5

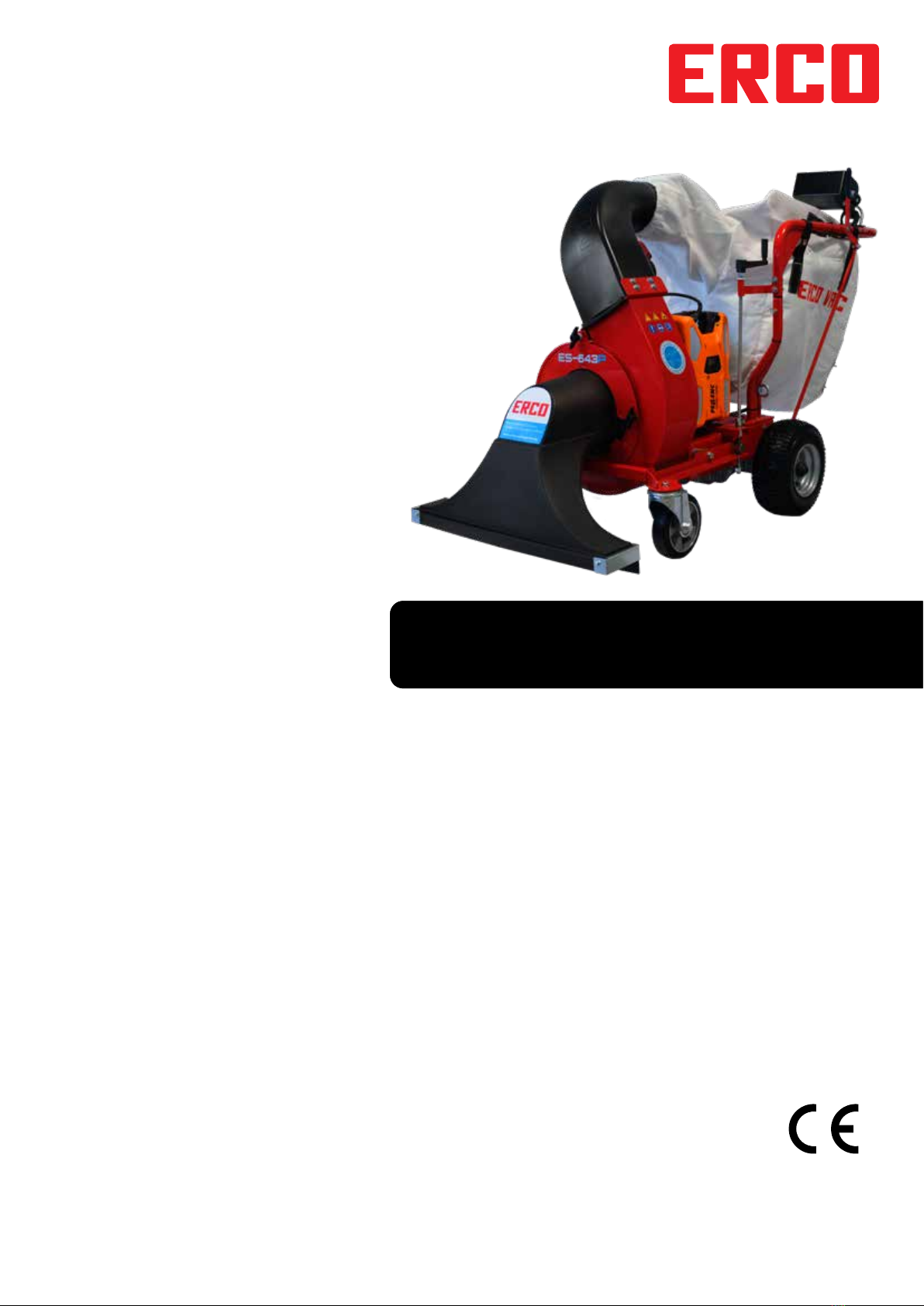

Operators Manual ES-643P

Intended use

The device is suitable as a leaf and waste vacuum clean-

er. Any other use is considered improper and is prohibited.

The manufacturer is not liable for any damage resulting

from this; the risk for this is borne solely by the user.

Intended use also includes the operating and main-

tenance conditions prescribed by the operating and

maintenance conditions prescribed by the manufacturer.

Possible misapplication

Do not vacuum wires, cables or heavy stones. Damage

to the machine and/or injury may result from propelling.

Do not push objects under the suction nozzle with your

foot under the suction nozzle. (Risk of injury!)

Do not suck in any objects that could cause the blower

to block (material damage!).

General sources of danger

Application and operation

Before starting work, the unit including all attachments

must be checked for proper condition and operational

safety.

The operator must use the device as intended.

The device may only be operated by persons who have

been instructed in its use or who have proven their ability

to operate it and who have been expressly authorized

to use it.

All protective devices must be properly attached and

functioning.

Never leave the machine unattended.

When leaving the machine, turn key switch to “OFF”,

remove key and secure the machine against accidental

movement.

Never operate the machine without a collecting bag.

The operator is responsible for accidents involving other

persons or their property.

Product-specic hazards

Do not suck in highly flammable substances or hot

objects (e.g. ashes, barbecue charcoal) (danger to life

from burns).

Dangers due to battery voltage

Only Pellenc batteries with the designation ULIB-1500

may be used. The safety regulations can be found in the

Pellenc battery operating instructions!

Defective or faulty batteries must be removed from the

device immediately and stored in a re-proof location!

Contact your Pellenc dealer immediately!

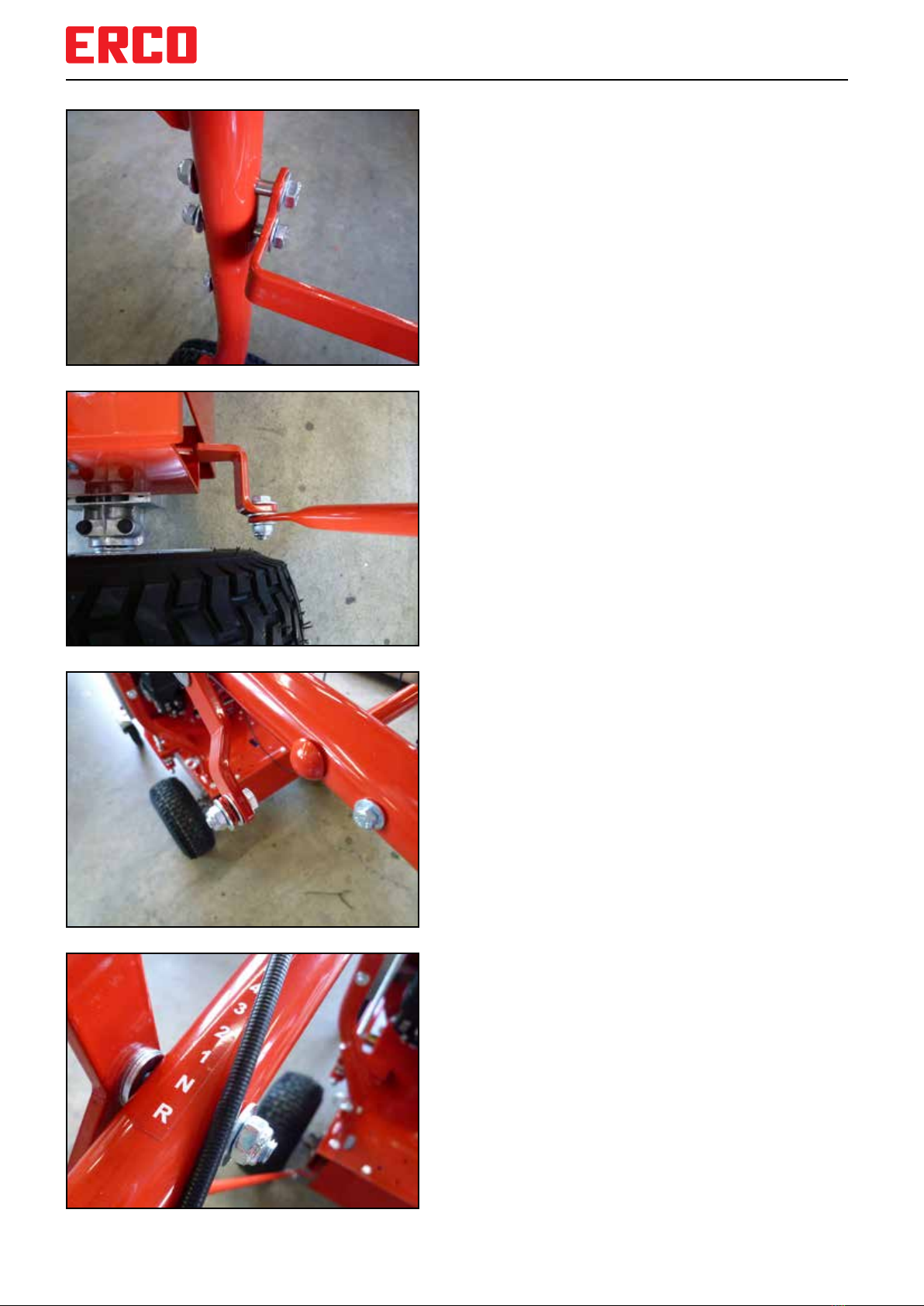

Dangers when driving

Only slopes up to a maximum of 20% may be driven on.

Special care must be taken when driving across the slope

(danger of tipping over).

Dangers for children, senior persons and animals

The operator must pay attention to the local conditions,

aswellastonoiseeectsonpersonsandanimals.

The device must never be parked on a slope.

Children, elderly persons and animals must not be in the

area near the machine.

Children must not play with the machine

Maintenance

Cleaning, repair and maintenance work as well as the

elimination of malfunctions may only be carried out when

the motor is shut down.

Set the key switch to “OFF” and remove the key.

The unit must not be cleaned with a water hose or

high-pressure cleaner (risk of short circuits or other

damage).

Observe the safety inspection according to the locally

applicable regulations for mobile commercially used

devices.

Always carry out work on the machine with suitable work

tools.

Only use original spare parts from the manufacturer.

Personnel and user qualication

Persons with reduced physical, sensory or mental capa-

bilities or lack of experience and/or knowledge are not

allowed to use the device unless a person responsible

for their safety supervises the operation or instruction.

Young persons under 16 years of age are prohibited from

operating the device.

The user’s ability to react must not be impaired, e.g. by

drugs, alcohol or medication.

The operator must have been instructed in the use of

the device.

The operator must be familiar with the instructions in the

operating manual.

Safety instructions