Solarbotics BEAM Robotics Solar Kit 5 User manual

The BEAM

SolarSpeeder 1.1 Solaroller©

The BEAM

SolarSpeeder 1.1 Solaroller©

BEAM Robotics Solar Kit #

5:

®

BEAM Robotics Solar Kit #

5:

®

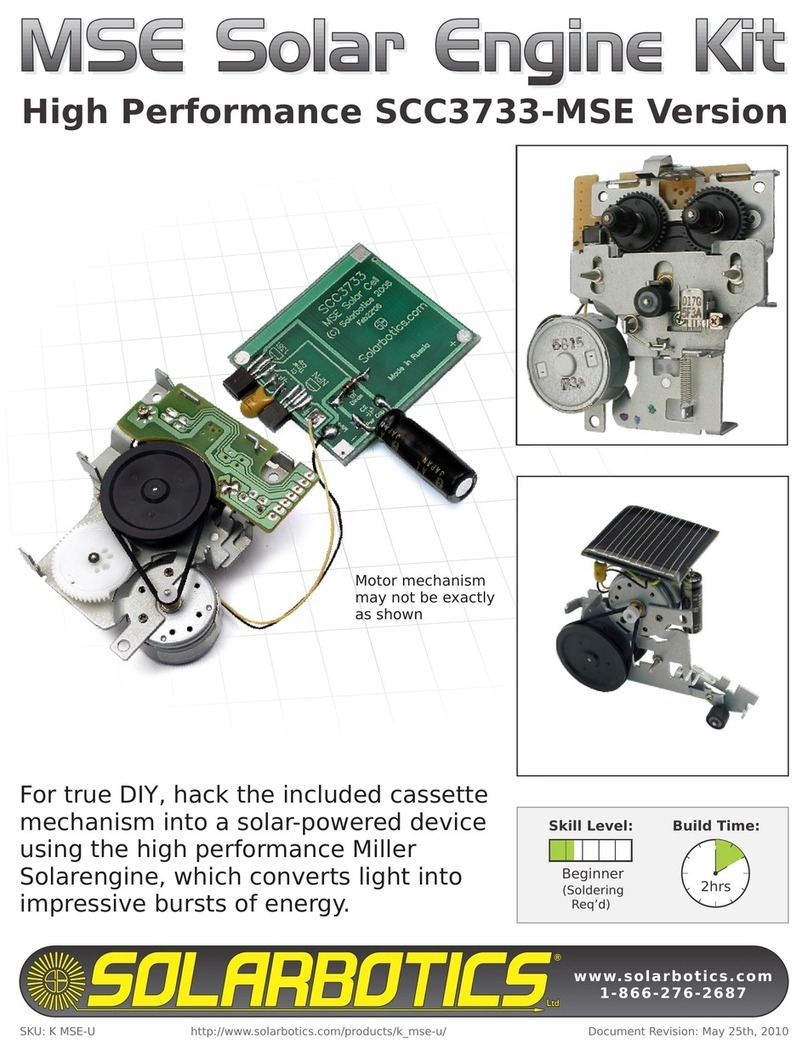

This Solar-Powered Car is designed for high-speed racing, and can zoom over 3

meters (10 feet) in under a minute in direct sunlight! (Soldering skill required)

A Complete BEAM Robotics Solar-

Powered Car Kit Inside

®

Produced by

12345

Skill Level

Ltd.

TM

Document Revision August 26 2003

Contents

SolarSpeeder 1.1Parts & Materials List ................................................................................................. 1

Introduction - The SolarSpeeder 1.1 Solaroller ...................................................................................... 2

Circuit Overview ............................................................................................................................... 3

Construction - Soldering ..................................................................................................................... 4

Construction - Electronics ................................................................................................................... 5

Construction - Wheels, and the Motor .................................................................................................. 6

Construction - Motor Mount Support & Drive Wheel ............................................................................. 7

Construction - Axles Trimming and Solarcell Preparation ......................................................................... 8

Running, Tuning, and Upgrading ......................................................................................................... 9

RUNNING ........................................................................................................................................ 9

TUNING ......................................................................................................................................... 9

UPGRADES ..................................................................................................................................... 10

THE “IMPATIENCE”SWITCH ............................................................................................................ 10

DIODE VOLTAGE UPGRADE ............................................................................................................ 11

“ITDOESN’TGO!” ..................................................................................................................... 12

“ITDOESN’TROLL SMOOTHLY” ...................................................................................................... 12

Final Notes ..................................................................................................................................... 13

i

SolarSpeeder 1.1 Parts & Materials List

We

strongly

suggest you inventory the parts in your kit to make sure you have all the

parts listed under the sections ‘Mechanical Parts’ and ‘Electronic Parts’. Check off

each box as you locate them. If anything is missing, contact Solarbotics Ltd. for

replacement parts information.

Mechanical Parts

(1) SolarSpeeder 1.1Printed Circuit Board (PCB)

(1) High-efficiency Coreless Motor

(1) Motor Mounting Clip

(3) Rubber Wheels on Nylon Hubs

(1) 43mm long 1.40mm diameter (1.7" long, 0.055" diameter) Steel Rod

(2) Black Plastic Wheel Retainers

Electronic Parts

(1) 0.33F 2.5V Gold Capacitor

(1) 3904 Transistor

(1) 3906 Transistor

(1) 1381 Voltage Trigger

(1) 2.2k?Resistor (colour bands Red/Red/Red/Gold)

(1) SC2433 24x33mm 2.7V Solarcell

(1) Pair Solarcell wires

(1) 25mm (1") length 18 Gauge wire

Tools Required

A Soldering Iron

A pair of Needle-nose pliers

Side-cutters or strong Scissors

File and/or Sandpaper

Glue, Rubber Cement, or Hot-Glue (or Superglue, if you’re

very

careful)

Safety Glasses - VERY important when clipping and snipping!

Disclaimer of Liability (i.e.: stuff to keep the Lawyer happy)

Solarbotics Ltd. is not responsible for any special, incidental, or consequential damages resulting

from any breach of warranty, or under any legal theory, including lost profits, downtime, good-

will, damage to or replacement of equipment or property, and any costs or recovering of any

material or goods associated with the assembly or use of this product. Solarbotics reserves the

right to make substitutions and changes to this product without prior notice.

In other words - be careful! We will help you any way we can to assure the successful completion

of your kit, but can’t be responsible for putting band-aids on any burns and other ouchies you

get while soldering, clipping, snipping, etc., etc...

1

Introduction - The SolarSpeeder 1.1Solaroller

The SolarSpeeder is a design that has a strong heritage in Solaroller Racing, which is a very

popular event at all BEAM Robot Games.

Solaroller racing requires two solar-powered drag-racers that race side-by-side down a 1

metre (3.3ft) track. When Solaroller Racing began, the 1 metre times were in the 10 and 20

minute ranges. As the electronics and mechanics advanced, the times lowered to 6 minutes, 2

minutes, and now there are Solarollers capable of a metre in under 30 seconds! The SolarSpeeder

uses many of these new technology advances in it’s design, which allows a well-built SolarSpeeder

to travel 3 metres (10ft) in under 60 seconds of direct sunlight.

“SC-1” - A modified Slot-Car

racer. One of the first to use the

new technology to make it quite

quick.

“Herbie” - A 4-wheel drive Solaroller

designed for the rough-terrain Class-B

event. Almost as fast as “Sluggy, Too”!

“Scooter” - Best competition time of 1 minute 4

seconds, narrowly beating out 3rd place by only a

second. 1

st

and 3

rd

place were won by 11 year old

boys!

“Sluggy, Too” - Ex-champion Solaroller with

a 2 minute 9 second metre record.

“SolarSizzler” - This one is one of the

prototypes for the SolarSpeeder. It uses

a soft rubberized shell as it’s body.

2

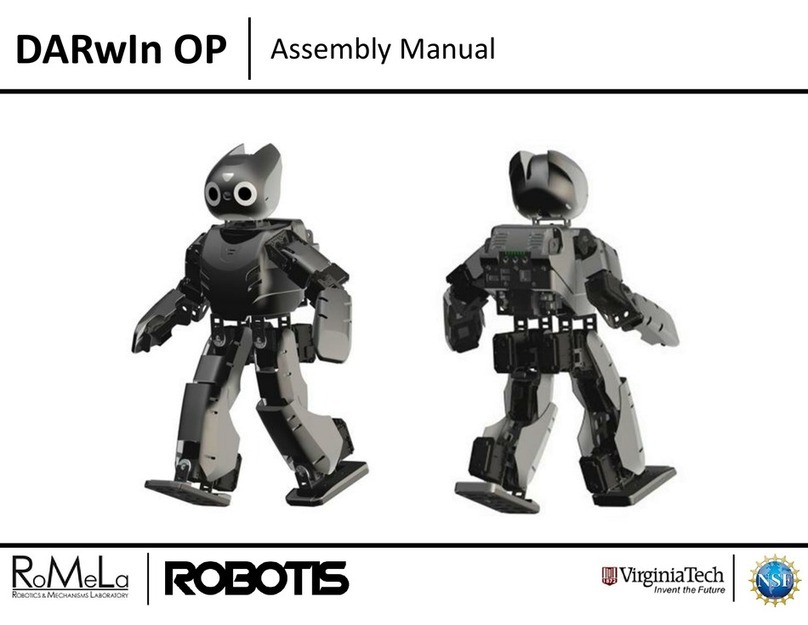

Circuit Overview

3

Gold Cap 2.5V 0.33F

The heart and soul of the SolarSpeeder is the high-performance Solarengine. The three

components that are most responsible for the increased performance of the Solarengine are the

0.33 Farad capacitor, the 1381 trigger, and the coreless motor.

The 0.33F storage capacitor is strong for its size. To put it in

perspective, this storage cell holds 100 times the power of regular capacitors 5 times the physical

size. These capacitors are specially designed for low-voltage, high power applications - perfect for

Solarollers!

The transistors are the actual electronic switches that route the power from the

storage capacitor to the motor. The transistor’s left and right legs (the “emitter” and “collector”)

are the actual pathways for the majority of the current, while the middle leg (the “base”) is where

you put the tiny signal current to turn the transistor on. The SolarSpeeder uses 2 types of

transistors, an NPN (2n3904), and a PNP (2n3906). The only difference is that one is turned on

by current being pushed into it, and the other by pulling the current out.

The resistor is simply an electrical constrictor, which the flow of electrons. In

the SolarSpeeder kit, it is used to divide the current between the transistor switches and the

motor.

The coreless motor is a very small, efficient device that is specifically

designed to run at approximately 1.5 volts. Since the Solarengine is designed to run at a maximum

of 2.5 volts, this places the motor almost exactly in the range we want it to run. And being so small

and compact, it is ideal for this BEAM application.

The 1381 voltage trigger is a small three pin integrated chip (IC) that looks much

like a transistor. It was originally designed to detect low voltage levels in the batteries of portable

electronic devices, like cellular telephones and portable computers. It uses very little power to

monitor the voltage, making it much more efficient than older trigger devices like zener diodes or

flashing LEDs.

The 1381 voltage trigger makes your SolarSpeeder wait until there is sufficient charge stored

up in the 0.33 Farad capacitor before it starts. This means that you can expect to get much more

action in direct sunlight than under an incandescent or halogen desk-lamp. This doesn’t mean that

you are restricted to placing it under concentrated light, as your SolarSpeeder will be able to work

under light levels suitable for reading (but you will have to be patient).

The solarcell converts light energy into electrical energy. Although not

very powerful (about as strong as a watch battery), they have a very long

lifetime, up to 20 years. The solarcell included with your kit is designed to

generate about 2.9V at 16 milliamperes.

very

resists

4

Solar

Cell

0.33F

Capacitor

2N3904

2N3906

2.2 kOhm Resistor

Motor

3

2

1

1381

When the circuit starts charging, the 2N3904 transistor is off, so the current can’t go

through the motor back to the solar cell. Instead, it charges the storage capacitor. While this

is happening, the 1381 monitors the voltage climb through its pins 2 and 3. When the

voltage level matches a preset point in the 1381, it sends a pulse out to the 2N3904 tran-

sistor, turning it on. As soon as it turns on, some power splits off through the 2.2k resistor

and goes into the 2N3906 transistor. This transistor keeps the 2N3904 on even when the

1381 turns back off, and keeps the whole circuit running until the power runs out.

Construction - Soldering

The most important skill needed to successfully construct your device is soldering. Make

sure you start by using

electronics solder,

not plumber’s solder. The main trick to getting a

successful solder connection is to heat the junction up before applying the solder to the heated

area. Do NOT try to melt some solder onto the tip of the iron and smear it onto the joint - you

won’t get a strong joint.

If the heat is applied unevenly, you will get solder blobs (see below). To better apply heat,

keep your soldering iron tip clean by wiping it frequently on a damp sponge or cloth. The tip

should always be shiny, and not covered in burned flux.

Solder

Soldering Iron

PCB Solder Pad

PCB

Component Leg

Bad

No flow from leg to pad

Good

Flows from leg to pad

Bad

Solder “bridge” across pads

Bad & Good Solder Joints

X

X

á

Construction - Electronics

Now is the time to gather your tools together and warm up your soldering iron. Remember,

good soldering technique means you heat up both the component

and

the solder pad before

applying the solder. Assembly is quite straightforward - simply go through the numbered steps,

checking off each box as you go. That way, you’ll be sure not to miss any steps.

5

Solar

Speeder 1.1

1381 3906

Opt. Diode

Mtr

Red

Opt.

Switch

Mtr Blk

Clip

Resistor

+

-

Gold Cap 2.5V 0.33F

21

3

Solar

Speeder 1.1

1381 3906

Opt. Diode

Mtr

Red

Opt.

Switch

Mtr Blk

Clip

Resistor

+

-

5

4

6

7

Step 1:

Step 2:

Step 3:

Slide the through the holes labeled “rod” so it’s about

centered.

Bend the leads of the 90° down right against

it’s body and place the leads into the printed circuit board (PCB) as

shown. Make sure it goes in with the stripe side (negative) on the left.

Turn the PCB over and solder the leads to the solder pads. Trim off

the excess leads.

Put the in place as shown on the PCB.

Same as in step 2, solder it in, and trim off the leads.

axle

0.33F capacitor

2.2kOhm resistor

Step 4:

Step 5:

Step 6:

Step 7:

Place the in place as shown, with the

transistor facing upwards so you can read the numbers. Solder &

trim the leads.

Place the in place on the PCB, but

so you can’t read the numbers. It’s shown face up on the diagram

so it’s easier to identify. Solder & trim the leads.

Insert the into position, and again (just like

the 1381 trigger), so you can’t read the numbers. Solder

& trim the leads.

Push the into the holes labelled ‘Clip’, making

sure that the . This will align the motor

when you install it into the clip.

3904 transistor

1381 trigger

3906 transistor

motor clip

flip it over

flip it over

tabs are facing to the left

This is what it should look like when

you’ve finished steps 1, 2, and 3.

Completion of steps 4 through 7 looks

like this.

Construction - Wheels, and the Motor

6

8

Solar

Speeder 1.1

1381 3906

Opt. Diode

Mtr

Red

Opt.

Switch

Mtr Blk

Clip

Resistor

+

-

Mtr Blk

Gold Cap 2.5V 0.22F

Solar

Speeder 1.1

1381 3906

Opt. Diode

Mtr

Red

Opt.

Switch

Mtr Blk

Clip

Resistor

+

-

Mtr Blk

Gold Cap 2.5V 0.22F

Mtr Blk

9

10

Step 8: Snap the as shown. Rotate the motor

body in the clip until the red wire is closest to the PCB (makes it easier to

solder later). Be sure to push the motor as far to the left as you can so it’s

pushed up right against the tabs on the clip. If the clip is too wide for the

motor, pinch it closer together with your fingers, then check how the motor

fits in the clip again.

motor into the motor clip

Step 9:

Step 10:

Place a on the axle and give it a spin. Make sure the wheel

isn’t rubbing the PCB. If so, trim a bit off the PCB. When it’s spinning nice

and free, slide the on. It’s easy to poke your finger with

the axle when doing this!

Solder the red wire to the pad labelled “Mtr Red”, and the blue to

one of the holes right near to the motor clip.

wheel

retainer Be careful!

Motor Soldering Detail

Push the motor up against the

mounting tabs

3906

1381

+-

Construction - Motor Mount Support & Drive Wheel

7

+- 11

Step 11: Find your small thick piece of wire, and pull the insulation off

so you are left with a small piece of solid

copper wire.

Bend one end 90 degrees down, and shown

on the illustration. This gives your motor mount more strength, and allows

you the option of aligning the motor so you can adjust where your

SolarSpeeder goes.

(SAVE

the insulation - you’ll need it!)

solder the wire onto the pads

Mount wire

insulation on

motor shaft,

then wheel

12

Step 12: Time to mount the wheel; Let’s start by taking that insulation you

saved from the last step, and cutting it down to a short length about 5/32 long

(here-make it as long as this line: ). Slide it onto the motor shaft, making

sure you shove it all the way to the side of the motor (it rubs, and slows

it down).

Slide the wheel on top of the sleeve, and glue the sleeve, wheel, and motor

shaft together with the amount of glue. You don’t need much, and you

don’t want to accidently glom up the motor with too much glue!

don’t

tiniest

Close-up of stripped copper wire

soldered onto motor mount support

pads

Slide the sleeve onto the motor

shaft... ...then add the wheel. A drop of glue

in the wheel hole to secure the

works, and you’re done!

This is how it looks finished... almost.

We’ve pulled the sleeve and motor apart a

bit so you can see how they go together.

When finished, the wheel sits right on top

of the sleeve.

Note that there’s a space between the

sleeve and motor body, so there’s no

chance of rubbing!

Bare Pad

Properly

Tinned Pad

14

Construction - Axles Trimming and Solarcell Preparation

Step 13: All that you have to do here is trim the extra axle off with your

snips. Then file or sand the edges rounds so it isn’t sharp anymore, or pull

the wheel retainers over the end of the wire so it covers up the sharp points.

If you find that your wheel retainers are a little loose on the axle, now would

be a good time to glue them down, but only apply the glue on the side away

from the wheel, so it doesn’t get gummed up.

Step 14: If your solarcell doesn’t have pre-tinned solder pads (ie: the

solder is already on it), you’ll have to do it yourself. This can be potentially

the most delicate part of building your SolarSpeeder, so take your time.

Pre-tin the pad by melting solder to the pad in a quick, smooth motion. You

don’t want to apply too much heat to the pad, or you’ll ruin it. You can tell

when this happens, as it gets dark and no solder will stick to it.

Step 15: Solder the wires to the solarcell , red to ‘+’ and the black to ‘-’,

and secure it to the solarcell by gluing it down to the back. THIS IS IMPOR-

TANT. You can easily rip the wires off the solarcell if you don’t!

Step 16: Connect the solarcell wires to the PCB, red to ‘+’,

black to ‘-’, just like in the illustration. Once you’ve done

that, your SolarSpeeder is “ALIVE”, but not finished - you

have to glue the solarcell to the PCB with epoxy, or similar

gap-filling glue (use hot-glue only as a last resort - it softens

under the heat of a desklamp).

Secure the solarcell to the PCB only after you’re sure it

works. Make sure it doesn’t rub on the wheels, and that the

solder pads on the solarcell don’t touch any of the solder

pads on the PCB.

Glue wires down

only in this area

15

8

13

+-

+-

Panasonic

BP -2433

16

Running, Tuning, and UpgradingRunning, Tuning, and Upgrading

Running, Tuning, and UpgradingRunning, Tuning, and Upgrading

Running, Tuning, and Upgrading

Running

Your SolarSpeeder is

very

quick for a solar-powered device, but it is slow compared to a

battery powered car of about the same size. When it’s first finished, you will have to be patient

for it to make it’s first mad dash across the table. Our tests show that your SolarSpeeder should

activate from a dead startup (absolutely no power) in approximately 3 minutes when lit by a

100Watt incandescent bulb 20cm (8”) above it. In direct sunlight, it should trigger in under 1

minute, and then under about every 40 seconds after that. Your times may vary a bit because

the storage capacitors are rated 0.33 Farads, minus 20% to plus 80%. This means your 0.33F

capacitor can range between 0.264F and 0.594F! Being smaller than 0.33F isn’t a bad thing -

it just means it will trigger more often, but not travel as far. And being larger than 0.33F...well,

that means you’d better have quick feet to catch up to it!

If you have a voltmeter and you care to monitor the SolarSpeeder as it charges, you will

notice that it will always trigger around 2.2 volts, which is the voltage the 1381trigger is preset

to. After its first cycle of charging and triggering, it will dump all it’s energy until the voltage

drops to 0.7 volts, which is the voltage where most electronics naturally stop working. This is

why all cycles after the first have shorter charging times - that 0.7V stays in the storage capaci-

tor.

If you want to make your SolarSpeeder do donuts or run in curves, feel free to adjust the

alignment of the motor. Don’t worry about breaking the thin PCB neck - the thick copper wire

we soldered in will be more than sufficient to support it after the PCB cracks.

Tuning

The design of the SolarSpeeder does not allow for much tuning, but if you are so inclined,

you can experiment with changing the solarcell and bias (2.2kOhm) resistor. Changing the

solarcell will make an obvious difference to the charge time, but the distance it travels should

remain approximately the same. Changing the resistor for a 10kOhm trim pot or simply for a

different resistor will modify the efficiency of the Solarengine. Higher values make the electron-

ics more power efficient, but will decrease the initial amount of energy it can provide to the

drive motor. Lowering the resistance will give the motor much better starting torque (like spin-

ning the tires on a car when you floor the gas pedal), but at the expense of a shorter distance

run. The resistor we’ve included in the kit is a good compromise between power and endurance.

9

Upgrades

The SolarSpeeder has been designed to be upgraded with two extra options, one being the

“Impatience Switch” (for those who just can’t wait for the SolarSpeeder to trigger on it’s own),

and the other being the “Diode Voltage Upgrade” to supercharge your SolarSpeeder, at the

expense of a longer charge time.

The “Impatience” Switch

Are you the type of person that reads the last page of a detective novel first? Or opens all

your Christmas gifts in early November? If so, the Impatience switch will be a

must-have

option

to install on your SolarSpeeder. It simply is a manual trigger that activates your SolarSpeeder,

bypassing the voltage trigger. Kinda handy when you need to show off your creation to an

impatient audience. And it’s easy to build - got a paperclip? Good - let’s start!

Step 1 - 4: Pretty straightforward - just follow the steps so that your paperclip looks like this one. The only

thing to watch is that the right end of the paperclip in step 4 should extend down a bit so that it can go in

the hole of the SolarSpeeder PCB.

Step 5: The next step is to place a solder blob on the pad indi-

cated. This will be the contact pad that the switch will touch to

activate the SolarSpeeder.

5.

Step 6: Solder the clip to the pad shown. Bend the clip so it just

clears the pad you put a solder blob on in step 5. The closer it is

without touching, the better.

There - now to activate your So-

larSpeeder manually, simple press down

on the end of the paperclip. The elbow

bend in the clip will contact the solder

blob, and activate the SolarSpeeder.

This clip also acts as a shorting gate for

solaroller racing. Hold it down to drain

all

the power from your Speeder, and

release it to start the charging cycle.

6. The wire elbow comes

close, but doesn’t touch the

solderpad. When it touches -

ZOOOM!

10

Diode Voltage Upgrade

This option allows you to trick your SolarSpeeder into storing more energy than usual

before it triggers. This means instead of 3 meter runs, you’ll be going somewhat farther, more

like 4 meters or more, but at the expense of a longer charge time. If you’re looking to get as

much performance out of your SolarSpeeder as possible, this upgrade is for you!

You have two options when performing this upgrade, one being to use a regular old diode

(little glass cylinder with a stripe on one end), or a regular old Light Emitting Diode (LED). Both

can be easily found in practically any discarded electronic device. Each one offers a difference

effect in what they will do for your SolarSpeeder. By itself, the SolarSpeeder will wait until it has

stored about 2.2 volts before firing. A regular diode will trick the SolarSpeeder into waiting for

2.4 volts, and a LED will force it to trigger at about 2.8 volts. More stored power means a

quicker and longer running SolarSpeeder, but also means a longer charge time.

Step 1: Using a sharp knife or razor, trim through the vertical trace

under the green soldermask that runs up from the “-” pad. Make

sure that trace gets fully cut through. Hold it up to the light to see if

you can see fully through where the trace is cut.

Doing this disconnects the 1381 voltage trigger from “viewing” the

voltage being stored.

Step 2: Install the LED (adds ~ 0.7 volts), OR the diode (adds ~

0.3 volts).

If you are installing the LED, make sure the shorter leg (the one

nearest the flat spot on the LED) goes into the lower hole. If you

don’t have enough space to fit the LED under the PCB, you can

solder it on the topside, or bend it out to the side where it won’t rub

the ground.

If you are installing the diode, make sure the end with the stripe

around it goes into the lower hole.

Note Cut

LED

There - that’s it. Assum-

ing your SolarSpeeder

worked before this modi-

fication, it will now store

up a bit more power be-

fore activating.

If it has stopped working,

chances are your LED/di-

ode is in backwards, or you

have a bad solder connec-

tion.

11

+-

Make cut

through trace

TOP

1

Solar

Speeder 1.1

1381 3906

Opt. Diode

Mtr

Red

Opt.

Switch

Mtr Blk

Clip

Resistor

+

-

Solar

Speeder 1.1

1381 3906

Opt. Diode

Mtr

Red

Opt.

Switch

Mtr Blk

Clip

Resistor

+

-

OR

BOTTOM

2

Install the

LED or

diode

“It Doesn’t Go!”

Since your SolarSpeeder uses a relatively simple circuit, there are only a few things that

can go wrong. Go through the list and see if any of these answers fix it:

• Transistor/Trigger Placement and Orientation. Make sure that they’re facing the

correct directions, as they all don’t face up. With your SolarSpeeder sitting on its

wheels, make sure that:

- The transistor at the nose is the 3904 and facing down.

--

--

- The transistor on the left is the 3906 and facing is facing up.

- The transistor on the right is the 1381 trigger facing up.

••

••

• Perform a ‘wiggle’ test on all the components. That is, grip each of the components

on the PCB and give it a firm wiggle. Closely watch where the wire legs are soldered to

the PCB. They all must be firmly soldered to the pads, and not sliding through the

holes at all. THIS WILL DETECT THE MAJORITY OF PROBLEMS!

••

••

• There cannot be anyjumpers between the solder pads. These are blobs of solder

that cross from one pad to the next and short out the electronics. Examine the sets of

three pads that each of the transistors are attached to - these are most likely to have

solder jumpers.

• Make sure that the red motor wire is soldered to the correct pad on the main body of

the PCB.

• Are the wire connections to the solarcell still good? A

gentle

tug on the wire will be

enough to check this. If it comes loose, you probably have a wrecked solarcell solder

pad. If you want to try to salvage the solarcell, try using automotive defogger paint, or

a conductive ink pen.

• Lift the solarcell off the surface of the PCB - does it work now? You may be accidently

shorting the electronics with one of the solarcell solder pads. Cover it with some tape

or make sure it’s insulated from the PCB with glue.

• Prop the SolarSpeeder up so the drivewheel is suspended off the ground. Does it run

now? If so, check the drag on the other two wheels. You should be able to give your

SolarSpeeder a flick with your finger and it should roll at least 15cm (6”).

If nothing else, you can send it back to Solarbotics for free repair (or replacement if

necessary). We stand 100% behind our products, and will do everything we can to

make your kit perform like it should.

“It Doesn’t Roll Smoothly!”

If something is rubbing, chances are it will be

the storage capacitor. You can make more clear-

ance underneath your SolarSpeeder by bending

the drive motor downward.

12

Final NotesFinal Notes

Final NotesFinal Notes

Final Notes

We sincerely hope you had fun building your SolarSpeeder, and you have just as much fun

giving your local neighbourhood cat something to chase after. But if you want to try your hand

at Solaroller racing, here are the basic rules:

• Maximum solarcell area of 8.06 cm2(1.25 inches2). Your SolarSpeeder’s solarcell is

7.68 cm2(1.19 inches2), 95% of the maximum allowed.

• The Solaroller must fit in a cube measuring 15.24cm a side (6 inch cube).

• The track is 1 metre long (3.3 feet) with two lanes separated by a lane wall 2.5cm (1

inch) tall, with a 15.24cm (6 inch) starting and finishing square at each end for each lane.

• The Solaroller must have shorting wires coming out from it that can cross a shorting bar

that is placed at the back of the starting square. This ensures the competitors are fully discharged

until the moment the race begins when the shorting bar is removed.

• Light is guaranteed to be a minimum of one 500 Watt halogen lamp placed 50cm (19.7

inches) above the race platform (often there is much more light).

• Devices must conform to a 2 second stationary rule which means the solaroller cannot

move for a full two seconds after the race has begun. This is to ensure some sort of electronics

have been implemented rather than NASA-quality solarcells connected directly to ultra-preci-

sion motors (it’s been done!).

Your SolarSpeeder won’t technically qualify for ‘Official’ Solaroller racing, as the general

rules specify that kit-built devices (unless modified) are not elegible for competition. But with

what you learn building the SolarSpeeder, you should be able to build your own!

If you are interested in finding out more about BEAM Robotics, the BEAM Robot Games,

and what other products we have to offer, please contact us at:

13

Solarbotics Ltd.

179 Harvest Glen Way N.E.

Calgary, Alberta, Canada T3K 4J4

Ph: (403) 232 6268, Toll-free:(866) 276 2687

Fax: (403) 226-3741

Website: http://www.solarbotics.com

Email: [email protected]

© Copyright Solarbotics Ltd., 1998, 2003

Solarbotics often sponsors a SolarSpeeder race at many of the robot games we attend. If

you can aim your SolarSpeeder to roll through a10cm wide gate 2.4 meters away, you have

a shot at some great Solarbotics prizes!

The Solarbotics

SolarSpeeder 1.1

is a high-performance Solar Racer, using simple and

efficient electronics to store up light energy and release it in a burst of power that

results in a 3 meter (10 foot) zoom!

This Racer design is the result of several years of Solaroller racing at the BEAM Robot

Olympics®, combining a high-quality motor, lightweight frame, and optimized elec-

tronics. All that’s needed to complete it is some basic handtools and a soldering iron!

The Solaroller family, with some of the many designs that finally resulted with the

SolarSpeeder (front row, center).

For more information about our kits and products, please contact us at:

Solarbotics Ltd.

179 Harvest Glen Way N.E.

Calgary, Alberta, Canada T3K 4J4

Ph: (403) 232 6268, Toll-free:(866) 276 2687

Fax: (403) 226-3741

Website: http://www.solarbotics.com

Email: [email protected]

© Copyright Solarbotics Ltd., 1998, 2003

This manual suits for next models

1

Table of contents

Other Solarbotics Robotics manuals