sunlight and therefore boost current and

power. In addition, colder temperatures can

substantially increase voltage and power.

Solartec modules are constructed with

tempered glass, but still must be handled with

care. If the front glass is broken or if the

polymer backskin is torn, contact with any

module surface or the frame can produce

electrical shock, particularly when the module

is wet. Broken or damaged modules must be

disposed of properly.

Refer to Section 690-8 of the National

Electric Code for an additional multiplying

factor of 1.25 which may be applicable.

The modules have been evaluated by UL

for a maximum positive or negative design

loading of 30 lbs/ft2.

Installation Condition

Installation shall be in accordance with

CSA C22.1, Safety Standard for Electrical

Installations, Canadian Electrical Code, Part 1.

Sit Selection

PV modules should be installed in a location

where there is no shading throughout the year.

In the northern hemisphere, PV modules

should typically face south, and in the

southern hemisphere, PV modules should

typically face north. Please make sure that

there are no obstructions in the surroundings

of the site of installation. Artificially

concentrated sunlight shall not be directed on

the module. Take proper steps in order to

maintain reliability and safety in case the PV

modules are installed in areas that have heavy

snow / extreme cold / strong winds /

installations over, or near, water and areas

where installations are prone to salt water

exposure or on small islands or in desert

areas..

Operating Conditions

A. Modules are intended for use in

terrestrial applications only—no outer

space use.

B. Modules must not be installed nor

operated in areas where, salt, hail,

snow, sand, dust, air pollution,

chemically active vapors, acid rain, soot,

etc., are excessive.

C. The recommended standoff height is 20

cm. If other mounting means are

employed this may affect the UL Listing.

D. The ambient temperature should be

within –20°C (-4°F) to 46°C (115°F). The

temperature limits are defined as the

monthly average high and low of the

installation site.

E. The wind pressure load of the

installation site should be less than

2,880N/m2 (60PSF).

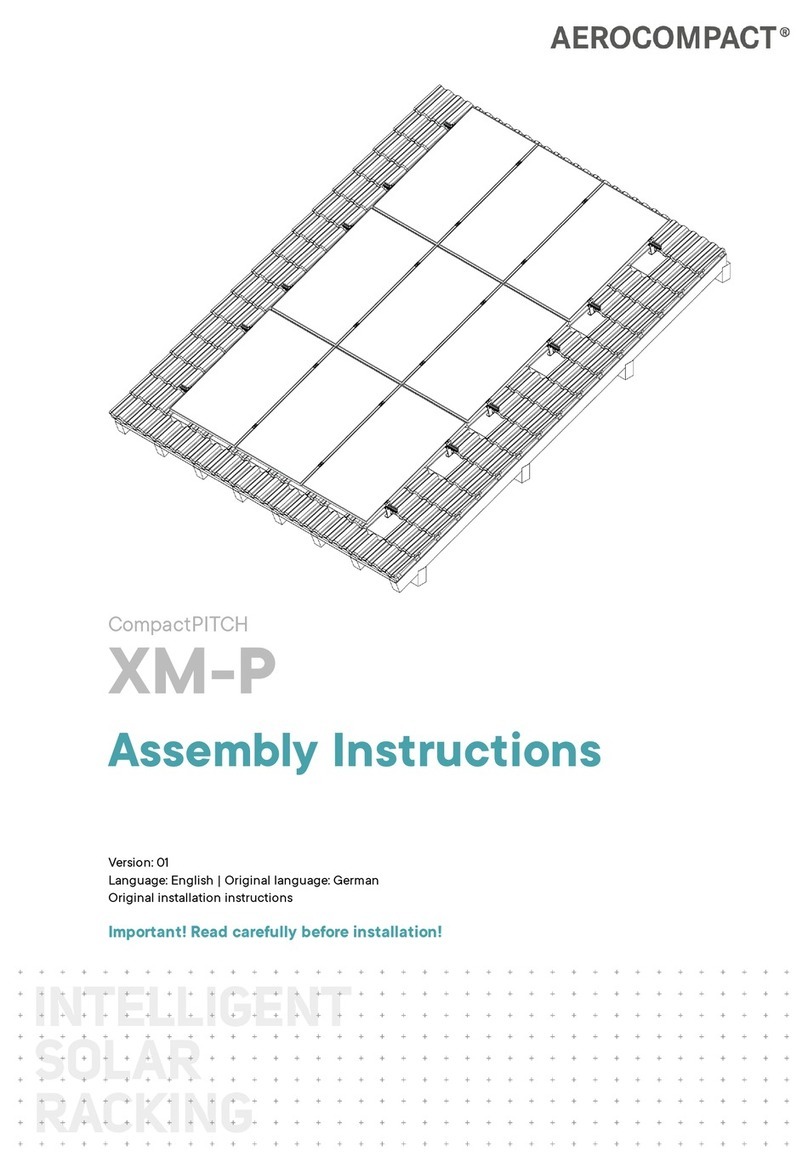

Mechanical Installation

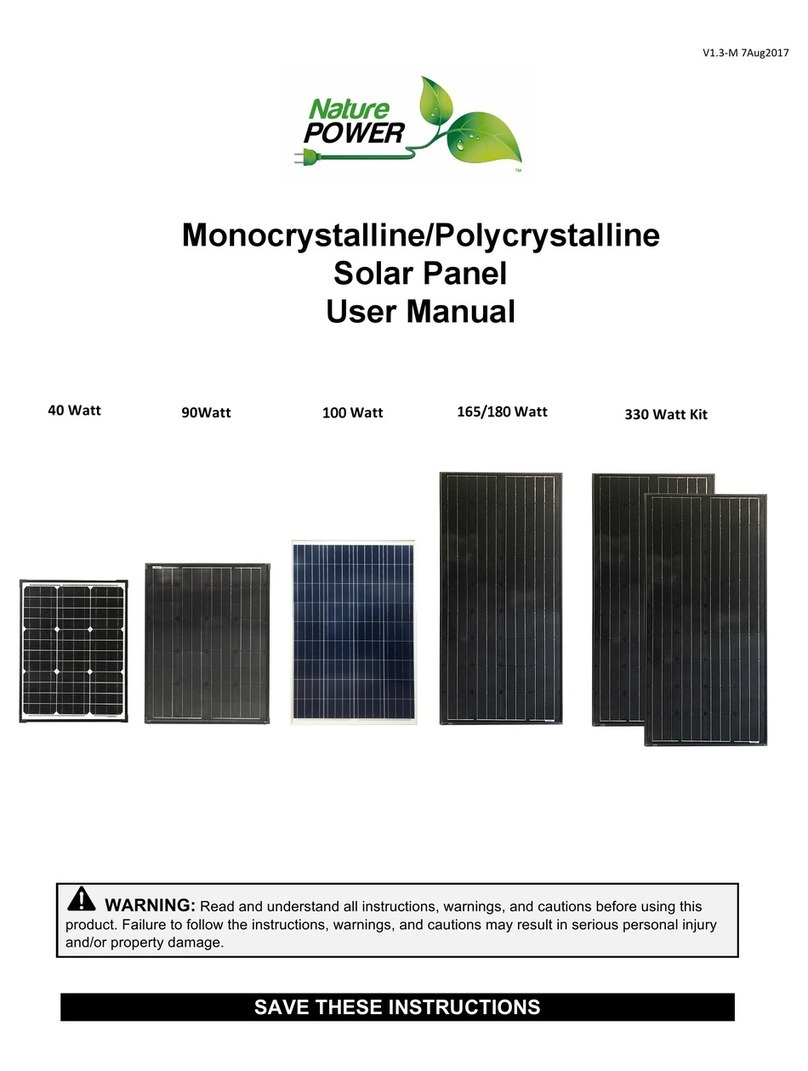

Modules may be mounted at any angle from

a vertical orientation to a horizontal one. The

appropriate fixed tilt angle and azimuth

orientation should be used in order to

maximize the exposure to sunlight. They may

be mounted in either orientation, in

“landscape” or “portrait.”

There are several approved ways to mount

these Solartec Modules to a support structure.

They may be mounted either using the bolt

holes provided or using frame clamps (not

provided). For roof mounting applications the

assembly is to be mounted over a fire resistant

roof covering rated for the application

Mounting Using Frame Bolt Holes

The modules may be fastener to a support

using the bolt holes in the bottom of the frame,