2 Safety information

Electrical conductivity

The probability of corrosion usually decreases with

decreasing electrical conductivity of the heating

water.

Low salt driving - filling with demineralised

water, see VDI 2035 sheet 2.

Low salt

Electrical conductivity at 25°C < 100 µS/cm

In the low-salt mode, the replenishment of water that

is not fully desalinated can significantly influence the

pH value and shift it into a critical range.

►Check the pH value regularly.

3.8 Notes on the hydraulic connection

Return flow boosting (RFB)

–Functioning: If cold heating water (temperature <

55°C) flows from the heating circuit/buffer tank

into the hot boiler, the steam contained in the flue

gas condenses on the "cool" boiler heat

exchanger surfaces. In the long term this leads to

corrosion and damage in the boiler. To avoid this,

hot water from the boiler flow is added to the

boiler return.

–Return booster modules with a motor-controlled

mixer perform this task more accurately and

reliably than thermally controlled modules.

–In addition, they allow the use of residual heat:

When the temperature in the buffer cylinder has

fallen to lower than that in the burner, the pumps

start up again, the return mixer opens, and the

residual heat from the boiler is transferred to the

buffer.

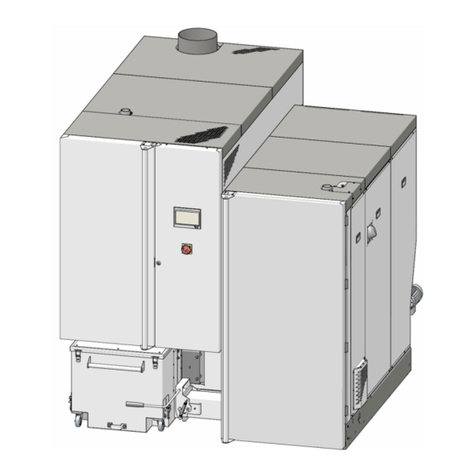

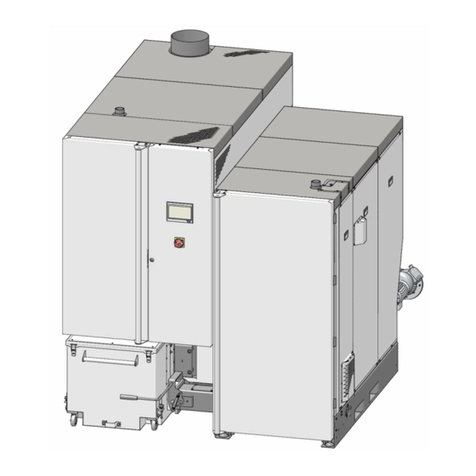

iThe ecotop zero/light has an integrated return

booster module; therefore no further mea-

sures are required in this regard.

Provide shut-off facilities in the pipes

–Position shut-off valves for each section (in buffer

tank, etc.) in order to minimise the quantity of

water that needs to be replaced in the event of

repairs or system extensions(: Avoiding the intro-

duction of oxygen, filling/supplementary water of

the heating system > 8).

Pressure compensation through expansion ves-

sel (ADG)

–The expansion vessel prevents air from being

sucked in when the system cools down (problem:

oxygen input, filling water of the heating system >

8)

–Dimension the expansion tank with a capacity of

12% of the total hydraulic system volume.

–Secure the expansion tank against shut-off. To do

this, either use the shut-off options on the way to

the expansion tank as cap valves, or unscrew the

hand lever (handwheel) and attach it to the expan-

sion tank with the wire in a clearly visible position.

–The installation of an expansion vessel or a pres-

sure maintenance system is mandatory. The use

of open expansion vessels is not permitted.

–The pressure in the heating system (readable on

the pressure gauge) and the pre-pressure set in

the expansion vessel must be checked regularly.

Attention with (older) diffusion-open plastic

pipes, e.g. existing underfloor heating system

–With older underfloor heating systems, the plastic

pipes, which are more open to diffusion, can lead

to increased oxygen ingress into the heating sys-

tem. This has a corrosive effect on components of

the heating system (keyword: Avoidance of cor-

rosion on the water side > 8).

–In this case, a system separation (by installing a

heat exchanger) must be carried out.

–Newer plastic pipes (approximately since the mid-

1980s) are diffusion-tight according to DIN 4726.

Buffer tank: Use, dimensioning

Advantages of installing a buffer tank:

–The boiler can always be operated in the optimum

load range. This leads to a longer boiler service

life and reduces emissions.

–Avoidance of unnecessary boiler start phases,

the higher fuel consumption during the start pha-

ses is significantly reduced.

–Heated water is continuously available in the buf-

fer tank for the heating circuits. This enables a

rapid heat supply to the heating circuits at any

time.

If the heating system is operated without a buffer

tank, the installation of a hydraulic separator > 9 is

required.

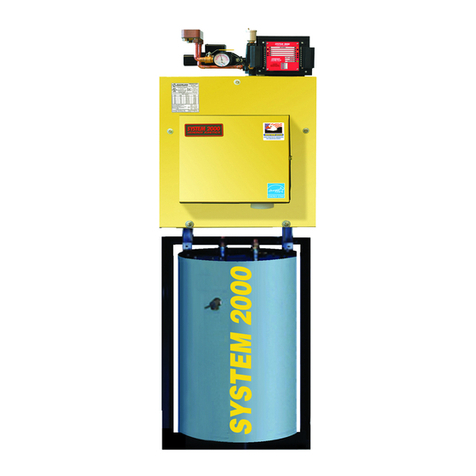

Dimensioning of the buffer tank:

For pellet boilers, a buffer volume of 30 litres per kW

heating output is recommended.

Hydraulic switch

–A hydraulic switch separates the flows in boiler

and heating circuits.

–If the heating system is operated without a buffer

tank, a hydraulic switch must be installed bet-

ween flow and return.

Installation manual ecotop-zero, ecotop-light 9