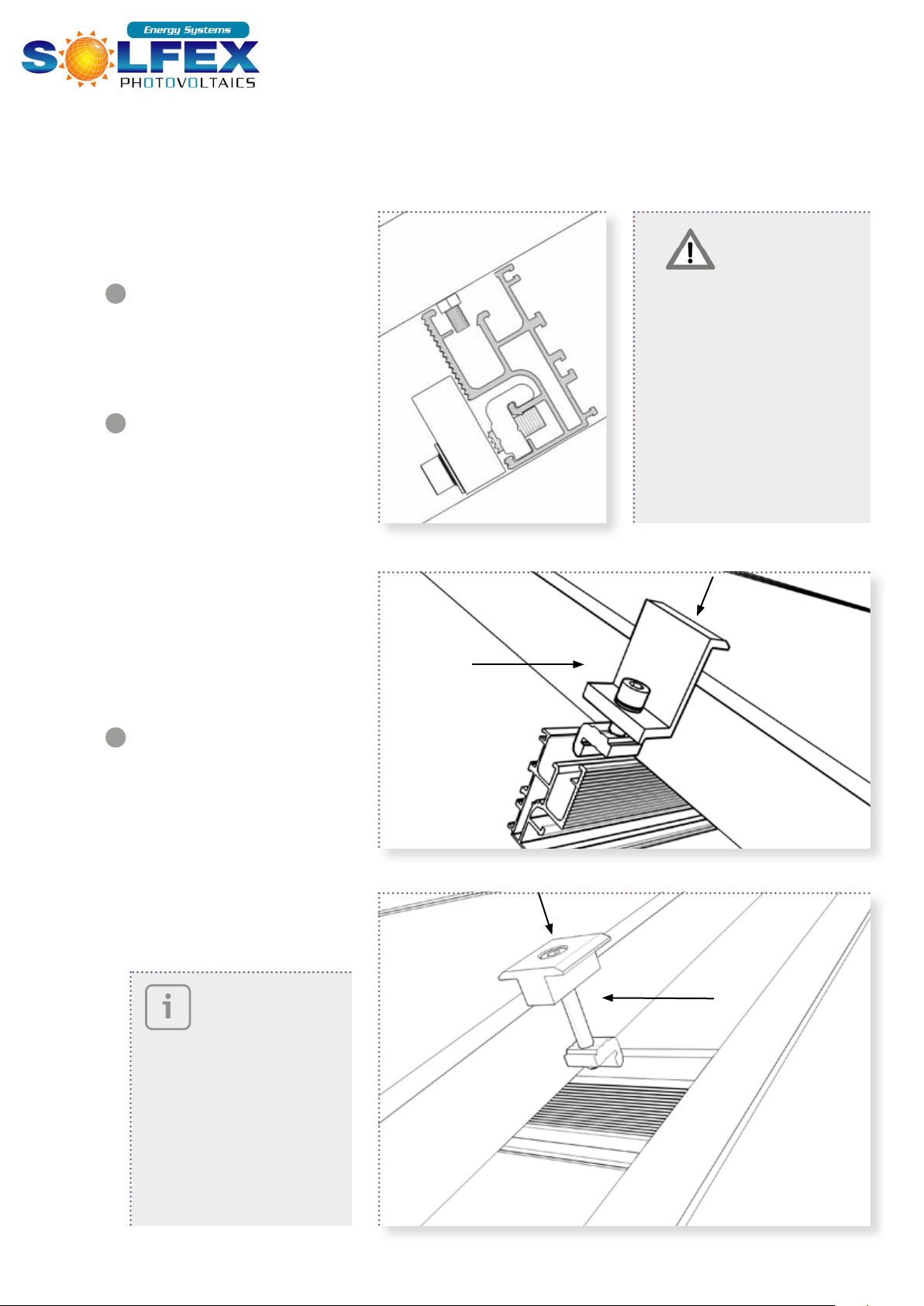

6.3 Installing the modules

6.3.1 Portrait installation

Module positioning

• Place the modules on the rails so

that the slip-guard bolts are in

the lowest rail channel.

Attaching the outer modules

• Insert the Quickstone of the

module end clamps in the top

channel of the base rail (the bolt

may not protrude on the under

side of the Quickstone) and

fasten them loosely.

• Before tightening, push the

modules under the module

clamps and align them.

• Tighten the module end clamps

(tightening torque 8 Nm).

Attaching the inner modules

• Insert the Quickstone of the

module clamp into the top rail

channel of the base rail, slide

them on to the previously

mounted module and fasten

loosely.

• Slide the second module onto the

module clamp, align it, and

tighten the bolts (tightening

torque 8 Nm).

1

2

3

CAUTION

i

When installing

laminates, special

laminate end and/

or laminate middle

clamps must be

used. The installa-

tion procedure is

identical. Slide the

laminate between

the rubber lips of the

laminate end clamp

before tightening.

6.3.2 Landscape installation

Mounting the lower module end clamps for landscape

installation

• Fix two module end clamps per module to the lower

base rail.

• Insert the Quickstone of the end clamp into the side

channel of the rail and fasten loosely.

• The distance between the clamps should be based on

the optimal clamping points of the respective module

specied by the manufacturer (usually marked by the

drill holes in the module frame, approx. ¼ of the

module length from the right and the left).

Module positioning

• Place the module in landscape position onto the

loosely mounted lower module end clamps.

• Align the modules. It is not necessary to leave any

space between the individual modules.

• Adjust the height of the lower module end clamp by

means of the slotted hole so that the clamp lies

directly on the module. Finally tighten the clamps in

this position (tightening torque 8 Nm).

Mounting the upper module end clamps

• Make sure that the upper edge of the upper rail row

is ush with the modules and that the side rail

channels and the X-stones point upwards (see

illustration page 12, point 3). If necessary, correct

the positioning of the base rail.

• Mount two end clamps per module to the upper base

rail, parallel to the positioning of the lower end clamps

and tighten nally (tightening torque 8 Nm).

1

2

3Material damage due to improper

mounting

• Improperly mounted module end

clamps may slip or rip out.

• All Quickstone connections must be

mounted according to instructions.

• After installation, ensure that the

bolted connections are tight.

CAUTION

| 15

www.solfex.co.uk

Fax: +44 1773 335277

Tel: +44 1772 312847

PR5 4DZ

Lancashire

Preston

off Shop Lane

Bannister Hall Works

Energy Arena

SOLFEX Ltd

Table of contents

Other Solfex Solar Panel manuals

Popular Solar Panel manuals by other brands

Thermann

Thermann EVACUATED TUBE SOLAR HOT WATER SYSTEM owner's manual

Technaxx

Technaxx TX-212 user manual

PHOTON

PHOTON Solar installation manual

XUNZEL

XUNZEL PACK ELITE+ Series user manual

Roger Technology

Roger Technology B75 Series Instruction and warnings for the installer

GOAL ZERO

GOAL ZERO Nomad 100 user guide