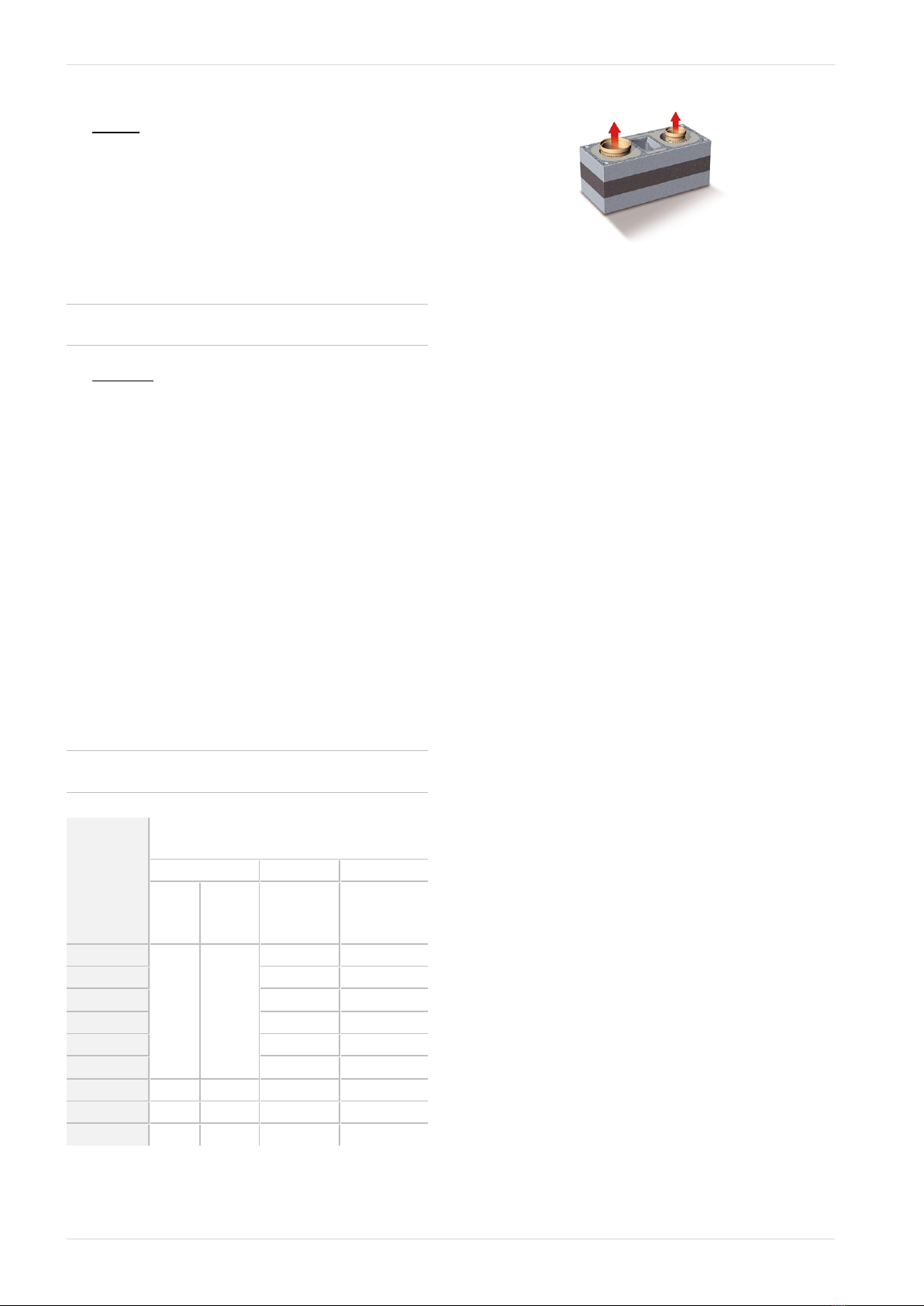

5 Prior to assembly

Supply air/exhaust air in Boiler room

For Austria (according to standard H 5170):

–For the supply air, 2 cm² per kW thermal output of

the fuel, but allow at least 200 cm² free cross-sec-

tion. (Fuel heat capacity = boiler capacity / effi-

ciency)

–For the exhaust air, allow at least 180 cm² free

cross-section up to 100 kW nominal heat and an

additional 1 cm² free cross-section for every further

kW.

iCalculate at least a further 20 % for wire mesh

in the aeration cross-section.

For Germany In accordance with the Model Firing Ordi-

nance:

–For heating appliances with a nominal output of up

to 35 kW, a combustion air opening of at least 150

cm² or 2 x 75 cm² routed directly into the open air

must be provided.

–Alternatively, a door/window leading outside and a

room content of at least 4 m³/kW nominal heat out-

put are suitable. If the Boiler room does not abut

onto an outside wall, combustion air supply via

connecting rooms is possible. Here, the com-

bustion air is supplied via a sufficiently dimen-

sioned adjacent room which abuts onto an outside

wall.

–From 35 to 50 kW, provide a free aeration cross-

section of at least 150 cm². From 50 kW upwards,

for aeration and ventilation, provide a minimum

free cross-section of 150 cm² for each, plus 2 cm²

per KW in excess of 50 kW.

iCalculate at least a further 20 % for wire mesh

in the aeration cross-section.

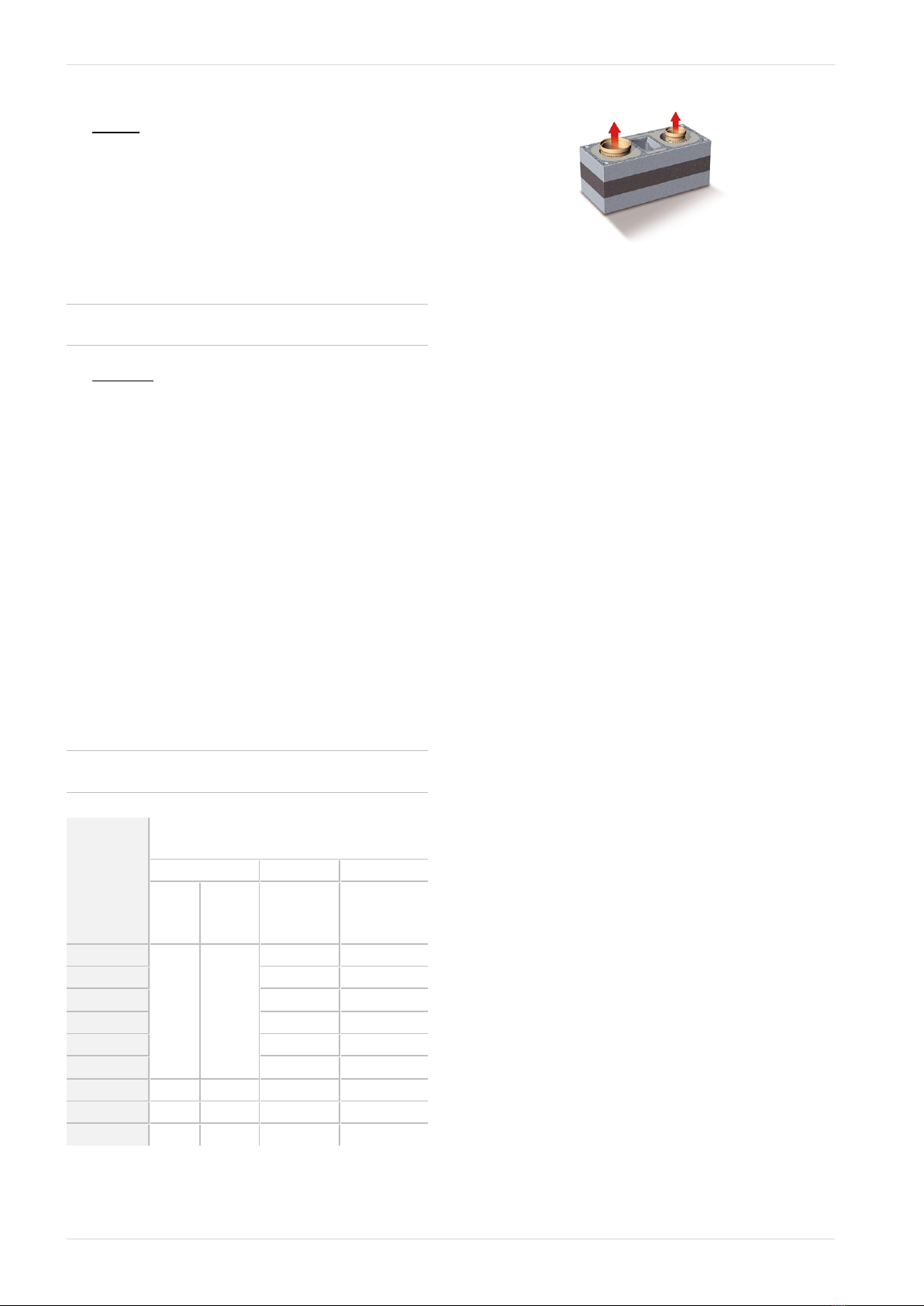

Boiler

power

[In kW]

Minimum space [in cm²] including 20%

surcharge for grids

Austria Germany Switzerland

Supply

air

Exhaust

air

Supply

air/Exhaust

air

Supply air

20 kW

>240 >216

>180 >206

25 kW >180 >258

35 kW >180 >361

50 kW >228 >515

70 kW >228 >721

90 kW >276 >927

130 kW >347 >252 >372 >1339

200 kW >533 >336 >540 >2060

400 kW >1067 >576 >1020 >4120

5.3 Chimney, flue gas pipe

Chimney cross-section and chimney height

The necessary cross-section depends on the nominal

output of the heating system and the effective chim-

ney height (at least 6.5 m). We recommend that you

have the calculations performed by an expert.

Chimney execution

–The chimney must be resistant to moisture. Use

fire brick or stainless steel.

–The chimney must conduct away the flue gases

reliably at all times.

Connect the chimney condensate drain to the

sewage system

–Connect the condensate drain line of the chimney

to the domestic sewage system (to drain con-

densate, rainwater).

–Use DN 25 diameter pipe, install siphon.

Provide each boiler with its own chimney

–The boiler and the fireplace must be coordinated.

This is the only way to ensure the proper func-

tioning of the heating system and the correct

discharge of the flue gases.

–If there is only one chimney available for two boi-

lers, there is a risk (considering the different ope-

rating states of the boilers - full load/partial load).

This can lead to problems (e.g. the flue gas has too

low energy during the ascent, and does not lift off

sufficiently from the chimney mouth, ...odour pol-

lution by flue gases).

–Singly equipped chimneys are more reliable and

safer than multi-fuelled fireplaces.

Do not connect a gas boiler and blower boiler to

the same chimney

Do not connect a wood-burning stove and blower

boiler to the same chimney

–A wood-burning stove typically requires a larger

chimney diameter than the blower boiler.

–Acoustic disturbance from the blower boiler may

be possible in the living room (by the wood-burning

stove).

–Unnecessary risk due to gas leakage, e.g. if the

blower boiler is defective.

14 Operation manual maximus